Photomask and glass substrate manufacturing method

A manufacturing method and technology for glass substrates, which are applied in the photoengraving process of the pattern surface, the originals for optical mechanical processing, optics, etc., can solve the problems of film breakage, affecting the yield of finished products, short circuit of the common electrode of pixels, etc. The effect of being less prone to breakage and reducing the risk of residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

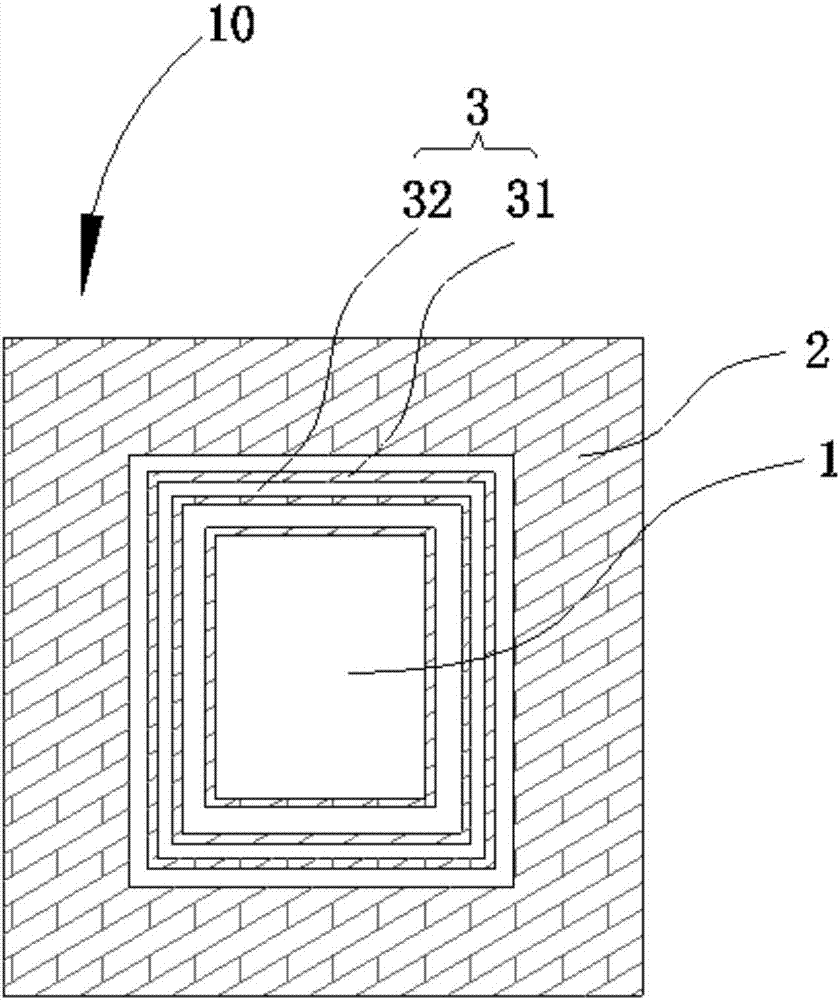

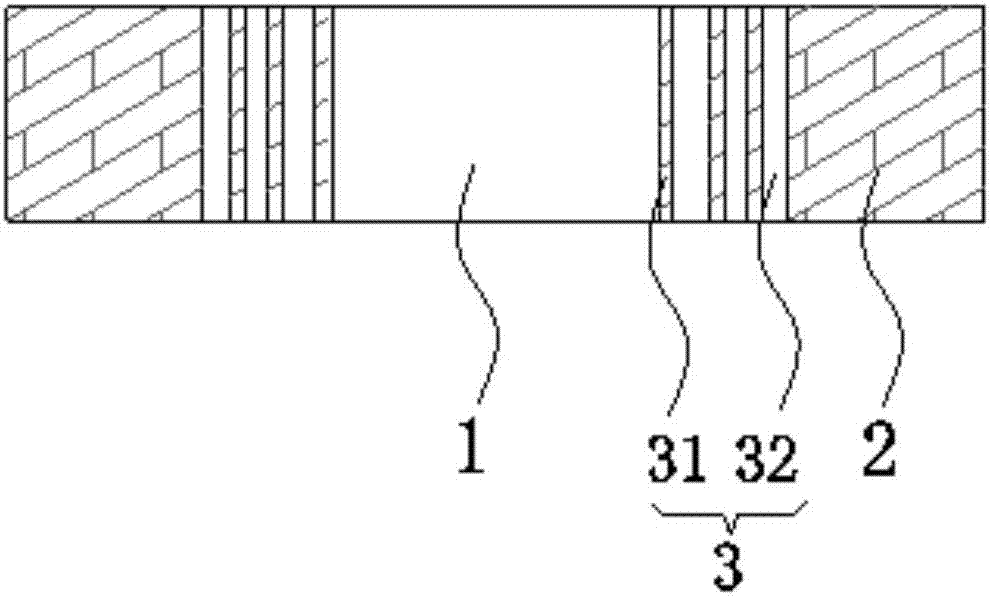

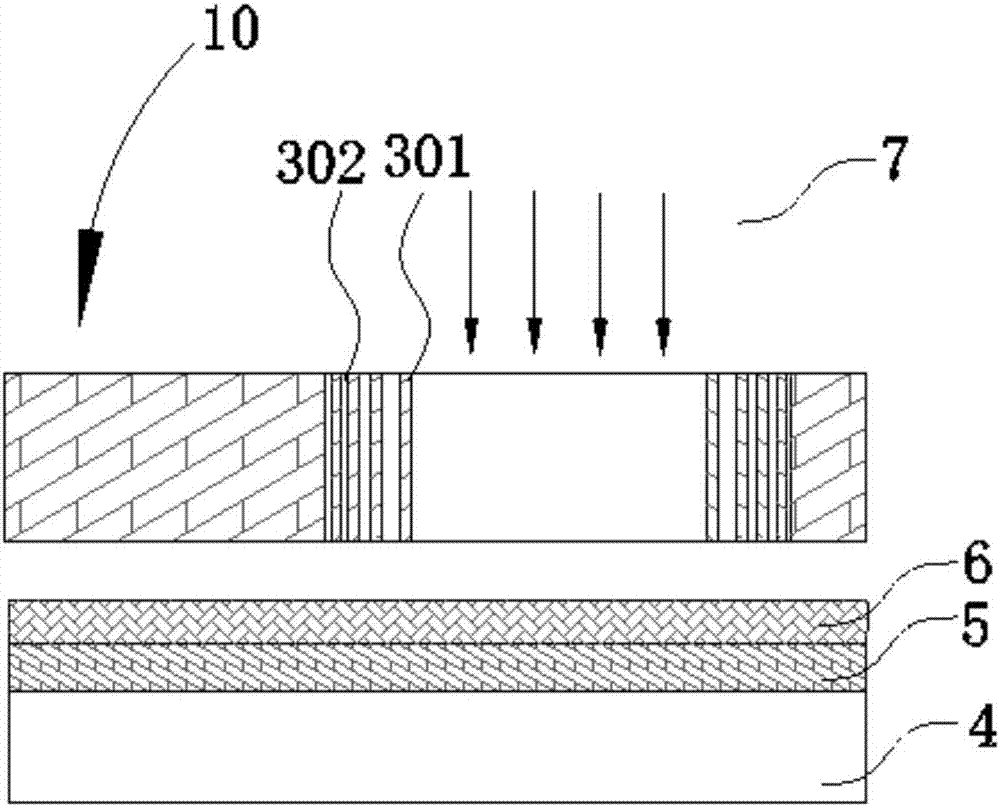

[0039] figure 1 and figure 2 They are respectively a plan view and a cross-sectional view of the photomask of the embodiment of the present invention. see figure 1 and figure 2 , the photomask 10 includes a light-transmitting region 1 and a light-blocking region 2, and the photomask 10 also includes a partially light-transmitting region 3; the partially light-transmitting region 3 is located between the light-blocking region 2 and the light-blocking region 1 to allow light to partially pass through; the partially transparent area 3 includes several identical light-shielding films 31, and light-transmitting gaps 32 are formed between adjacent light-shielding films 31, and the transmittance of the partially light-transmitting area 3 is along the The light-transmitting area 1 gradually decreases toward the light-blocking area 2 .

[0040] It should be noted that the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com