Method for improving adhesive force between metal film layer and high-dielectric-constant ceramic substrate

A high dielectric constant, ceramic substrate technology, applied in the manufacture of circuits, electrical components, semiconductors/solid devices, etc., can solve problems such as poor metal adhesion, achieve the effect of reducing difficulty, increasing operation difficulty, and improving roughening state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

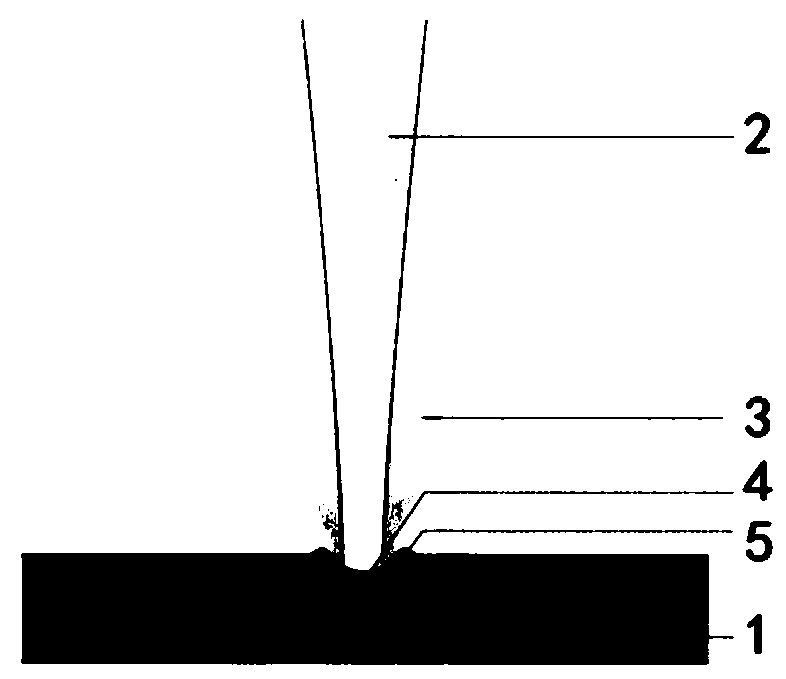

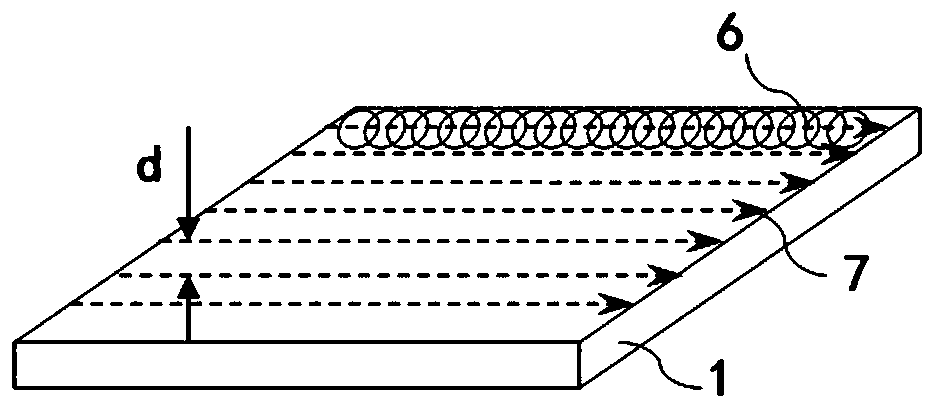

[0035] Ultraviolet laser roughening is the use of a specific ultraviolet laser, through a series of operations such as controlling laser parameters, using the energy of the ultraviolet laser, on the surface of the substrate to be processed, shallowly etches densely arranged fine grooves in a straight line , after two times of superimposed etching in the horizontal and vertical directions, a roughened structure with tooth-shaped bumps and ups and downs is etched on the surface of the substrate to achieve the effect of destroying the brightness and smoothness of the substrate surface. After high-temperature calcination, the surface of the roughened substrate is slightly melted, and the sharp structure at the "peaks" and "valleys" of the concave-convex undulating structure is appropriately weakened, so that the roughened structure after ultraviolet laser etching is obtained to a certain extent. Lubrication". Finally, a roughened surface with a uniform roughening effect and a Ra va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Spot diameter | aaaaa | aaaaa |

| Line spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com