A kind of production technology of vitamin d3

A production process and vitamin technology, applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as low product purity, serious environmental pollution, and numerous steps, and achieve improved process conditions and simplified processes Steps, Effects of Improving Purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

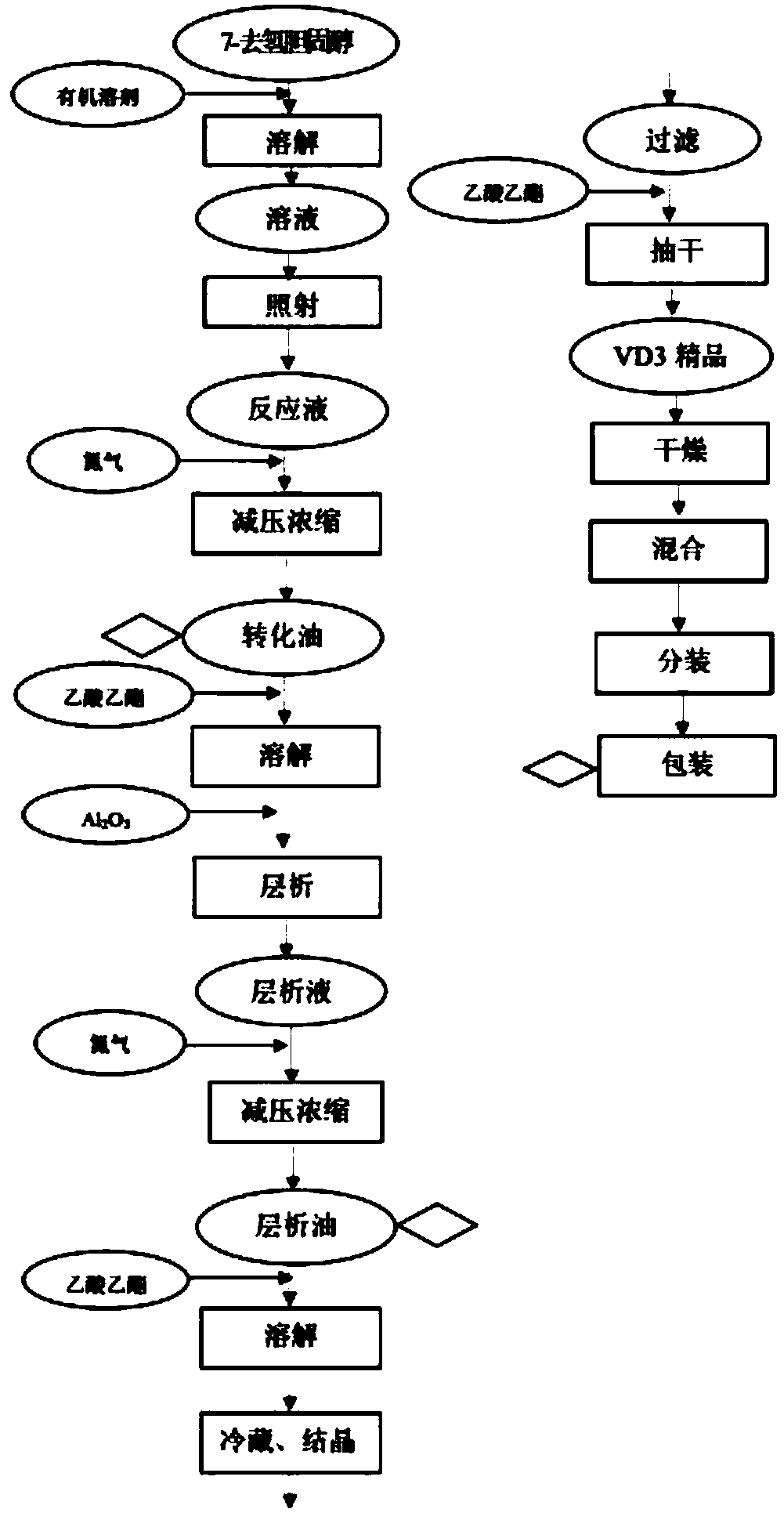

Method used

Image

Examples

Embodiment 1

[0027] Add 10kg of 7-dehydrocholesterol and 300L of methanol into the batching tank, start stirring and heat up to 32°C to prepare a photoreaction solution with a concentration of 3wt%, and keep it warm for 1.5 hours. The photochemical reaction is carried out by an ultraviolet irradiator with a light source power of 20kw, the temperature of the photoreaction solution is controlled at 65°C, the flow rate of the photoreaction solution is controlled at 120L / h, and then the irradiated reaction solution is concentrated under reduced pressure in a concentration pot. The material was transferred to a refrigerated and stirred tank at -16°C for freezing and crystallization for 10 hours, unreacted raw materials were recovered by filtration, and the filtrate was reacted at 60°C and -0.08Mpa for 2 hours to obtain 1.5 kg of converted oil, which was detected by liquid phase of which vitamin D 3 The content is 80wt%; 1.5 kg of converted oil and 3 times the amount of ethyl acetate are sent in...

Embodiment 2

[0029] Add 15kg of 7-dehydrocholesterol, 350L of methanol and 280L of cyclohexane into the batching tank, start stirring and raise the temperature to 30°C to prepare a photoreaction solution with a concentration of 2wt%, keep it warm for 2 hours, and then pass the photoreaction solution through flow The photochemical reaction is carried out by the ultraviolet irradiator with a light source power of 30kw, the temperature of the photoreaction solution is controlled at 60°C, the flow rate of the photoreaction solution is controlled at 110L / h, and then the irradiated reaction solution is reduced in the concentration pot. Concentrate under pressure, transfer the concentrate to a refrigerated stirring tank and freeze and crystallize at -15°C for 8 hours, filter and recover unreacted raw materials, react the filtrate at 65°C and -0.09Mpa for 1.5 hours to obtain 1.8 kg of transformed oil, transform Vitamin D in oil detected by liquid phase 3 The content is 83wt%; the converted oil and...

Embodiment 3

[0031] Add 12kg of 7-dehydrocholesterol and 260L of ethanol into the batching tank, start stirring and heat up to 35°C to prepare a photoreaction solution with a concentration of 4wt%, keep it warm for 1 hour, and then pass the photoreaction solution through the flowmeter through the nitrogen The ultraviolet irradiator with the light source power of 25kw carries out the photochemical reaction, the temperature of the photoreaction solution is controlled at 70°C, the flow rate of the photoreaction solution is controlled at 130L / h, and then the irradiated reaction solution is concentrated under reduced pressure in a concentration pot, and the concentrated The material was transferred to a refrigerated and stirred tank and frozen and crystallized at -20°C for 5 hours, unreacted raw materials were recovered by filtration, and the filtrate was reacted at 70°C and -0.095Mpa for 1 hour to obtain 1.68 kg of converted oil, which was detected by liquid phase of which vitamin D 3 The cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com