Processing technology of low-sodium crisp and tender salted waterfowl-meat product

A processing technology and poultry meat technology, applied in the field of food processing, can solve the problems of dark color, poor taste, and floury meat, and achieve the effects of reducing the risk of residual harmful substances, maintaining crisp and tender taste, and saving time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

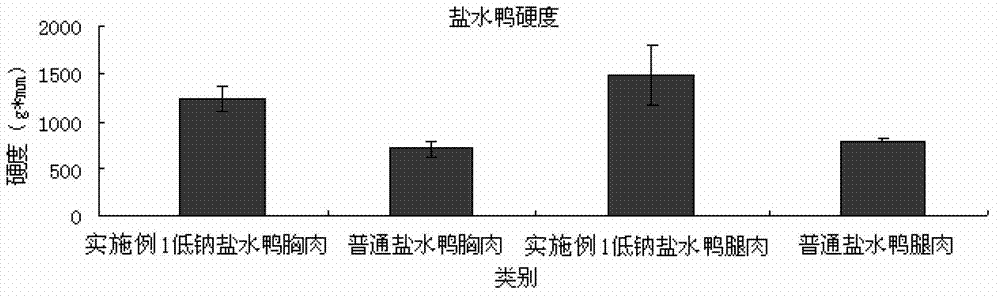

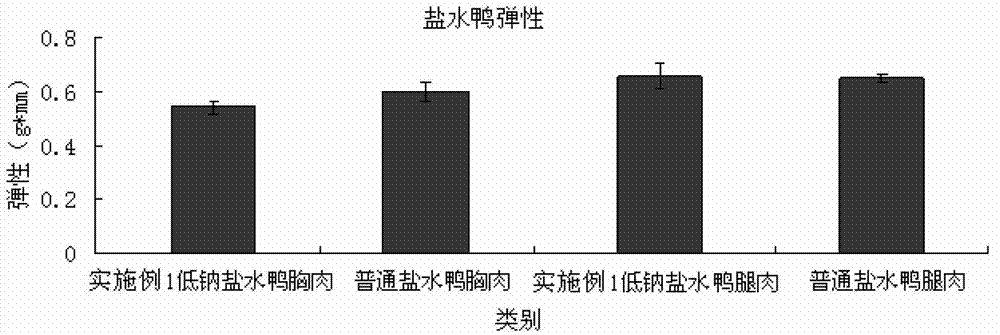

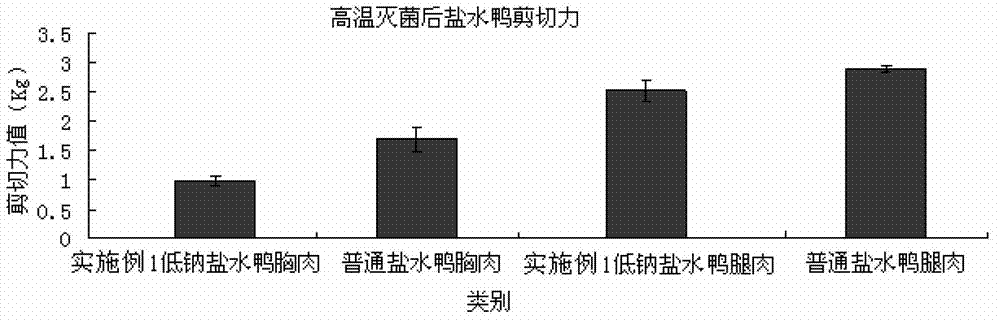

[0047]Example 1 Preparation of low-sodium crispy and tender salted duck

[0048] Preparation raw materials:

[0049] Preparation of low-sodium compound salt: Calculated by mass percentage, weigh 38% sodium chloride, 43% potassium chloride, 5.5% magnesium chloride, 2.5% sodium gluconate, 3.5% inosinic acid, 3.5% Gly, 2% Ala, His 2% mixed evenly.

[0050] Preparation of water-retaining agent (compound phosphate aqueous solution with a concentration of 20% by mass): Calculate by mass percentage, weigh 19% of sodium pyrophosphate, 12% of sodium hexametaphosphate, 34% of disodium hydrogen phosphate, and 20% of sodium tripolyphosphate %, 15% sodium dihydrogen phosphate is mixed evenly and dissolved in water to make a compound phosphate aqueous solution with a concentration of 20% by mass.

[0051] Preparation of dry marinade: Calculated in parts by mass, weigh 900 parts of low-sodium compound salt, 25 parts of star anise powder, 20 parts of pepper powder, 25 parts of chili powder,...

Embodiment 2

[0107] Example 2 Preparation of low-sodium crispy and tender salted goose

[0108] Preparation raw materials:

[0109] Preparation of low-sodium compound salt: Calculate by mass percentage, weigh 35% sodium chloride, 52% potassium chloride, 5% magnesium chloride, 2% sodium gluconate, 2% inosinic acid, 2% Gly, 1% Ala, His 1% mix well.

[0110] Preparation of water-retaining agent (compound phosphate aqueous solution with a mass percentage concentration of 15%): Calculated by mass percentage, weigh 10% sodium pyrophosphate, 15% sodium hexametaphosphate, 40% disodium hydrogen phosphate, and 15% sodium tripolyphosphate. %, 20% sodium dihydrogen phosphate mixed evenly, dissolved in water to make a compound phosphate aqueous solution with a concentration of 15% by mass.

[0111] Preparation of dry marinade: Calculated in parts by mass, weigh 800 parts of low-sodium compound salt, 20 parts of star anise powder, 15 parts of pepper powder, 15 parts of chili powder, 5 parts of cumin p...

Embodiment 3

[0122] Example 3 Preparation of low-sodium crispy and tender salted duck

[0123] Preparation raw materials:

[0124] Preparation of low-sodium compound salt: Calculate by mass percentage, weigh 40% sodium chloride, 42% potassium chloride, 5% magnesium chloride, 3% sodium gluconate, 3% inosinic acid, 3% Gly, 2% Ala, His 2% mixed evenly.

[0125] Preparation of water-retaining agent (compound phosphate aqueous solution with a mass percentage concentration of 25%): Calculate by mass percentage, weigh 25% of sodium pyrophosphate, 10% of sodium hexametaphosphate, 25% of disodium hydrogen phosphate, and 25% of sodium tripolyphosphate %, 15% sodium dihydrogen phosphate, after mixing evenly, dissolve in water to make a compound phosphate aqueous solution with a concentration of 25% by mass.

[0126] Preparation of dry marinade: Calculated in parts by mass, weigh 1000 parts of low-sodium compound salt, 30 parts of star anise powder, 25 parts of pepper powder, 35 parts of chili powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com