Preparation method of unsaturated fatty acid microcapsules

A technology of unsaturated fatty acids and microcapsules, which is applied in the field of microcapsule preparation, can solve problems such as prolonging product shelf life, affecting product shelf life stability, and microcapsule deterioration, so as to improve shelf life stability and raw material utilization , to avoid the effect of deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

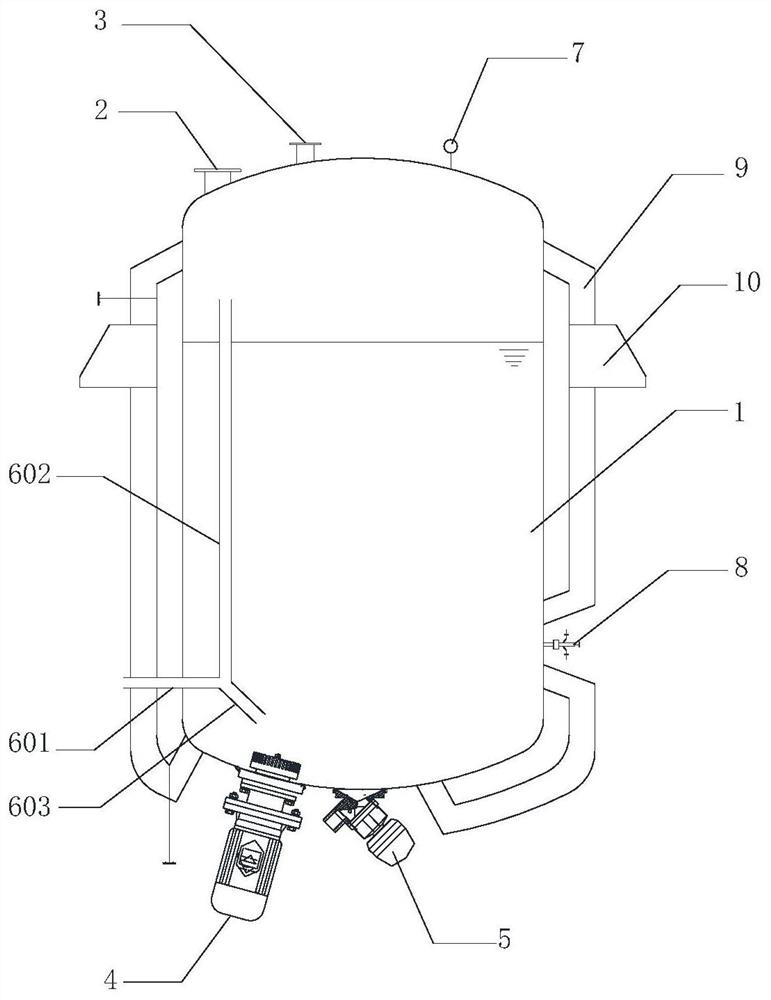

[0033] Such as figure 1 As shown, the vacuum emulsification tank used in the preparation of the emulsion in Example 1 includes a tank body 1 and a tank mounting bracket 9 arranged outside the tank body. Two lifting lugs 10 arranged symmetrically along the radial direction of the tank body are arranged on the tank body mounting bracket. The top of the tank is equipped with a liquid feed port 2, a vacuum port 3 and a vacuum pressure gauge 7, the bottom of the tank is equipped with a high-shear bottom emulsifier 4 and a discharge port 5, and the lower part of the side wall of the tank is provided with a sampling port 8. There is a gas-solid separator in the tank.

[0034] The gas-solid separator includes a solid-gas feed pipe 601, an exhaust pipe 602 and a powder outlet pipe 603 connected at one end. The solid-gas feed pipe is arranged at the bottom of the tank along the horizontal direction, and the other end protrudes from the side wall of the tank. There is a solid gas inlet...

Embodiment 2

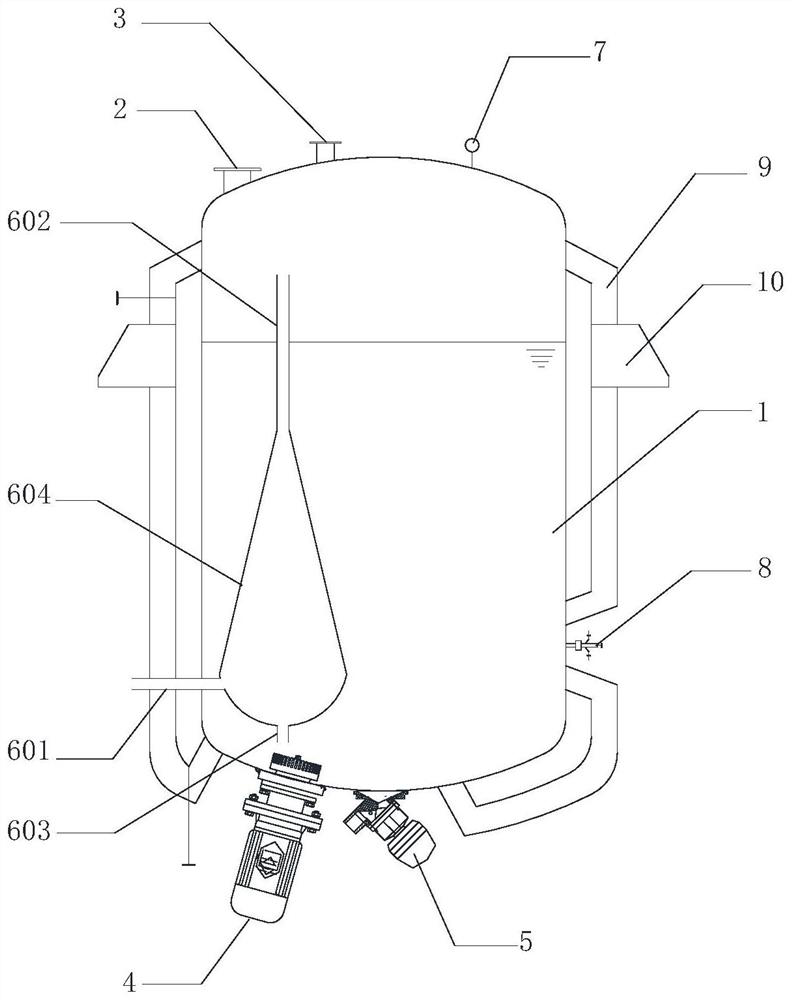

[0041] Such as figure 2 As shown, the gas-solid separator in the vacuum emulsification tank used when preparing the emulsion in Example 2 includes a solid-gas feed pipe 601, an exhaust pipe 602 and a powder discharge pipe 601 connected at one end through a tapered separation portion 604 with an arc-shaped bottom surface. Pipe 603, the solid gas feed pipe communicates with the bottom of the side of the conical separation part, the exhaust pipe communicates with the top of the conical separation part, and the powder outlet pipe communicates with the bottom of the conical separation part. The other end of the solid-gas feed pipe protrudes from the side wall of the tank and is provided with a solid-gas feed port, the other end of the exhaust pipe extends to the top of the tank and is provided with an exhaust port, and the other end of the powder outlet pipe It extends to the bottom of the tank and is provided with a powder outlet, which is located above the emulsifier at the bott...

Embodiment 3

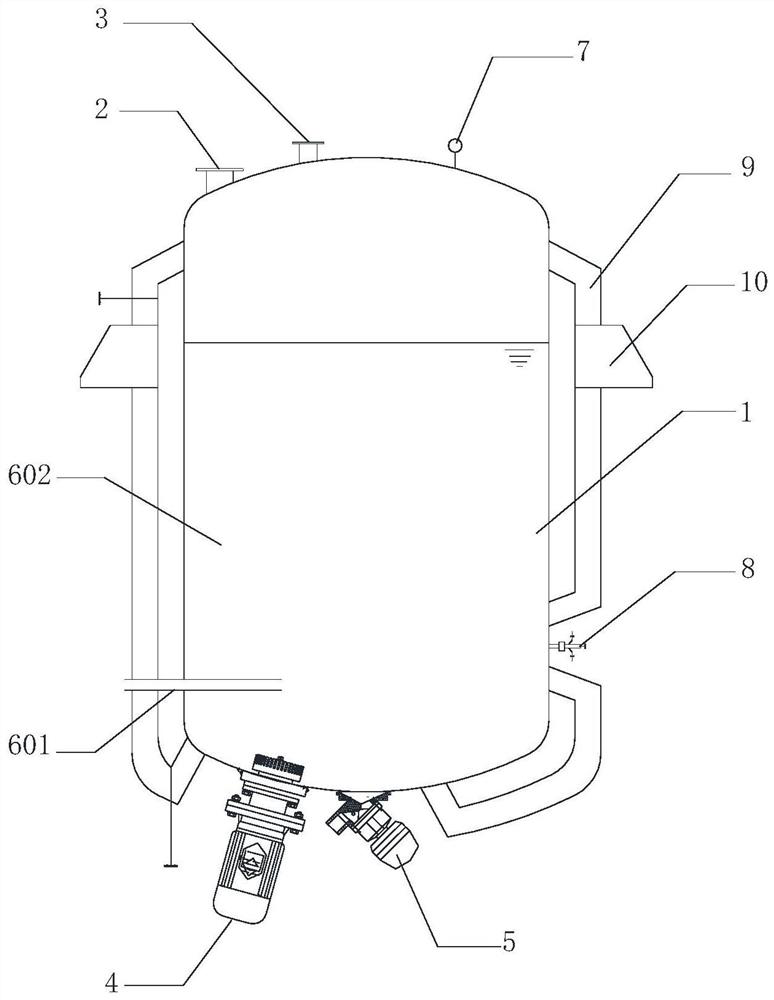

[0048] The structure of the vacuum emulsification tank used in Example 3 is the same as that in Example 2. A kind of method using above-mentioned vacuum emulsification tank to prepare EPA microcapsules, comprises the steps:

[0049] S1: Add water to the vacuum emulsification tank until the liquid level is above the solid gas inlet and powder outlet, and below the exhaust port, blow the wall material into the water in the tank along the solid gas inlet pipe with nitrogen gas, and adjust the pH to 5.0 , shear emulsification to obtain a pre-emulsion; wherein the wall material is lactose, maltodextrin and sodium starch octenyl succinate with a mass ratio of 10:10:80, the amount of water is 4 times the wall material quality, citric acid alone The concentration of glyceride in the pre-emulsion is 2wt%, and the concentration of vitamin E in the pre-emulsion is 4wt%;

[0050] S2: Add EPA to the pre-emulsion as the unsaturated fatty acid core material, and add monoglyceride citrate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com