Speed reducing centrifugal duster for cleaner

A technology for centrifugal dust removal and vacuum cleaners, which is applied to suction filters, swirl devices, and devices in which the axial direction of the swirl can be reversed. and other problems, to achieve the effect of good rotation effect, small airflow pressure loss and low sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

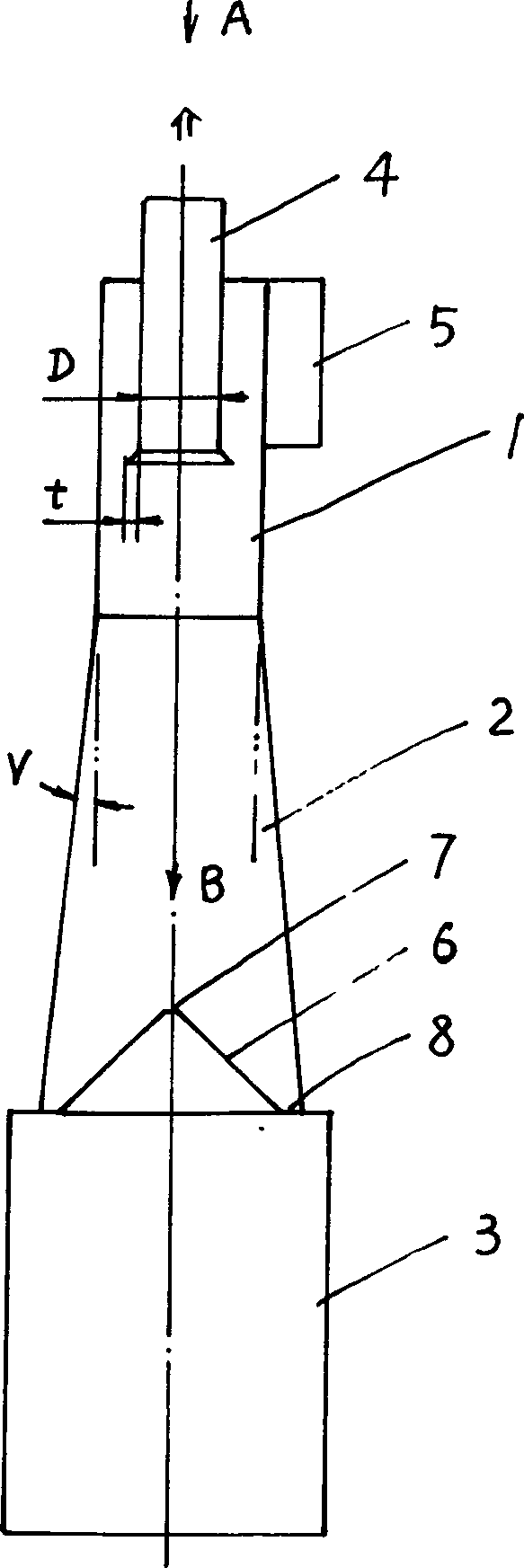

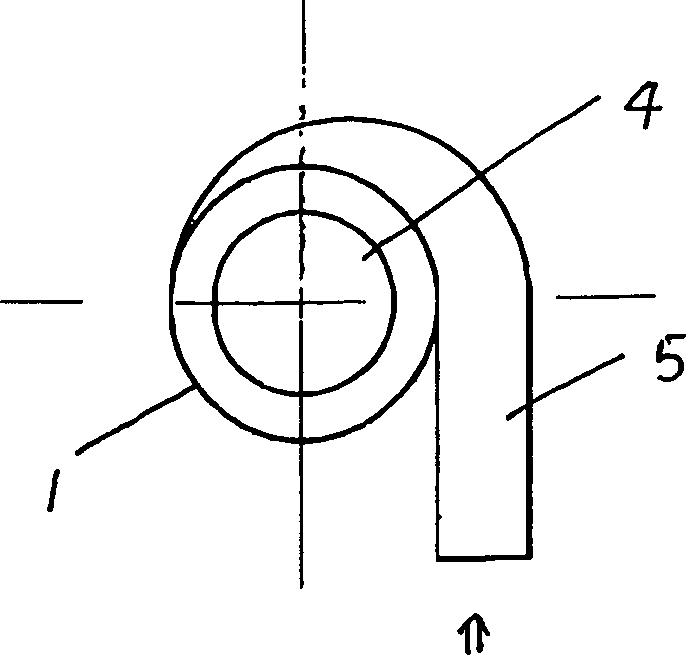

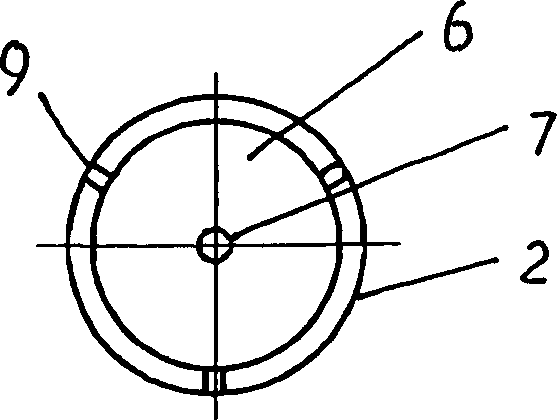

[0024] Example: as figure 1 , figure 2 , image 3 As shown in the figure, a deceleration centrifugal dust removal device for a vacuum cleaner is composed of a circular cylinder (1), a conical cylinder (2), and a dust collecting box (3) in order from top to bottom, and the top of the circular cylinder (1) extends The axis is provided with an air outlet pipe (4), the air outlet pipe (4) extends downward into the circular cylinder (1), the lower end surface of the air outlet pipe (4) is in the shape of a horn, and the circular cylinder (1) has a The outer side wall is connected with an air inlet pipe (5), and the air inlet pipe (5) at least extends the circular cylinder (1) around a 90° arc before entering the circular cylinder (1); the conical cylinder (2) It is in the shape of a small upper end and a large lower end, and the optimal range of the cone angle V is 5°--60°. The lower part of the conical cylinder (2) is provided with an umbrella-shaped reflection plate (6), and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com