Hyperbolic cooling tower muffler system

A hyperbolic cooling tower technology, applied in the direction of water shower coolers, sounding equipment, heat exchangers, etc., can solve the problems of high engineering cost and poor shielding effect, and achieve good weather resistance, good decoration and stability Effect of Intake Air Flow Velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solution and advantages of the present invention more clear, it is easy for those skilled in the art to implement. The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

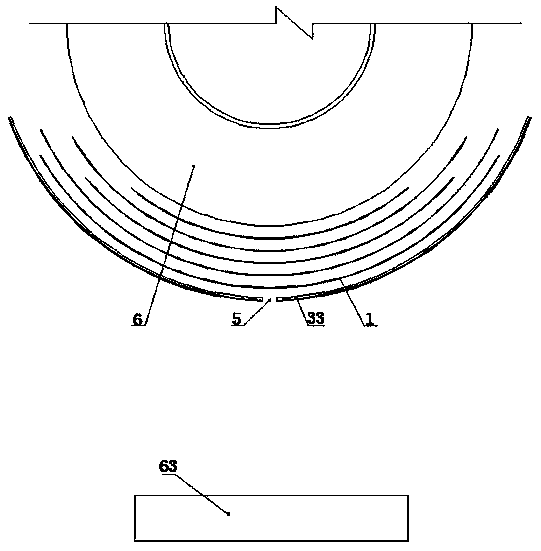

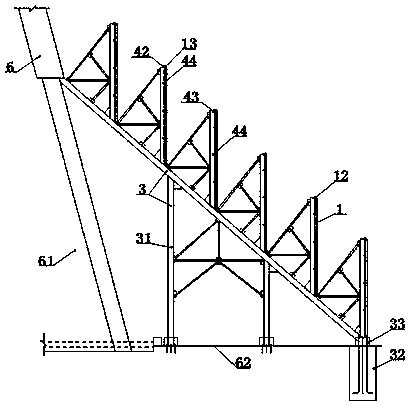

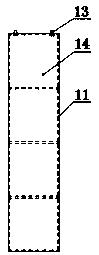

[0040] exist figure 1 , 2 In the first embodiment shown, the hyperbolic cooling tower noise reduction system consists of a decorative sound-absorbing module (1), an observation and daylighting module (2), an installation support structure (3), a module installation fastening structure (4) and maintenance channel (5), the decorative sound-absorbing module (1) has uniform specifications, and is installed by a steel structure frame (11), an inner sound-absorbing surface, an outer sound-insulating decorative surface, an elastic vibration-isol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com