Parallel type dust removing device of vacuum cleaner

A technology for dust removal devices and vacuum cleaners, which is applied in the direction of vacuum cleaners, suction filters, cyclone devices, etc., which can solve the problems of large volume of cyclone dust removal devices, troublesome use by users, and increased costs, so as to avoid dust raising, increase air volume, and air flow pressure loss small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

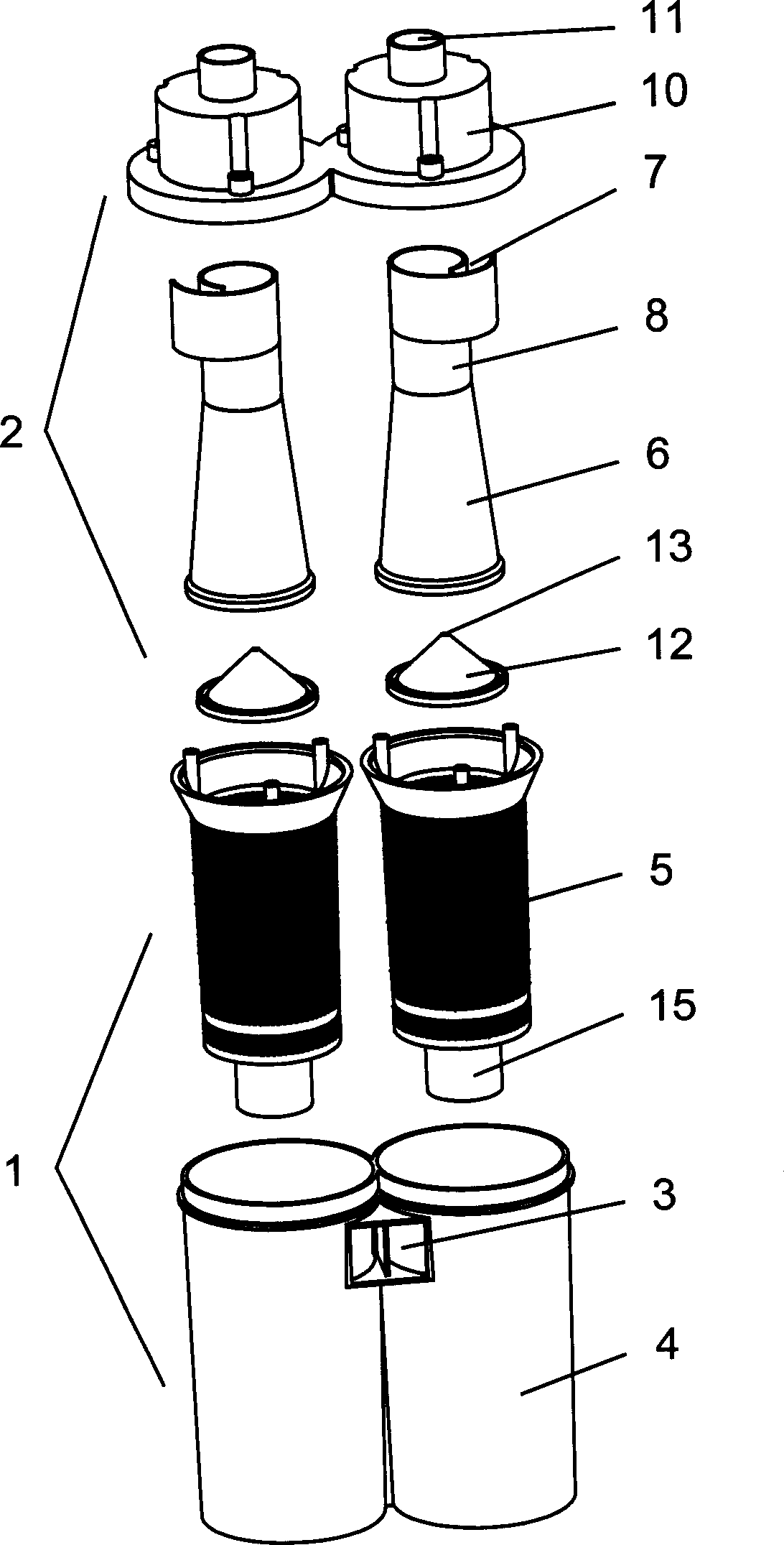

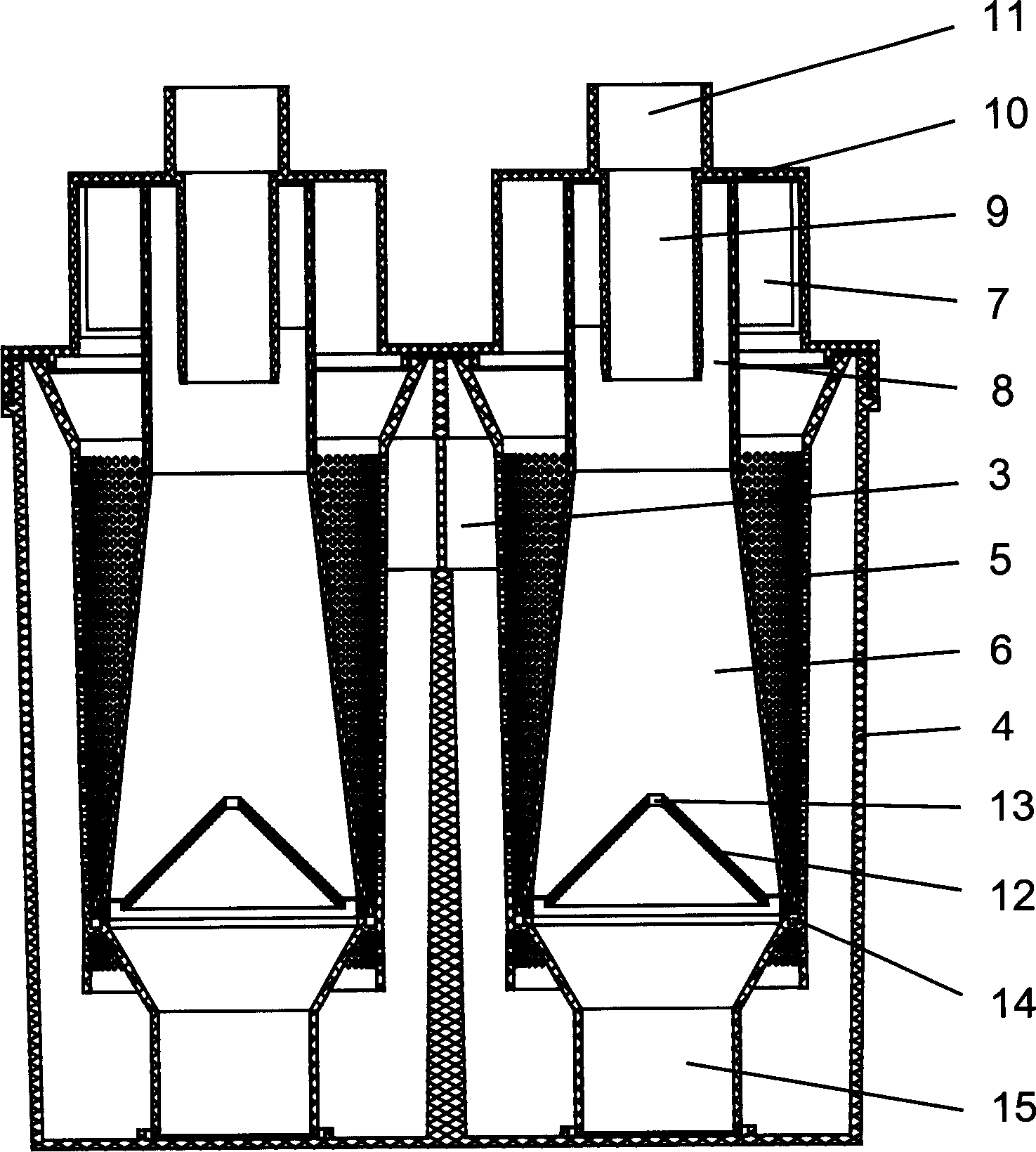

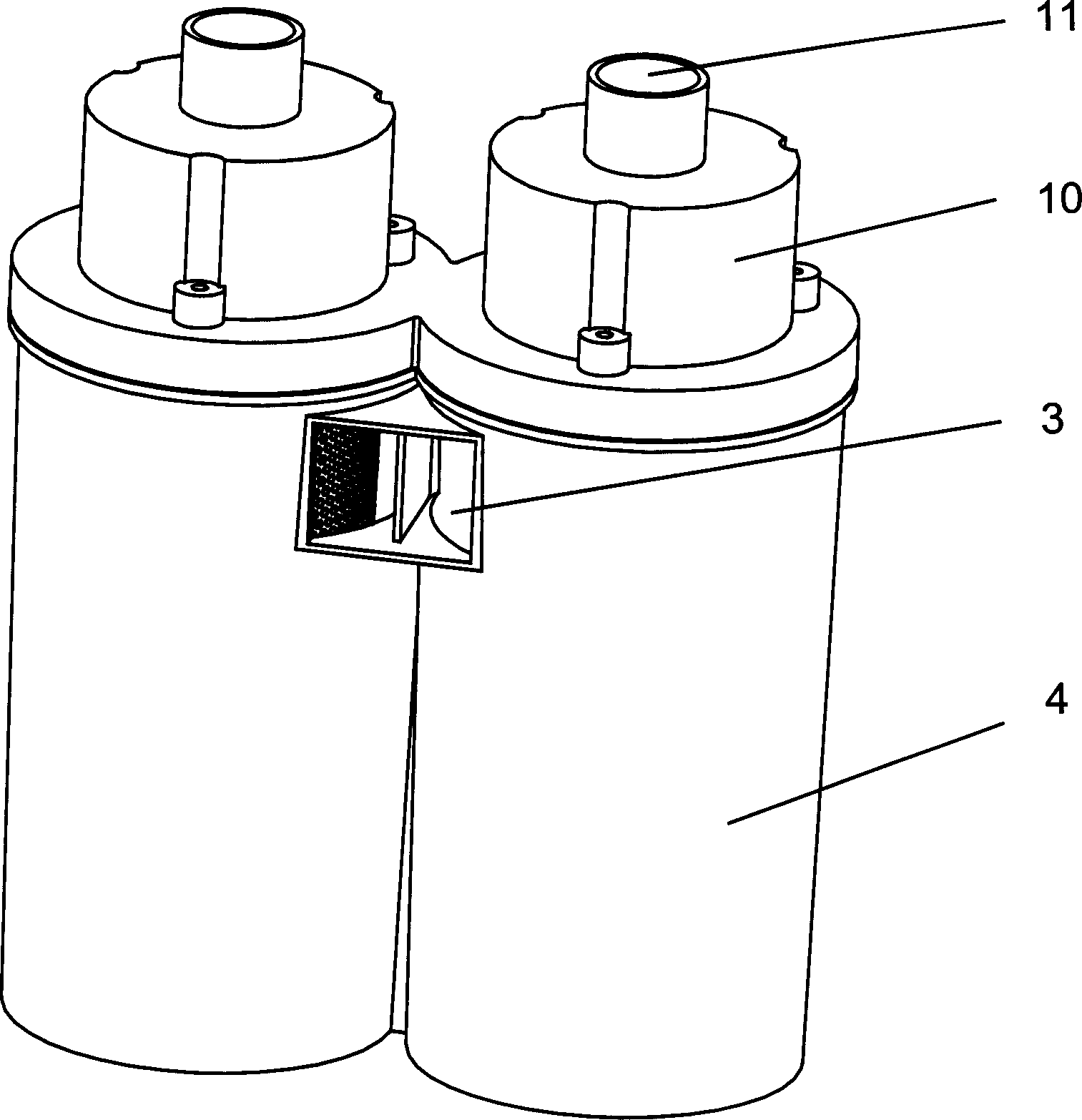

[0018] Example: such as figure 1 , figure 2 , image 3 As shown, a side-by-side vacuum cleaner dust removal device includes two upstream cyclone separators 1 arranged side by side. The upstream cyclone separator 1 includes a cylindrical dust cup 4 with a cyclone air inlet 3. Inside the cylindrical dust cup 4 A cylindrical filter cover 5 full of small holes is arranged coaxially, two cylindrical dust cups 4 are connected and fixed, and two cyclone air inlets 3 are adjacently arranged and communicated with the same air inlet pipe.

[0019] A downstream separator 2 is inserted in each of the upstream cyclone separators 1, and the downstream cyclone separator 2 includes a conical cylinder 6 and a cylindrical cylinder 8 with a cyclone air inlet 7, the cylindrical cylinder 8 Connected with the small end of the conical barrel 6, an air outlet pipe 9 is coaxially arranged inside the cylindrical barrel 8.

[0020] The conical shell 6 of the downstream cyclone separator 2 is inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com