Steel pipe cleaning equipment

A technology for cleaning equipment and steel pipes, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of not being able to use normally, not giving how to place the steel pipes, high labor intensity, etc., and achieving a practical structure. Reliable, excellent cleaning effect, easy subsequent operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is described in detail in the form of the embodiment, but the description of the embodiment is not a limitation to the technical solution of the present invention, and any equivalent transformation made according to the concept of the present invention is only in form and not in substance. The scope of the technical solution of the present invention.

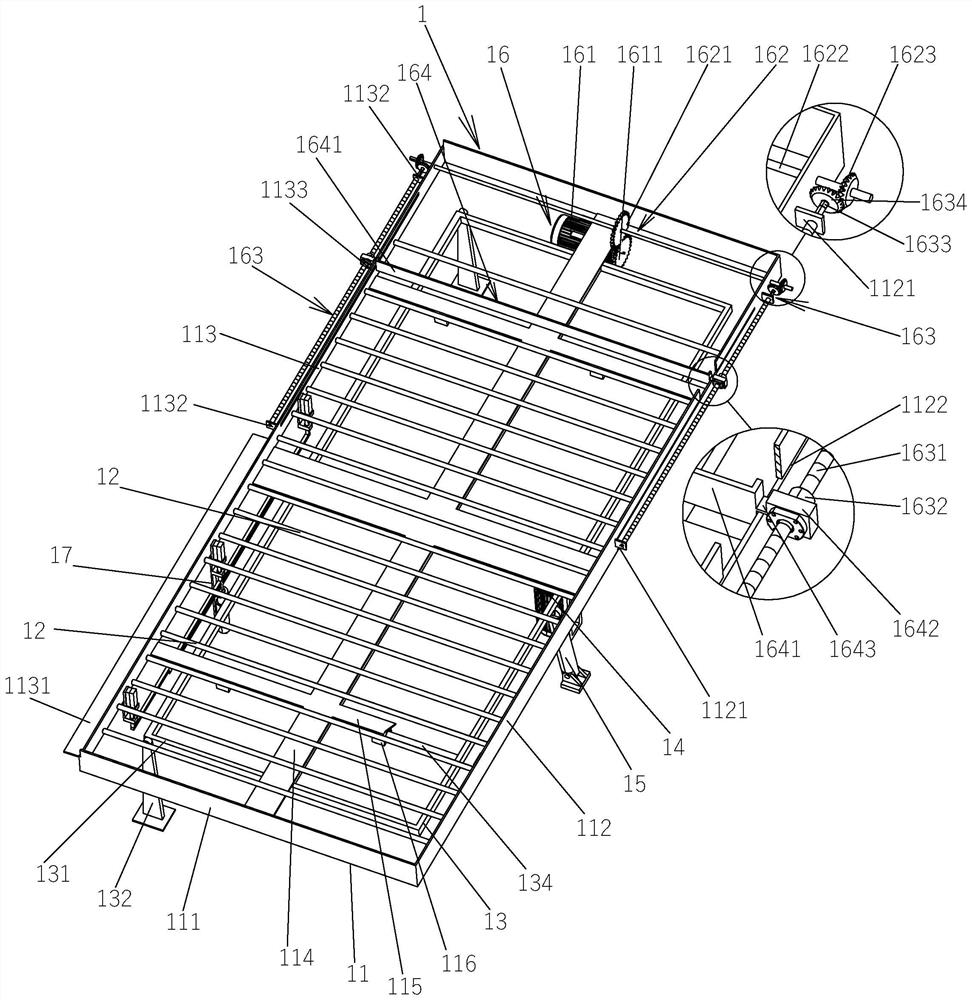

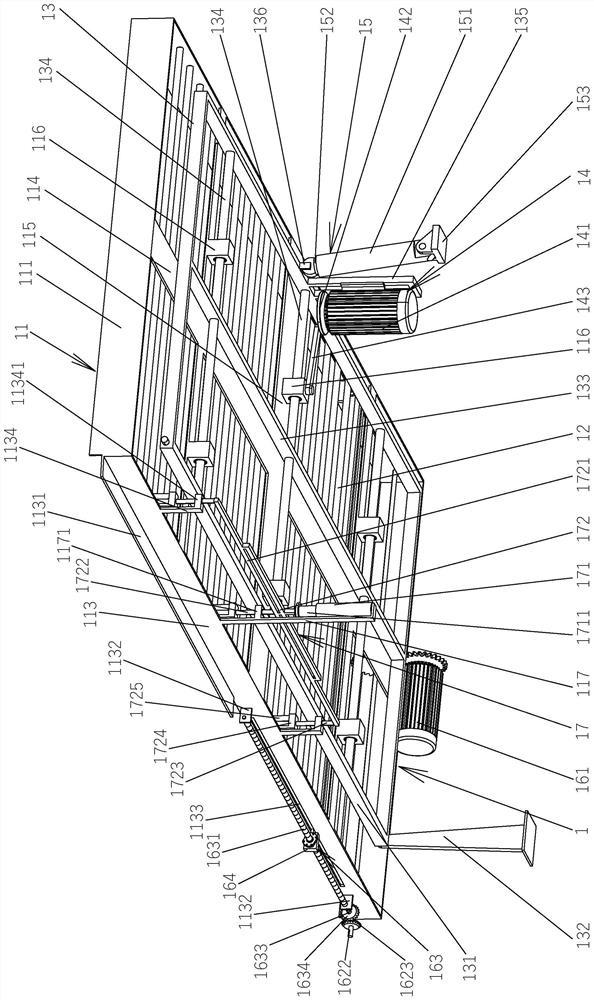

[0031] In the following descriptions, all concepts involving directionality or orientation of up, down, left, right, front and rear are aimed at figure 1 As far as the position and state of the present invention are concerned, it cannot be understood as a special limitation on the technical solution provided by the present invention.

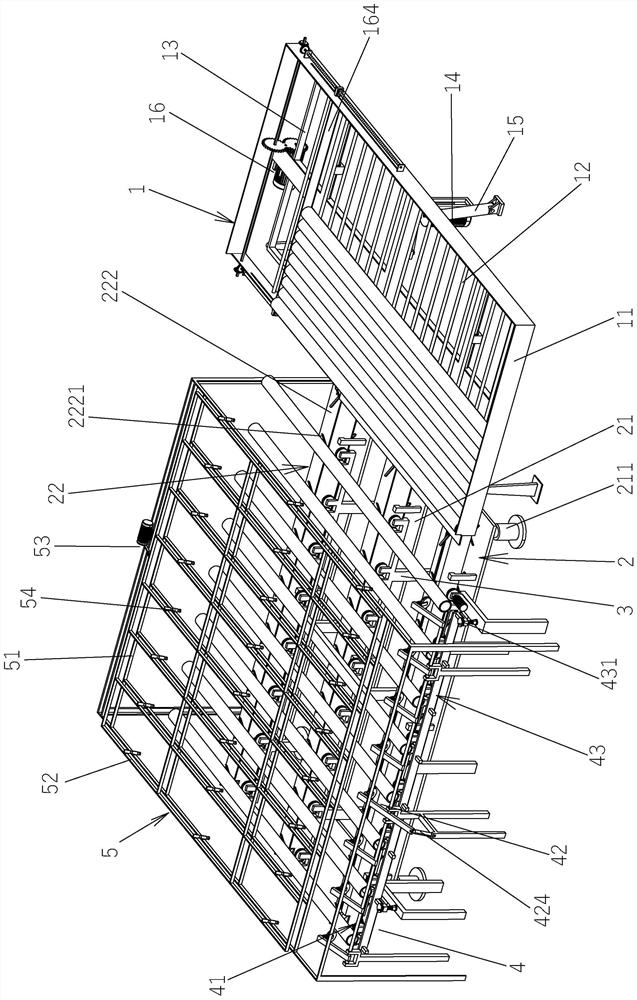

[0032] See Figure 1 to Figure 7 , shows a kind of steel pipe cleaning equipment, including: a steel pipe finishing mechanism 1, which can realize the folding operation of a plurality of steel pipes and can lift a plurality of steel pipes in sequence and send them out; a stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com