A dual-station integrated plastic bag sorting device

A technology of sorting device and plastic bag, applied in the directions of packaging, bag making, transportation and packaging, etc., can solve the problems of large location space, high production cost, complex structure, etc., to reduce costs, improve regularization efficiency, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

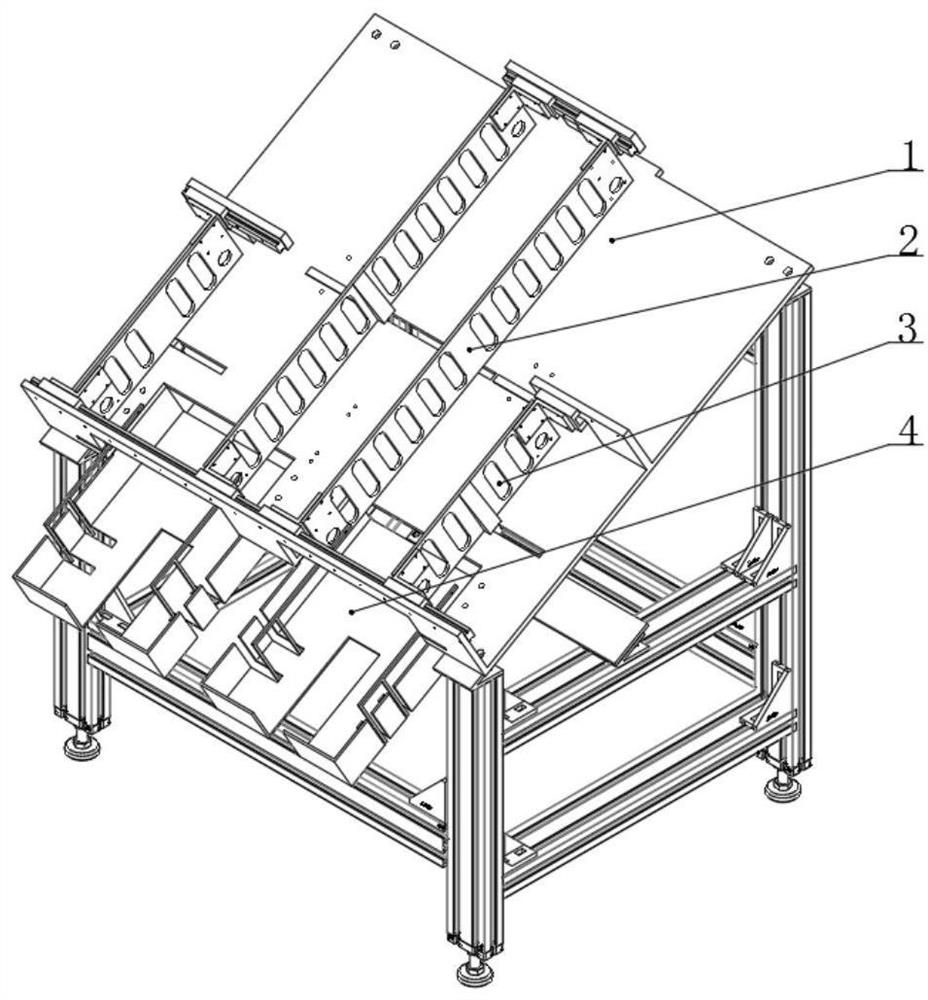

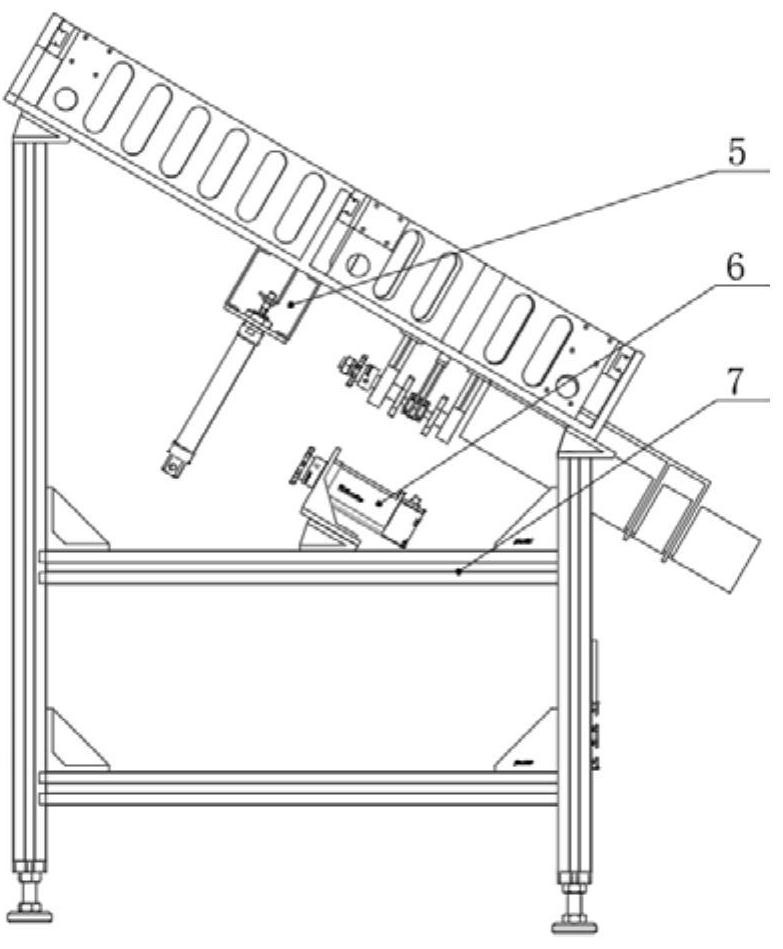

[0032] Such as Figure 1-15 Shown, a kind of plastic bag regulation mechanism of the present invention, wherein figure 1 and figure 2 It is a schematic diagram of the overall structure of the plastic bag regularization mechanism.

[0033] Such as figure 2 As shown, the speed of the motor 6 according to the bag making mechanism is 120 bags / minute, and in order to ensure the bags are smooth and regular, each plastic bag is slapped twice and the beat of the crankshaft is more than 240 revolutions per minute. Therefore, the preferred model is: The rated voltage is 220V, the rated power is 60W, and the rated speed is 90-1350rpm.

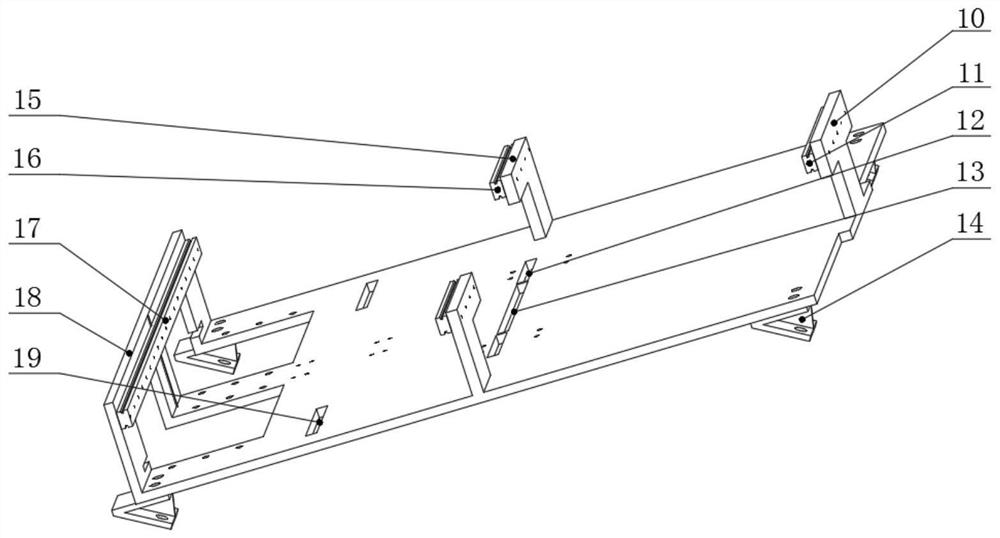

[0034] Such as image 3 As shown, the front rail 11 is fixed on the front baffle 10, and the front rail 11 is used to fix the front slider 21; the middle rail 16 is fixed on the middle baffle 15, and the middle rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com