Light and thin material conveying and stacking mechanism

A kind of material, light and thin technology, applied in the field of textile production, can solve the problems of time-consuming and labor-intensive, low production efficiency, restricting productivity, etc., and achieve the effect of easy manufacturing, high production efficiency and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

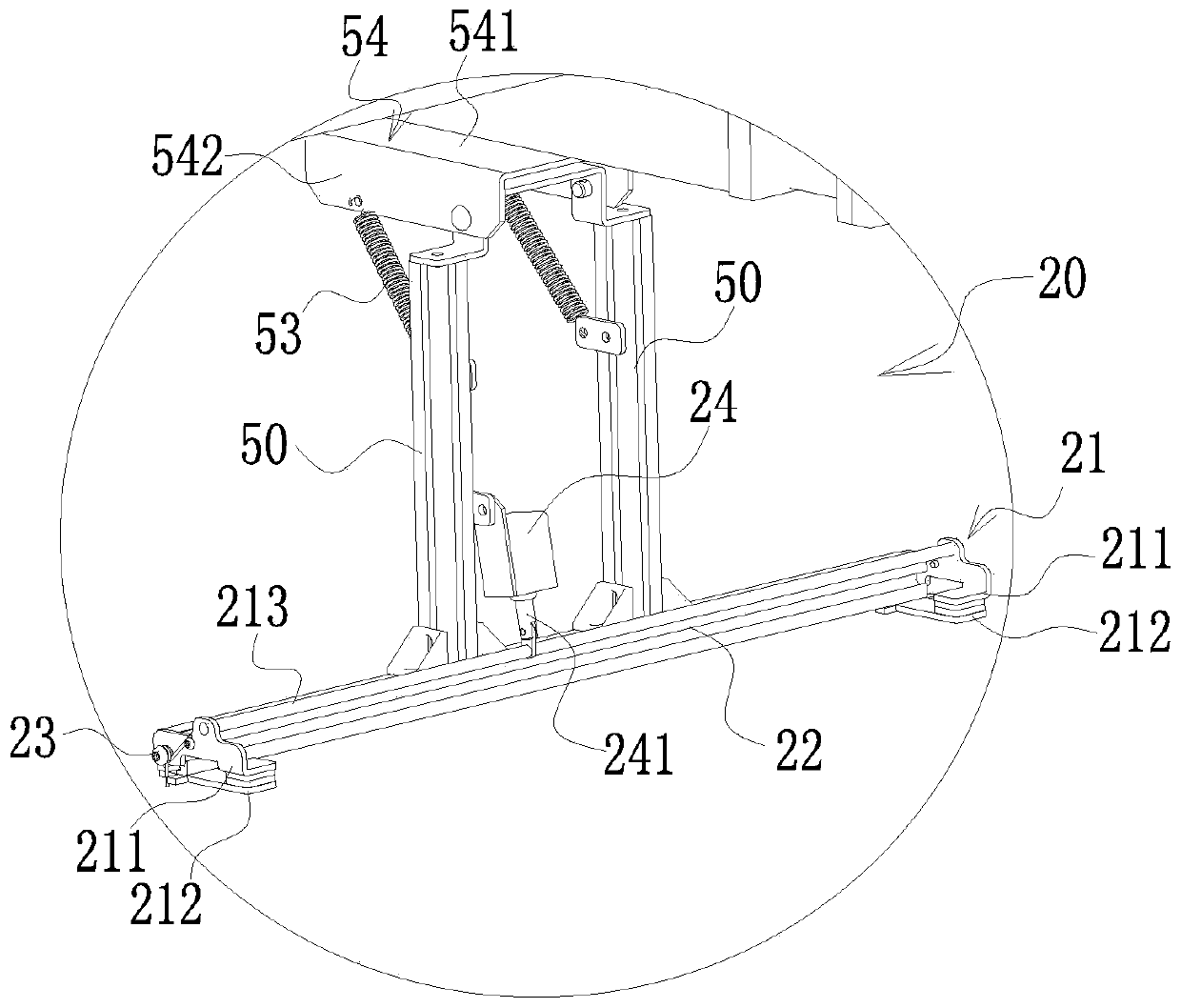

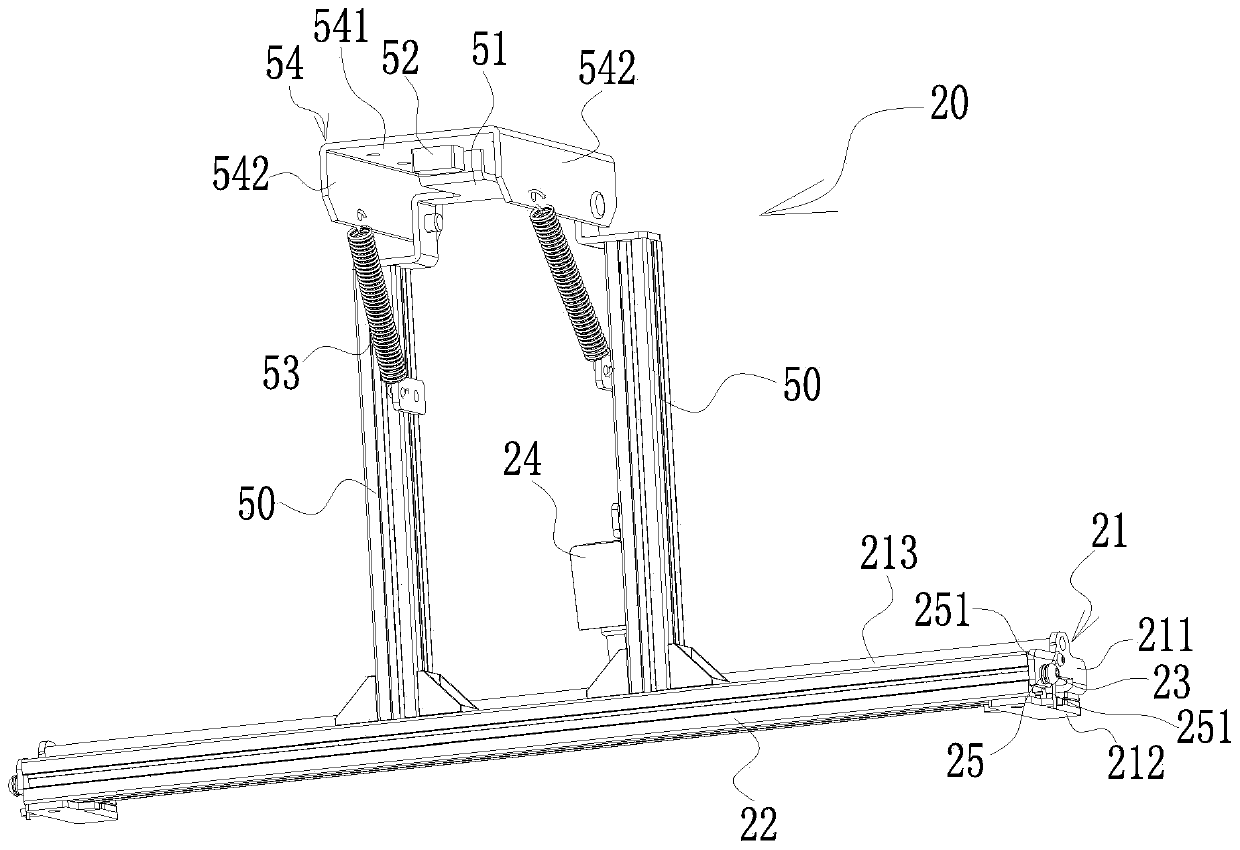

[0029] For ease of understanding, the present invention will be described in detail below in conjunction with the accompanying drawings.

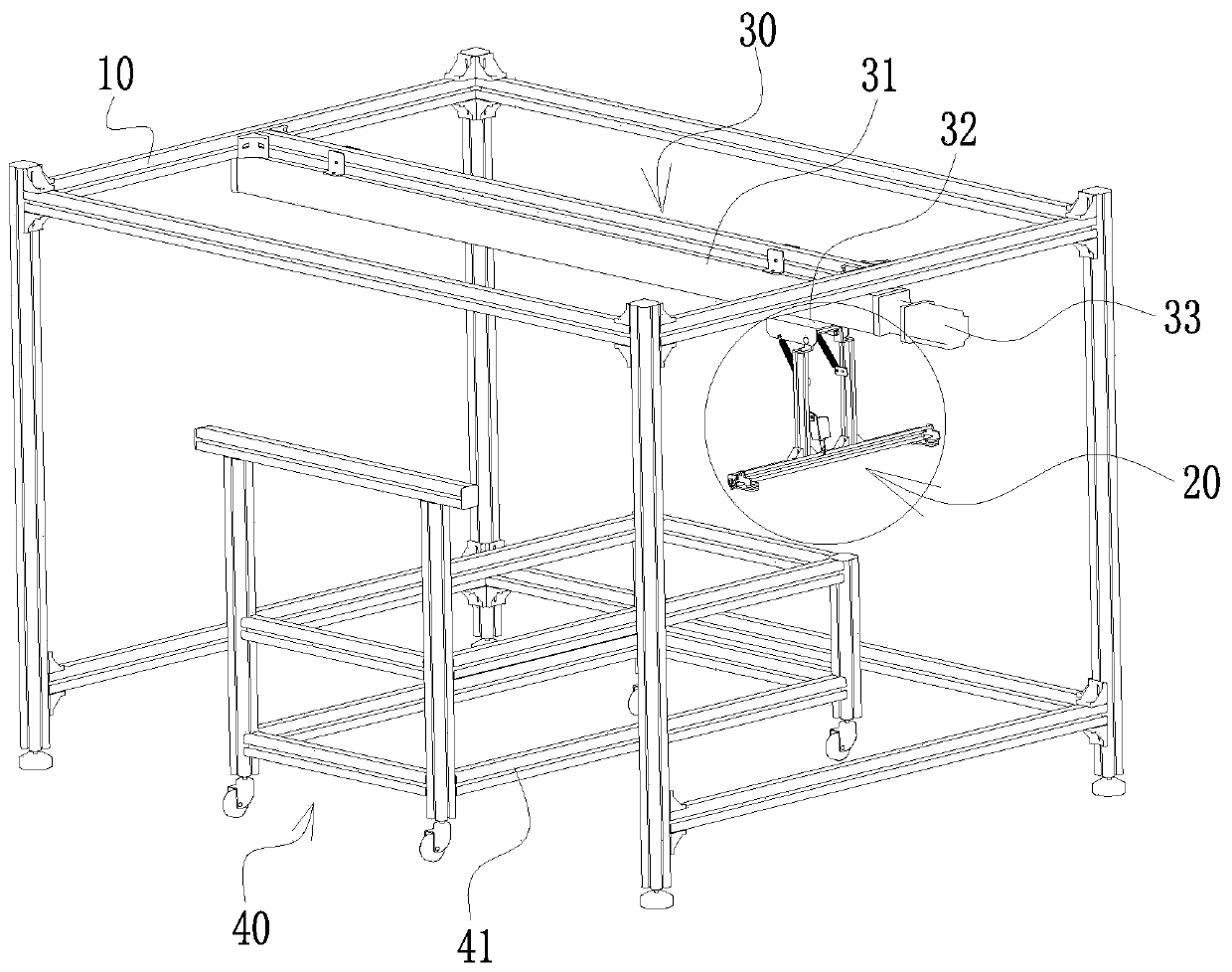

[0030] A light and thin material conveying and stacking mechanism, including a frame 10, a clamping unit 20 for clamping materials is arranged on the frame 10; the mechanism also includes a driving unit 30 connected with the clamping unit 20; A material stacking and transferring unit 40 is arranged on the moving path, and the driving unit 30 drives the clamping unit 20 to perform reciprocating motion between the receiving position and the discharging position of the stacking and transferring unit 40; the mechanism also includes an incoming material detection unit. When the upstream incoming material position of this mechanism cuts the material, the incoming material detection unit (can be placed on the frame 10 for fixed connection, can also be placed on the side of the frame 10, determined according to the actual site, not shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com