Method of welding hanging ring of large transfusion PP bottle

A large infusion and hanging ring technology, applied in applications, household appliances, and other household appliances, can solve problems such as the center of the bottom, bottle scrapping, elastic deformation, etc., and achieve the effect of standard shape, quality assurance, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

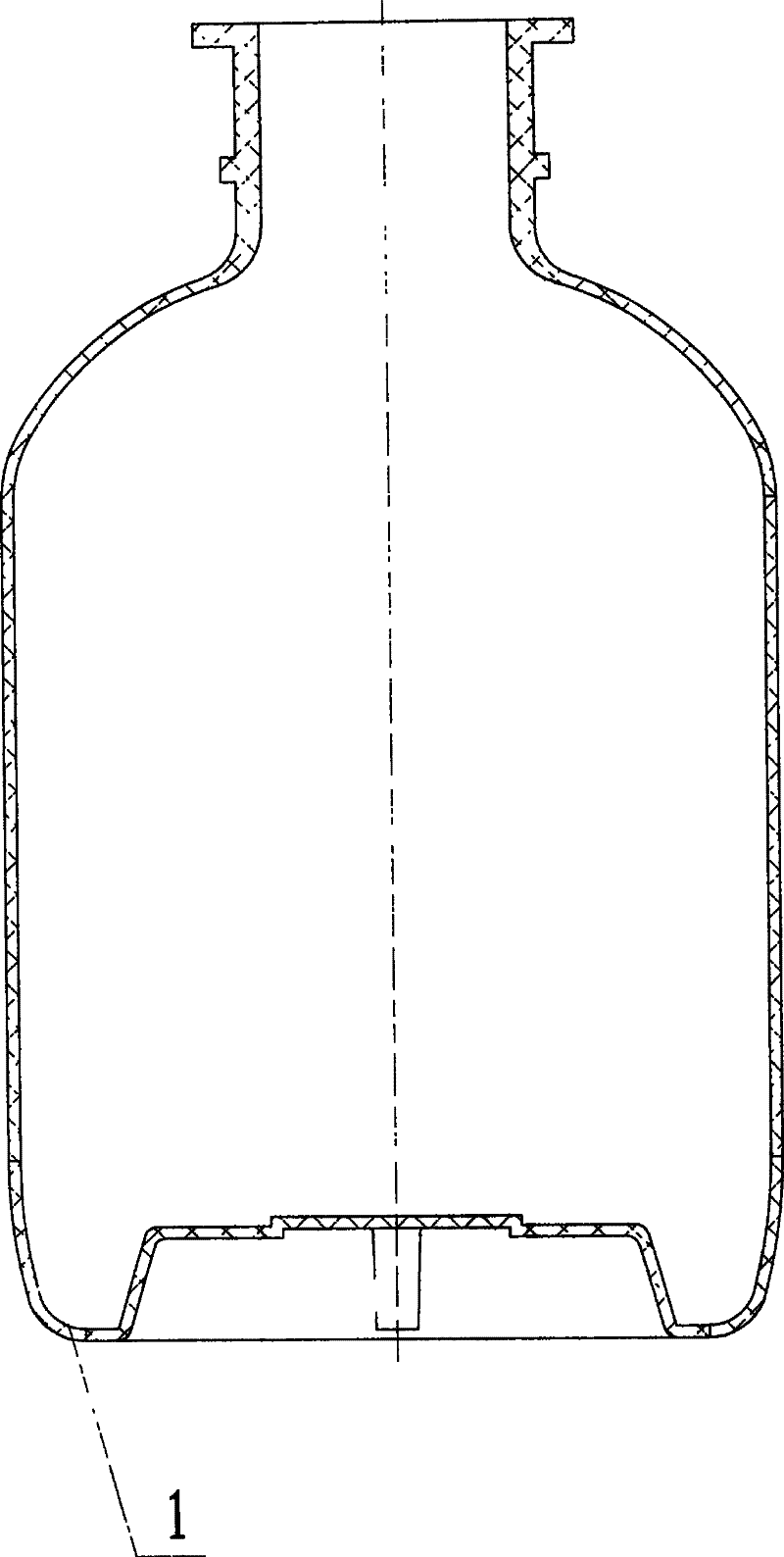

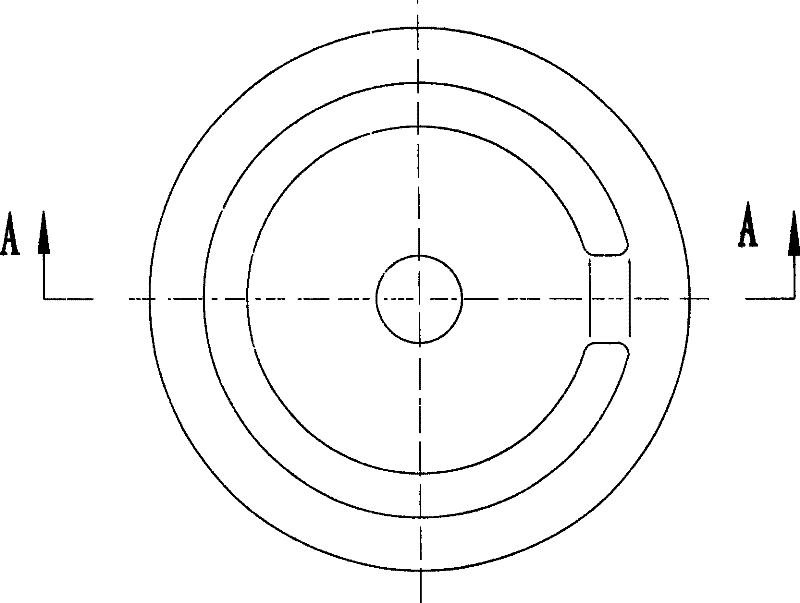

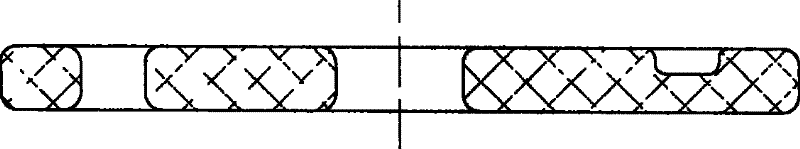

[0017] The method for the welding suspension ring of the large transfusion PP bottle of the present invention, its technological step is: first figure 2 , 3 Shown suspension ring 2 is welded on the bottle blank 3 before blow molding (seeing Figure 5 ) on the top of the bottom, as Image 6 As shown, due to the shape specification of the preform 3 shaped by the injection mold, the center of the lifting ring 2 is easy to align with the top of the bottom, and because the rigidity of the preform 3 is better, the welding quality is also good; The preform 3 is heated, and then the preform 3 is blow-molded into a large transfusion PP bottle 1 that is welded with a suspension ring 2. Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com