Tool for detecting coating condition of heat-conducting silicone grease

A technology for detecting tooling and thermal grease, applied in color measurement devices, mechanical thickness measurement, etc., can solve the problems of consistent coating thickness of thermal grease, observing and judging thermal grease, the influence of coating conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

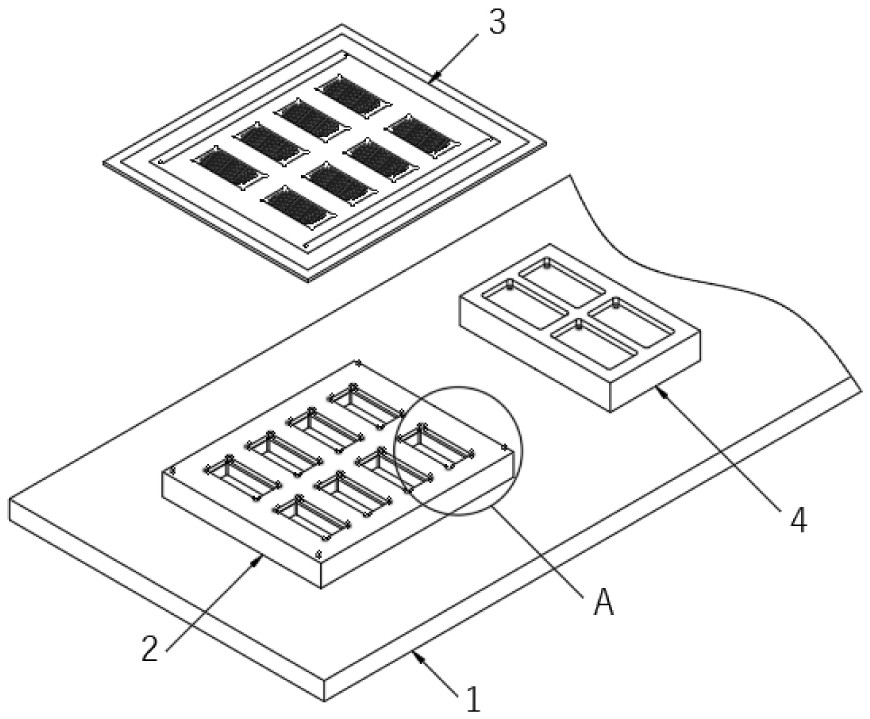

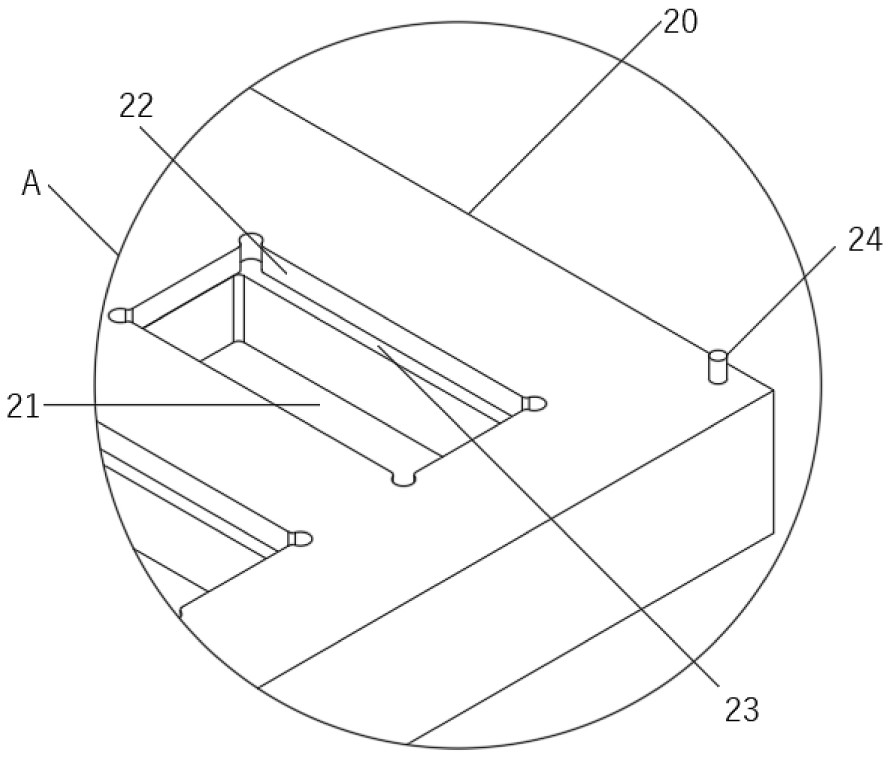

[0038] see Figure 1-Figure 4 , this embodiment provides a technical solution: a thermal conductive silicone grease coating condition detection tool, including a placement mold 2 arranged on the work table 1, the placement mold 2 includes a rectangular plate 20, and the rectangular plate 20 is provided with a plurality of The placement grooves 21 arranged in a matrix, a groove 22 is provided on the groove wall at the top position of the placement groove 21, and two symmetrical step surfaces 23 are arranged between the placement groove 21 and the groove 22. , it is convenient to place the module on the stepped surface 23, so that the bottom of the module is suspended, preventing the terminal at the bottom of the module from contacting the desktop or being squeezed to cause the module to fail;

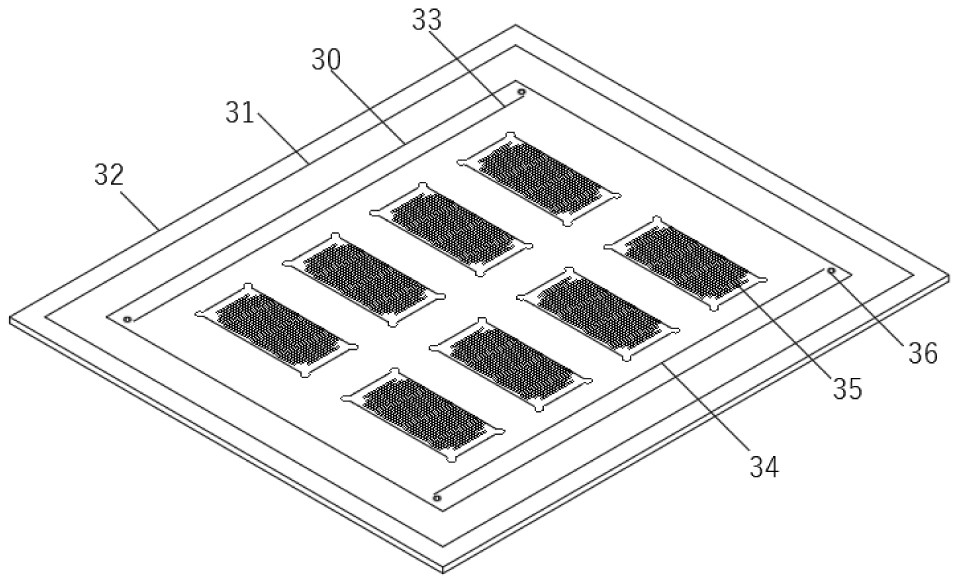

[0039] Specifically, a steel mesh 3 is provided above the placement mold 2, and the steel mesh 3 includes a center plate 30. A plurality of coating holes 35 communicated with the outside a...

Embodiment 2

[0047] see Figure 5-Figure 6 , the difference between this embodiment and Embodiment 1 is that a sleeve box 50 is fixedly installed on the bottom surface of the outer plate 31 , the sleeve box 50 is sleeved on the rectangular plate 20 , and the size of the rectangular plate 20 is just suitable for the size of the sleeve box 50 After the sleeve box 50 is placed on the rectangular plate 20, the outer plate 31 can be further positioned, so that the outer plate 31 can be correctly placed on the upper surface of the rectangular plate 20 more smoothly, which is further beneficial to ensure the central plate 30. The positional mismatch with the rectangular plate 20 is unlikely to occur.

[0048] In this embodiment, an annular groove 5 is provided on the work surface 1, and a pressing device 6 is arranged at the position of the annular groove 5. The pressing device 6 includes a bearing 60 whose outer ring is fixedly installed on the groove wall of the annular groove 5. A support col...

Embodiment 3

[0053] see Figure 7-Figure 8 The difference between this embodiment and Embodiment 1 is that an ejector device 7 is provided at the bottom of the work table 1, and the ejector device 7 includes a hydraulic cylinder 70 arranged under the work table 1, and a bottom plate is provided on the telescopic shaft of the hydraulic cylinder 70 72. A plurality of lifting plates 73 arranged in a matrix are fixedly installed on the top surface of the bottom plate 72. The lifting plates 73 are located in the placing groove 21 and are slidably connected with the placing groove 21, so as to facilitate the use of the hydraulic cylinder 70 to work and drive the The lifting plate 73 is lifted upwards to push out the modules in the placement slot 21 to the outside, so that the module can be taken out from the placement slot 21 more smoothly.

[0054] In this embodiment, a steel plate 71 is fixedly installed at the end of the telescopic shaft of the hydraulic cylinder 70 , and the bottom plate 72 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com