Labelling device for bottled drink

A beverage and bottled technology, which is applied in the field of container labeling machines, can solve problems such as weak strengthening of label bonding, bottle overturning, and easy label falling, so as to enhance bonding strength, ensure bonding strength, and high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

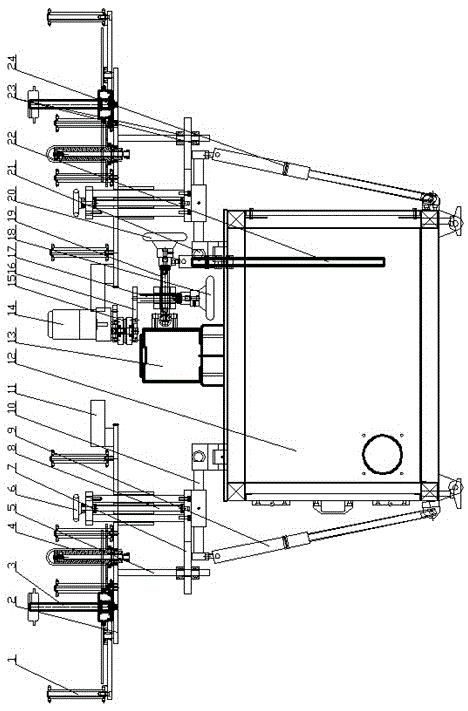

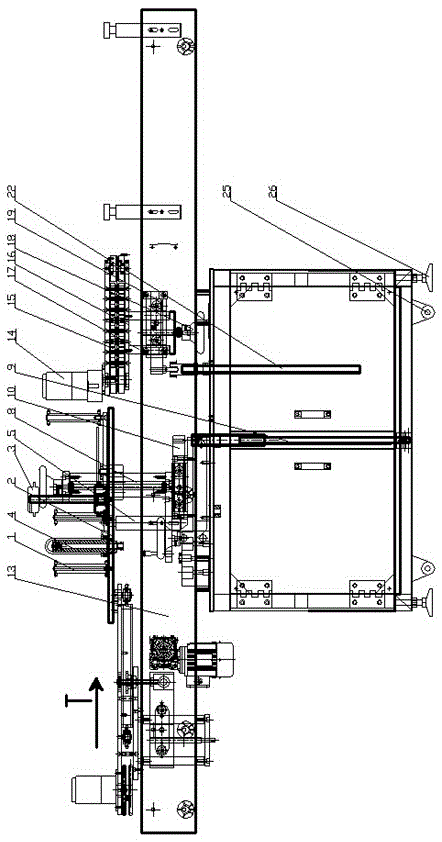

[0026] refer to Figure 1~3 , a bottled beverage labeling device of the present embodiment includes a beverage bottle conveying device 13, two label turntables 2, a frame 12 and a labeling protection wheel; the beverage bottle conveying device 13 is placed on the machine in an L shape One side of the frame 12; the label transfer tray 2 is fixed on the frame 12 through the movable adjustment pillar 8, and is located on both sides of the beverage bottle conveying device 13; the label protection wheel is fixed on the label transfer tray 2 along the Transmission device 13 transmission direction (as figure 2 One side of the T direction shown in ); the pressure marking guard wheel includes a first vertical strut 22, a horizontal fixing rod 19, a second vertical strut 17, and a wheel guard 15; the first vertical strut The rod 22 is provided with a first adjustment knob (not marked) for adjusting the inclination angle of the wheel guard 15; the horizontal fixed rod 19 is connected t...

Embodiment 2

[0034] A kind of bottled beverage labeling device of this embodiment has the following differences from Embodiment 1:

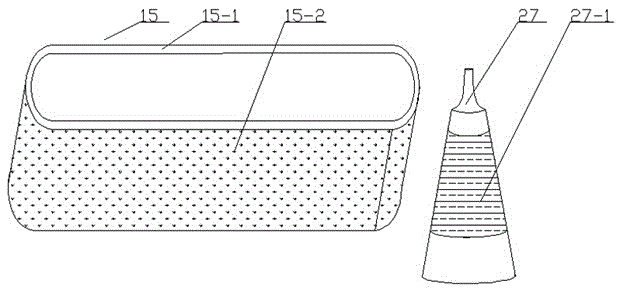

[0035] refer to Figure 4 and 5 , the wheel guard 15 also includes a detachable pressing block 28, the pressing block 28 is composed of a bonding bottom surface 28-1 and a label compacting body 28-2, and the label compacting body 28-2 is in the shape of "∏", Its shape matches with beverage bottle 27 structures.

Embodiment 3

[0037] A kind of bottled beverage labeling device of this embodiment has the following differences from Embodiment 1:

[0038] refer to Image 6 , the wheel guard 15 also includes a detachable pressing block 28, the pressing block 28 is composed of an adhesive bottom surface 28-1 and a label compacting body 28-2, and the label compacting body 28-2 is in the shape of “[”, Its shape matches with beverage bottle 27 structures.

[0039] The bottled beverage labeling device described in Embodiment 2 and Embodiment 3 is suitable for labeling beverage bottles 27 with conical or irregular cylinder bodies.

[0040] When beverage bottle 27 bottle bodies were irregular cylinders, a detachable briquetting block 28 was installed on the wheel guard 15, and the briquetting block 28 was fixed on the wheel guard 15 by the bonding bottom surface 28-1 at the bottom of the briquetting block 28. The shape of the upper part matches the structure of the beverage bottle 27. The label pressing body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com