Reinforcing rib pressing machine for color steel tile and its application method

A technology of reinforcing ribs and color steel tiles, applied in the direction of manufacturing tools, metal processing equipment, other manufacturing equipment/tools, etc., can solve the problem of inability to adjust the size, etc., to improve dimensional accuracy, expand the scope of application, and improve the aesthetics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

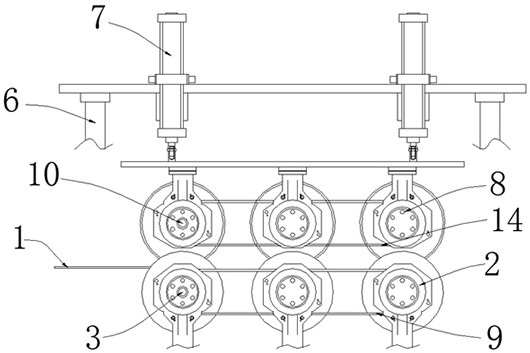

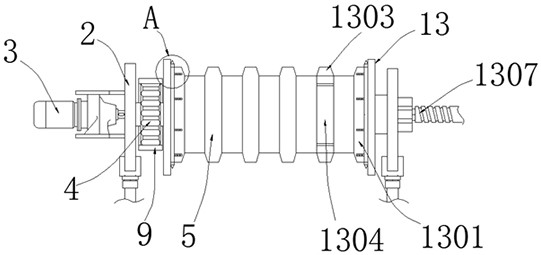

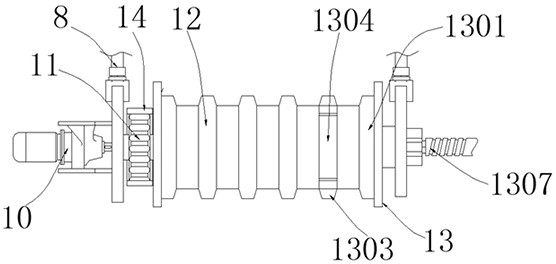

[0036] see Figure 1 to Figure 9, the present invention provides a technical solution: a reinforcing rib pressing machine for color steel tiles, including a steel plate body 1 and a size adjustment assembly 13, characterized in that: a first movable support 2 is arranged under the right end of the steel plate body 1, and One side of the first movable support 2 is fixed with a first motor 3, the output end of the first motor 3 is connected with a first gear 4, and one side of the first gear 4 is provided with a main supporting pressure roller 5, and the first gear 4 They are connected to each other through the first transmission belt 9, the top of the first mobile support 2 is provided with a pressing frame 6, and the surface of the pressing frame 6 is fixed with a hydraulic press 7, and the bottom of the hydraulic press 7 is connected with a second mobile support 8, And one side of the second movable support 8 is provided with a second motor 10, the output end of the second mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com