Patents

Literature

31results about How to "Avoid potholes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

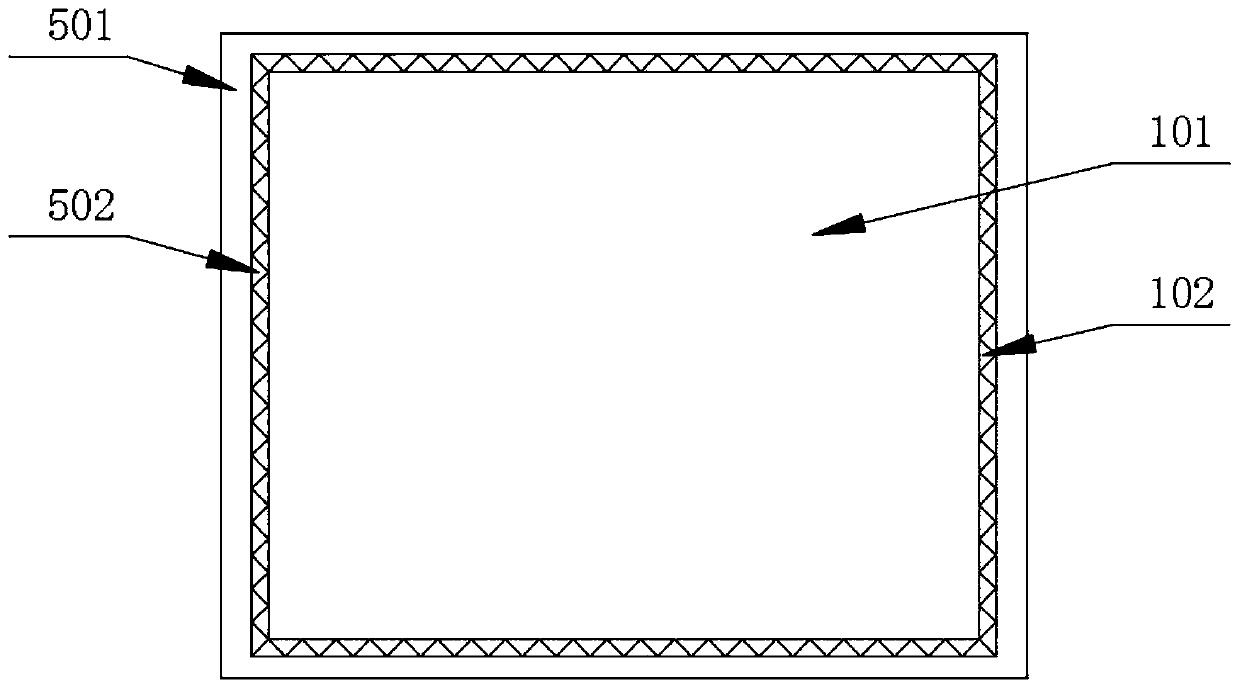

Cold-resistant, corrosion-resistant, flame-retardant and anti-interference double-sheath cable

ActiveCN110993171APrevent slippageImprove flame retardant performanceInsulated cablesCable/conductor manufactureEngineeringMoisture resistance

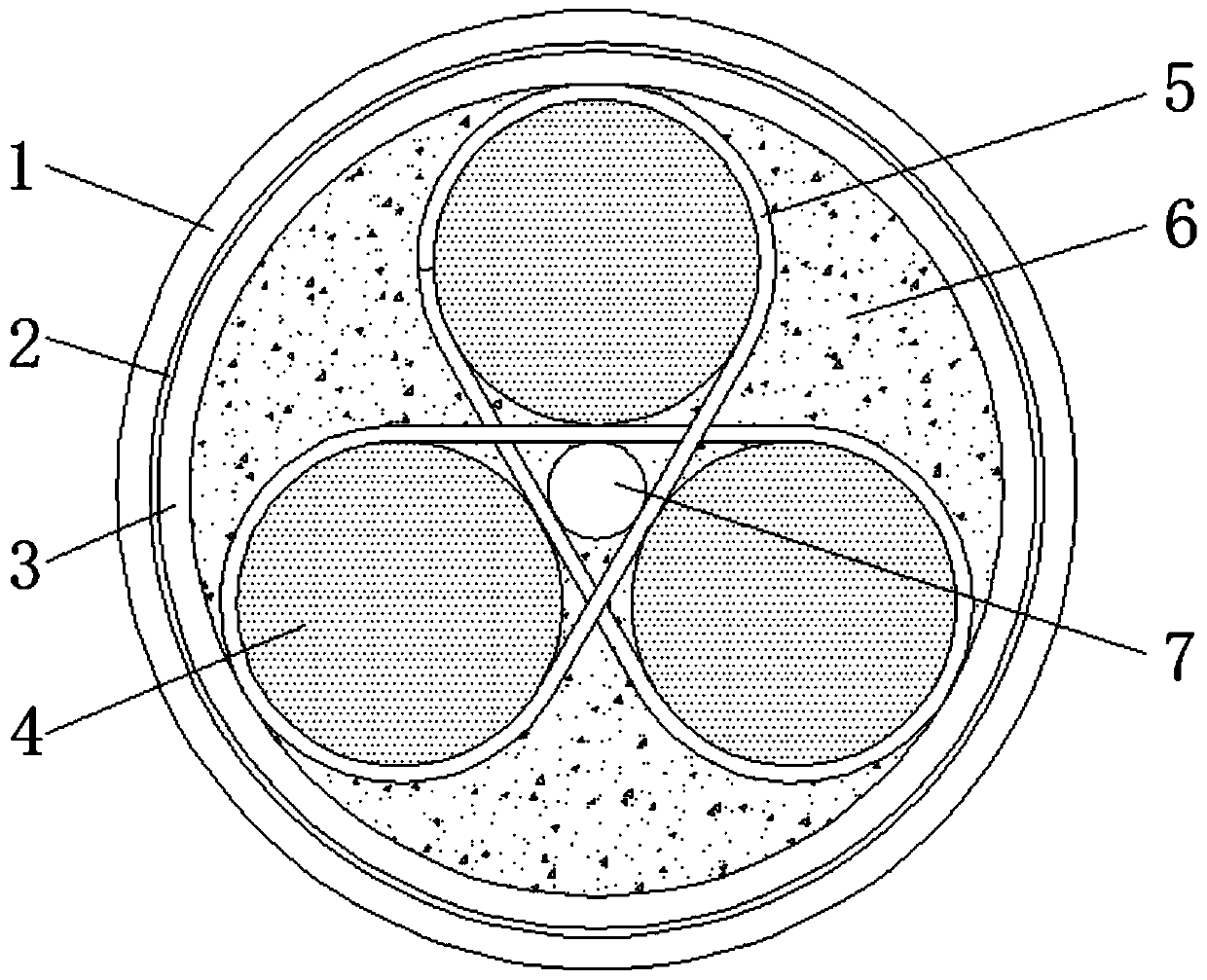

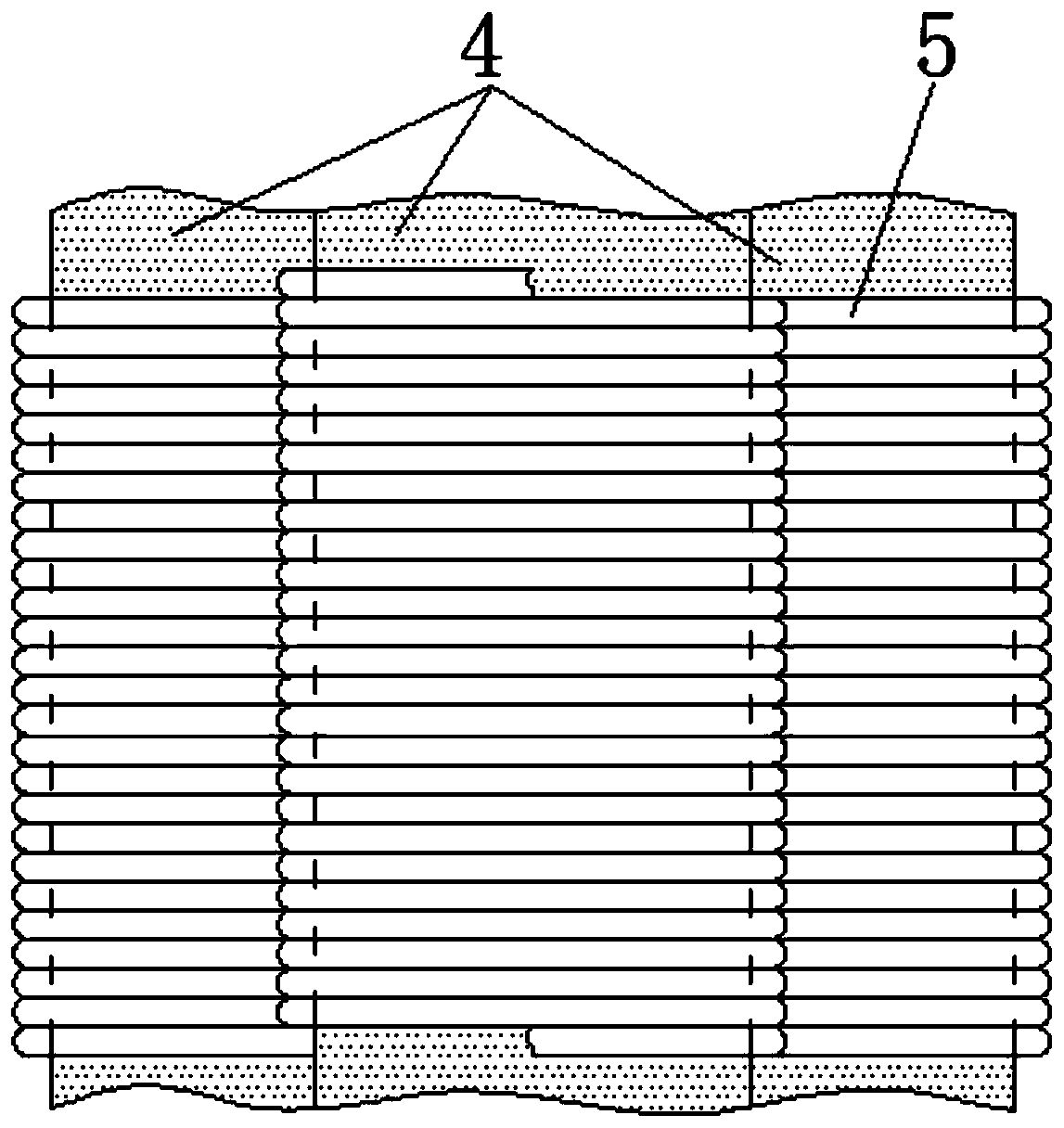

The invention discloses a cold-resistant, corrosion-resistant, flame-retardant and anti-interference double-sheath cable. The cable comprises an outer sheath, an anti-torsion layer, an inner sheath, awater-blocking filler and a cable core; the inner sheath is extruded on the outer side of the cable core, the anti-torsion layer is wrapped on the outer side of the inner sheath, and the outer sheathis extruded on the outer side of the anti-torsion layer; and the cable core comprises three wire cores, a tensile rope and a fixing rope. The inner sheath, the anti-torsion layer and the outer sheathare sequentially wrapped on the outer side of the cable core; double protection can be effectively performed on the cable; the cold resistance, moisture resistance and corrosion resistance of the cable are improved; the wire core can be effectively fixed and dragged through the fixing rope; the cable core is prevented from deforming and breaking due to mutual extrusion in the bending process, thefriction force between the cable core and the sheath can be effectively improved through the circularly wrapped fixing rope, the slippage between the cable core and the inner sheath is avoided, the generated stress is homogenized and eliminated through the ductility of the fixing rope, the cracking and deformation of the cable are avoided, and the service life of the cable is prolonged.

Owner:JINAN SHENGTONG POWER CABLE

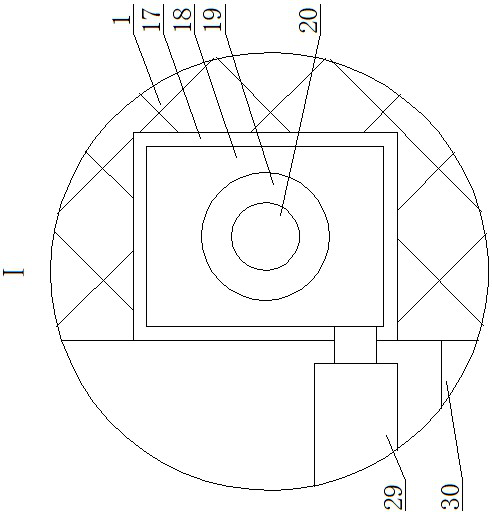

Rainwater collecting and recycling device for building

ActiveCN112411669APromote ruptureReduce impactFatty/oily/floating substances removal devicesSewerage structuresEnvironmental resource managementGreening

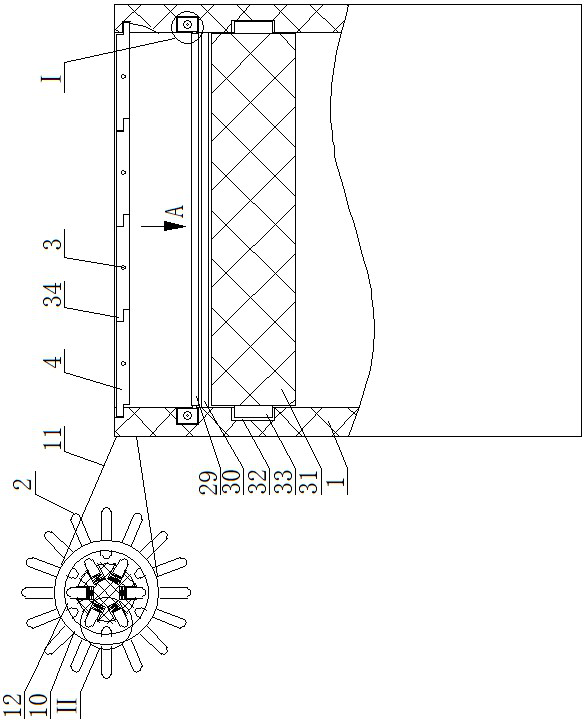

The invention discloses a rainwater collecting and recycling device for a building. The rainwater collecting and recycling device comprises a box with an opening in the top face and a blade roller, aplurality of rotating shafts are in the box, a strip-shaped plate is arranged outside the rotating shafts, a rack is outside the box, an air cylinder is connected to one end of the rack, a connectingrod is hinged to the other end of the rack, sliding grooves formed in the two sides of the inner wall of the box, sliding blocks in the sliding grooves, a guide sleeve is on the back face of the box,a movable rod penetrates the guide sleeve, the sliding blocks are connected through a first filter screen, a second filter screen is arranged below the first filter screen, and screen baskets are arranged in front of and behind the second filter screen. The device is started according to the rainfall, rainwater is not collected when the rainfall is small, rainwater is not hindered from nourishinga greening zone, the device is started when the rainfall is large, the impact force of the rainwater can be reduced through the blade roller, ground pits at a water outlet can be avoided, the impact force of the rainwater is fully utilized for movement of the strip-shaped plate and the first filter screen, energy is saved, when the strip-shaped plate is closed, external dust, animal waste and thelike can be prevented from entering the box body, and pollution to the interior of the box body is avoided.

Owner:CHONGQING UNIV

Efficient bulldozer for building

InactiveCN105839685ASimple structureEasy to useMechanical machines/dredgersBuilding materialEngineering

A high-efficiency construction bulldozer includes a base plate, a scraping device, a pushing device, a supporting device, a cylinder device, a positioning device and a holding device, and the base plate is provided with a first support block, a second support block, a first roller, a second A curved bar, the scraping device includes a first cross bar, a scraping plate, a first bracket and a second cross bar, and the pushing device includes a first push plate, a second push plate, a first spring, a third cross bar, a first vertical Rod, second roller, projection, collecting plate and first connecting rod, supporting device includes second vertical rod, first oblique rod, second bracket, second bending rod, second spring and third spring, and cylinder device includes Cylinder, push rod, third push plate, third bracket, fourth bracket, positioning device includes first support rod, horizontal plate, fifth bracket, power supply, sixth bracket, third vertical rod, glass plate and lamp, this The invention can push construction waste or construction materials on the construction site to the required position.

Owner:陈福生

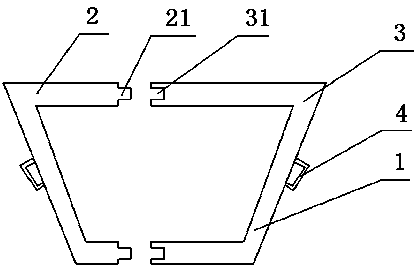

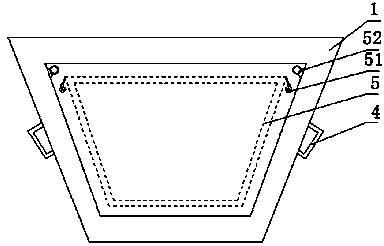

Lead cast die for molten lead cast

A lead cast die for molten liquid cast is characterized in that the die is of an inverted trapezoid structure, the die is composed of a left die body and a right die body in symmetry, and the left die body and the right die body are detachable. According to the lead cast die, on one hand, an operator can smoothly release the die, and time and labor are saved; on the other hand, lead ingot quality and cleanness of the inner wall of the die are guaranteed.

Owner:耒阳市诚松有色金属再生有限公司

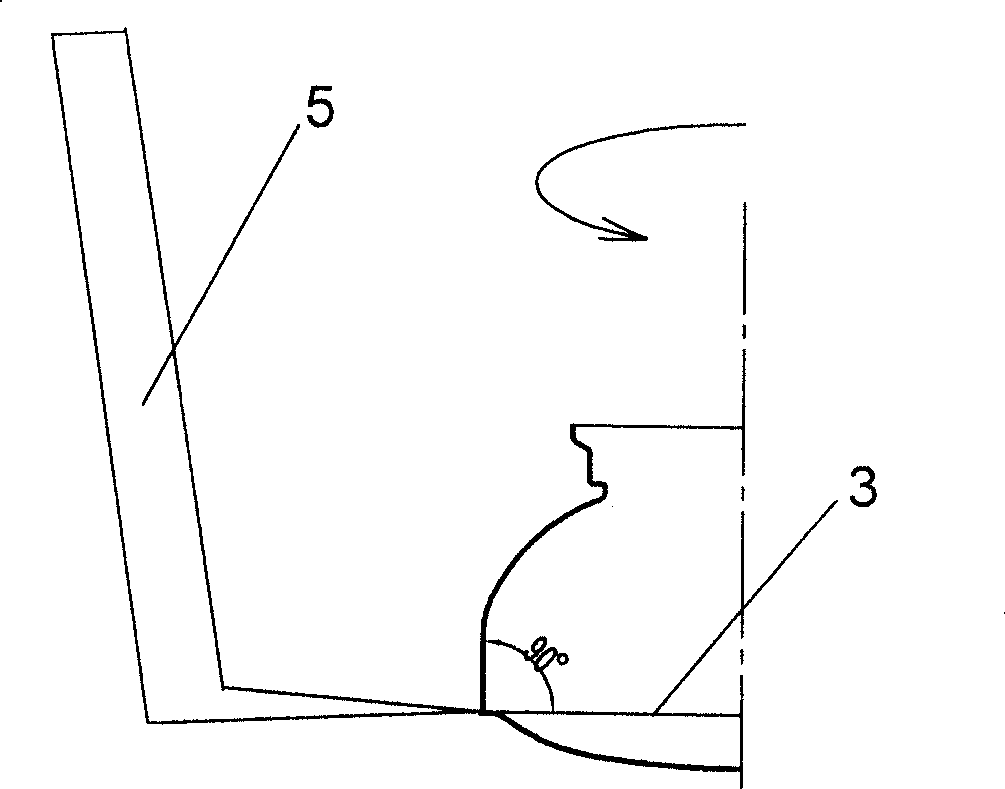

Reducing device and method for sticky substances for straw board paper

ActiveCN108468247ASpatula is convenientSpatula to preventCleaning using toolsGrain treatmentsPaper machine

The invention provides a reducing device and method for sticky substances for straw board paper. The device comprises a scraping mechanism used for removing the sticky substances on a paper machine drying cylinder; the scraping mechanism comprises a connecting frame fixedly connected with a paper machine frame, a rotating frame installed in the connecting frame, a scraping plate of which the middle shaft is connected with the rotating frame and a plurality of air cylinders installed in the connecting frame; and each air cylinder pushes one end of the scraping plate to be attached to the surface of the drying cylinder. The device and method provided by the invention are used for solving the problems that the straw board paper is easy to break and then void holes appear due to adhesion of the sticky substances in the drying process of the sticky substances.

Owner:湖北金庄科技再生资源有限公司

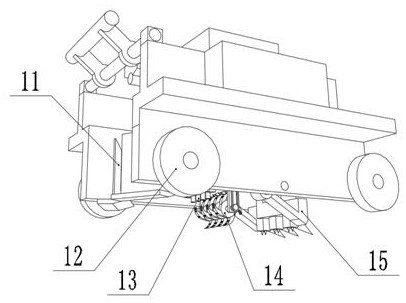

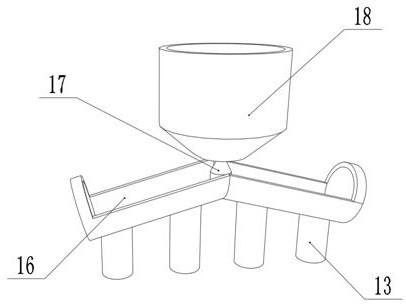

Soil fertilization device for nursery stock planting

InactiveCN112586114AEasy to moveMobile does not affectSpadesFertiliser distributersAgricultural engineeringTurning frames

The invention discloses a soil fertilization device for nursery stock planting, and relates to the technical field of nursery stock planting. In order to solve the problems that a shovel head is stained with soil or sundries, and the soil turning efficiency is affected, the device specifically comprises a vehicle body and a soil turning frame, a rotating rod is rotatably connected to the inner wall, close to the bottom, of the soil turning frame, a rotating wheel is clamped to the outer wall of the rotating rod, an arc-shaped soil turning plate is welded to the outer wall of the rotating wheel, soil turning claws are arranged on the outer wall of the soil turning plate and are in an inverted-m shape, and two or more inclined openings are formed in the inner wall of the soil turning plate.A scraper is fixed to the outer wall of one side of the soil turning frame through bolts. By arranging the soil turning frame, before work, a second electric push rod is controlled, the soil turning frame is rotated around a supporting rod, so that the soil turning claws make contact with soil, the depth of the soil turning claws entering the soil is controlled according to needs, then the soil turning claws on the soil turning plate turn the soil, when the soil turning claws are rotated to the position beside the scraper, a triangular plate squeezes out the soil on the soil turning claws, andthe soil turning claws can conveniently enter the soil again.

Owner:DATUANJIE AGRI CO LTD

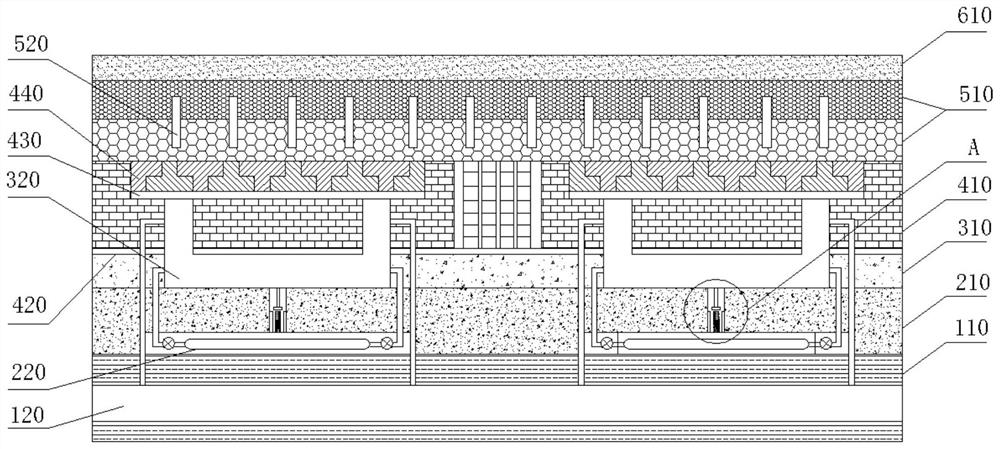

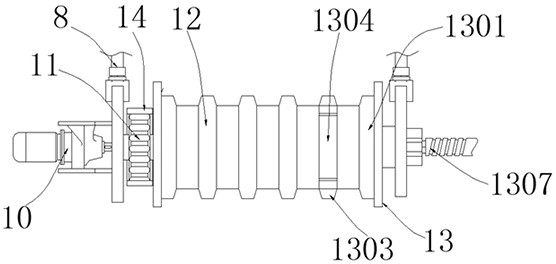

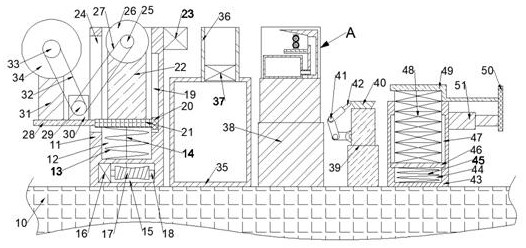

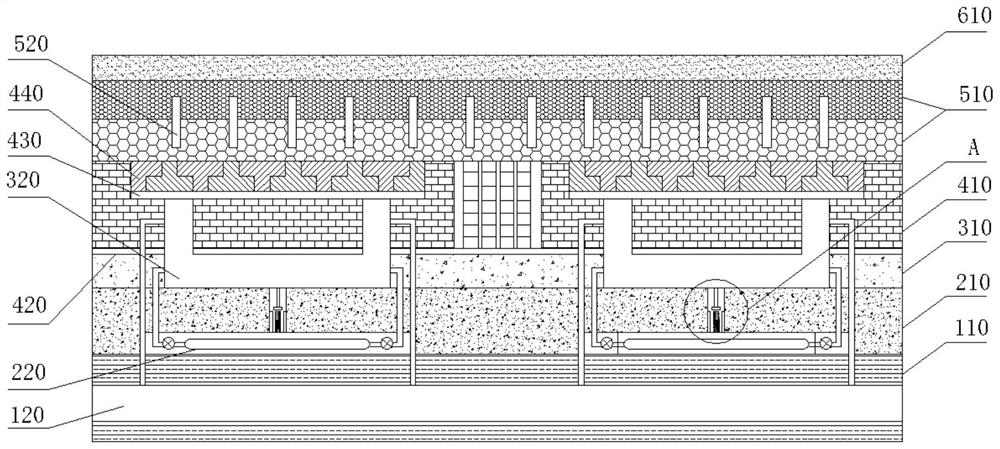

Rapid bus driving roadbed

ActiveCN113481777ASettlement controlImprove securityPaving reinforcementsPaving gutters/kerbsBrickSoil science

The invention discloses a rapid bus driving roadbed which comprises, from bottom to top, a soft soil base layer formed by leveling and tamping soft soil and pre-embedded with a main drainage pipe; a gravel layer which is formed above the soft soil base layer by pouring gravel and cement, wherein a retaining wall, a bearing frame and a monitoring structure are arranged in the gravel layer; a rubble layer which is formed by pouring rubbles and cement, wherein a water tank is arranged in the rubble layer; a water permeable brick layer which is a brick body formed above the gravel layer, wherein the water permeable brick layer is provided with a water permeable structure; an asphalt concrete layer which is formed above the water permeable brick layer, wherein the asphalt concrete layer comprises lower coarse-grain asphalt concrete, upper medium-grain asphalt concrete and stiffening rods inserted between the lower coarse-grain asphalt concrete and the upper medium-grain asphalt concrete; and a pavement layer which is formed above the asphalt concrete layer. According to the rapid bus driving roadbed, rapid drainage can be achieved, the safety of rapid bus driving in rainy days is improved, meanwhile, pavement settlement is controlled, effective jacking and timely response are conducted, and the service life of the rapid bus driving roadbed is prolonged.

Owner:CHINA ROAD & BRIDGE

Manufacturing method for sand mold casting machine tool

The invention discloses a manufacturing method for a sand mold casting machine tool. The main point of the technical scheme is the manufacturing method for the sand mold casting machine tool. The manufacturing method comprises the steps that mixed moulding sand is guided into a mould frame for fixing and forming, and a machine tool model is prefabricated in the mould frame; a plurality of independent sand mold moulds are arranged inside the mould frame, and flow channels allowing molten iron to flow are formed between every two adjacent sand mold moulds; the inner surface of the mould frame and the surfaces of the sand mold moulds are coated with fireproof coating agents in a flowing mode; the coating agents are mixed with alcohol and sintered on the surfaces of the sand mold moulds through ignition ; breathable through holes are formed in the side wall of the mould frame, and gas in the moulding sand is heated in the casting process and discharged through the breathable holes; and at the time of casting, the molten iron is cooled to 1360-1380 DEG C, then slowly guided into the molten iron flow channels, and the gas in the flow channels is ignited to be burned. The surface of the machine tool manufactured by the manufacturing method for the sand mold casting machine tool is smooth and level, air holes do not occur, and the rate of finished products is high.

Owner:浙江品川精密机械有限公司

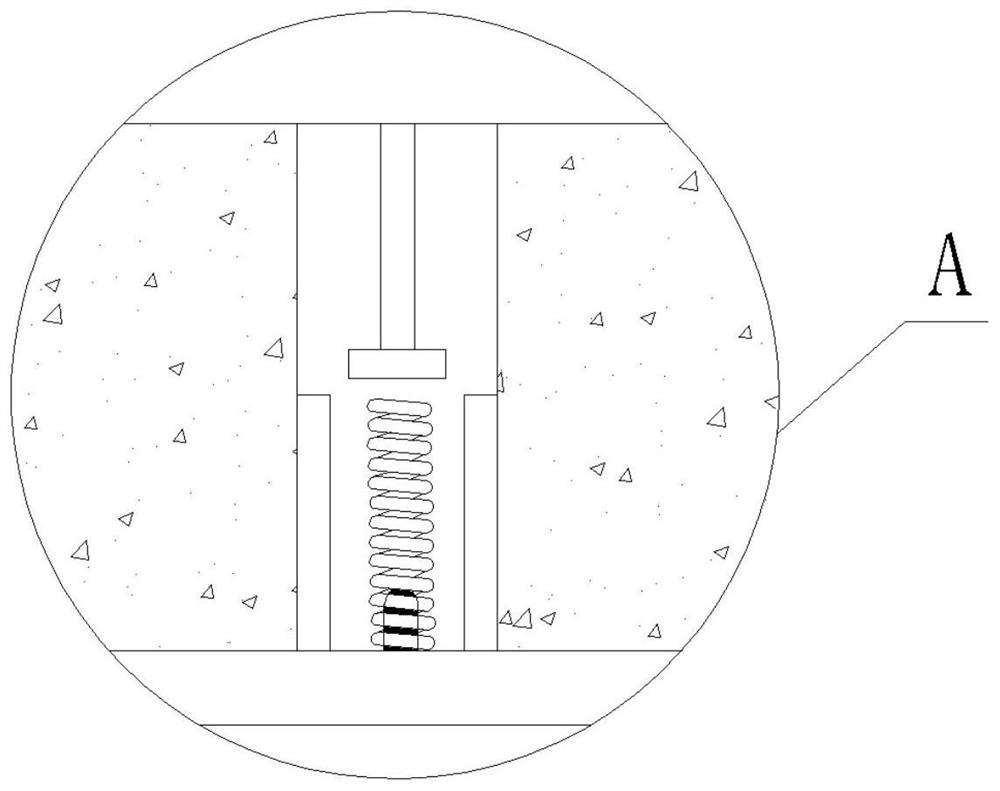

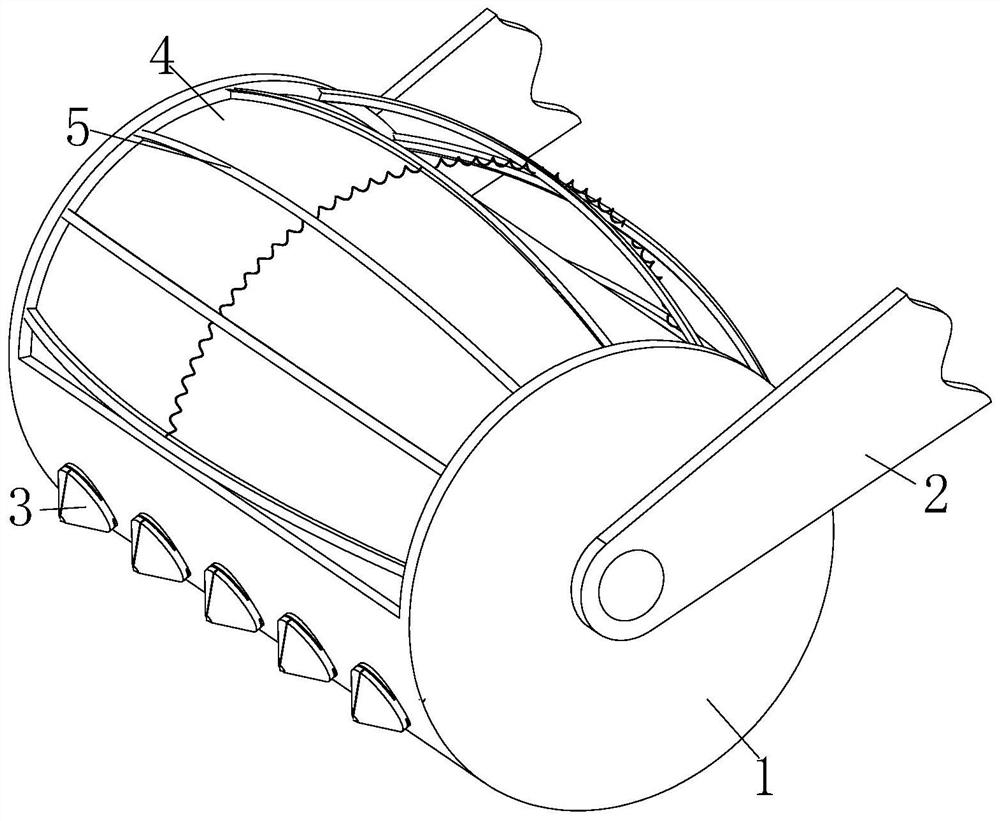

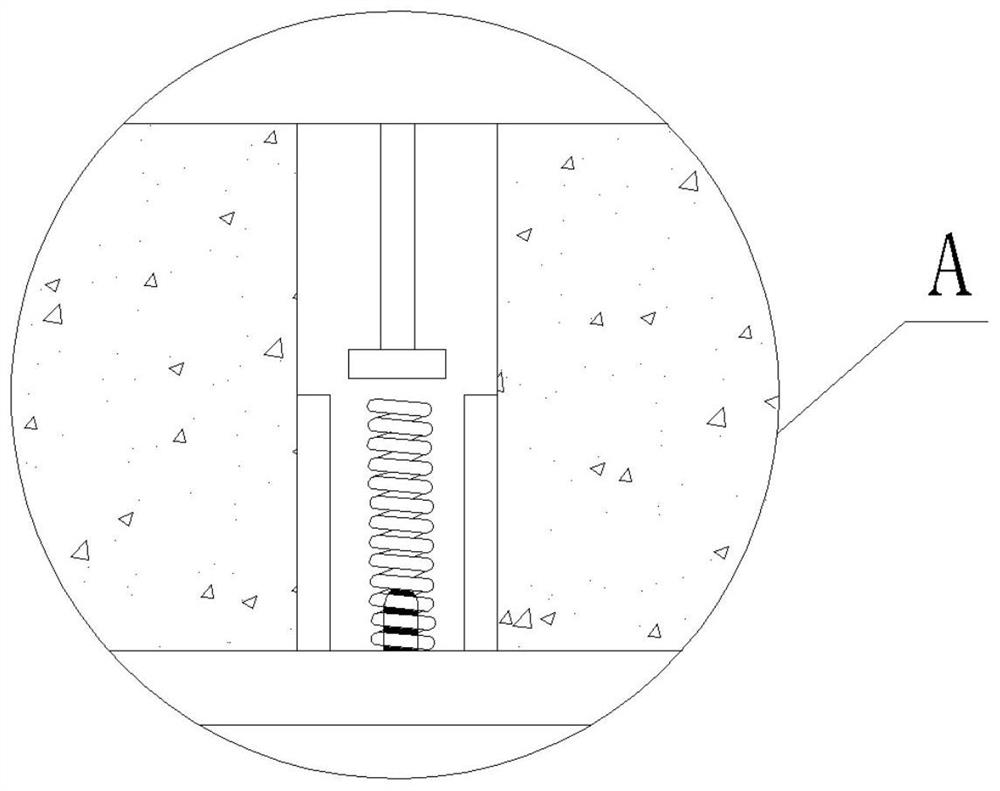

Pothole road deicing device for

InactiveCN113605298ASo crackedGood tearing effectSnow cleaningEnvironmental geologyStructural engineering

Owner:王芳秀

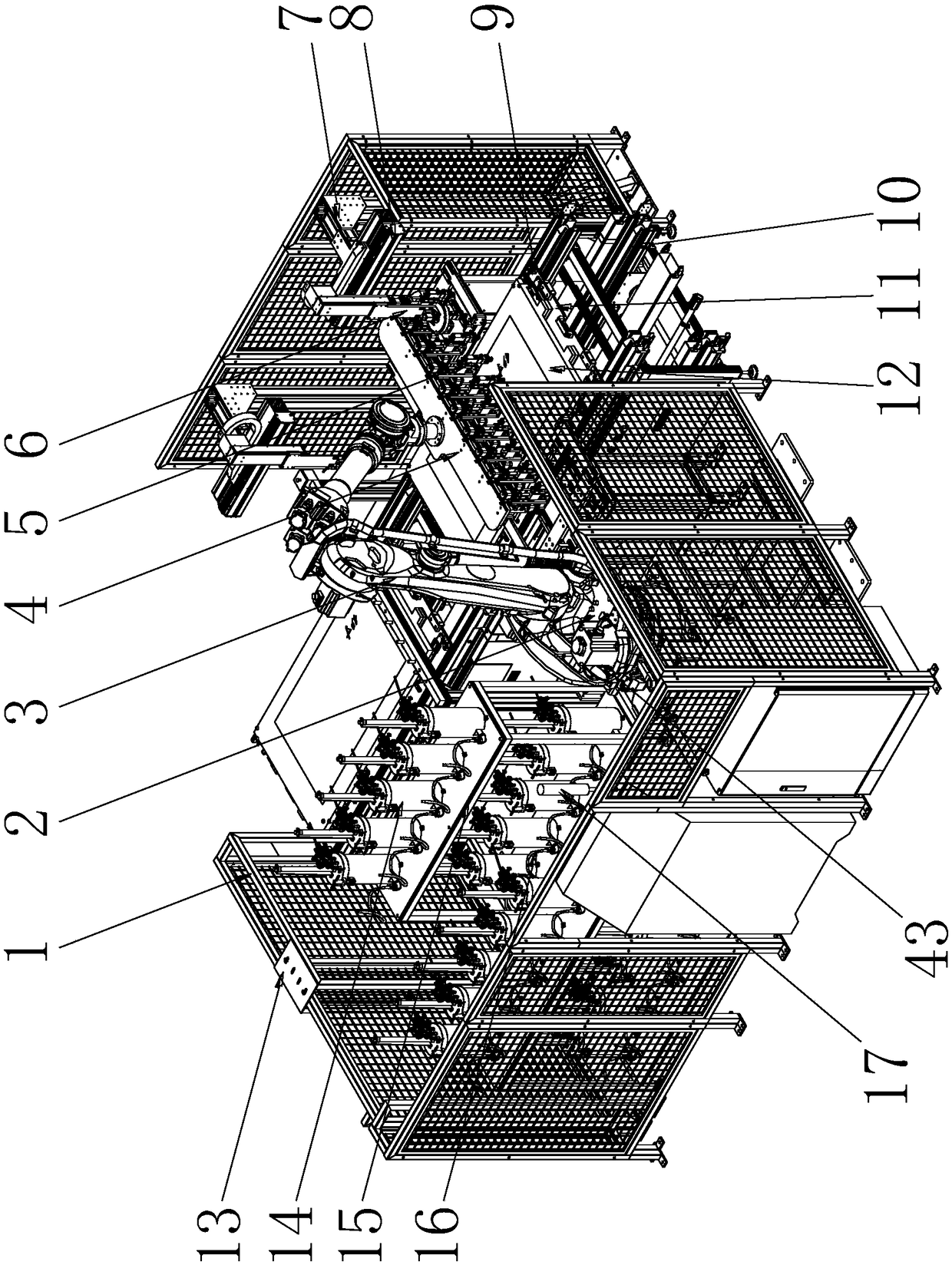

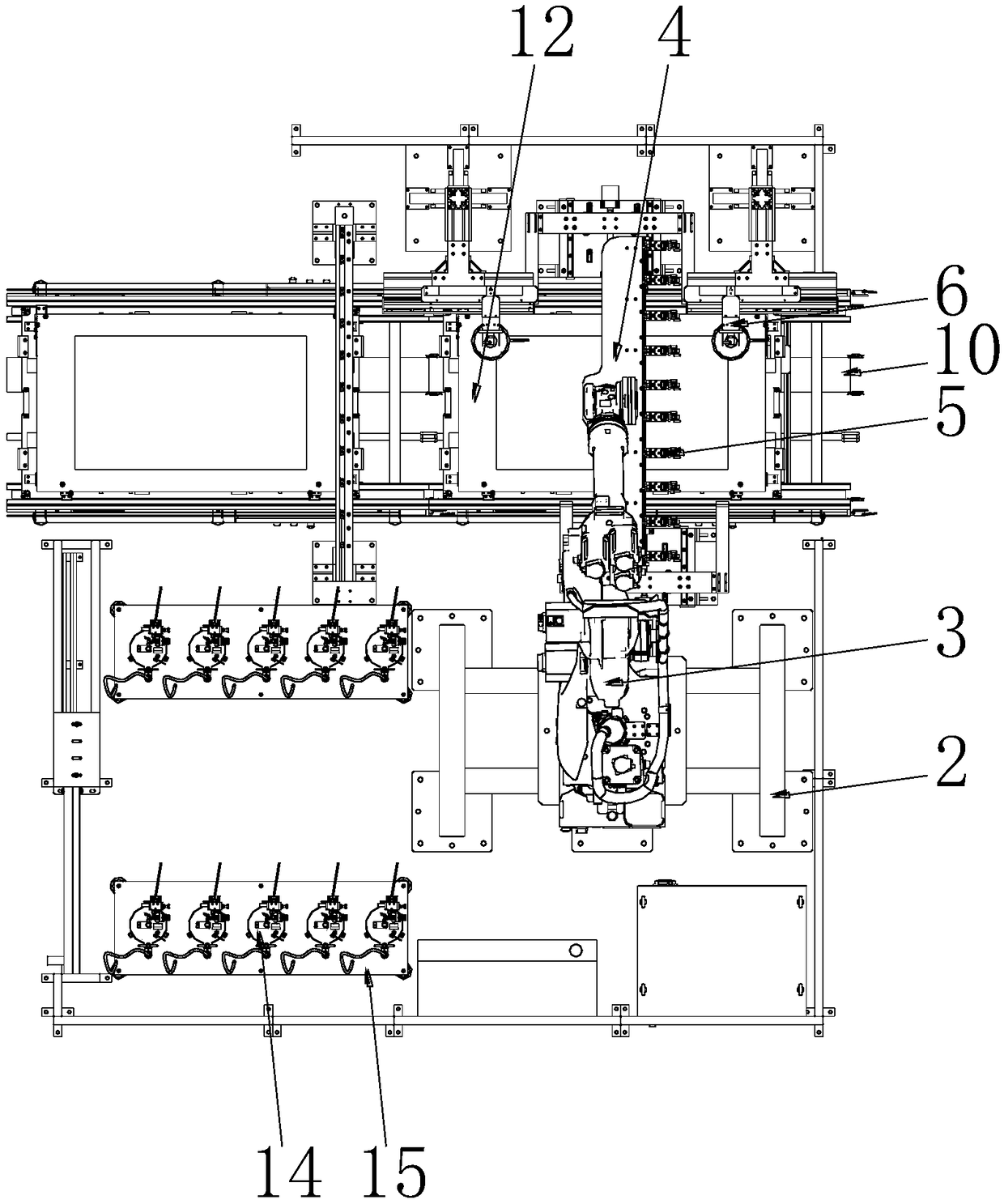

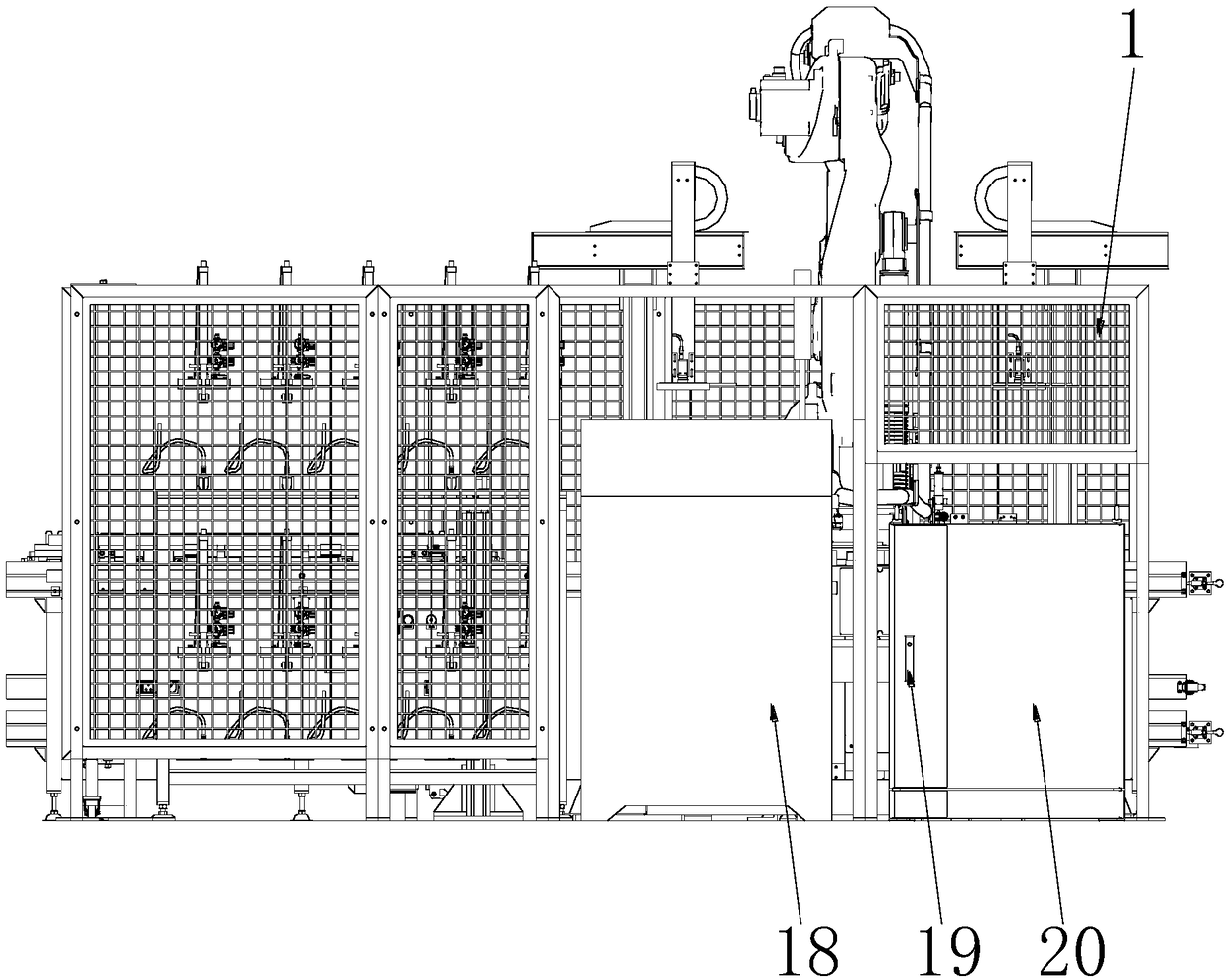

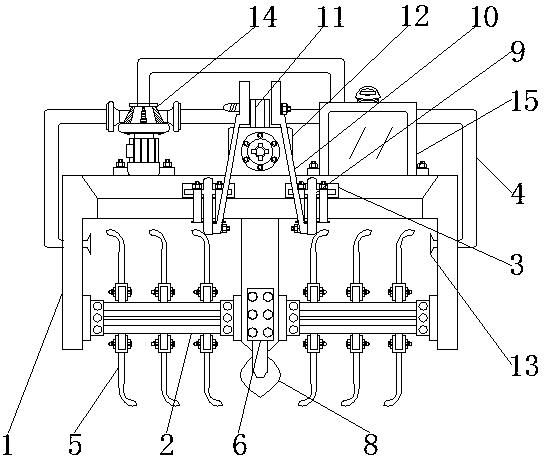

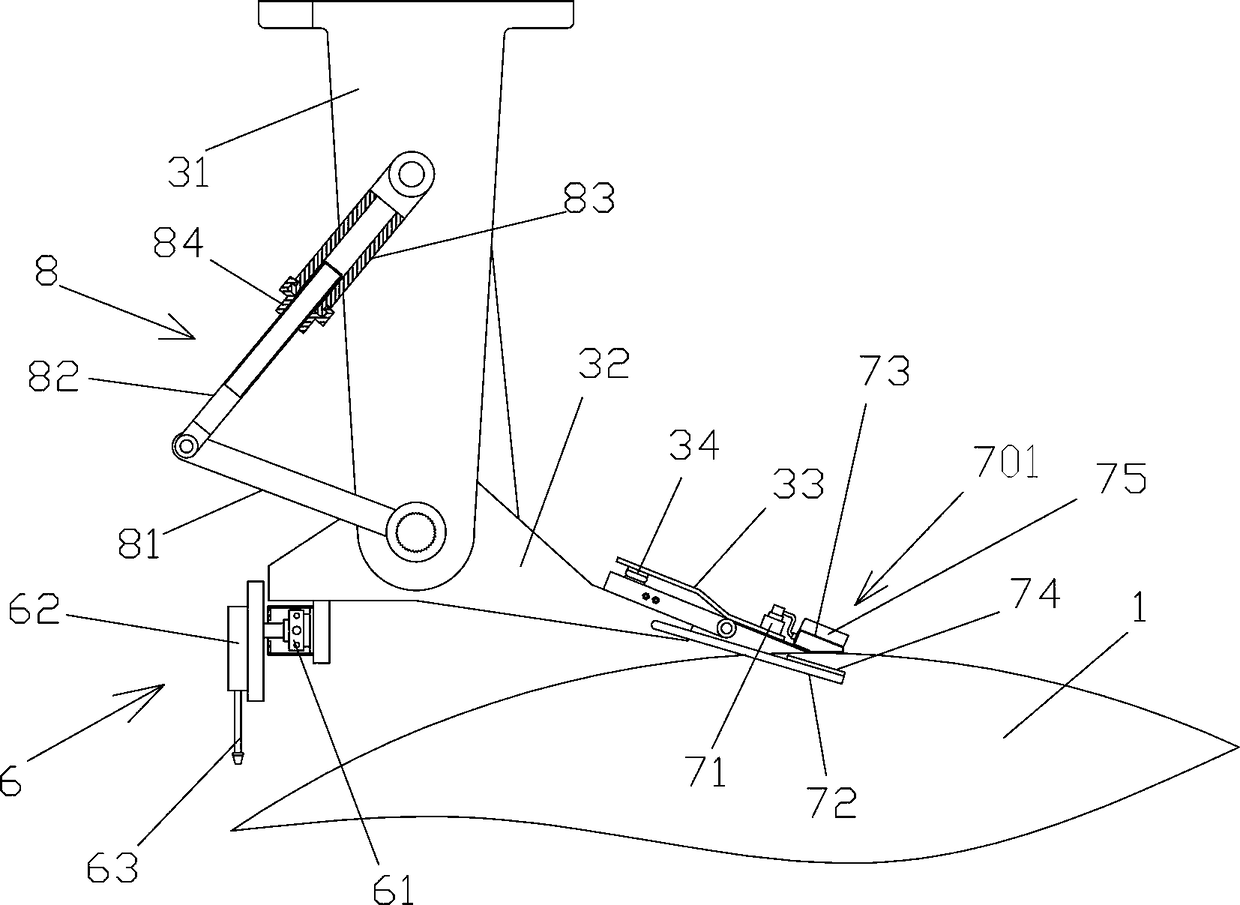

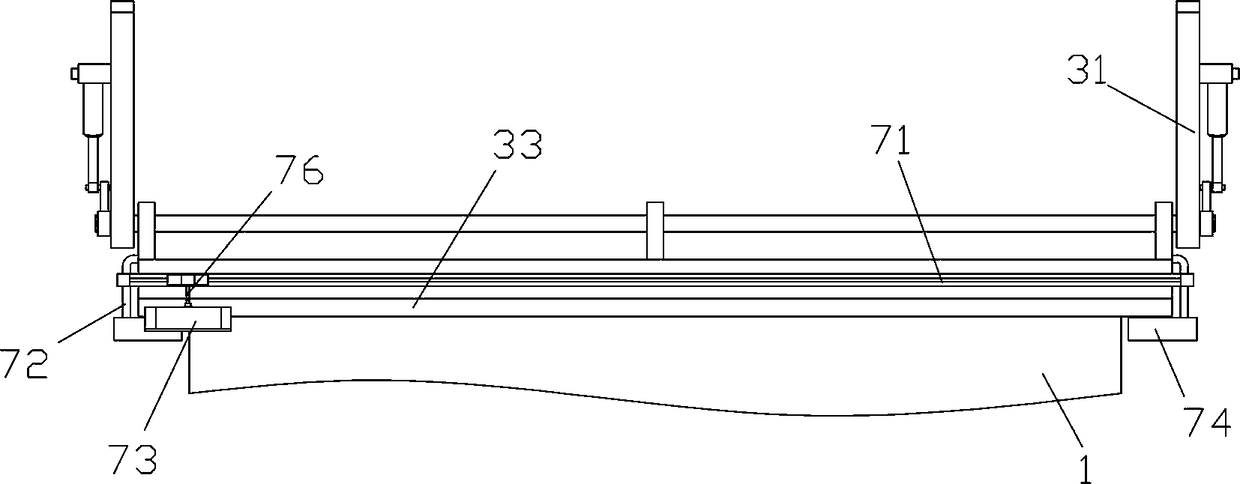

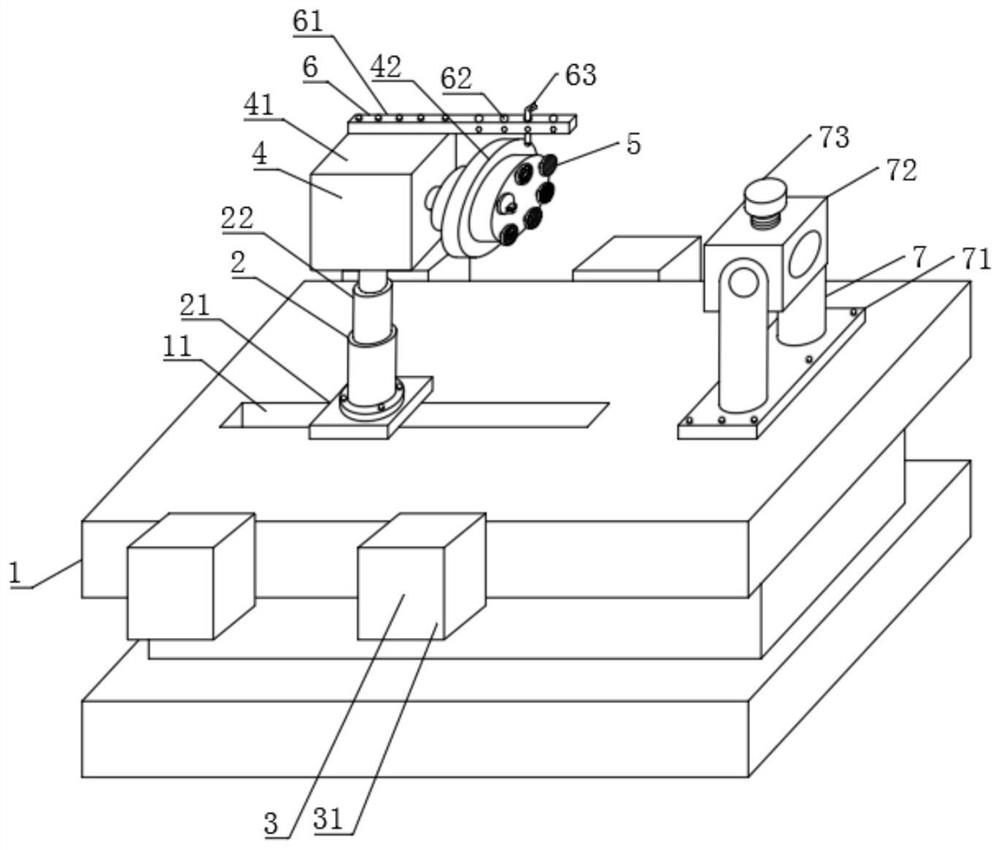

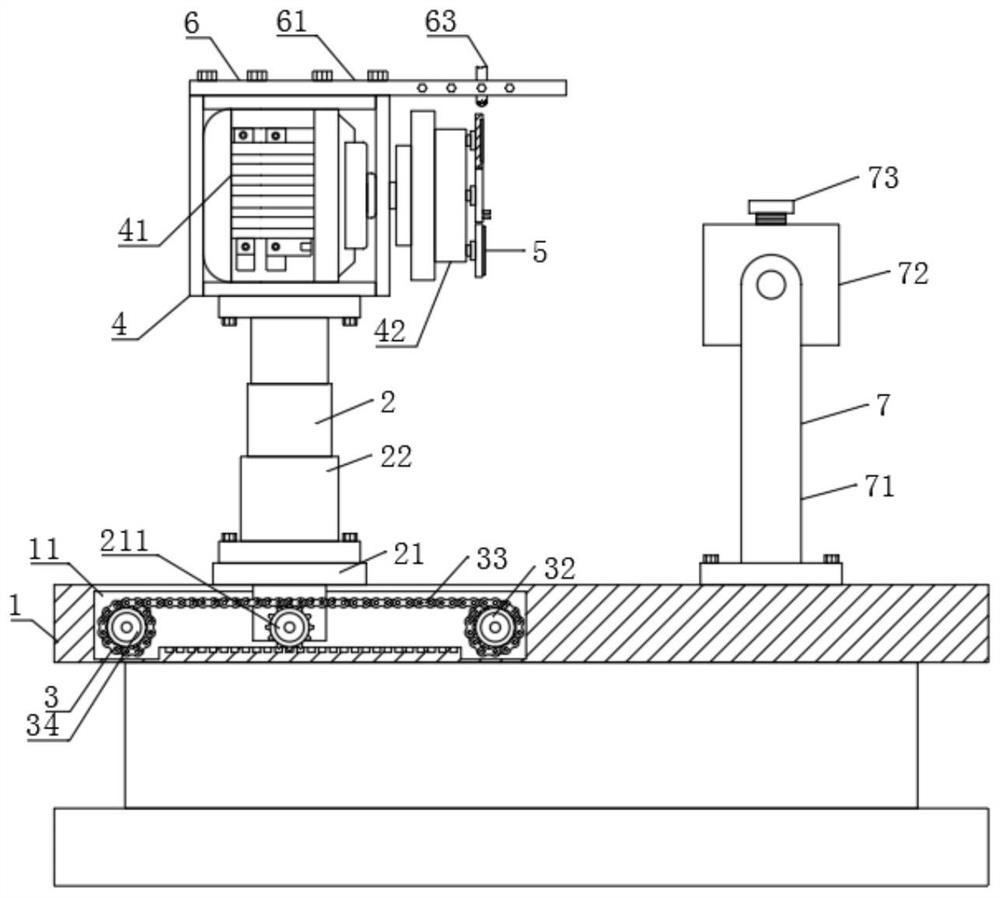

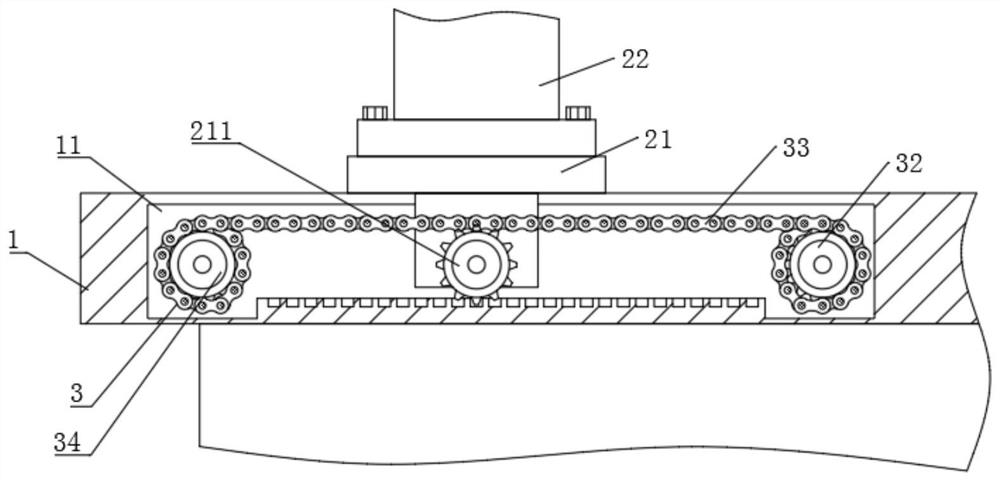

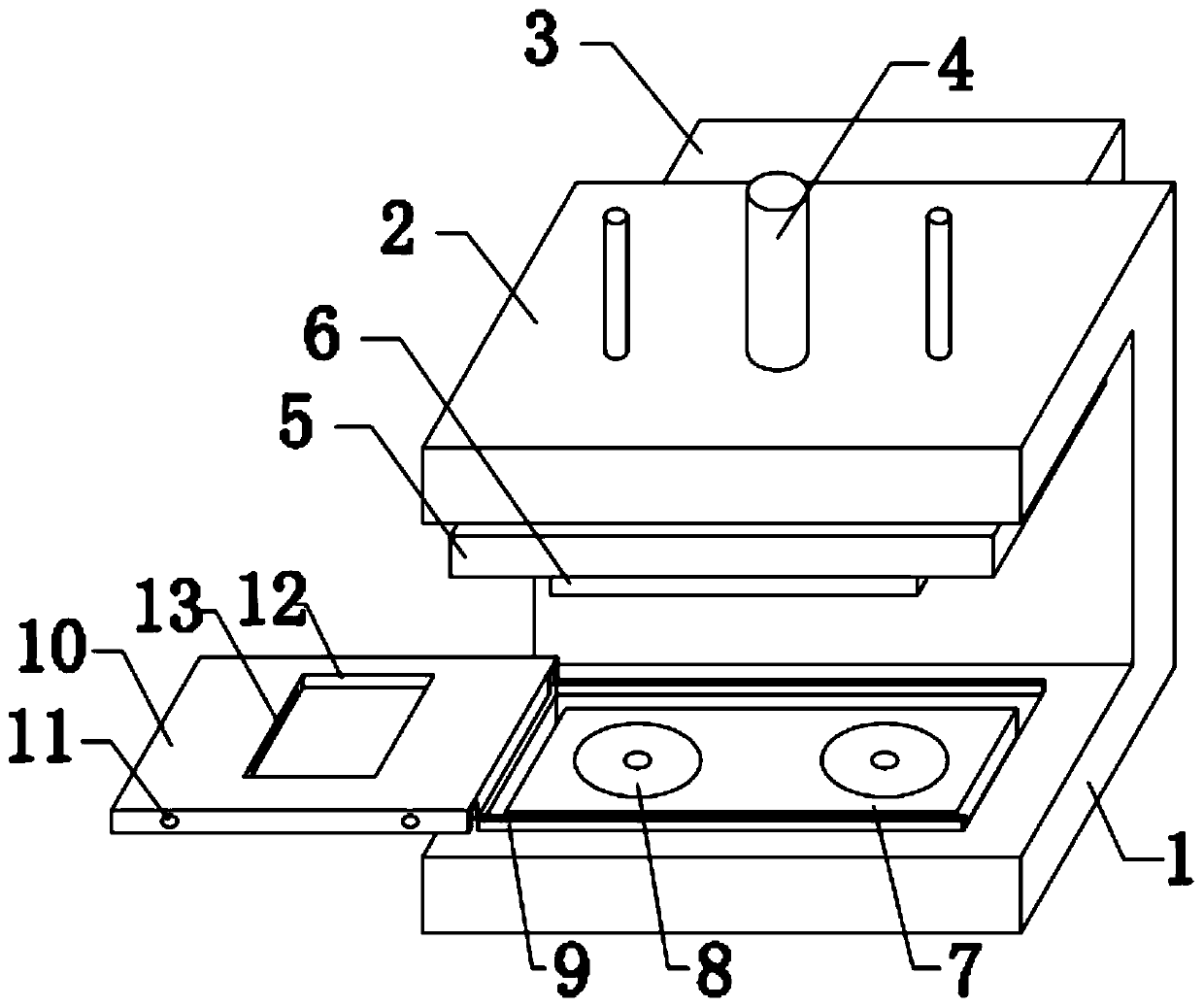

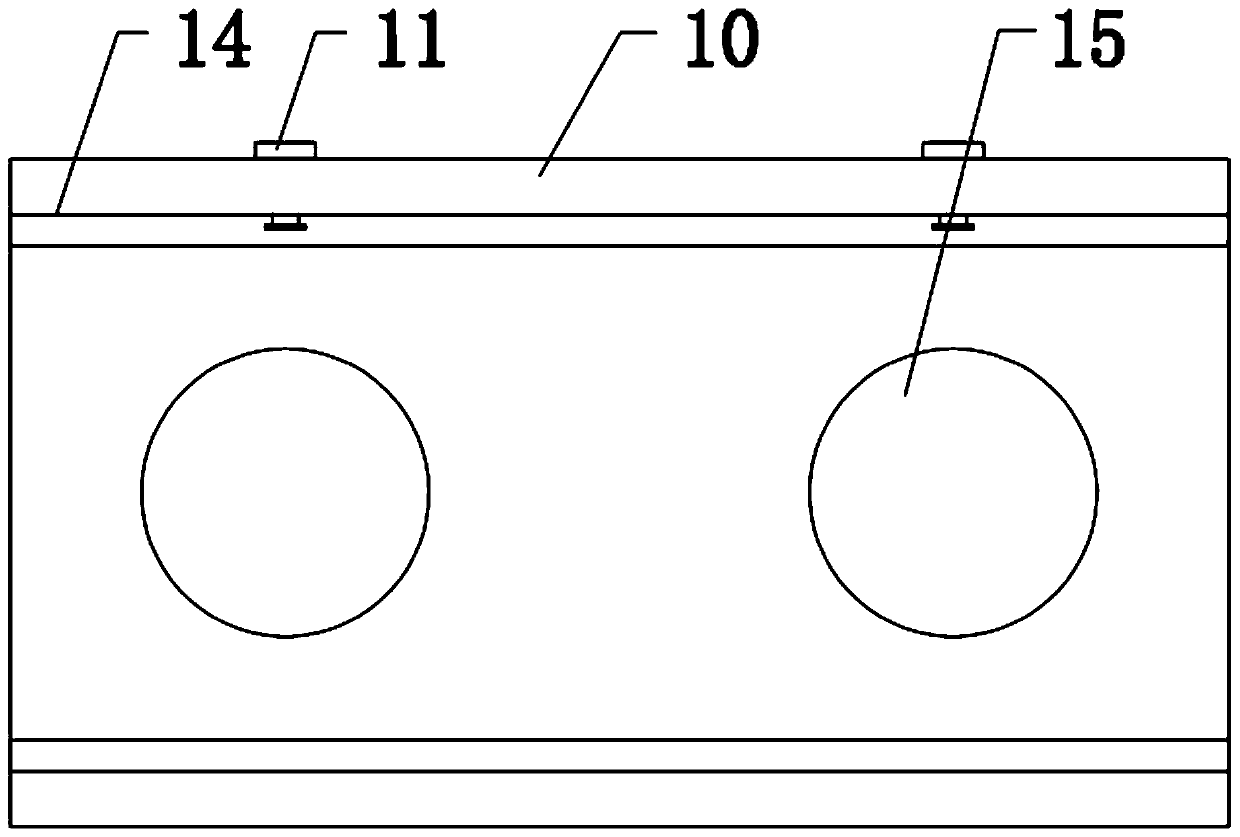

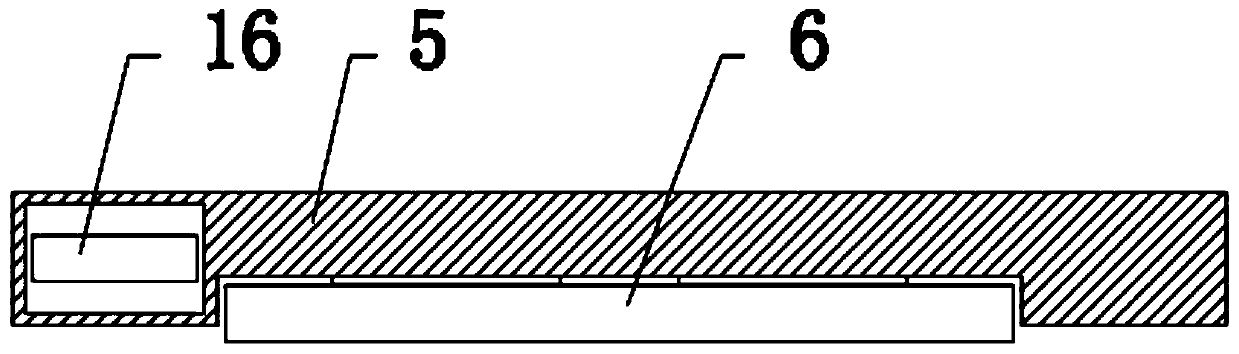

Automatic dispensing machine for modules

InactiveCN108889562AGood stabilityNot easy to shakeLiquid surface applicatorsCoatingsSystem safetyPlunger pump

The invention discloses an automatic dispensing machine for modules. The machine comprises a fence, a clamping sleeve is fixed to the upper end of the fence, and a base, a conveying line and supportsare arranged at the inner side of the fence; a mechanical arm is mounted at the upper end of the base, a dispensing plate is fixed to the output end of the mechanical arm, and glue guns are installedat the lower end of the dispensing plate; glue barrels are connected to the input ends of the glue guns through plunger pumps in sequence, the supports are located at one side of the base, and the glue barrels are installed in the supports in sequence; every two adjacent glue barrels are connected through a penetration mode and a communication pipe, a protection box and a safety door are arrangedat the exterior of the fence, and a handle is installed on the safety door. According to the automatic dispensing machine for the modules, by arranging the fence, the dispensing plate, the glue guns,a CCD correction base, the conveying line, the glue barrels, the communication pipes, an alarm and the plunger pumps, the problems are solved that during use, a dispensing device at this stage is poorin stability and is short of a positioning mechanism, and a glue supply system is poor in safety.

Owner:SHENZHEN NARI TECH

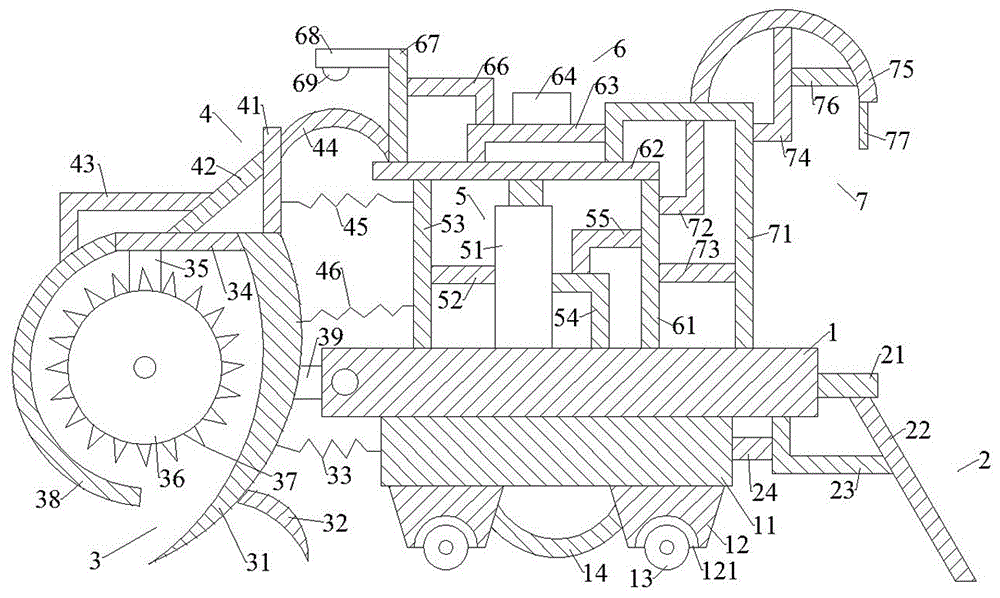

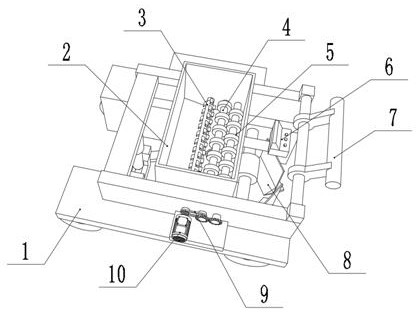

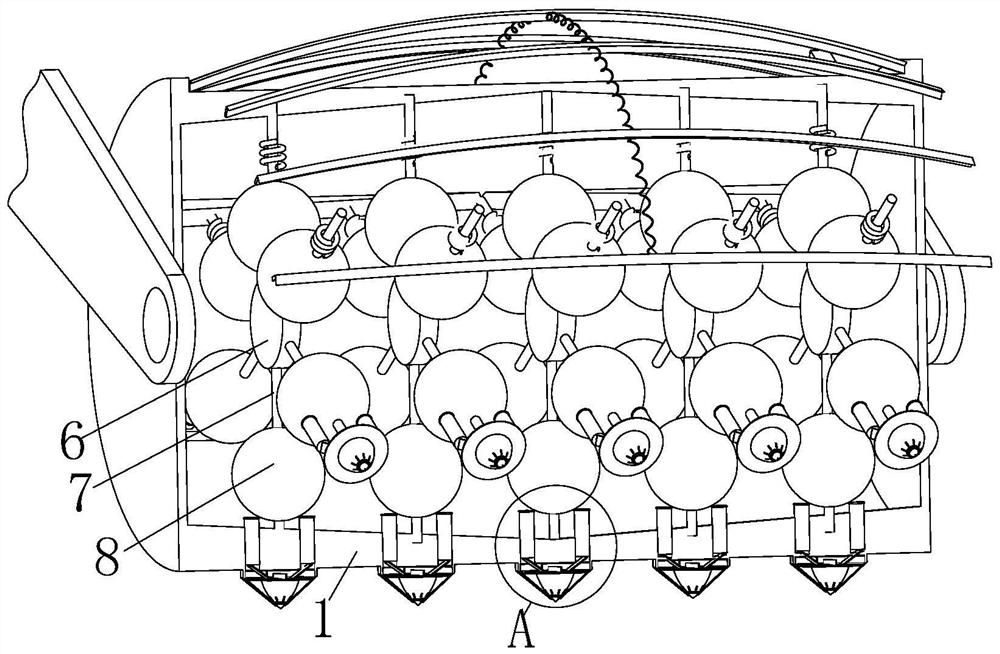

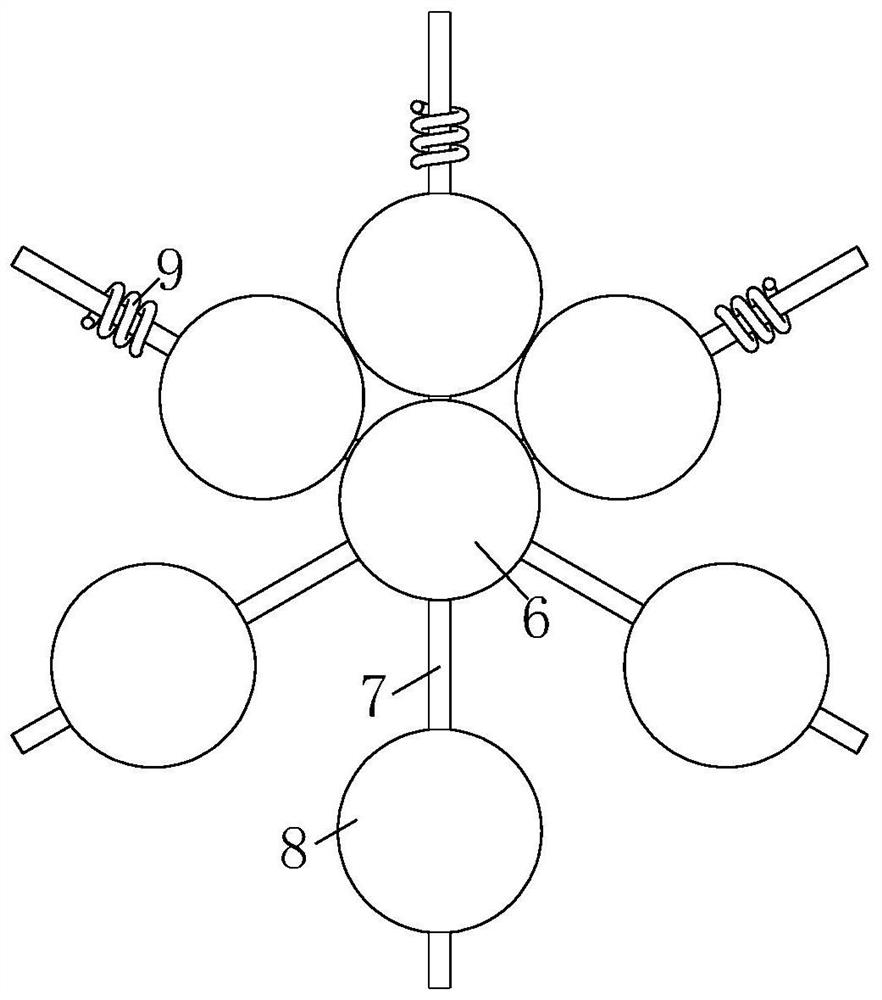

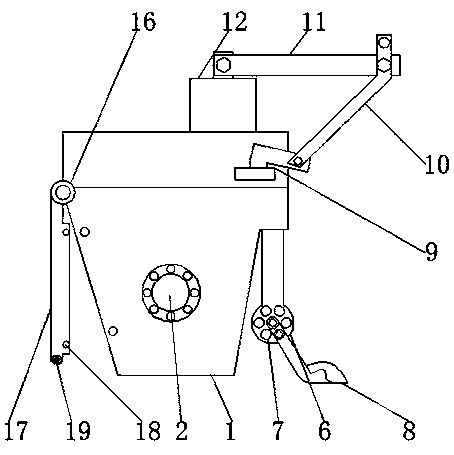

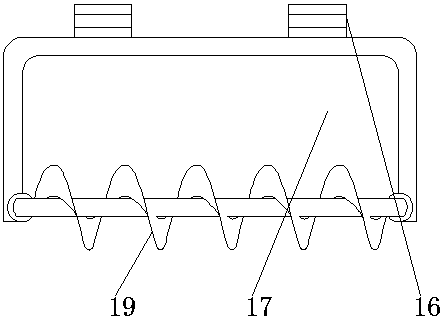

Soil loosening device for agricultural production

InactiveCN108848704AGood loose soilAvoid potholesSpadesAgricultural machinesSpray nozzleAgricultural engineering

The invention discloses a soil loosening device for agricultural production. The device comprises a device body, a rotation rod, fixing grooves, a water pipe, a fixing block, a fixing shaft, a baffleand a screw. The device body is provided with the rotation rod, the fixing grooves and the water pipe, the rotation rod is rotatably connected to the interior of the device body, and reamers are installed on the outer wall of the rotation rod; an iron plough fixing block is installed at one side of each reamer, the iron plough fixing block is installed on the portion, away from the fixing grooves,of the outer wall of the device body, a first through hole is formed in the portion, away from the fixing grooves, of one end of the iron plough fixing block, and an iron plough is installed on the portion, away from the fixing grooves, of one end of the iron plough fixing block; the fixing grooves are formed in the outer wall of the device body, and fixing plates are inserted in the fixing grooves through penetration. The soil loosening device for agricultural production is provided with the water pipe, spray nozzles, a water pump and a water tank, and under the effect of the water pump, water in the water tank is sprayed out from the spray nozzles through the water pipe; under the effect of the spray nozzles, soil on the reamers can be flushed away, and the reamers can be better used for soil loosening.

Owner:黄春梅

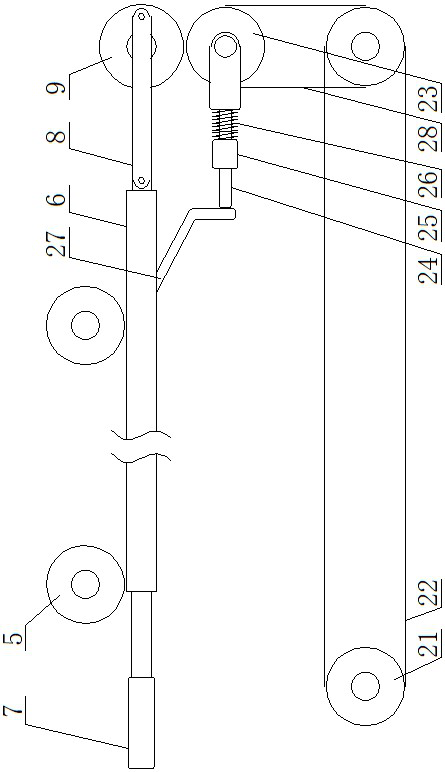

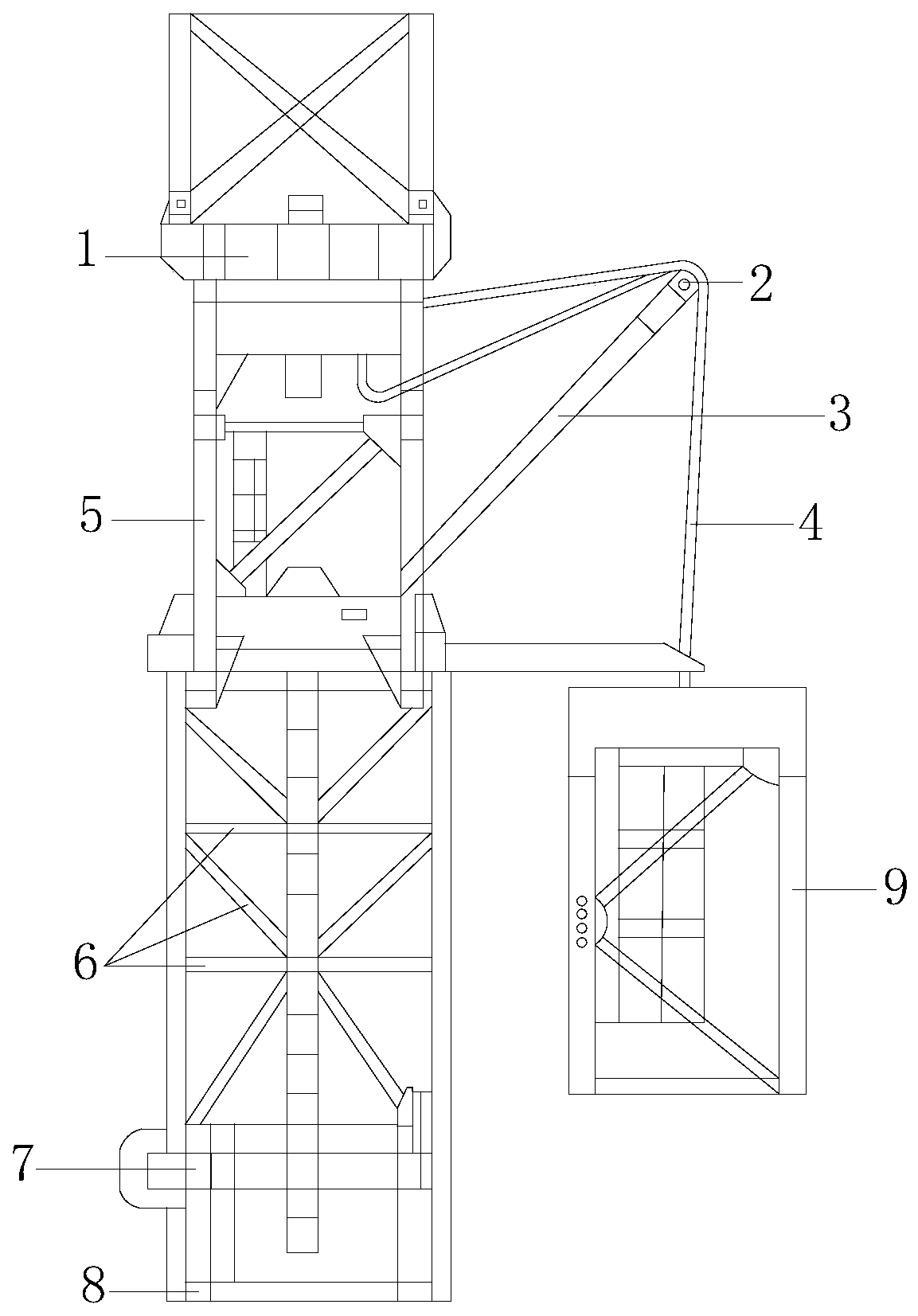

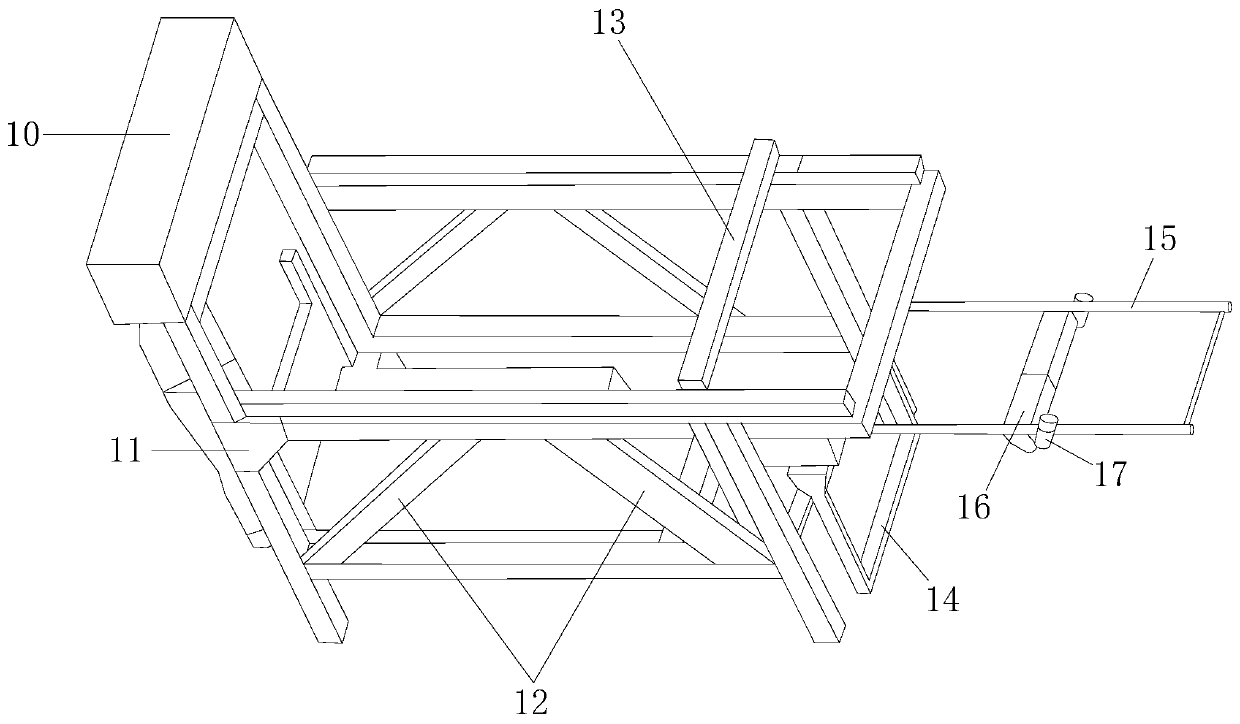

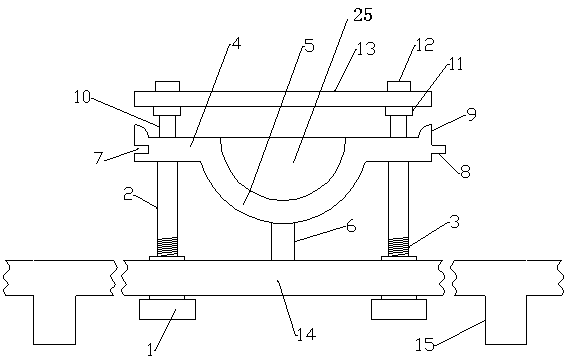

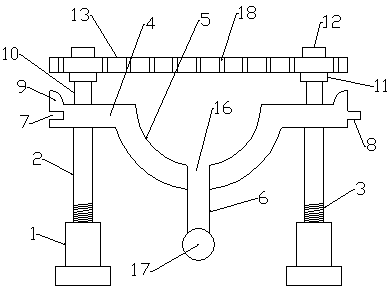

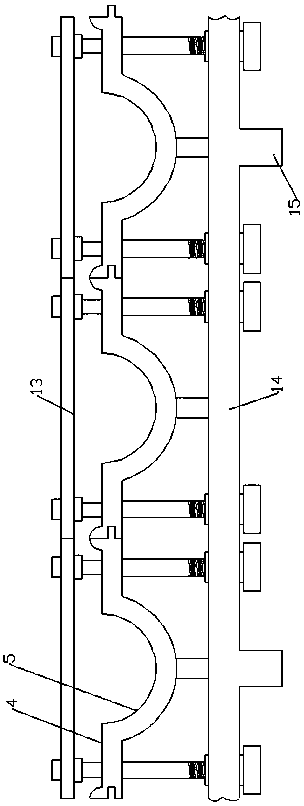

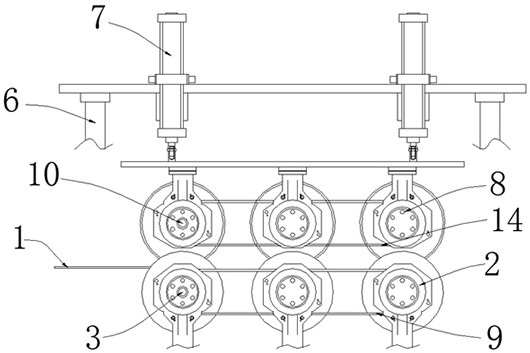

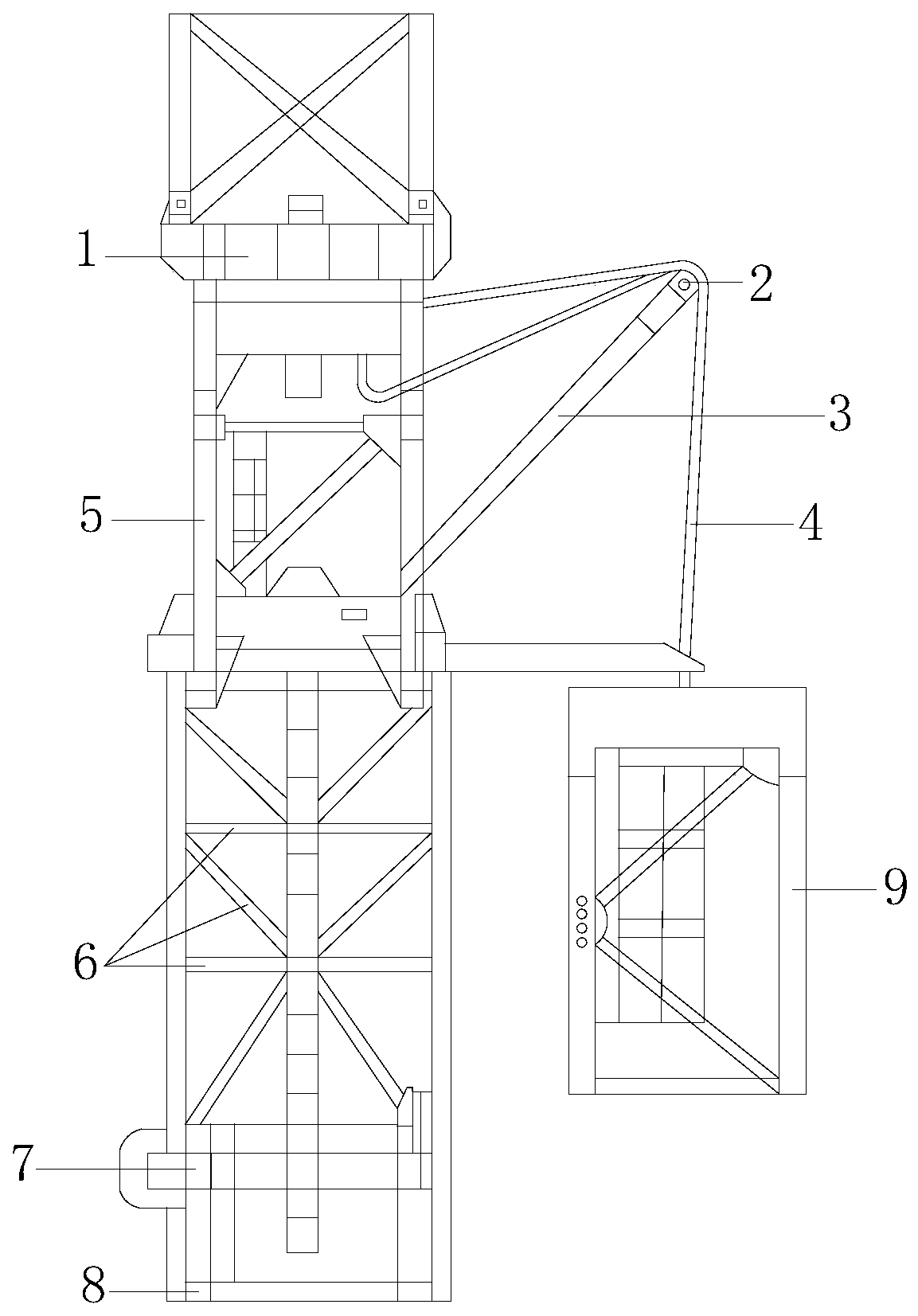

Lifting-hoisting equipment for overhead working tempered glass

ActiveCN110329920ASolve the problem of smaller compressive stressAvoid potholesCranesSafety gearPotential energyHigh probability

The invention discloses lifting-hoisting equipment for overhead working tempered glass. The lifting-hoisting equipment for the overhead working tempered glass structurally comprises a bearing tower, apulley, an ascending-descending rod, a hoisting rope, an operation tower, a support, a load-bearing tower, a base and a hoisting tower. The lifting-hoisting equipment for the overhead working tempered glass has the following beneficial effects: the problem is solved by researching and developing an anti-collision device on the hoisting tower, the anti-collision device is provided with ball bags and air bags at the two sides and the top which are parts with high probability of making contact with and even colliding with an outer wall surface, or directly making contact with and even collidingwith the outer wall surface separately, and an impact force generated during the collision on the device is eliminated by virtue of the elastic potential energy and the flexible characteristics of themembers; and due to the structure arrangement of the anti-collision device, direct contact between tempered glass and the outer wall surface can be effectively avoided, and pits and unfilled cornersgenerated on the surface and the edge of the glass due to the impact force are avoided, so that the use performance and the compression stress of the tempered glass are ensured.

Owner:中核华兴达丰机械工程有限公司

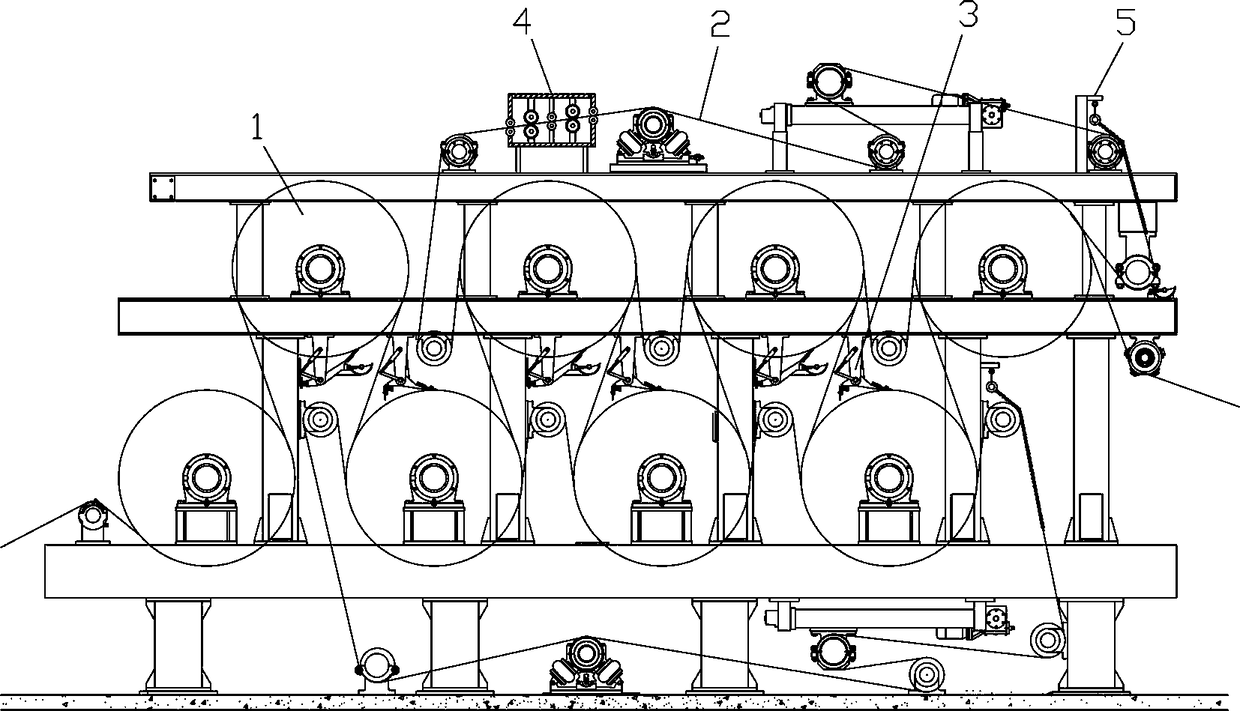

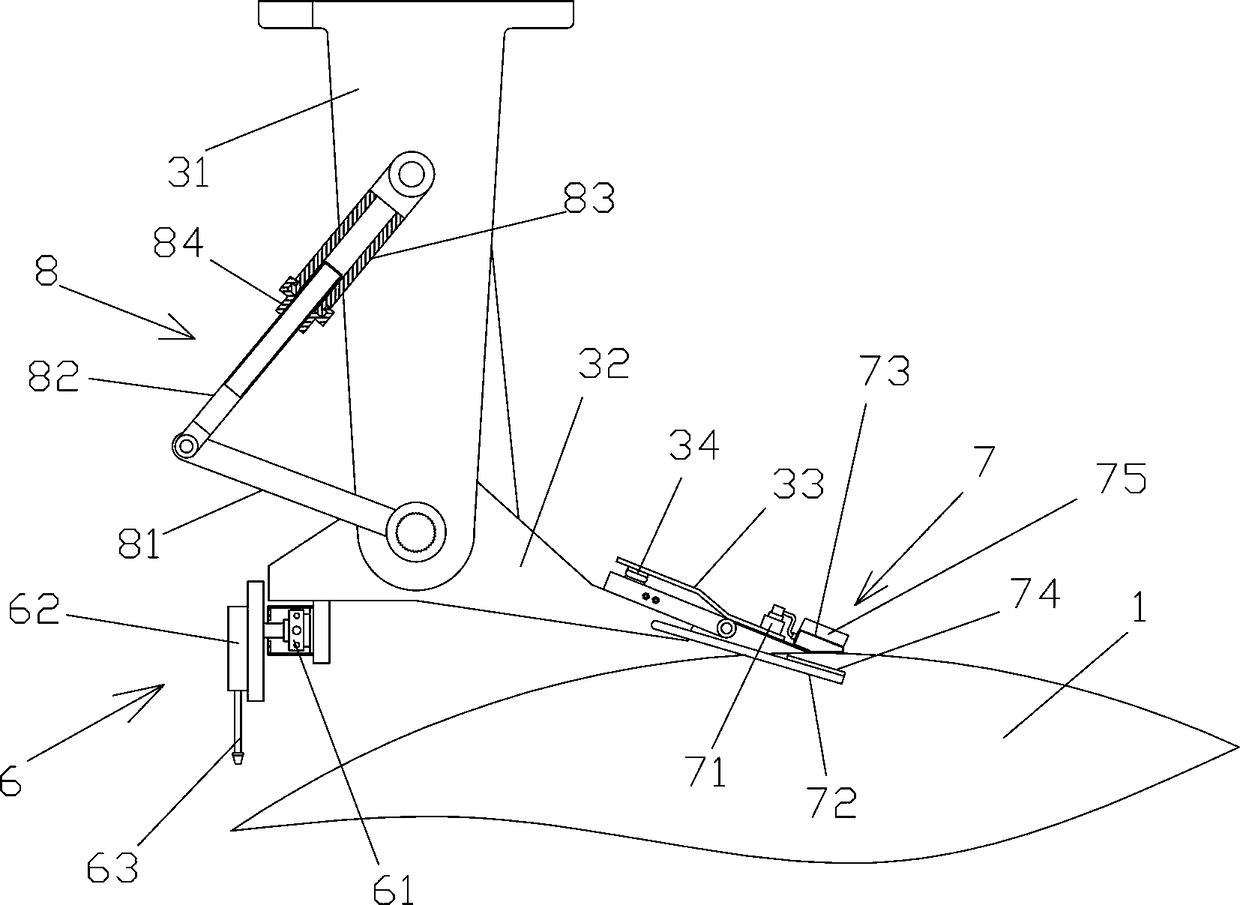

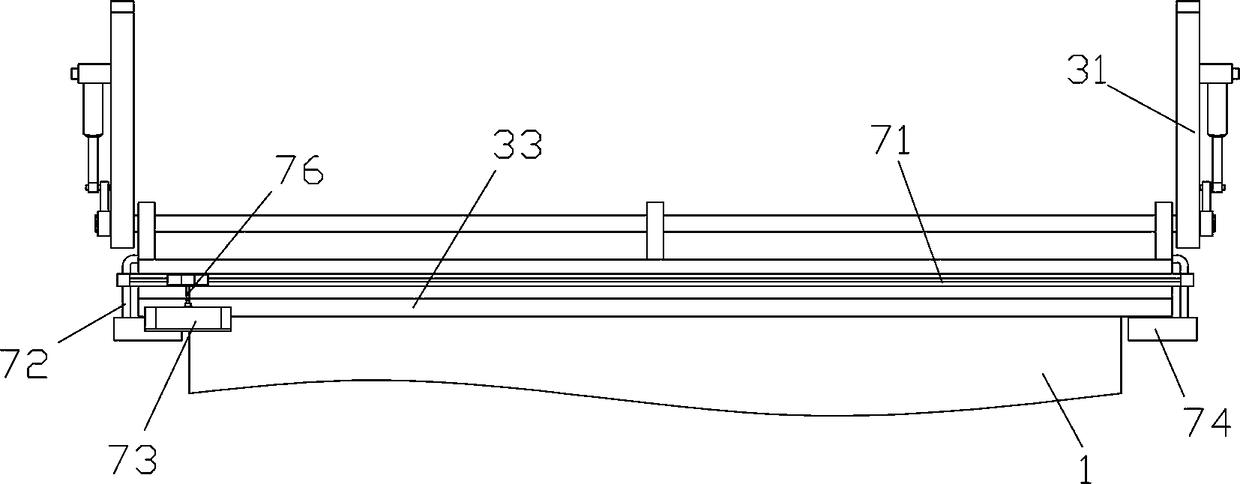

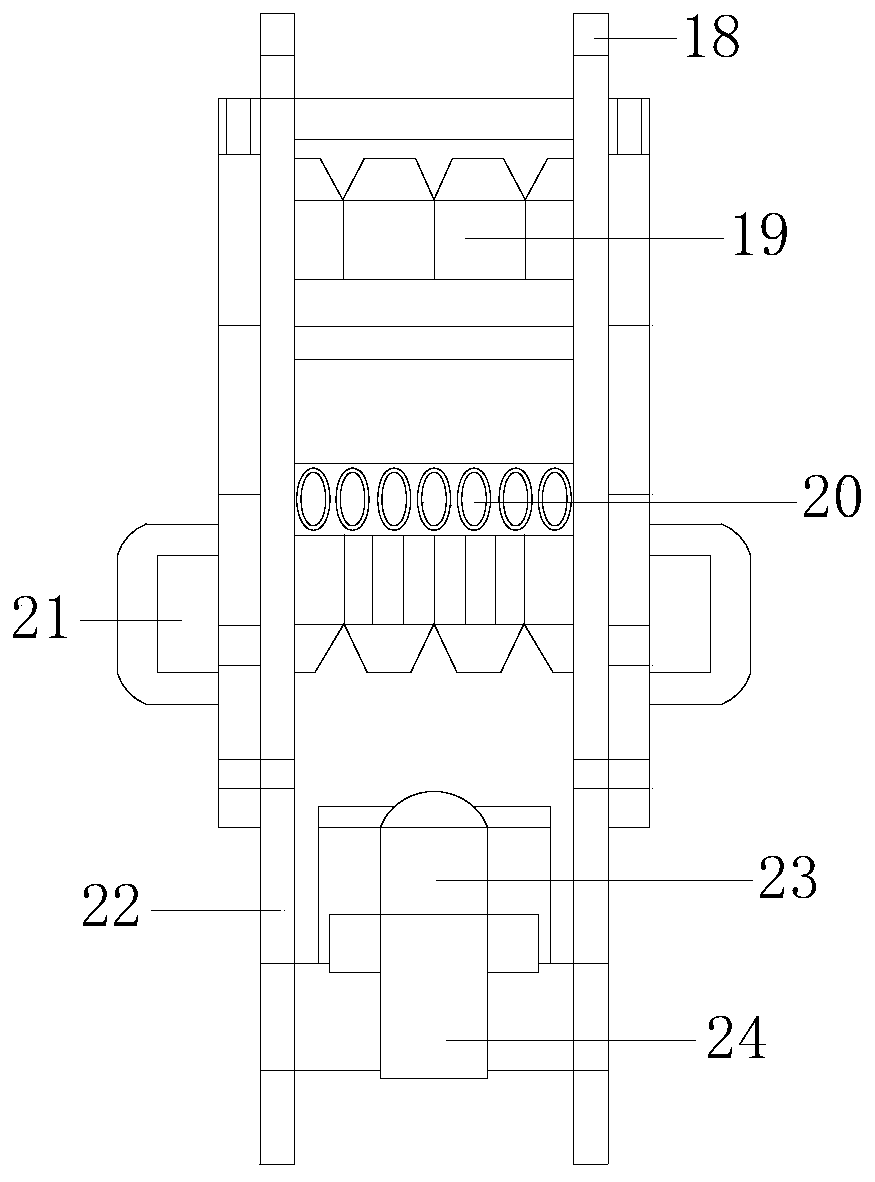

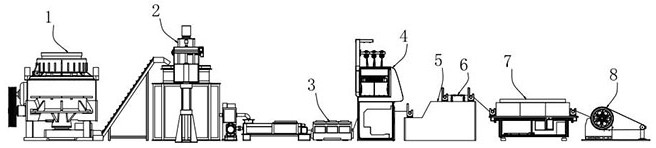

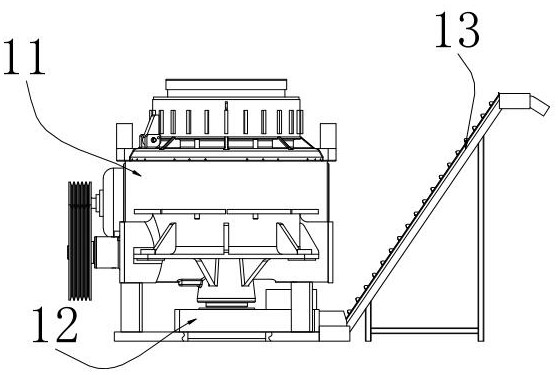

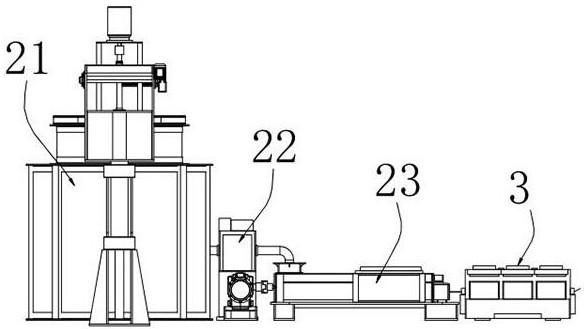

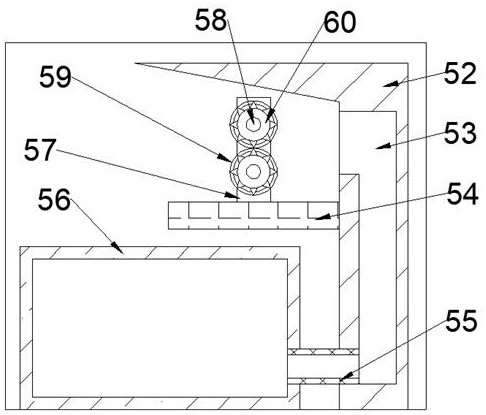

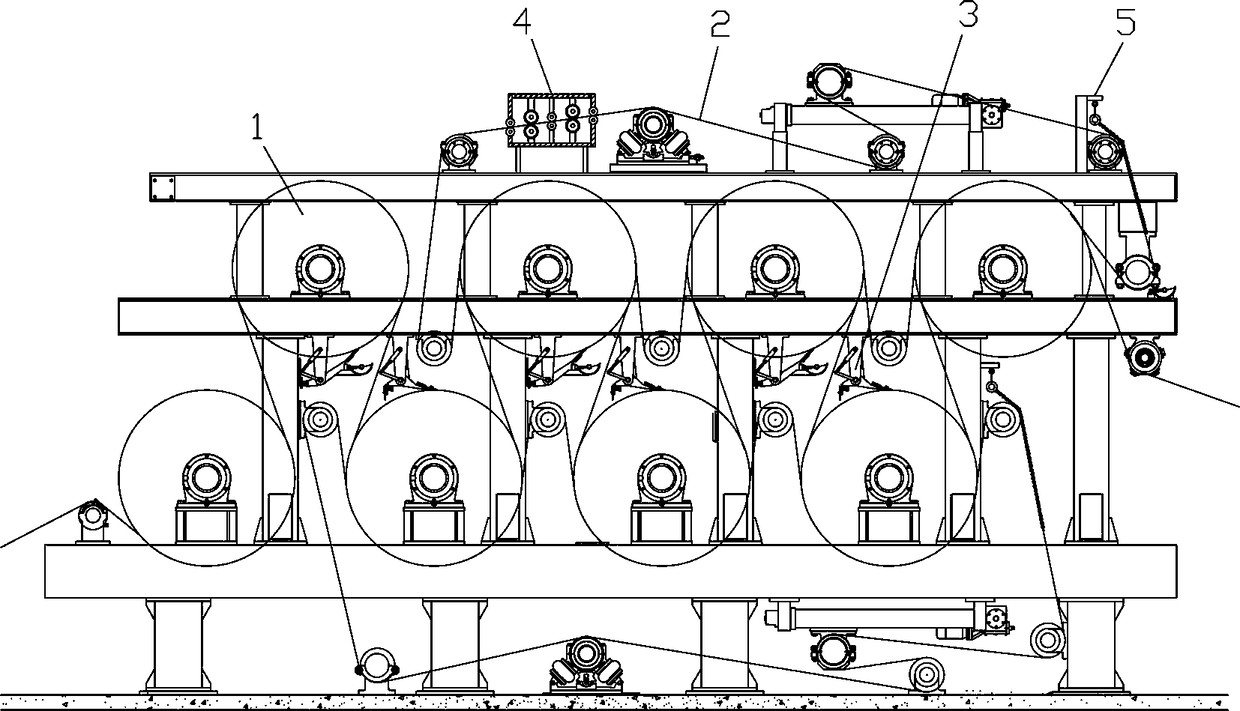

Glass fiber gridding cloth production system

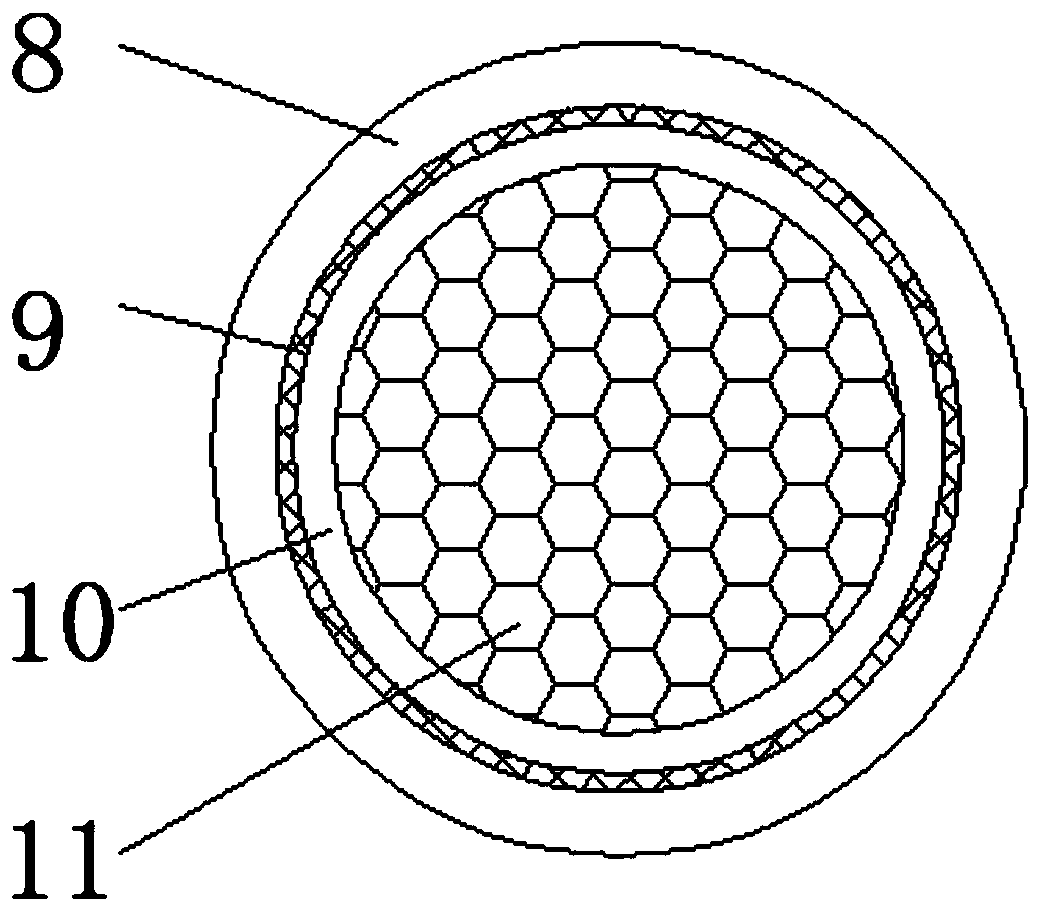

InactiveCN112680978AHigh degree of continuityIncrease productivityLiquid surface applicatorsCoatingsFiberGlass fiber

The invention belongs to the field of glass fiber gridding cloth, and particularly relates to a glass fiber gridding cloth production system. The system comprises a fiber gridding cloth production line composed of a batching system, a discharging system, a drying machine, a knitting machine, a dip dyeing device, a surface treatment device, an air drying device and a winding machine in a matched mode; the batching system is used for proportioning, mixing and conveying raw materials; the discharging system is used for hot melt extrusion of the mixed materials; and the drying machine is used for thermally drying produced glass fiber filaments. After being subjected to emulsion dip dyeing treatment in a dip dyeing tank, the glass fiber gridding cloth is conveyed to the position above a collecting tank along conveying rollers and passes through an interval clamped between an upper scraping plate and a lower scraping plate in the conveying process, and redundant emulsion can be scraped off through a hollow screen plate, so that the emulsion on the surface of the glass fiber gridding cloth is kept evenly distributed, the surface of the glass fiber gridding cloth is prevented from being uneven, the surface treatment effect of the glass fiber gridding cloth is improved, and cooling and setting of the glass fiber gridding cloth are facilitated.

Owner:单县鑫誉玻璃纤维复合材料有限公司

Building top layer anti-seepage structure

ActiveCN111395662AAvoid the phenomenon of shortened service life due to agingAvoid low temperaturesRoof drainageRoof covering insulationsArchitectural engineeringWater leak

The invention relates to a building top layer anti-seepage structure. An anti-seepage device comprises a trough plate mounted on the top wall of a building; transverse plates are fixedly arranged on the two sides of the trough plate; longitudinal support columns are fixedly arranged below the transverse plate; the bottom of the trough plate is in communication with a water outlet pipe; the water outlet pipe is in communication with a water delivery pipe; the water delivery pipe is in communication with a drain pipe; the lower part of the drain pipe is in communication with a blow-off pipe; theblow-off pipe is in communication with the top of a longitudinal drainage hole of the building; a top flat plate is arranged above the trough plate; the top flat plate is provided with water leakageholes; and the inner side bottom of an outer waterproof layer is fixedly connected with the tops of the transverse plates. The building top layer anti-seepage structure has the advantages of convenience in operation, high working and running efficiencies, long service life, good waterproofing effect, remarkable heat-insulating effect, high overall outer flatness, complete drainage, insusceptibility to storing of water, assembled structure, convenience in transportation, mounting and disassembling, and good social and economic benefits.

Owner:泰利建设集团有限公司

Production method for coated bare concrete

InactiveCN105345918AFlat surfaceNot easy to stickCeramic shaping liningsUltimate tensile strengthRust

The invention relates to the field of buildings, in particular to a production method for coated bare concrete. The production method comprises the following steps that a, a layer of thin film is laid on the molding surface of a mold, so that the thin film is flatly attached to the molding surface of the mold; b, the surface of the thin film is smeared with mold-releasing oil; c, a steel reinforcement cage is put into the mold; d, stirred concrete is poured into the mold, and the upper surface of the concrete inside the mold is flattened; and e, after the intensity of the concrete meets the requirements, the mold is detached, the bare face of the molded concrete is sprayed with protective agents, and the product is obtained. The surface of the thin film is flat and smooth, rubbish or rust is not likely to adhere to the surface of the thin film, the decorative effect of the bare face of the concrete can be ensured only by laying one layer of thin film on the mold, hollows in the surface of the concrete are avoided, the concrete is molded at a time and does not need to be repaired, and the veneer colors of the concrete are uniform.

Owner:安徽海龙建筑工业有限公司

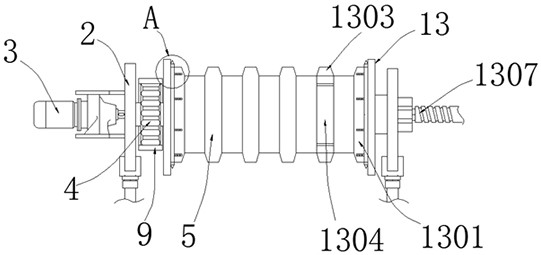

Reinforcing rib pressing machine for color steel tile and its application method

ActiveCN113333538BImproved aesthetics and dimensional accuracyReduce volumeMetal sawing devicesOther manufacturing equipments/toolsGear wheelTransmission belt

Owner:南通德泰隆钢结构工程有限公司

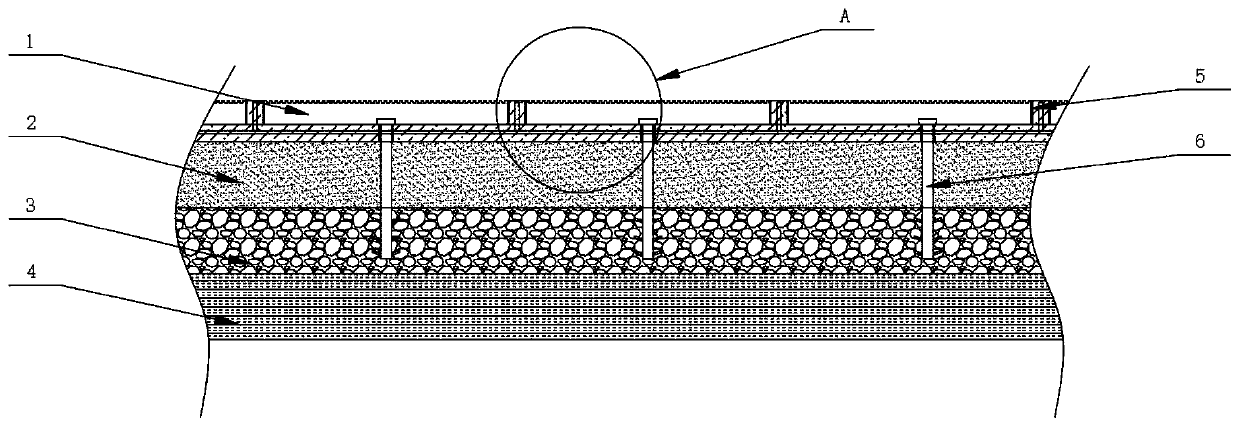

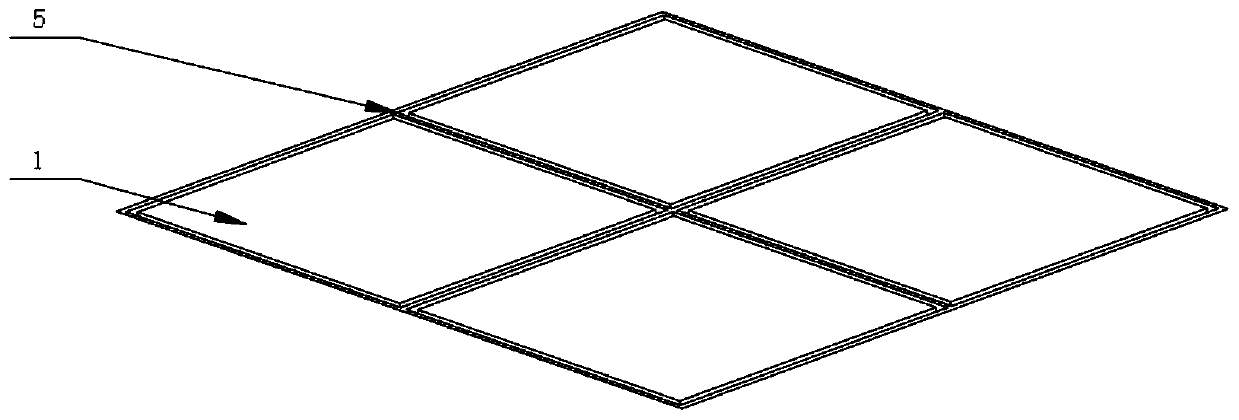

Stone slab building block paving structure suitable for traffic loads at all levels

InactiveCN110820459AImprove structural strengthIncrease pressureSingle unit pavingsRoads maintainenceFlagstoneArchitectural engineering

Owner:盐城市兆泉项目管理有限公司

External crack repairing device for metallurgical furnace in work

InactiveCN112710154AAvoid damageAvoid potholesLinings repairCleaning using toolsMetallurgyEngineering

The invention discloses an external crack repairing device for a metallurgical furnace in work. The external crack repairing device comprises a moving carrier and a cleaning box arranged on the moving carrier, wherein a cleaning cavity is formed inside the cleaning box, and a moving groove is formed in the right side of the cleaning cavity. The external crack repairing device can be tightly attached to the metallurgical furnace after being stretched, damage to a machine body due to overheating is prevented, and the external crack repairing device can drive a sweeping mechanism to rotate to clean and brush powder particles such as dust on the surface of the metallurgical furnace during attachment movement, so that subsequent crack searching is facilitated, the external crack repairing device can spray gravel after finding cracks for melting and filling by using internal heat, and meanwhile, the external crack repairing device can scrap and recycle redundant gravel, so that waste is reduced, the bumpy phenomenon on the surface of the metallurgical furnace is prevented, and the external crack repairing device can weld metal on an outer layer after filling, so that the metallurgical furnace is reinforced, next cracks are prevented from continuing to be generated, and meanwhile, the external crack repairing device achieves automation of the treatment process, improves the treatment efficiency greatly, and saves labor force.

Owner:杭州聿乾贸易有限公司

Lifting and hoisting equipment for toughened glass for aerial work

ActiveCN110329920BSolve the problem of smaller compressive stressAvoid potholesCranesSafety gearClassical mechanicsTower

The invention discloses lifting-hoisting equipment for overhead working tempered glass. The lifting-hoisting equipment for the overhead working tempered glass structurally comprises a bearing tower, apulley, an ascending-descending rod, a hoisting rope, an operation tower, a support, a load-bearing tower, a base and a hoisting tower. The lifting-hoisting equipment for the overhead working tempered glass has the following beneficial effects: the problem is solved by researching and developing an anti-collision device on the hoisting tower, the anti-collision device is provided with ball bags and air bags at the two sides and the top which are parts with high probability of making contact with and even colliding with an outer wall surface, or directly making contact with and even collidingwith the outer wall surface separately, and an impact force generated during the collision on the device is eliminated by virtue of the elastic potential energy and the flexible characteristics of themembers; and due to the structure arrangement of the anti-collision device, direct contact between tempered glass and the outer wall surface can be effectively avoided, and pits and unfilled cornersgenerated on the surface and the edge of the glass due to the impact force are avoided, so that the use performance and the compression stress of the tempered glass are ensured.

Owner:中核华兴达丰机械工程有限公司

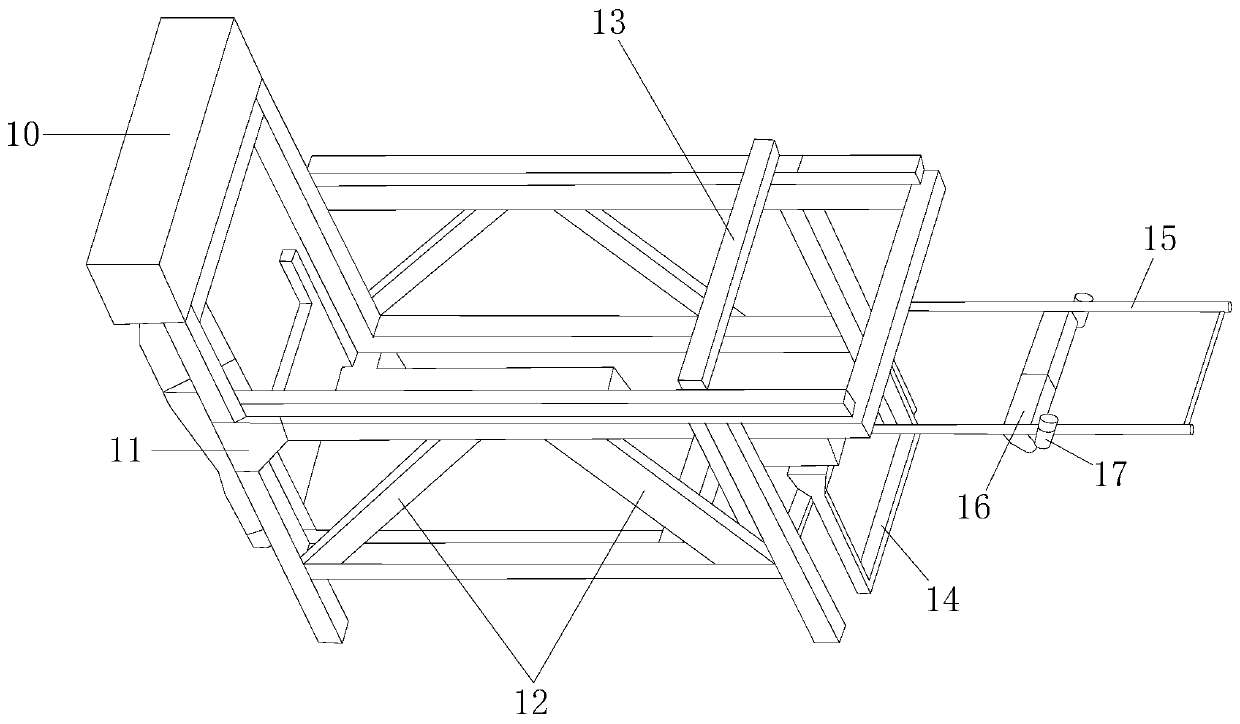

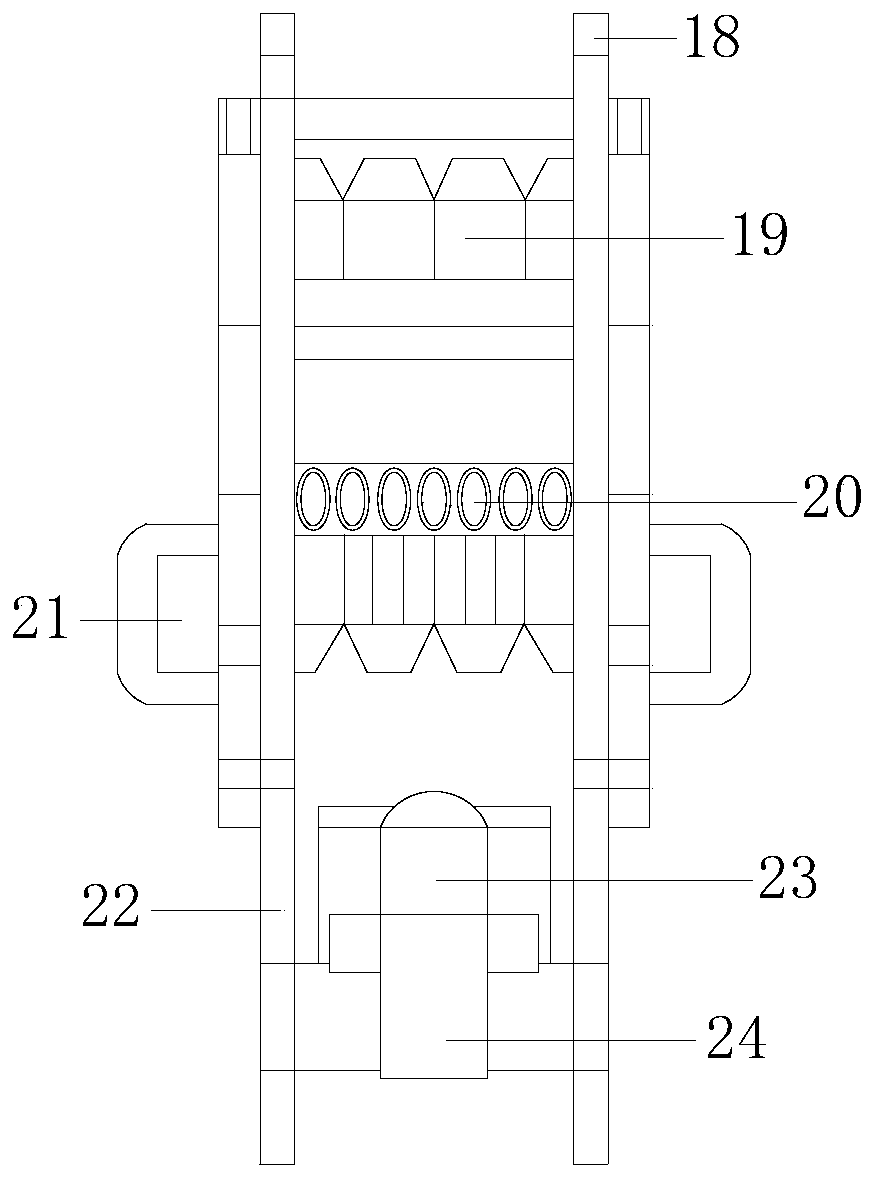

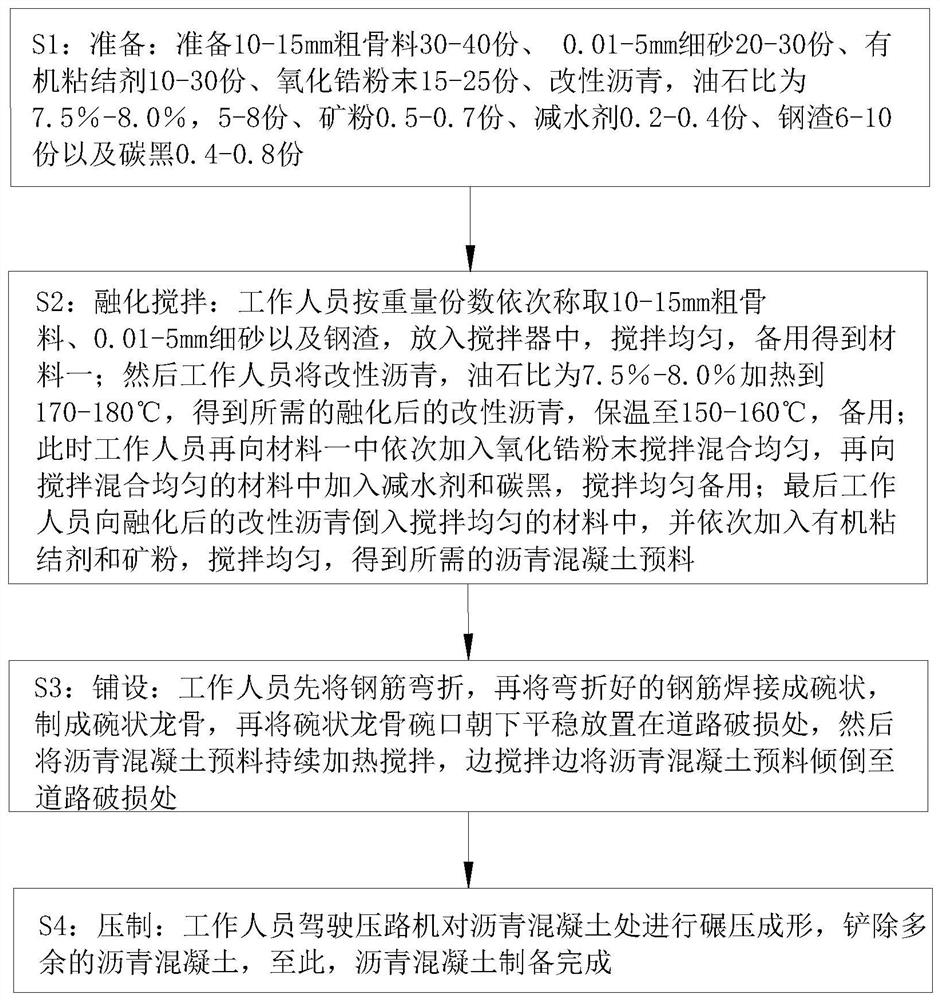

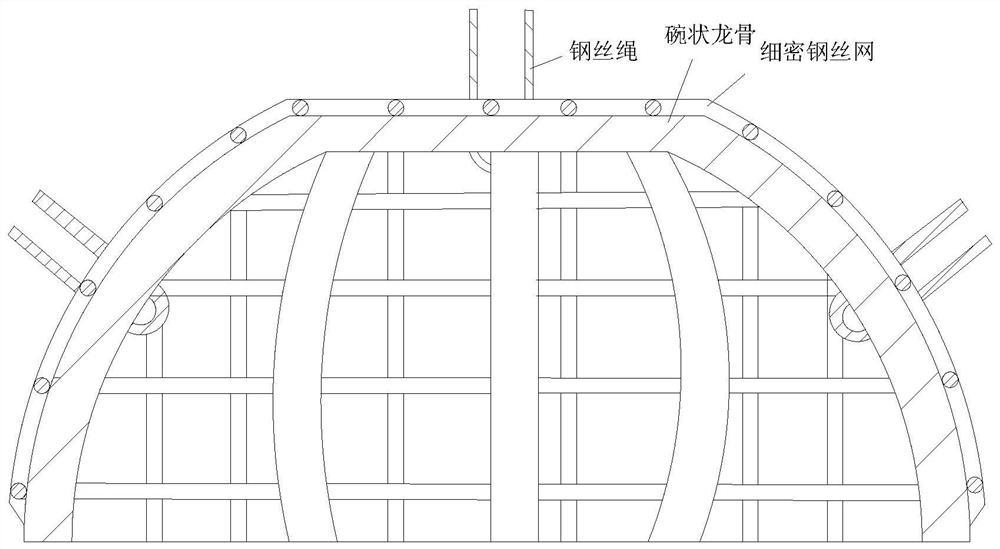

Preparation method of asphalt concrete

ActiveCN113912328AImprove stress resistanceAvoid deformationSolid waste managementRoads maintainenceArchitectural engineeringStructural engineering

The invention relates to the technical field of asphalt concrete, in particular to an asphalt concrete preparation method which comprises the following steps: S1, preparing; S2, melting and stirring; S3, laying; and S4, pressing; wherein in the process of installing the bowl-shaped keels in the step S3, the bowl-shaped keels are connected through iron wires, and the iron wires are in sliding connection with the bowl-shaped keels; after the bowl-shaped keels are installed, the iron wire is pulled out; according to the preparation method of the asphalt concrete, the bowl-shaped keel is placed at the damaged part of the road, and the molten and stirred asphalt concrete pre-material is poured at the damaged part of the road for matching, so that the purpose of improving the pressure resistance of the asphalt concrete is achieved, and the asphalt concrete is prevented from being deformed after being pressed by a heavy truck. the condition that potholes occur on asphalt concrete pavement can be avoided, therefore, the service life of the asphalt concrete is prolonged, and the repeated repair frequency of the asphalt concrete is reduced.

Owner:内蒙古高建路桥工程有限公司

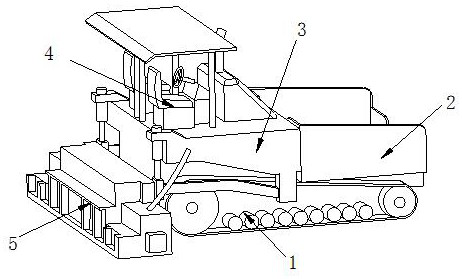

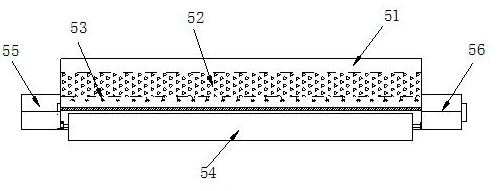

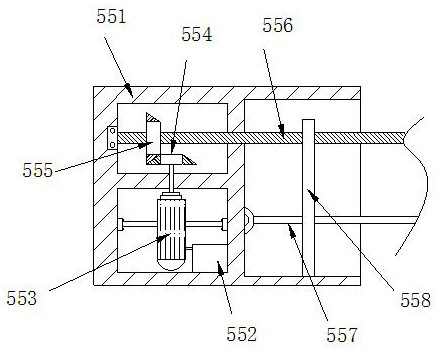

Cement concrete road shoulder pressing and paving machine

InactiveCN112195724AAvoid potholesIncrease profitRoads maintainenceArchitectural engineeringStructural engineering

The invention discloses a cement concrete road shoulder pressing and paving machine which structurally comprises a driving crawler belt, a loading frame, a main machine, a cab and a pressing and paving block. The top of the driving crawler belt is fixedly connected with the loading frame. The bottom of the main machine is fixedly installed on the top face of the driving crawler belt. The right side of the pressing and paving block is mechanically connected with the left side of the main machine. The left side of the loading frame is mechanically connected with the right side of the main machine. According to the cement concrete road shoulder pressing and paving machine, the compression roller can be automatically cleaned at regular intervals through the cleaning structure, cement on the compression roller is cleaned and scraped away before solidification, the compression roller is kept in a flat state, the surface of a pressed and laid road shoulder is prevented from being bumpy, and meanwhile, after cleaning, cement residues left on the cleaning block after cleaning are cleaned through the recycling structure and stored at the bottom of the shell of the recycling structure, the cement residues can be reused as paving raw materials, and the utilization rate of concrete is increased.

Owner:广州美旭信息科技有限公司

Production method of sand blast fair-faced concrete

InactiveCN105155848AUniform colorUniform finish colorCeramic shaping apparatusBuilding material handlingSand blastingArchitectural engineering

Owner:安徽海龙建筑工业有限公司

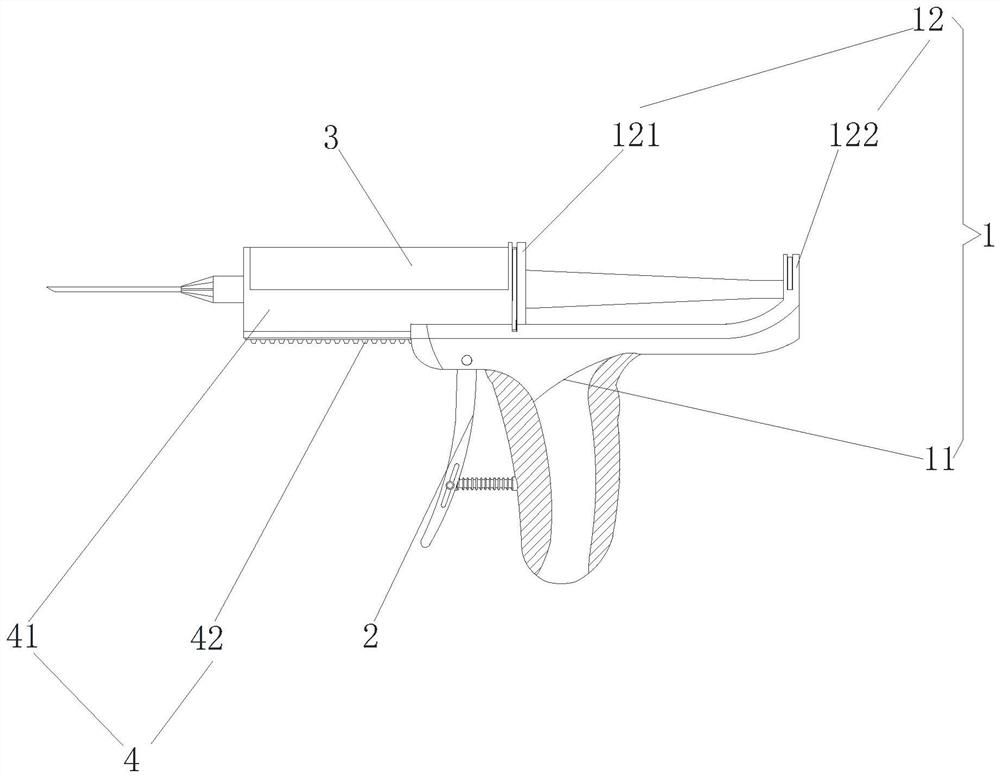

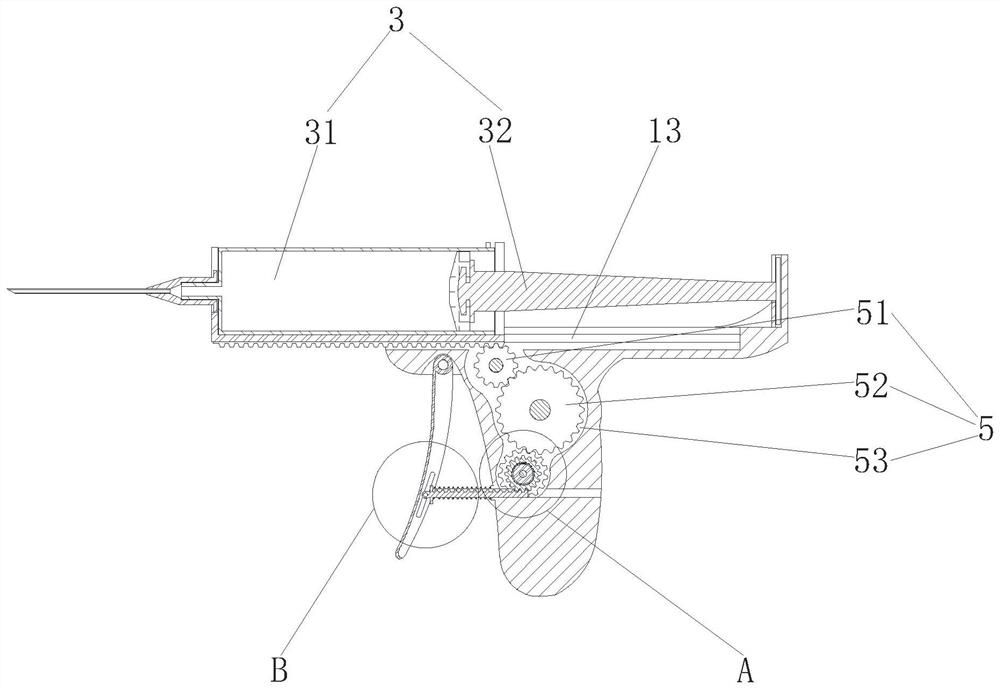

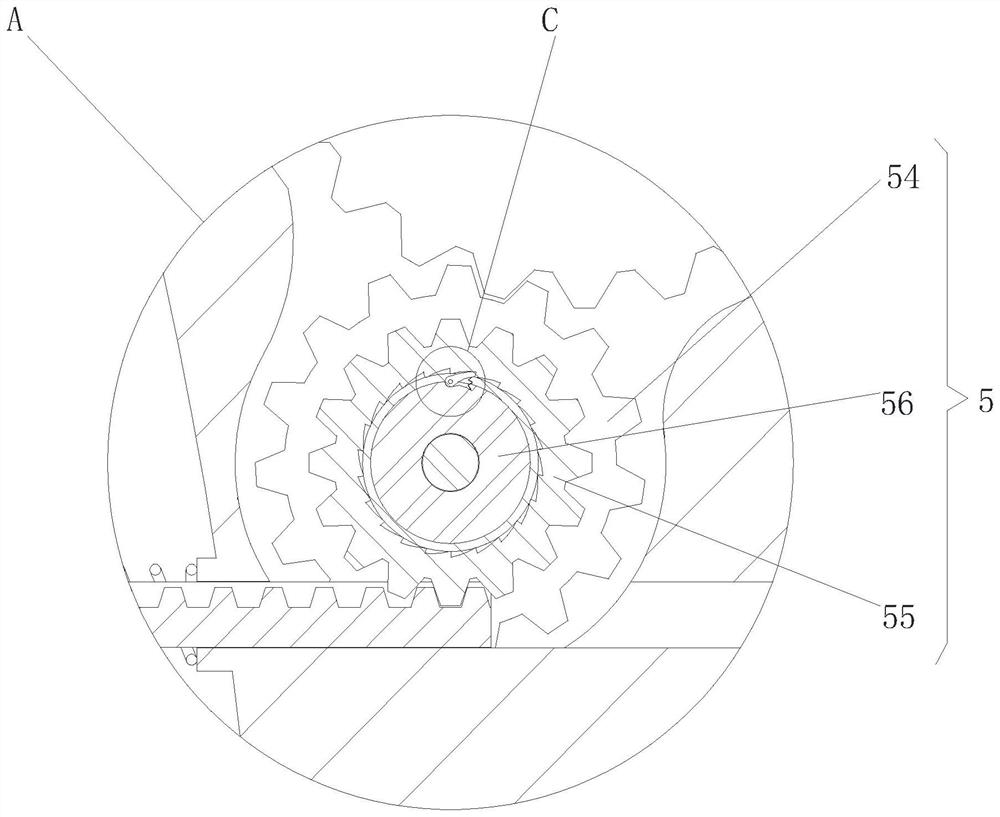

Injection device for face lifting and repairing based on Anti-G repair and use method of injection device

The invention provides a face lifting and repairing injection device based on Anti-Grepair.The face lifting and repairing injection device comprises a holding device and a movement device, the movement device is arranged on the inner wall of the holding device, a driving mechanism is arranged on the side, close to the movement device, of the holding device, a transmission device is arranged in the holding device, and the transmission device is connected with the movement device. The driving mechanism and the moving device are in transmission connection with the transmission device, an injector is arranged in the moving device and comprises a needle cylinder and a push rod, and the push rod is inserted into the needle cylinder; the injector is pushed to pierce into an injection position, the driving mechanism is pulled, and the transmission device drives the movement device to carry the needle cylinder back. By means of the structure, the injector is retreated for injection once, the hand holding the holding device is kept still, uneven adipocyte injection caused by one-heart dual-purpose of an operator is avoided, facial bumpiness after face filling is prevented, adipocytes can be evenly laid in skin tissue conveniently, and the face lifting and repairing effect is improved.

Owner:南京市河西医院有限公司

Manufacturing method of sand casting machine tool

The invention discloses a manufacturing method for a sand mold casting machine tool. The main point of the technical scheme is the manufacturing method for the sand mold casting machine tool. The manufacturing method comprises the steps that mixed moulding sand is guided into a mould frame for fixing and forming, and a machine tool model is prefabricated in the mould frame; a plurality of independent sand mold moulds are arranged inside the mould frame, and flow channels allowing molten iron to flow are formed between every two adjacent sand mold moulds; the inner surface of the mould frame and the surfaces of the sand mold moulds are coated with fireproof coating agents in a flowing mode; the coating agents are mixed with alcohol and sintered on the surfaces of the sand mold moulds through ignition ; breathable through holes are formed in the side wall of the mould frame, and gas in the moulding sand is heated in the casting process and discharged through the breathable holes; and at the time of casting, the molten iron is cooled to 1360-1380 DEG C, then slowly guided into the molten iron flow channels, and the gas in the flow channels is ignited to be burned. The surface of the machine tool manufactured by the manufacturing method for the sand mold casting machine tool is smooth and level, air holes do not occur, and the rate of finished products is high.

Owner:浙江品川精密机械有限公司

A device and method for reducing stickies of yellow cardboard

ActiveCN108468247BSpatula is convenientSpatula to preventCleaning using toolsGrain treatmentsPaper machineCardboard

A device and method for reducing adhesives on yellow board paper, including a scraper mechanism for removing adhesives on the dryer cylinder of a paper machine; the scraper mechanism includes a connecting frame fixedly connected to the frame of the paper machine, an installation There is a turret in the connecting frame, a scraper with a middle axis connected to the turret and a plurality of cylinders installed in the connecting frame; each cylinder pushes one end of the scraper to stick to the surface of the drying cylinder. The invention is used to solve the problem of sticky matter. During the drying process, the yellow cardboard is prone to breakage and holes due to the adhesion of adhesives.

Owner:湖北金庄科技再生资源有限公司

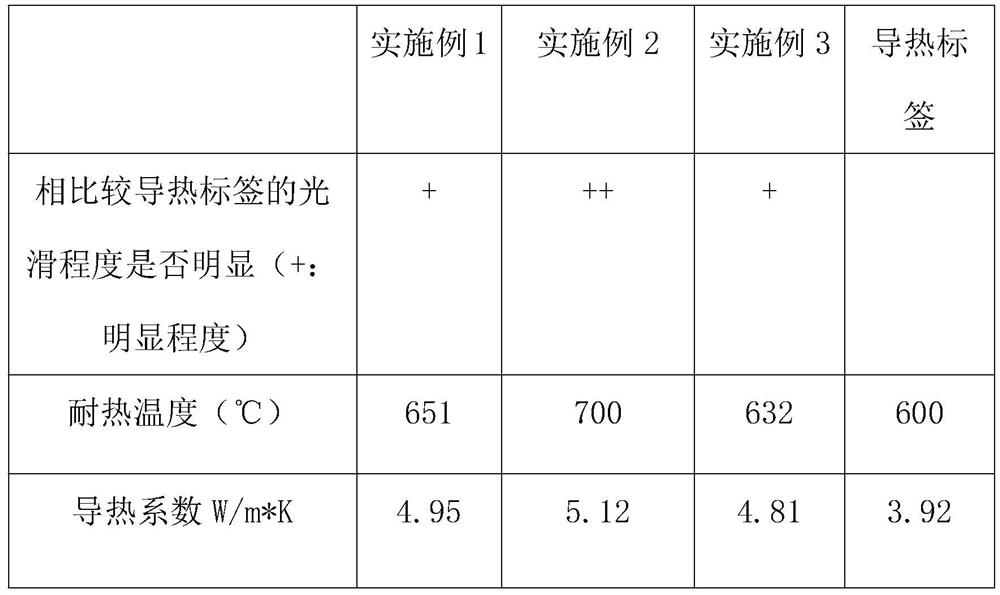

Flame-retardant synthetic film with excellent thermal conductivity and preparation method thereof

PendingCN113372840AImprove heat resistanceImprove securityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceThermal adhesive

The invention discloses a flame-retardant synthetic film with excellent thermal conductivity and a preparation method thereof, belonging to the technical field of electronic heat-conducting surfaces and PCBs (printed circuit boards). The main components of the flame-retardant synthetic film with excellent thermal conductivity in the invention comprises: a heat-conducting adhesive, wherein the heat-conducting adhesive comprises main raw material components including flame-retardant polyacrylate, isocyanate and graphite heat-conducting powder in a ratio of 100: (0.1-5): 5.5; and a heat-conducting coating, which comprises main raw material components including modified polyurethane and graphite heat-conducting powder in a ratio of 100: (10-100), wherein the heat-conducting adhesive coats the heat-conducting coating. By adopting the related proportion of the graphite heat-conducting powder in the heat-conducting adhesive, the heat resistance of the heat-conducting adhesive can be improved, so the safety of the heat-conducting adhesive during use is improved; and the particle size of the graphite heat-conducting powder in the heat-conducting adhesive and the heat-conducting coating is in a range of 1-3 microns, so adhesive lines on an adhesive surface caused by overlarge particles on the adhesive surface of the heat-conducting adhesive can be prevented, and the surface of the heat-conducting coating is prevented from generating pits.

Owner:SHENZHEN LICHANGSHI ADHESIVE PROD

BRT roadbed

ActiveCN113481777BSettlement controlImprove securityPaving reinforcementsPaving gutters/kerbsBrickSoil science

The invention discloses a rapid transit roadbed, which comprises sequentially arranged from bottom to top: a soft soil base, which is formed by leveling and compacting soft soil, and a drainage main pipe is pre-buried in the soft soil base; a gravel layer, which is poured with gravel and cement Formed above the soft soil base, the gravel layer is equipped with retaining walls, load-bearing frames and monitoring structures; the gravel layer is formed by pouring gravel and cement, and a water tank is installed inside the gravel layer; the permeable brick layer is brick The body is formed above the gravel layer, and the permeable brick layer is provided with a permeable structure; the asphalt concrete layer is formed above the permeable brick layer, and the asphalt concrete layer includes coarse-grained asphalt concrete below and medium-grained asphalt concrete above, and interposed between two the stiffeners between them; the pavement layer, which is formed above the asphalt concrete layer. The invention can quickly drain water, improve the safety of the rapid transit bus running in rainy days, control road surface settlement at the same time, perform effective jacking and timely response, and improve the service life of the rapid transit roadbed.

Owner:CHINA ROAD & BRIDGE

Tubular hardware polishing device and using method thereof

InactiveCN113579869AQuick sandingSanding easilyRevolution surface grinding machinesGrinding drivesPolishingWorkbench

The invention belongs to the technical field of tubular hardware polishing, and particularly relates to a tubular hardware polishing device and a using method thereof. The tubular hardware polishing device comprises a workbench, a rotating device and a spraying device, and further comprises a telescopic device connected to the left end of the interior of the workbench, driving devices arranged at the two ends of the interior of the workbench, a grinding device detachably installed at the output end of the rotating device and a limiting device installed at the right end of the workbench through a bolt; the bottom end of the telescopic device is connected to the interiors of the driving devices in a meshed manner, and the rotating device is installed at the top end of the telescopic device through a bolt; and the top end of the rotating device is provided with the spraying device through a bolt. According to the tubular hardware polishing device, the effects that different polishing modes are provided for metal hardware of different materials and different properties, and the conditions of potholes, deformation and damage after polishing are prevented are achieved, and the effects that the hardware does not need to be fixed with the hands, and the safety performance is improved are achieved.

Owner:王连俊

Ultrasonic grinding device in shoemaking device

InactiveCN110666601AAvoid potholesAvoid scrappingShoemaking devicesGrinding/polishing safety devicesHydraulic cylinderCooling effect

The invention belongs to the technical field of shoemaking, and specifically provides an ultrasonic grinding device in a shoemaking device. The ultrasonic grinding device comprises a base. A support is integrally formed on the top of the base. An ultrasonic generator is installed on the rear side of the support. A hydraulic cylinder is installed on the top of the support. The bottom of the outputend of the hydraulic cylinder penetrates through the support. The bottom of the output end of the hydraulic cylinder is connected with a rising and falling plate. A grinding plate is installed at thebottom of the rising and falling plate. According to the ultrasonic grinding device, a fixed groove is formed, the grinding plate is arranged, the size of the fixed groove is the same as the size of the grinding plate, comprehensive ultrasonic grinding is conducted on shoe materials, and the situation that due to conical grinding, part of areas are ground for an excessively long time, the pot holeproblem is caused to the shoe materials and products are scrapped is avoided. A fixed plate which is connected in a clamping manner is arranged, a cooling box is arranged at the bottom, the cooling effect of the shoe materials fixed to the fixed plate is effectively improved, and the situation that due to the excessively-high temperature, the phenomenon that the materials are burnt is avoided.

Owner:石狮市友联服装设计有限公司

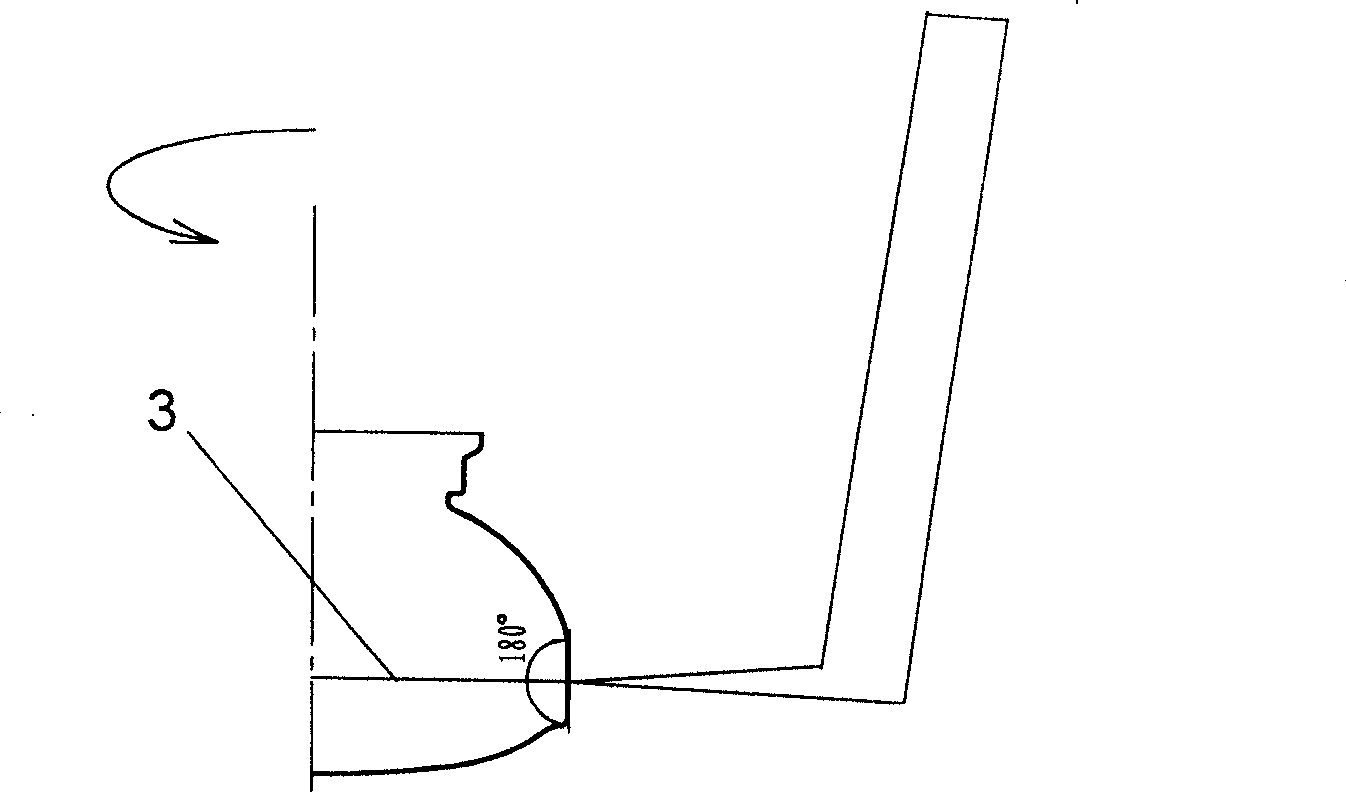

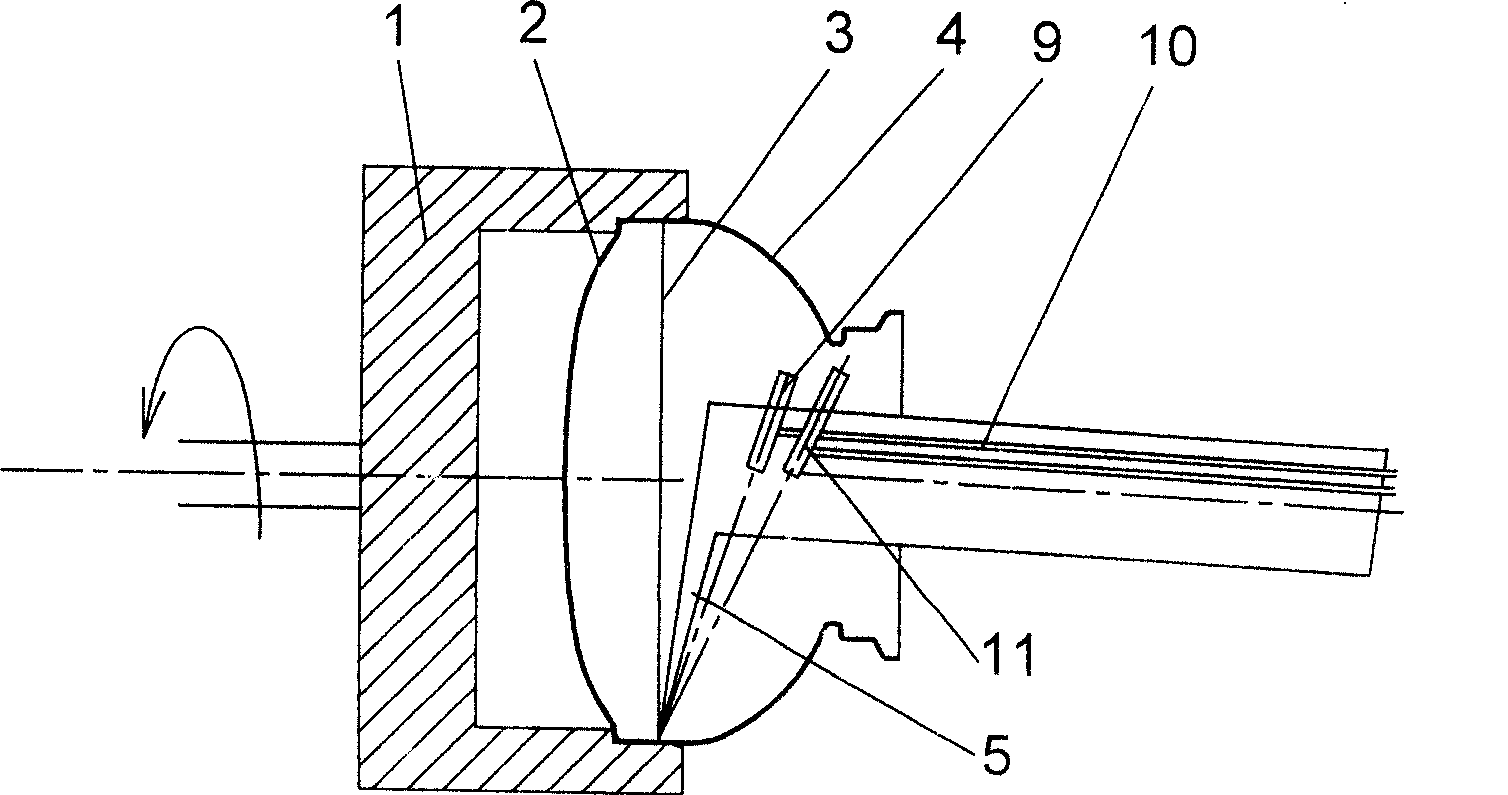

Method for welding two-layered stainless steel heat preservation inner bladder

InactiveCN100491041CAvoid potholesSimple processDomestic vesselsWelding accessoriesThermal energyEngineering

A method for welding the internal container of a dual-layer insulating canteen made of stainless steel includes such steps as degrasing the position to be welded, putting the workpiece in a rotary profile mould, fixing, inserting an argon-arc welding torch in the workpiece, fixing, driving the profile mould to rotate, starting electric arc, and welding by more than a turn.

Owner:卢晨熙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com