A device and method for reducing stickies of yellow cardboard

A technology for stickies and yellow cardboard, applied in chemical instruments and methods, cleaning methods using tools, cleaning methods and utensils, etc., can solve problems such as voids and yellow cardboard easily broken

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

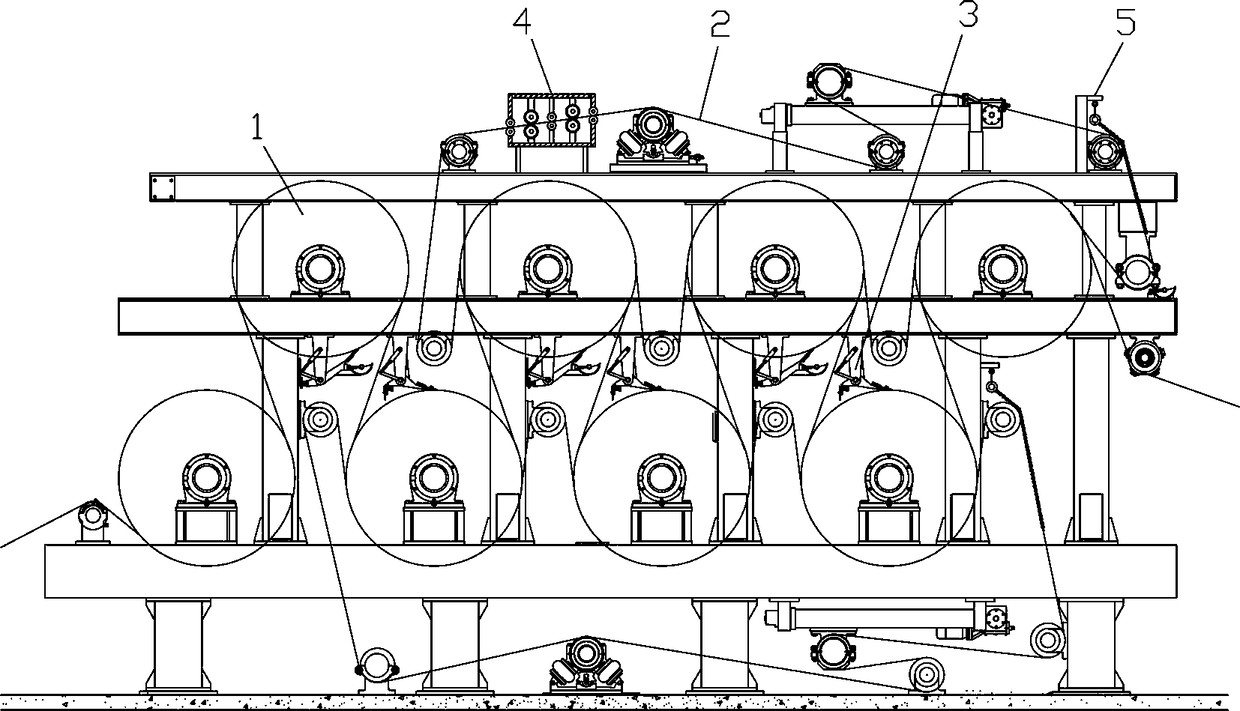

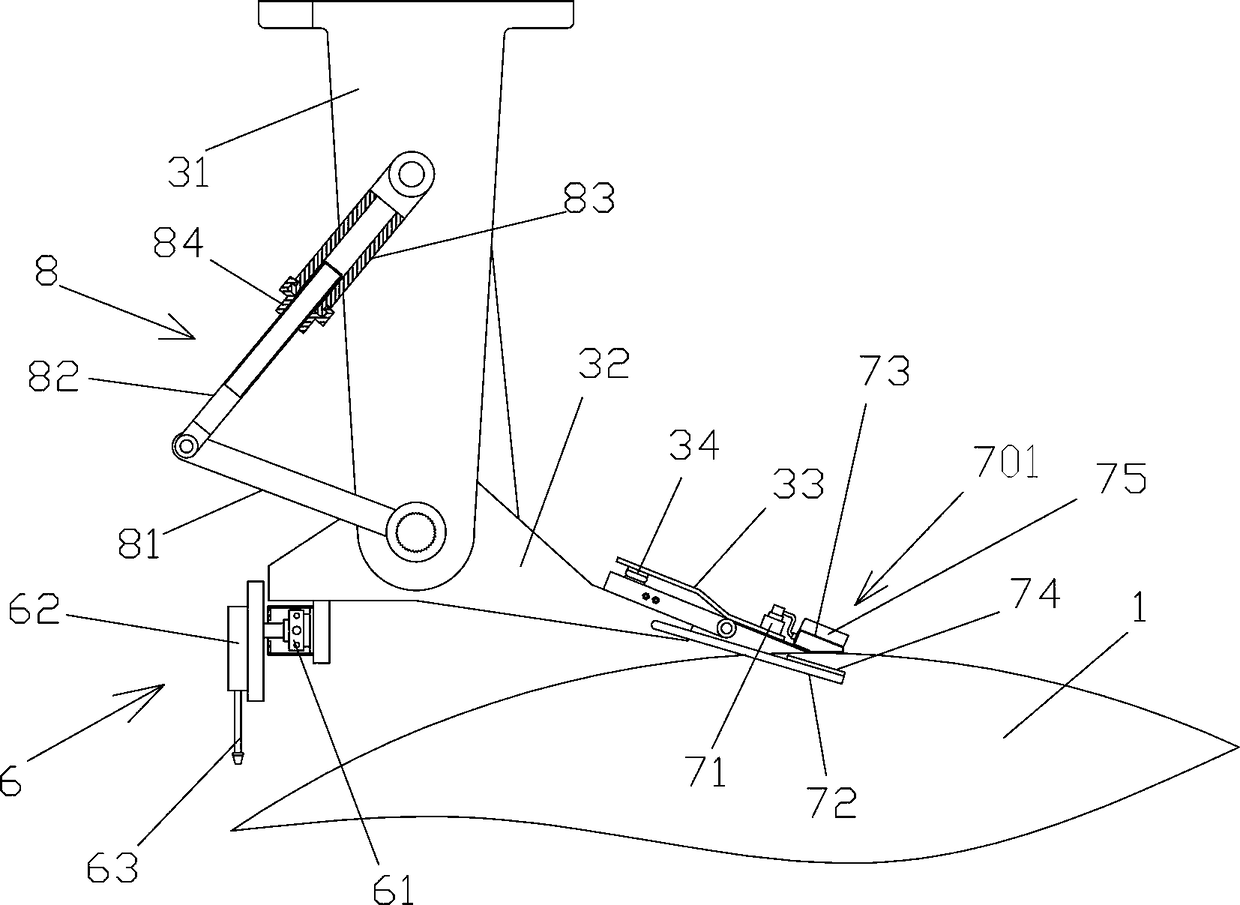

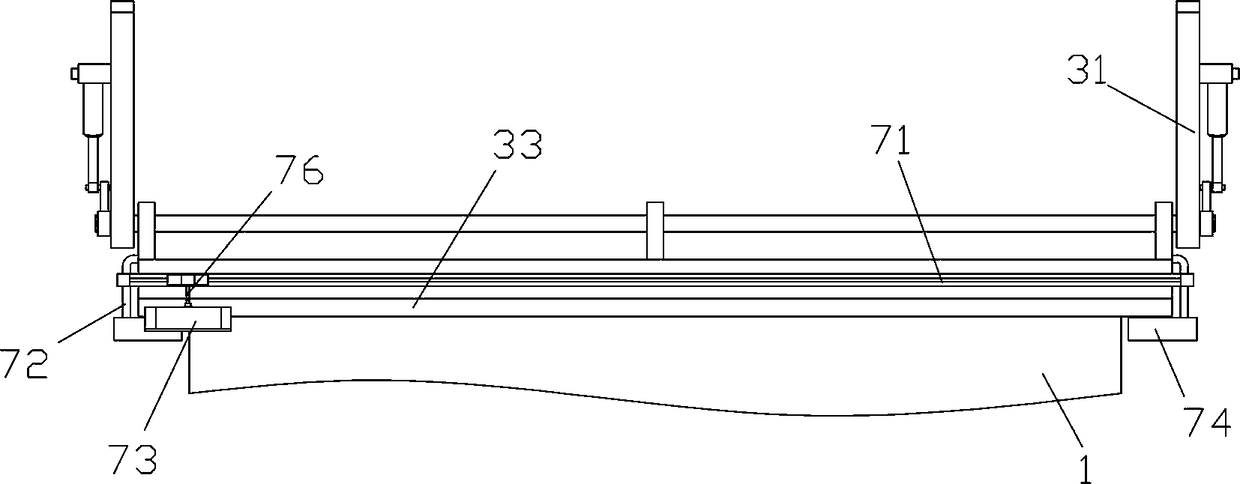

[0036] Such as Figures 1 to 3 As shown, a device for reducing stickies of yellow board paper includes a scraper mechanism 3 for removing stickies on the drying cylinder 1 of a paper machine;

[0037] Described scraper mechanism 3 comprises the connection frame 31 that is fixedly connected on the frame of paper machine, the turret 32 that is installed in the connection frame 31 and the scraper 33 that middle shaft is connected on the turret 32, and a plurality of air bag cylinders 34 are installed Between the turret 32 and the scraper 33; each airbag cylinder 34 pushes one end of the scraper 33 to stick on the surface of the drying cylinder 1, and inflates the airbag cylinder 34 to push the scraper 33 to tilt toward the drying cylinder 1, so that the scraper The plate 33 can be attached to the surface of the drying cylinder 1 in real time, and the sticky matter adhered to the surface of the drying cylinder 1 is cleaned by using the scraper 33 to prevent the sticky matter f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com