Tubular hardware polishing device and using method thereof

A hardware and tubular technology, applied in the field of tubular hardware grinding devices, can solve the problems of curved grinding surface, low grinding efficiency, deformation of nozzles, etc., and achieve the effect of preventing potholes, round and smooth surface, and more surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

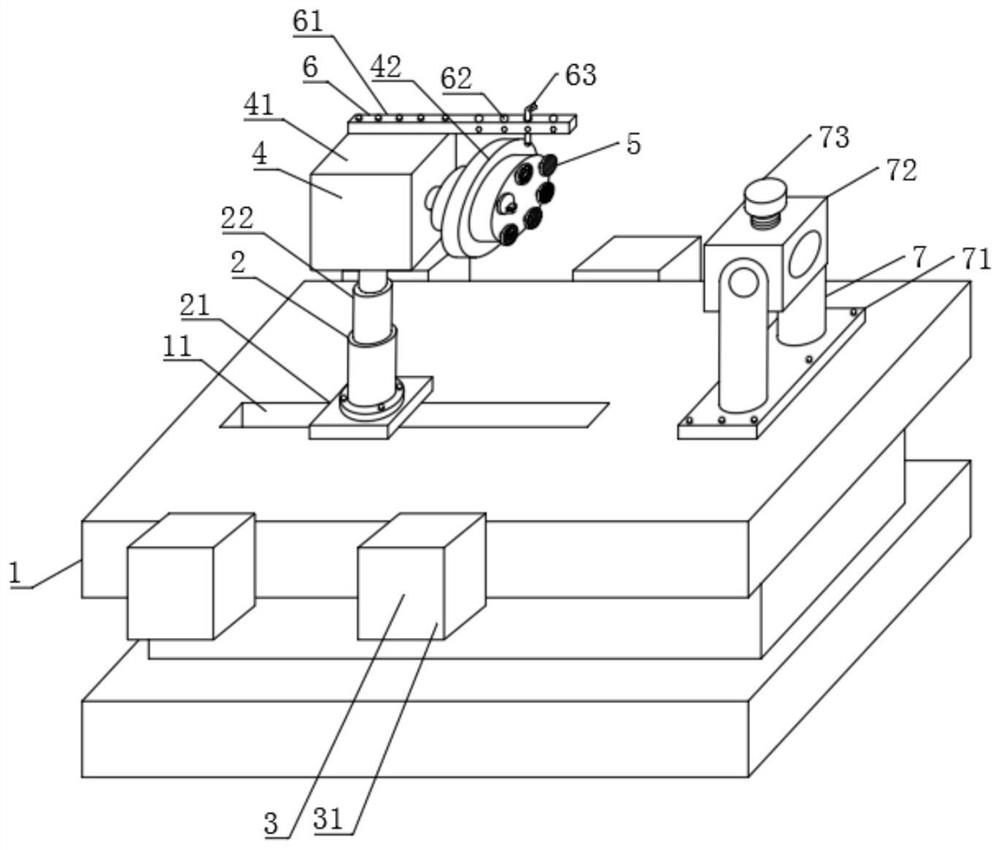

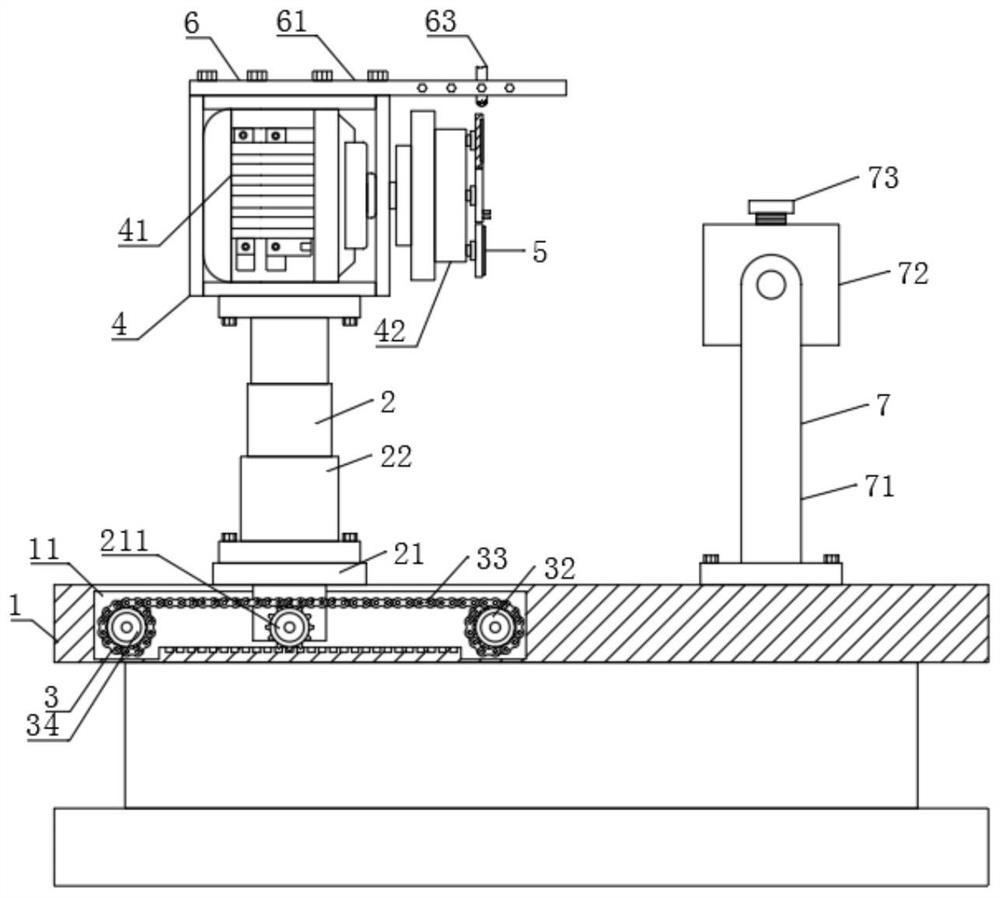

[0051] The invention provides a tubular hardware grinding device and its use method, which has the advantages of automatic grinding, different grinding methods for hardware of different materials, and more fine grinding. Please refer to Figure 1-9 , including a workbench 1, a telescopic device 2, a drive device 3, a rotating device 4, a grinding device 5, a spray device 6 and a limit device 7;

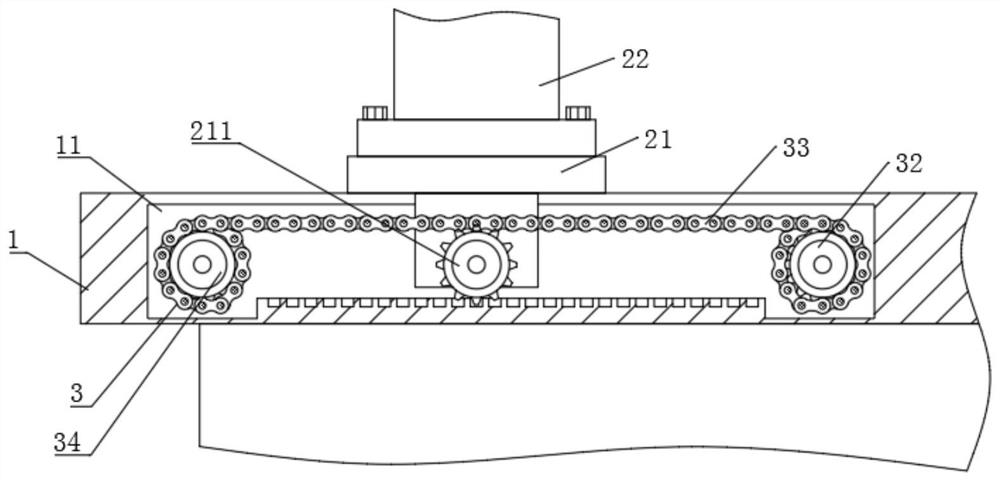

[0052] Further, the telescopic device 2 is movably installed at the top left end of the workbench 1, and the workbench 1 includes a moving groove 11. Specifically, the inner left end of the workbench 1 is provided with a moving groove 11, and the inner left end of the workbench 1 is provided with a moving groove 11, and the moving groove The inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com