Building top layer anti-seepage structure

A technology for building and anti-seepage water, applied in building structure, construction, roof drainage, etc., can solve problems such as loss of anti-seepage function, low temperature in the top room, and difficult evaporation of deposited water, and achieve thermal insulation effect. Visible, thorough drainage, avoid potholes or uneven effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

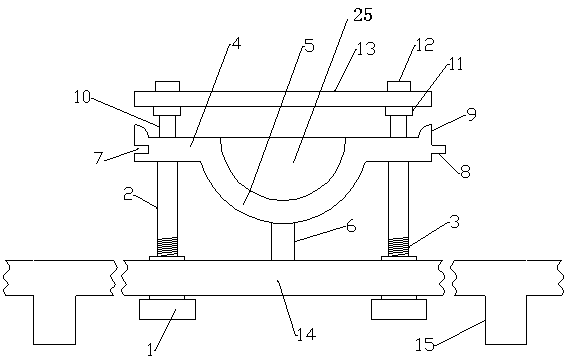

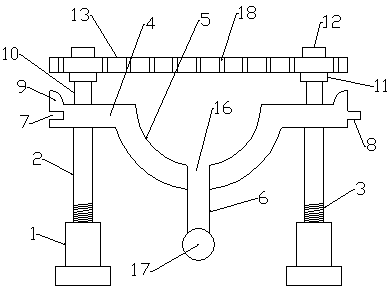

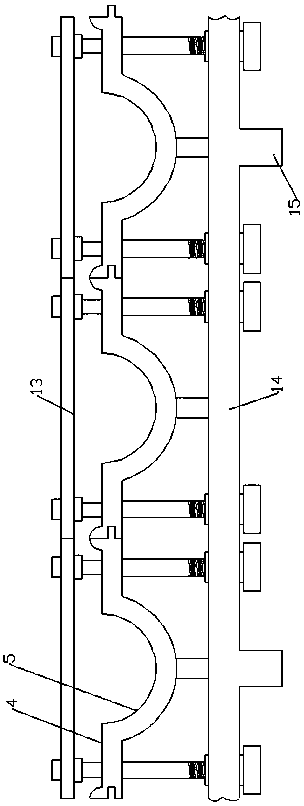

[0026] like figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, a kind of anti-seepage structure on the top floor of a building includes an outer edge waterproof layer 22 arranged on the top of the building exterior wall 19 and an outer edge waterproof layer 22 bottom The anti-seepage device between the roof wall 18 of the building, the anti-seepage device includes a groove plate 5 installed on the roof wall 18 of the building, and both sides of the groove plate 5 are fixedly equipped with a horizontal plate 4, and the horizontal plate 4 A longitudinal support 2 is fixedly installed at the bottom, the bottom of the groove plate 5 is connected with the water outlet pipe 6, the water outlet pipe 6 is connected with the water delivery pipe 17, the water delivery pipe 17 is connected with the drain pipe 14, and the bottom of the drain pipe 14 is connected with the sewage pipe 15 The sewage pipe 15 communicates with the top of the vertical drain 20 of the building, the top flat plate 13 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com