Plastic gear injection mold and using method thereof

A technology for injection molds and plastic gears, applied in gears, applications, household appliances, etc., can solve problems affecting product quality, low barrel temperature, and product brittleness, so as to prevent brittleness, improve quality, and avoid low temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]In order to make the techniques, creative features, objective and efficacy of the present invention, and the embodiments are further illustrated in connection with the specific embodiments.

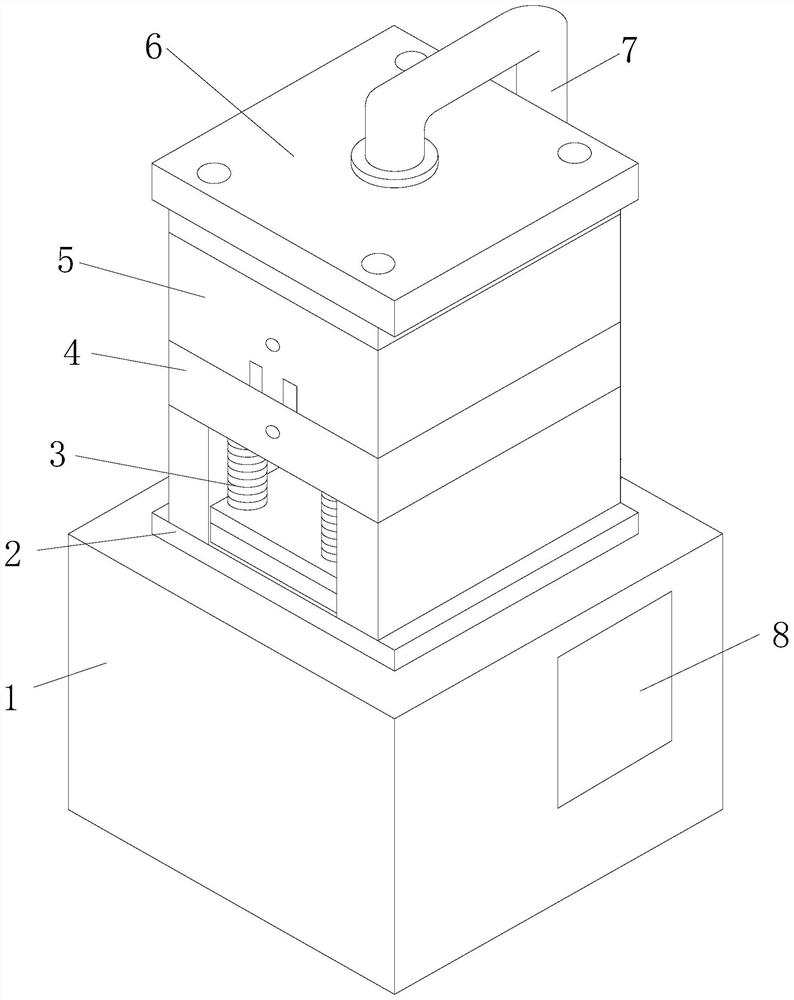

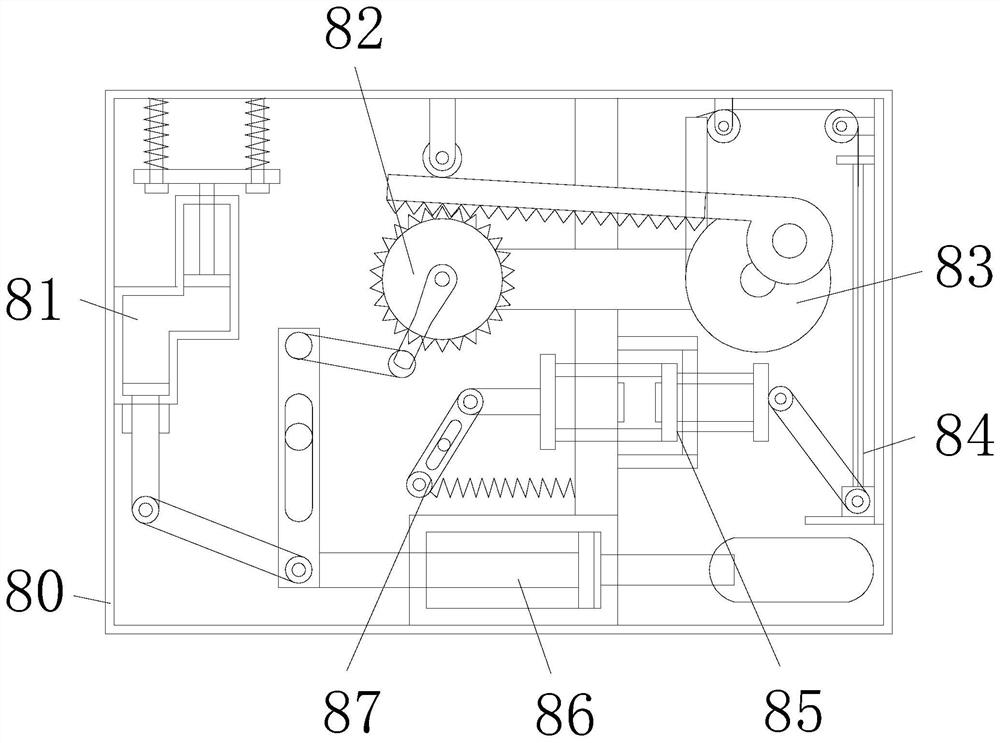

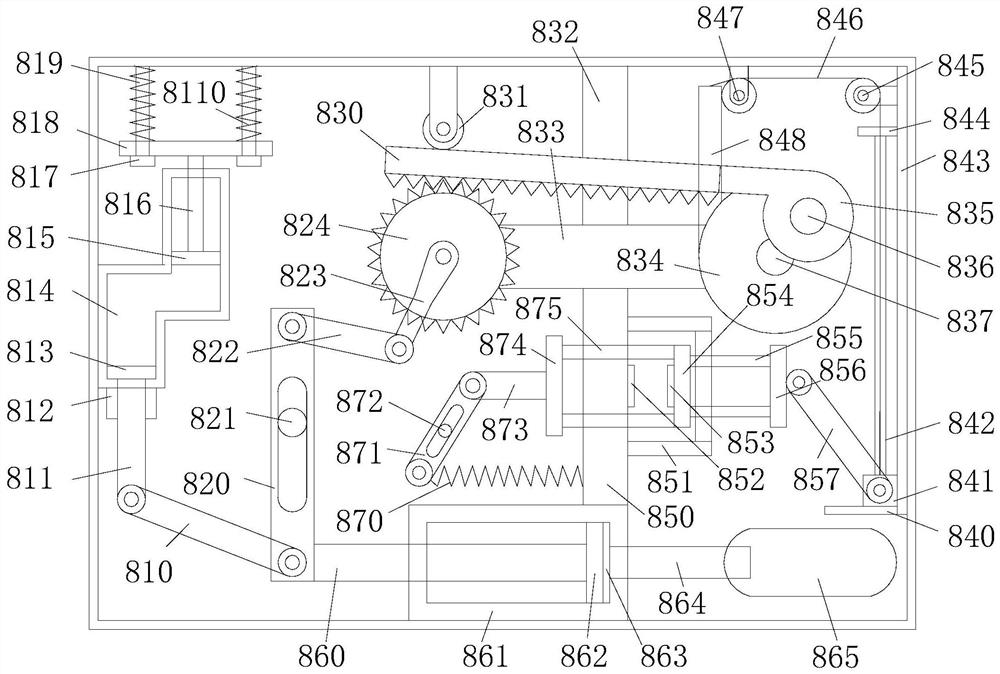

[0024]SeeFigure 1 - Figure 4The present invention provides a plastic gear injection mold and a method of use thereof: The structure includes a tank 1, a lower die 2, a spring 3, a lower mold 4, a mold 5, an upper molding seat 6, a tube 7, a switch Apparatus 8, the lower mold 2 is fixed to the top of the lower mold 2, and the lower mold 5 is connected to the lower mold 4, and the lower mold 4 is fitted to the upper mold 5, the upper mold. 5 is fixed to the upper mold seat 6, and the upper molding seat 6 is attached to the tank 1 and the tube 7, and the mold box 1 is attached, and the lower mold 4 is provided with the upper mold 5. Spring 3, the switching device 8 is composed of housing 80, a reset device 81, a linkage device 82, a transmission 83, a pulling device 84, a power distribution app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com