Cement concrete road shoulder pressing and paving machine

A technology of cement concrete roads and machinery, applied in the field of concrete equipment, can solve problems such as difficult cleaning, uneven road shoulders, high hardness of concrete, etc., and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

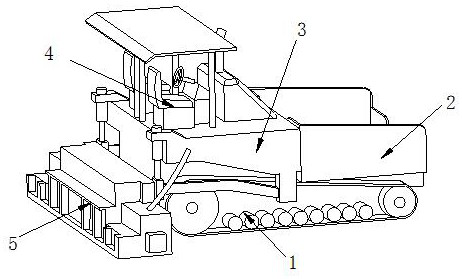

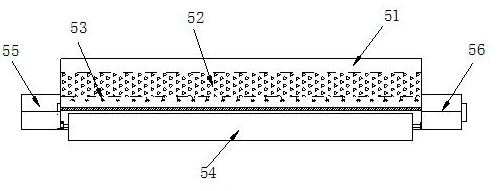

[0024] see Figure 1-Figure 4 , the specific embodiment of the present invention is as follows: a kind of cement concrete shoulder paving machine, its structure comprises drive crawler 1, charging frame 2, main engine 3, driver's cab 4, pressing block 5, described drive crawler 1 top and charging The frame 2 is fixedly connected, the bottom of the main engine 3 is fixedly installed on the top surface of the driving crawler 1, the bottom surface of the cab 4 is welded on the top surface of the main engine 3, the right side of the pressing block 5 is mechanically connected to the left side of the main engine 3, and the The left side of the charging rack 2 is mechanically connected to the right side of the main machine 3; the press block 5 includes a top cover 51, a cement silo 52, a discharge valve 53, a pressure roller 54, a cleaning structure 55, and a recovery structure 56. The top cover 51 The bottom surface is hingedly connected to the top surface of the cement silo 52, the...

Embodiment 2

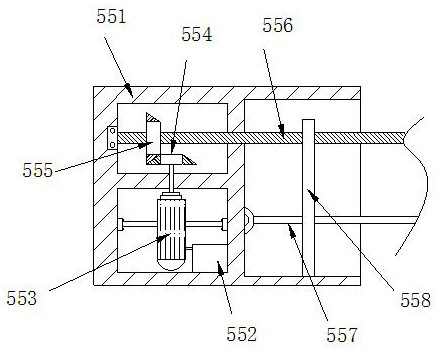

[0029] see Figure 5-Figure 7 The specific embodiment of the present invention is as follows: the recovery structure 56 includes a water pipe 561, a shower head 562, a drive structure 563, a brush layer cleaning stick 564, a housing 565, and a silica gel film 566. The bottom of the water pipe 561 and the shower head 562 The outer rings are connected to each other, the right side of the brush layer cleaning stick 564 is connected to the right side of the threaded rod 556 through the driving structure 563, the driving structure 563 is fixedly installed on the right side of the housing 565, and the silicone membrane 566 is fixedly installed on the housing On the left side of the body 565, the lower end of the sprinkler head 562 is provided with a plurality of atomizing nozzle structures, which is conducive to generating a wide range of uniformly dispersed water mist, so that the scraped cement can be kept moist to avoid solidification.

[0030]Wherein, the driving structure 563 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com