Flame-retardant synthetic film with excellent thermal conductivity and preparation method thereof

A thermal conductivity, synthetic film technology, applied in the direction of film/sheet adhesive, adhesive type, adhesive additive, etc., can solve the problems of affecting the heat resistance of thermally conductive labels, poor coating, safety hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

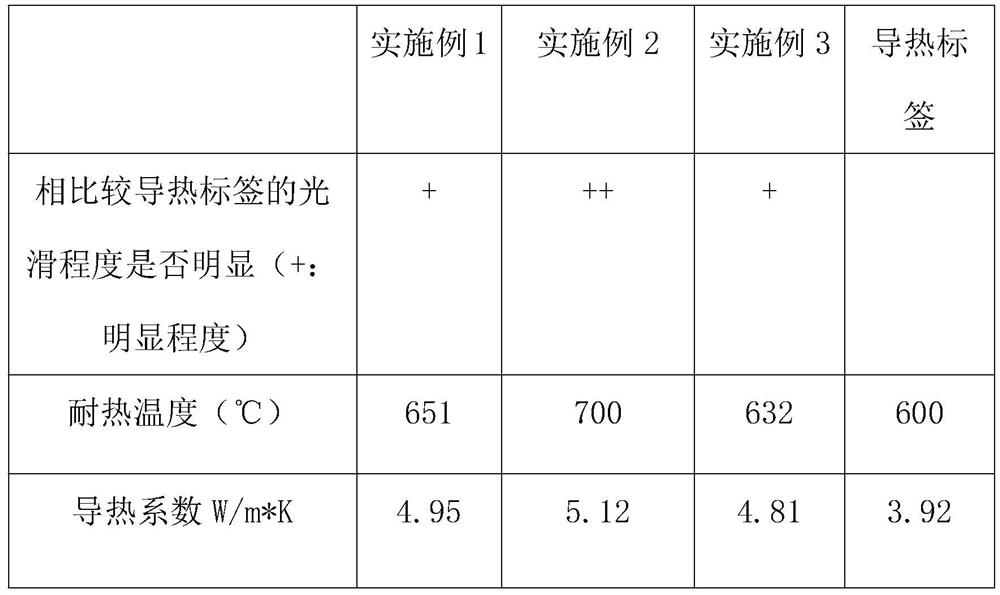

Examples

Embodiment 1

[0034] A flame-retardant synthetic film with excellent thermal conductivity, the main components include:

[0035] Thermally conductive adhesive, the main raw material component ratio of thermally conductive adhesive is flame retardant polyacrylate: isocyanate: graphite thermally conductive powder = 100: (0.1-5): 5.5;

[0036] Thermally conductive coating, the main raw material component ratio of the thermally conductive coating is modified polyurethane: graphite thermally conductive powder = 100: (10-100);

[0037] Wherein, the thermally conductive adhesive is coated on the thermally conductive coating.

[0038] It should be understood that, by adopting the relevant ratio of graphite heat-conducting powder in this heat-conducting adhesive, the heat resistance of the heat-conducting adhesive can be improved, thereby improving the safety of the heat-conducting adhesive during use; The particle size is 1-3um, which can prevent the rubber surface of the thermally conductive adhe...

Embodiment 2

[0046] A method for preparing a flame-retardant synthetic film with excellent thermal conductivity, mainly comprising the following steps:

[0047] A. The thermally conductive coating is prepared from 55 parts of graphite thermal powder and 100 parts of modified polyurethane. Since the ink in the thermally conductive coating has a solid content of about 36%, and the viscosity of the ink is high, the thermally conductive coating should be pretreated first. , filter the thermally conductive coating, and add curing agent and ethyl acetate to dilute after filtering;

[0048] B, prepare heat conduction glue, add 2.5 parts of graphite heat conduction powders in the aqueous solution that is mixed with surfactant, make graphite powder solution;

[0049] Add 100 parts of flame retardant polyacrylate, 2.5 parts of isocyanate, 7.5 parts of polydimethylsiloxane, 11 parts of polyethylene glycol ether and crosslinking agent to the graphite powder solution and mix, so that the graphite powde...

Embodiment 3

[0059] A method for preparing a flame-retardant synthetic film with excellent thermal conductivity, mainly comprising the following steps:

[0060] A. The thermally conductive coating is prepared from 100 parts of graphite thermal powder and 100 parts of modified polyurethane. Since the ink in the thermally conductive coating has a solid content of about 36%, and the viscosity of the ink is high, the thermally conductive coating should be pretreated first. , filter the thermally conductive coating, and add curing agent and ethyl acetate to dilute after filtering;

[0061] B, prepare heat-conducting glue, add 5.5 parts of graphite heat-conducting powders in the aqueous solution that is mixed with surfactant, make graphite powder solution;

[0062] Add 100 parts of flame-retardant polyacrylates, 5 parts of isocyanate, 10 parts of polydimethylsiloxane, 12 parts of polyglycol ether and cross-linking agent to the graphite powder solution and mix, so that the graphite powder particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com