Lifting-hoisting equipment for overhead working tempered glass

A technology for tempered glass and hoisting equipment, applied in safety devices, transportation and packaging, load hanging components, etc., can solve the problems of weakened glass performance, missing corners, and increased installation of tempered glass.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

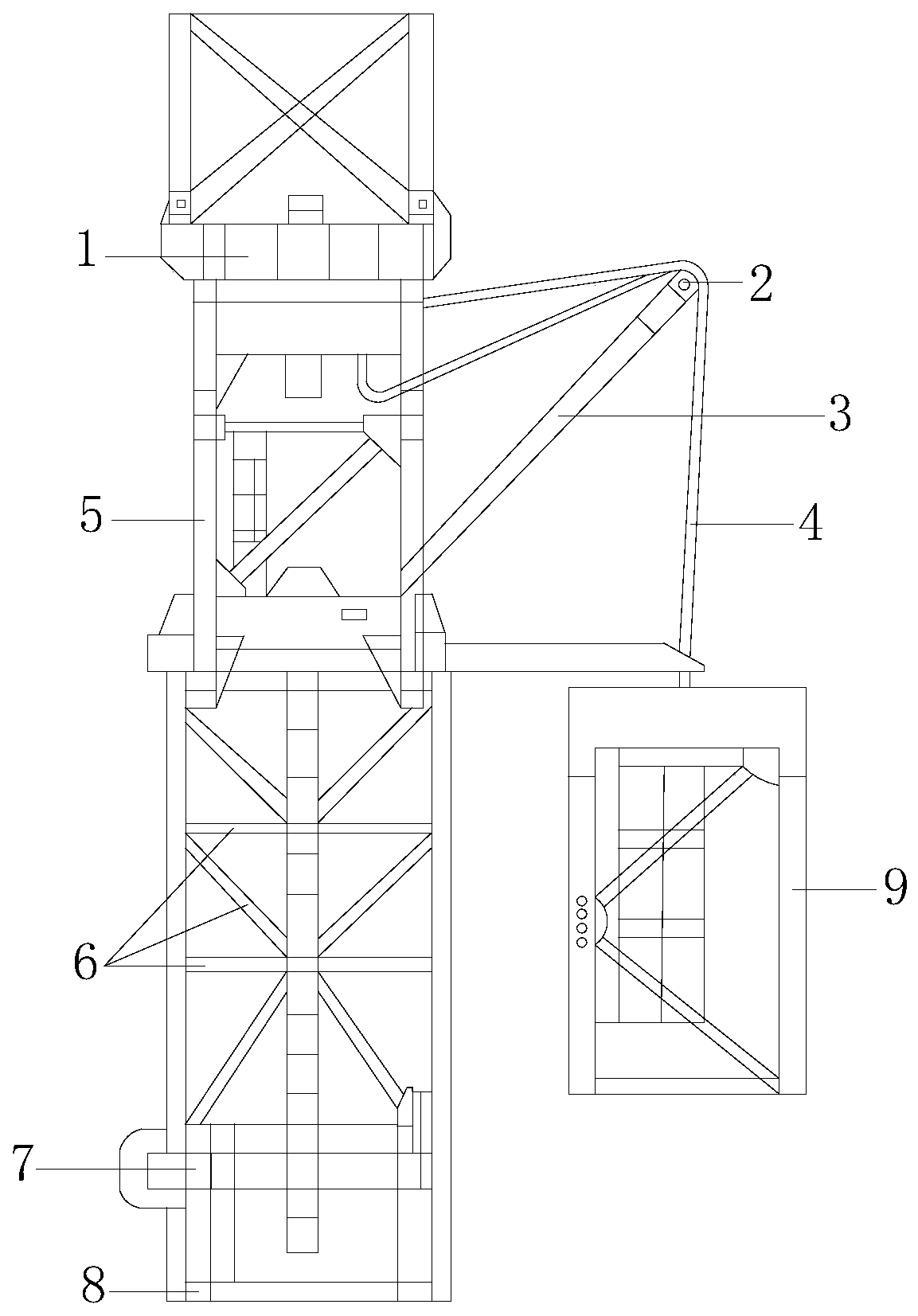

[0019] see figure 1 , the present invention provides a lifting and hoisting equipment for tempered glass for aerial work, its structure includes: receiving tower 1, pulley 2, landing bar 3, sling 4, operation tower 5, bracket 6, load-bearing tower 7, base 8, hoisting tower 9. The receiving tower 1 is vertically movably connected with the operation tower 5 through its own slide rails. The receiving tower 1, the operating tower 5 and the load-bearing tower 7 are all rectangular frame structures. The receiving tower 1, the operation tower 5 and the load-bearing tower The size of 7 increases sequentially in equal proportions. The pulley 2 runs through and connects to the end position of the landing bar 3. The sling 4 is connected to it through the annular groove on the surface of the pulley 2. When the sling 4 passes through the pulley 2, it will cause the pulley 2 Rotate, while the pulley 2 is in motion and the landing bar 3 connected to it remains stationary to provide sufficie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com