Stone slab building block paving structure suitable for traffic loads at all levels

A block and stone slab technology, which is applied in the field of stone block pavement structure, can solve the problems of easy water accumulation, cracks, and uneven road surface, and achieve the effect of avoiding pedestrians slipping, reducing surface cracks, and preventing potholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

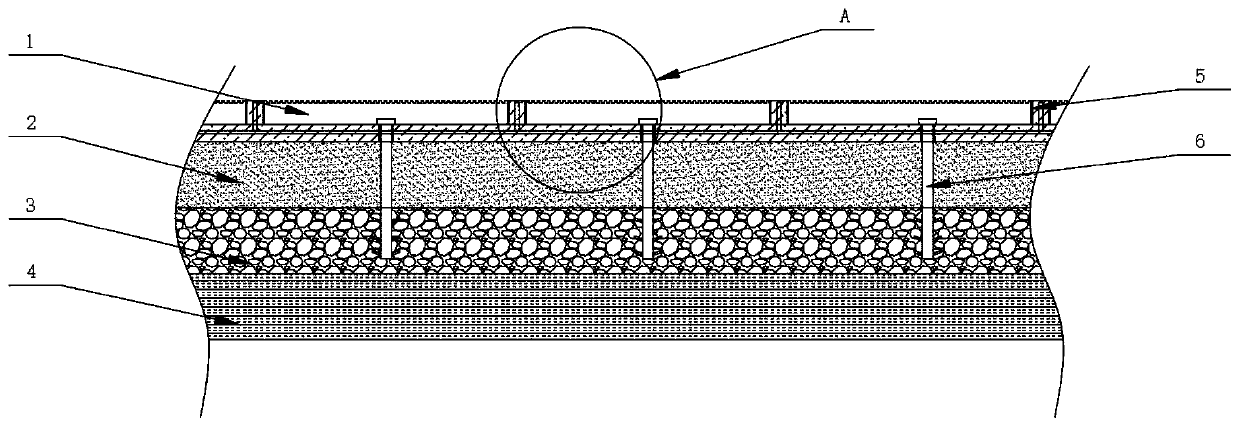

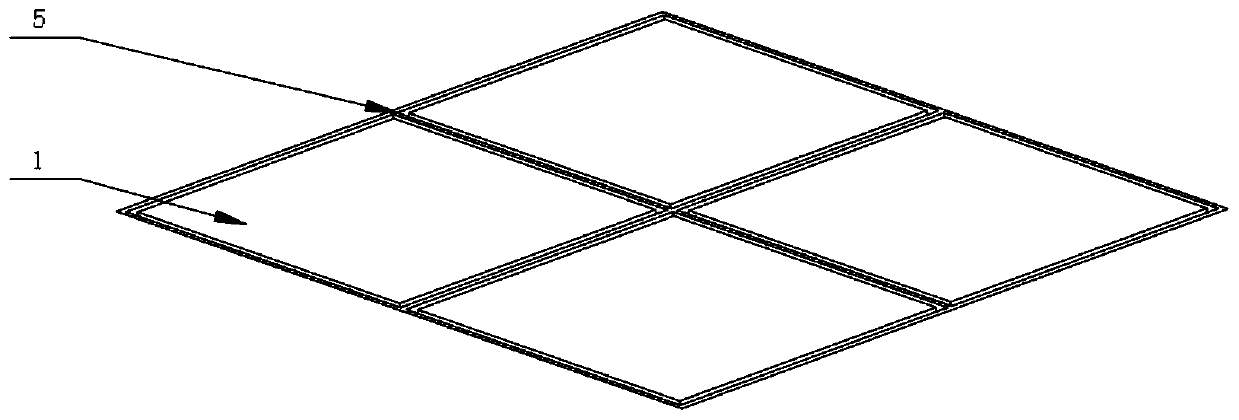

[0022] see Figure 1~5 , in an embodiment of the present invention, a pavement structure of slate blocks suitable for traffic loads at all levels includes a soil bottom layer 4, the upper surface of the soil bottom layer 4 is covered with a fine stone concrete layer 3, and the upper surface of the fine stone concrete layer 3 Covered with a sandy soil layer 2, the upper surface of the sandy soil layer 2 is installed with a fixed assembly 5, the upper surface of the fixed assembly 5 is embedded with a block stone slab assembly 1, and the upper surface of the fixed assembly 5 is installed with a fixed anchor rod 6, The fixed anchor rod 6 is a member made of stainless steel, and the lower end of the fixed anchor rod 6 passes through the sandstone soil layer 2 and is fixedly connected with the fine stone concrete layer 3 .

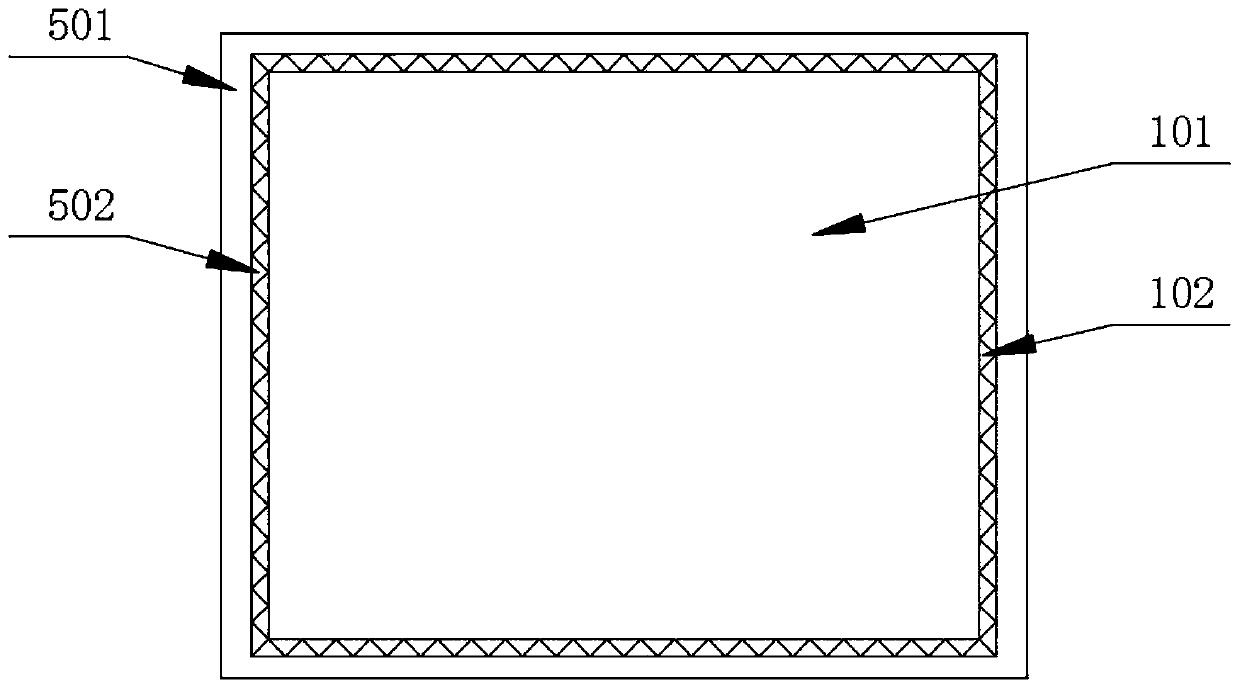

[0023] exist figure 2 Middle: The upper surface of the sand and gravel soil layer 2 is equipped with a fixed assembly 5, the fixed assembly 5 includes a bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com