Patents

Literature

46results about How to "Good tearing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

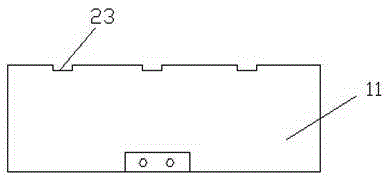

Efficient raw cotton loosening machine capable of removing dust

ActiveCN105386162AQuality improvementEvenlyFibre cleaning/opening by toothed membersPulp and paper industryWool

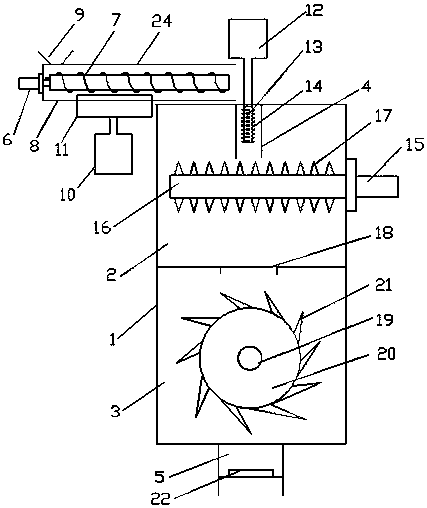

The invention discloses an efficient raw cotton loosening machine capable of removing dust. The efficient raw cotton loosening machine comprises an auger conveying device and a machine case. A feeding port is formed in the upper portion of the machine case and is of a transverse V-shaped structure, an air cylinder is arranged above the auger conveying device, a baffle is connected to the lower portion of the air cylinder and stretches into a support, a second motor is arranged at the front end of the upper half section of the machine case, the second motor is connected with a longitudinal stirring blade, and barbs are arranged on the longitudinal stirring blade. A third motor is arranged on one side of the lower half section of the machine case and connected with a transverse stirring shaft, staggered spikes are arranged on the transverse stirring shaft, a filter plate is arranged below the transverse stirring shaft, an impurity area is arranged below the filer plate, an outlet is formed below the impurity area, a discharging pipe is arranged on the other side of the lower half section of the machine case, and a suction fan is arranged in the discharging pipe. According to the efficient raw cotton loosening machine, feeding is continuous and orderly, the wool tearing effect is good, produced raw cotton is fluffy, fine and soft, and the efficient raw cotton loosening machine is simple in structure, convenient to use, high in safety, small in equipment burden and high in production efficiency.

Owner:SHANDONG LICHANG TEXTILE TECH

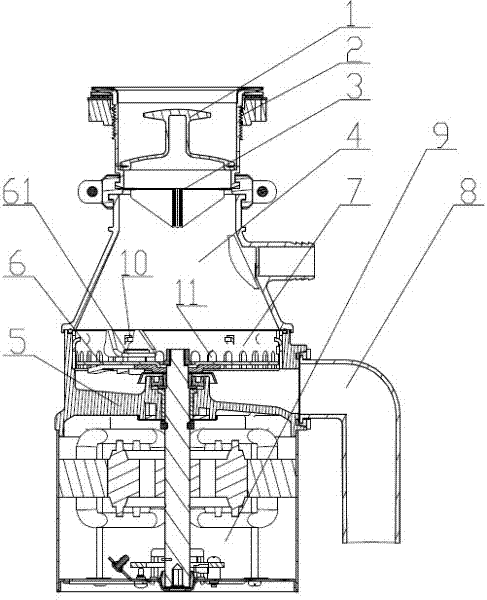

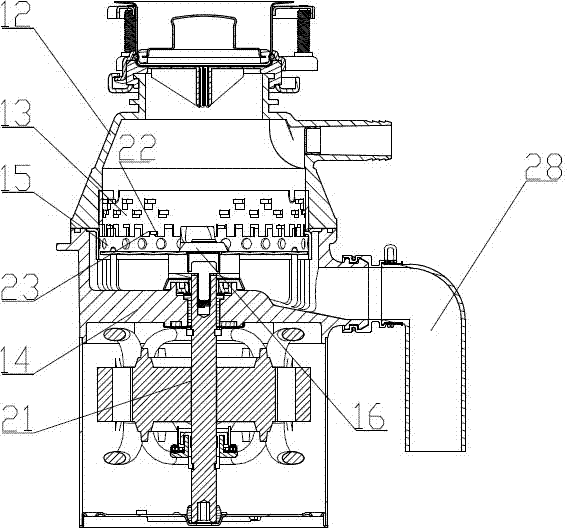

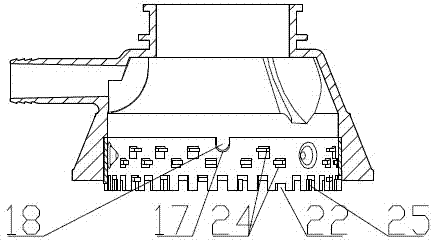

A food waste disposer

The invention is a food waste disposer. It includes a casing, an upper crushing chamber, a lower crushing chamber, a cutter head assembly, and a motor assembly, wherein the upper crushing chamber for holding food waste is arranged on the upper part of the casing, and the lower crushing chamber is arranged under the bottom of the upper crushing chamber. The upper grinding ring is installed in the upper crushing chamber, the cutter head assembly is placed in the lower crushing chamber, the motor assembly that drives the cutter head assembly to rotate is installed in the lower part of the housing, and the lower grinding ring is installed in the lower crushing chamber. In the present invention, a coaxial connecting ring is formed between the upper grinding ring and the lower grinding ring, and this structure can gather a certain amount of food waste, especially fibrous food waste. In addition, since the upper grinding ring is provided with staggered grinding grooves and transverse protrusions, the grinding fineness and grinding speed of food can be effectively improved, the impact of bone food waste on the upper grinding chamber can be avoided, and the upper grinding chamber can be extended. The service life of the crushing chamber; the invention is easy to assemble and has excellent performance.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

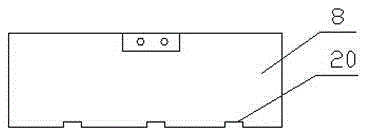

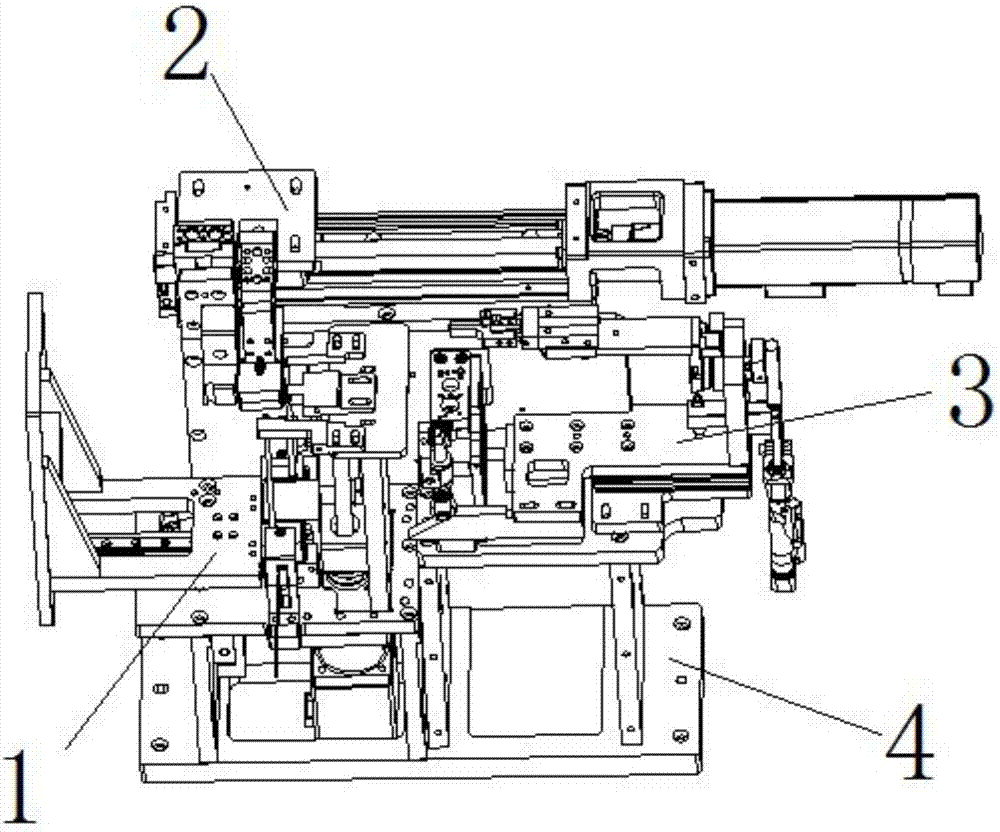

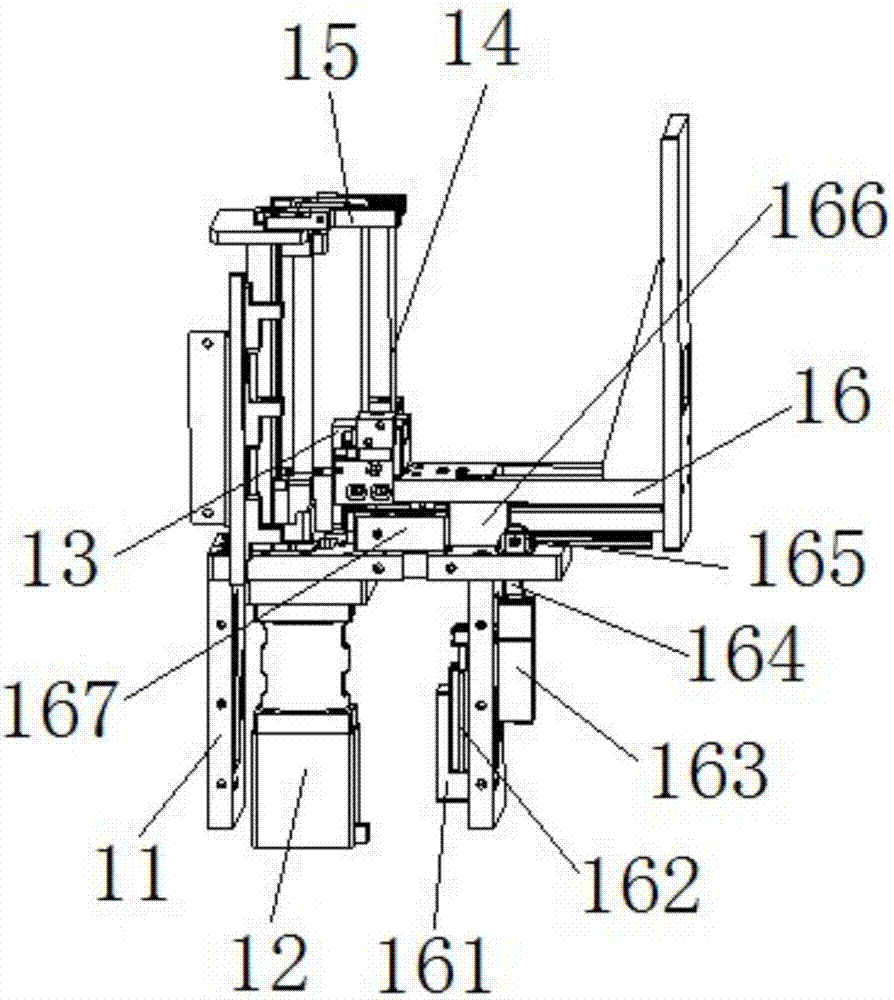

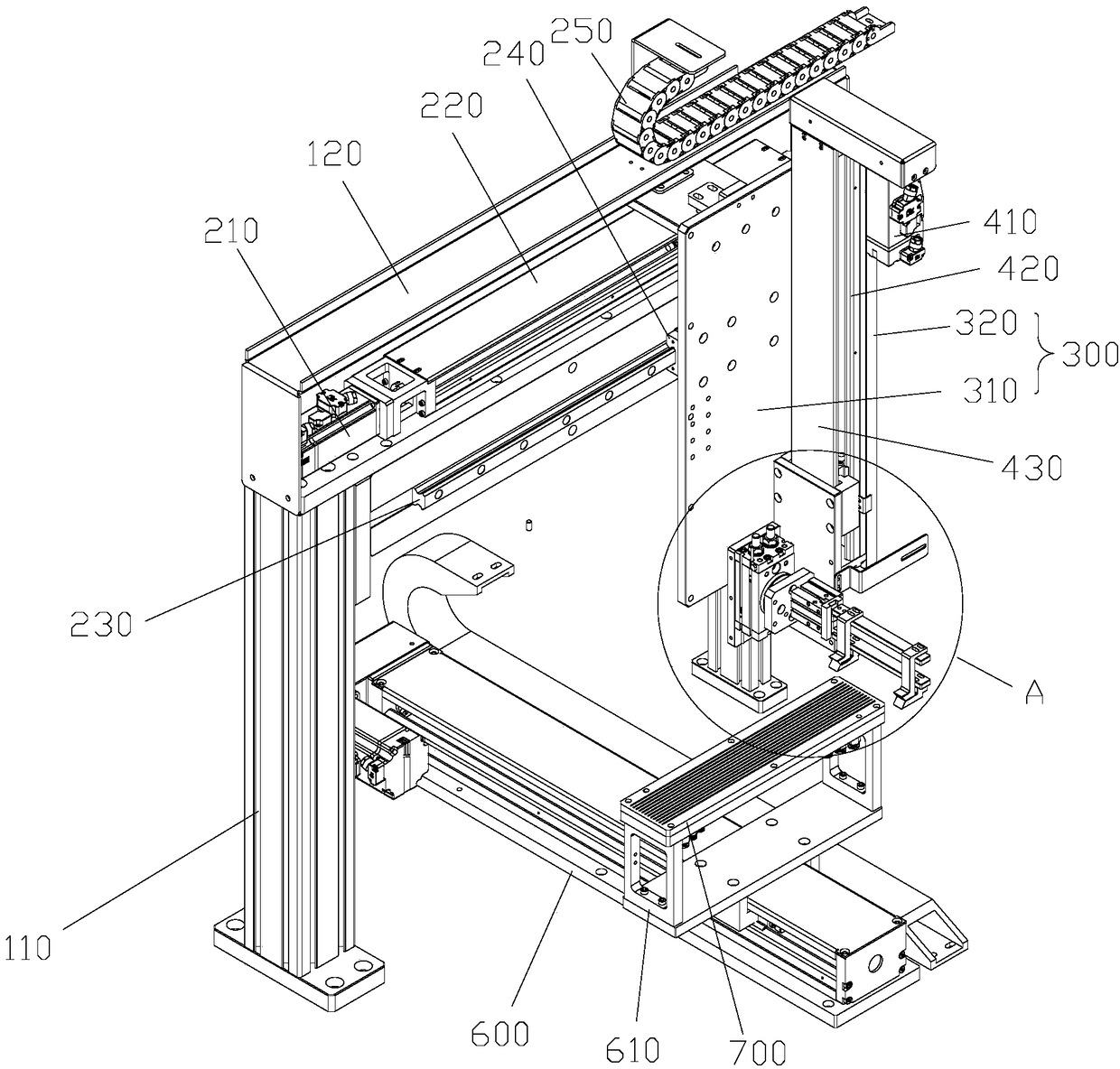

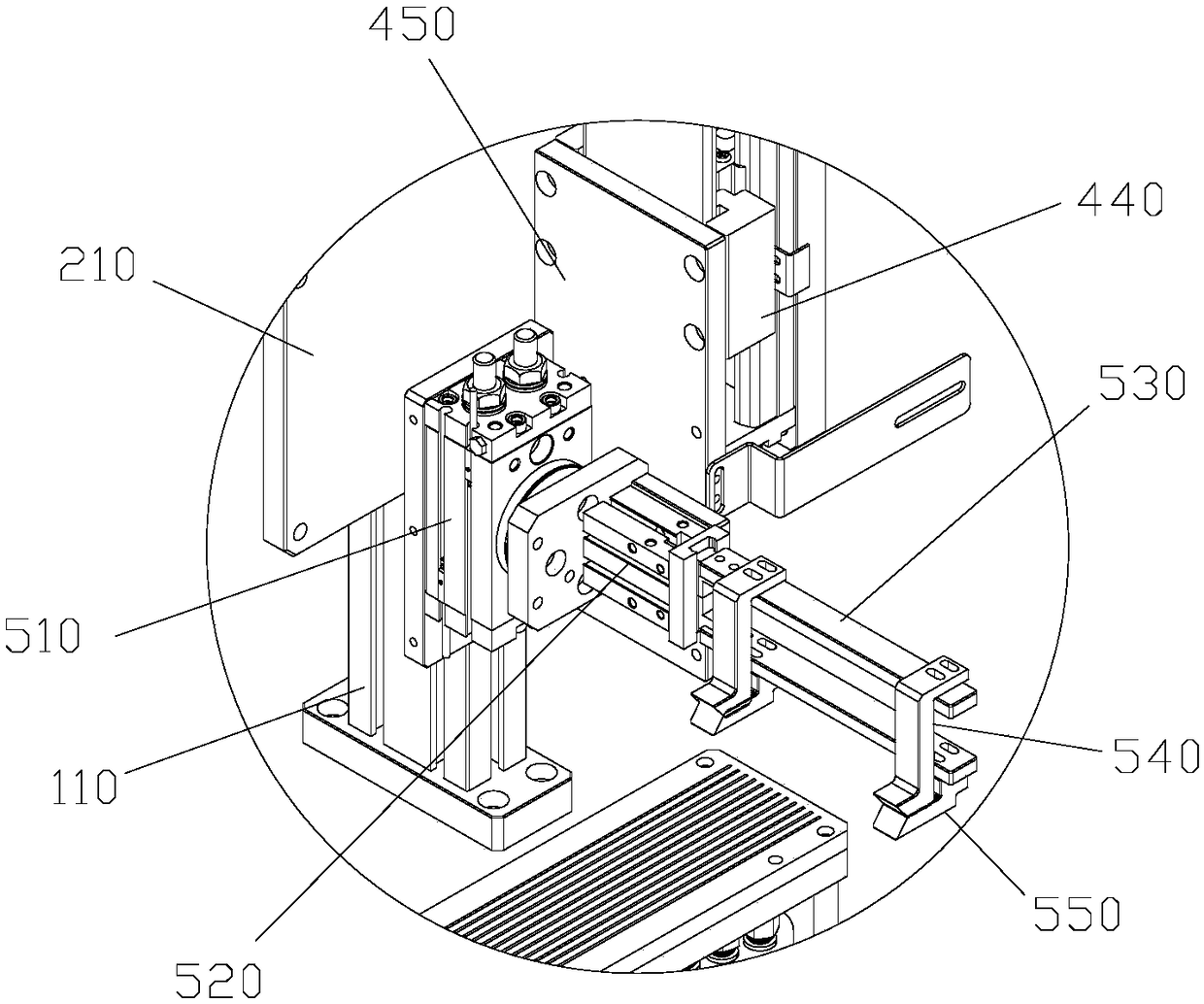

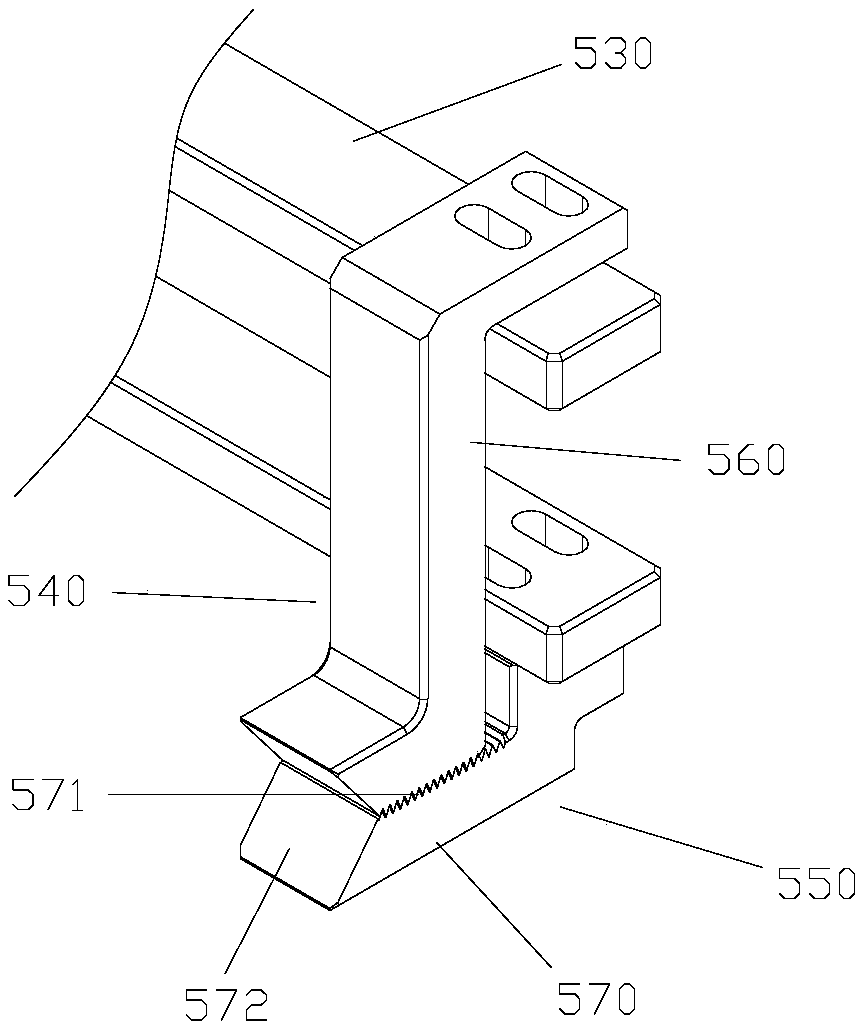

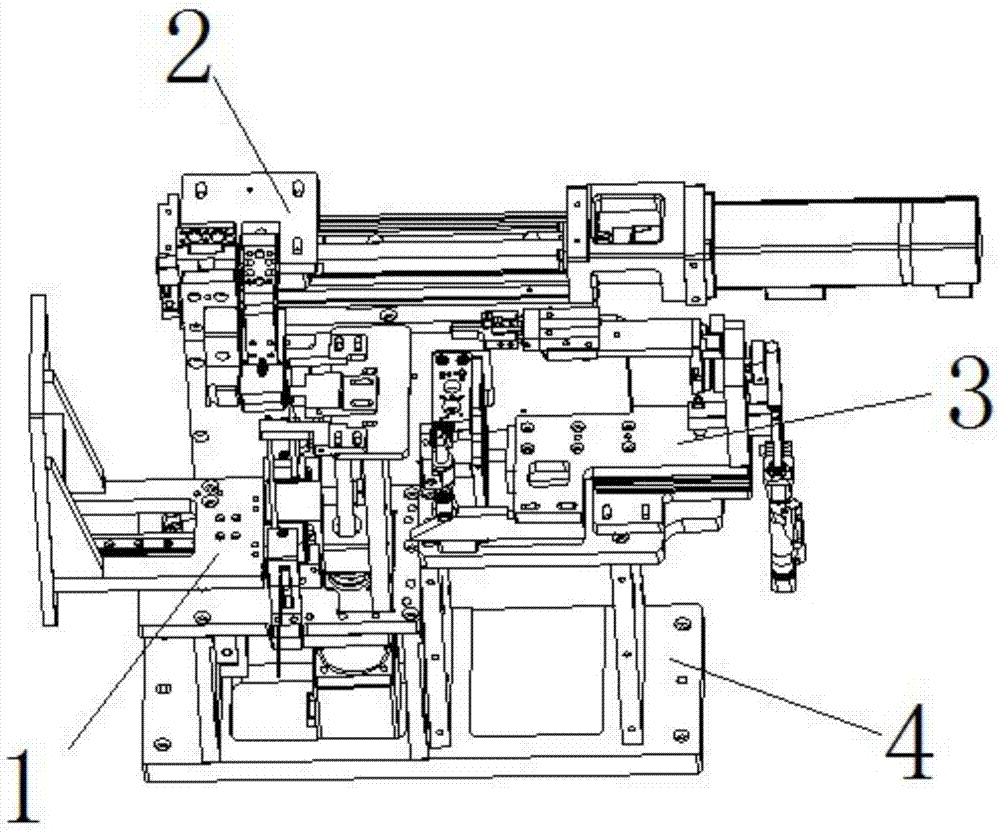

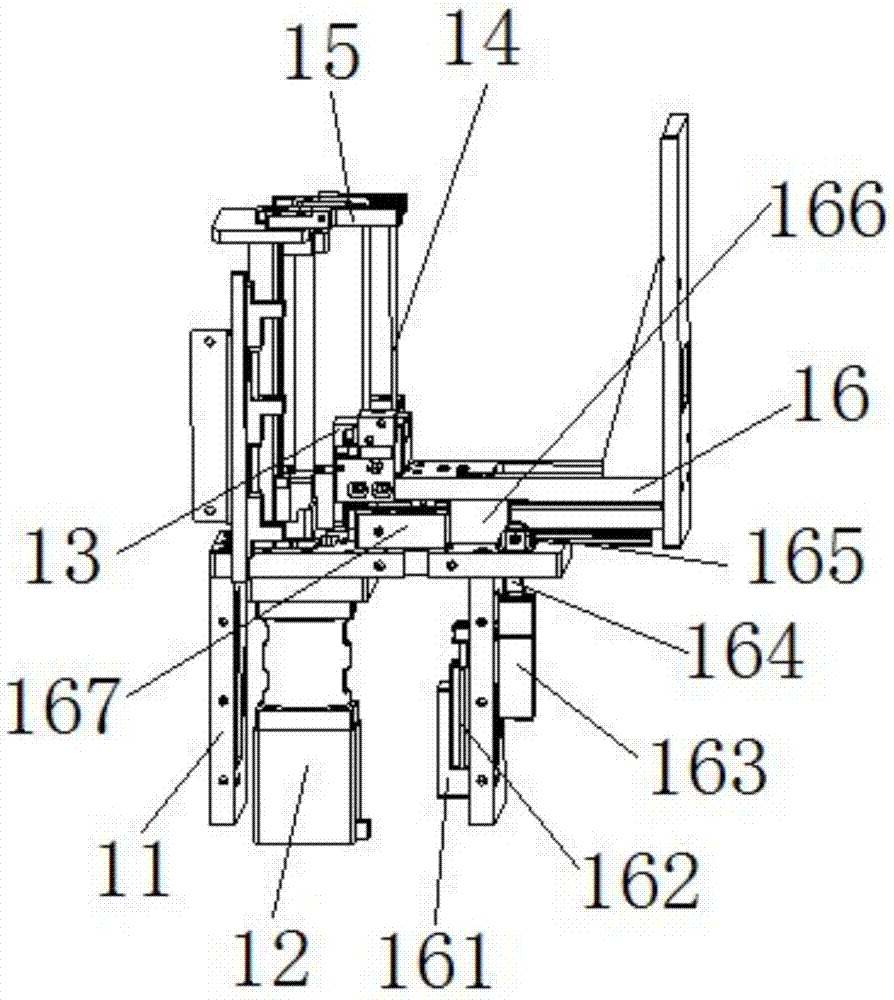

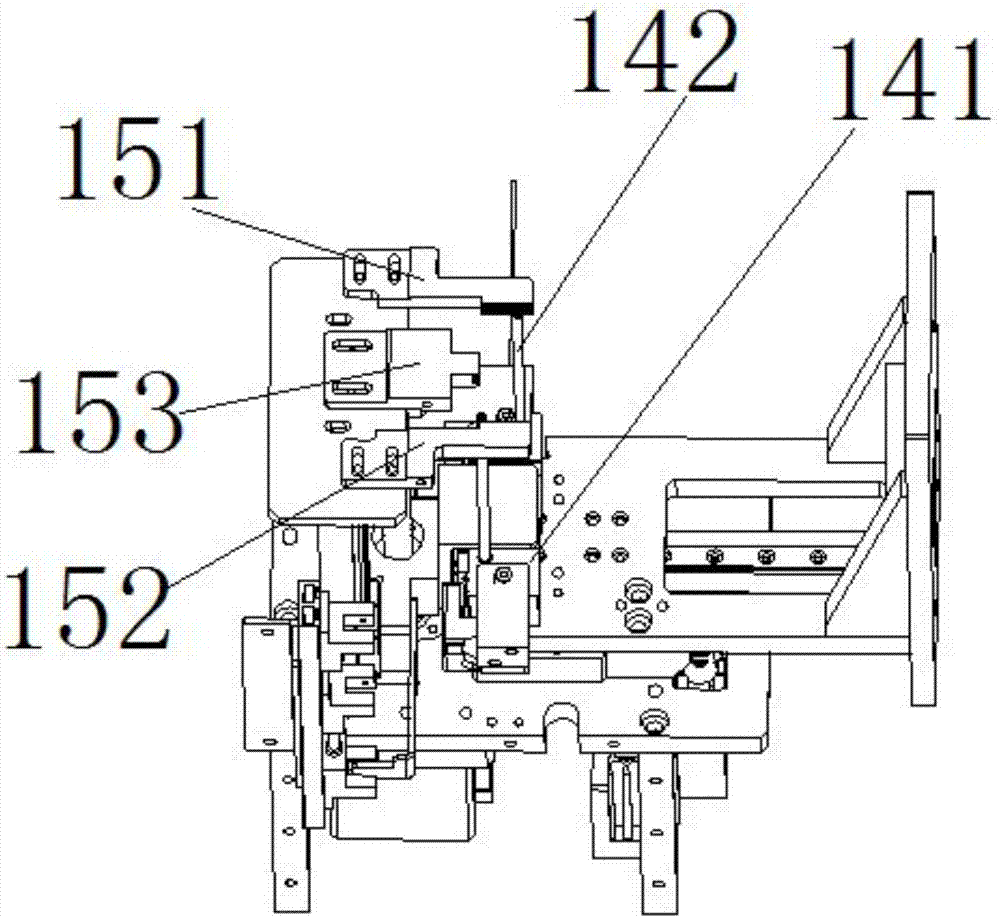

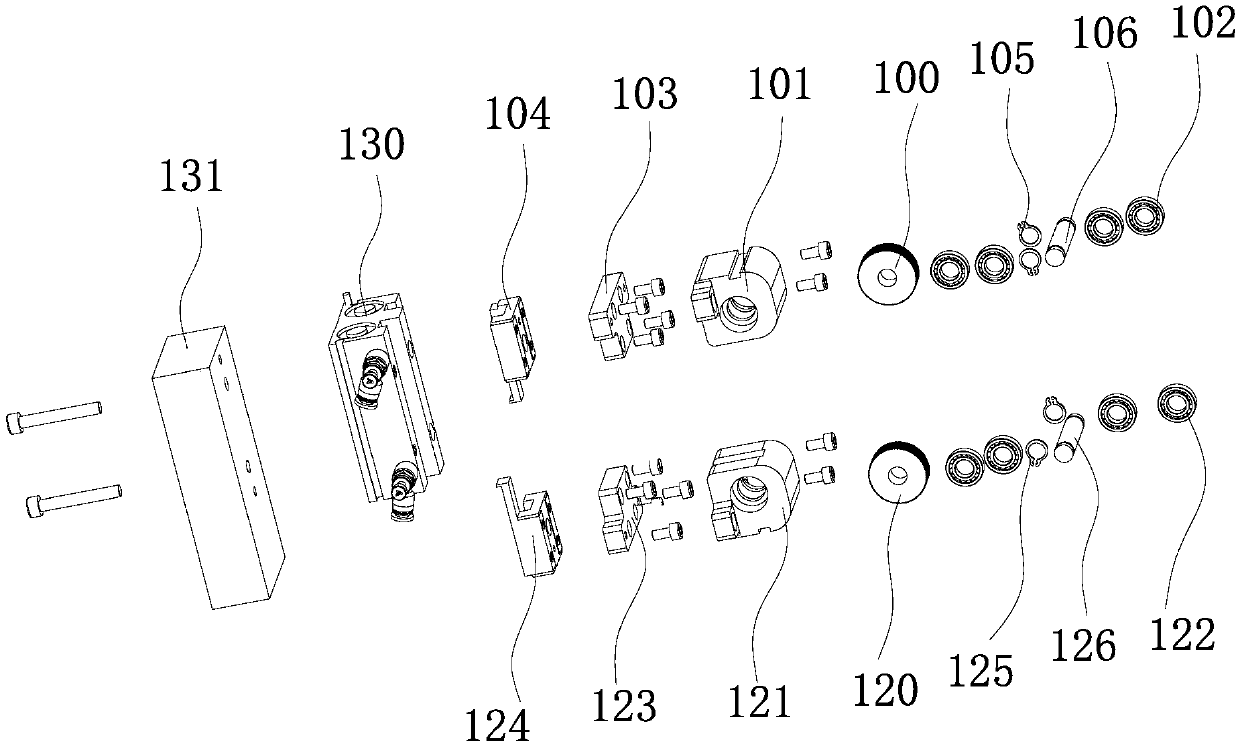

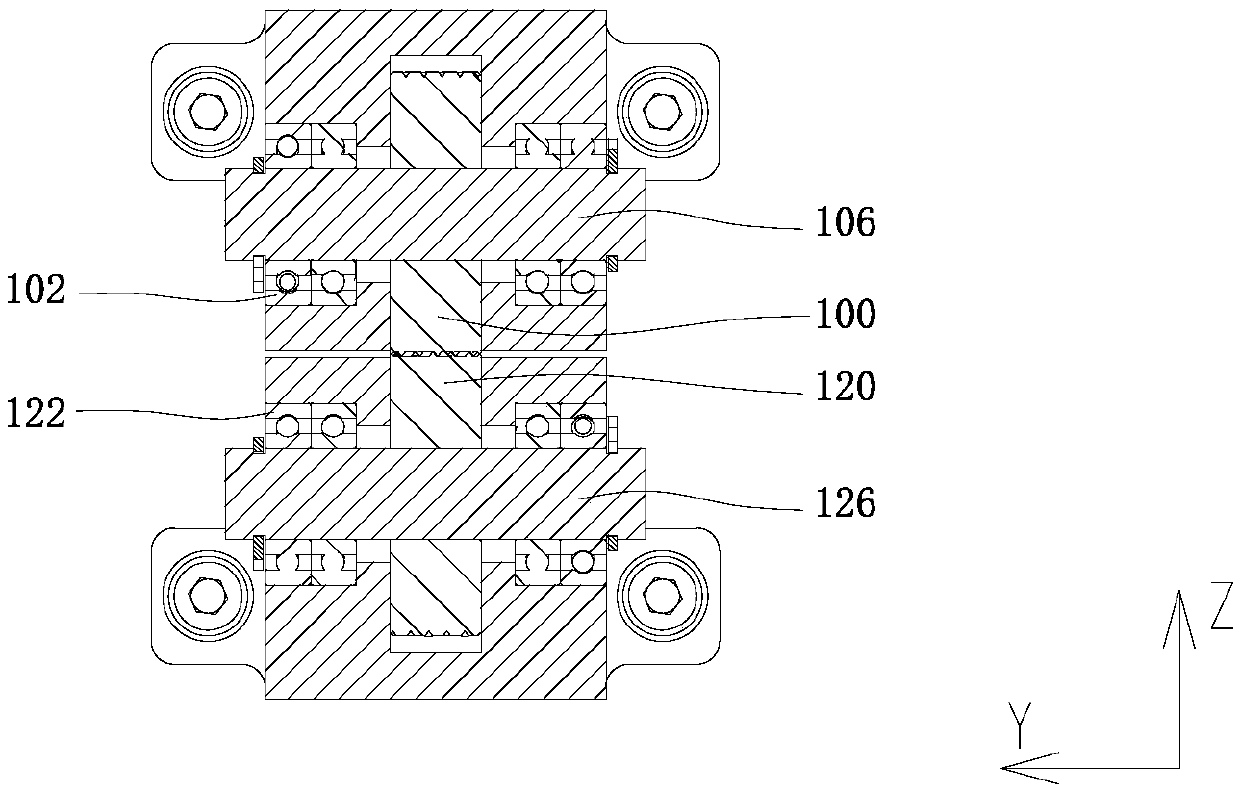

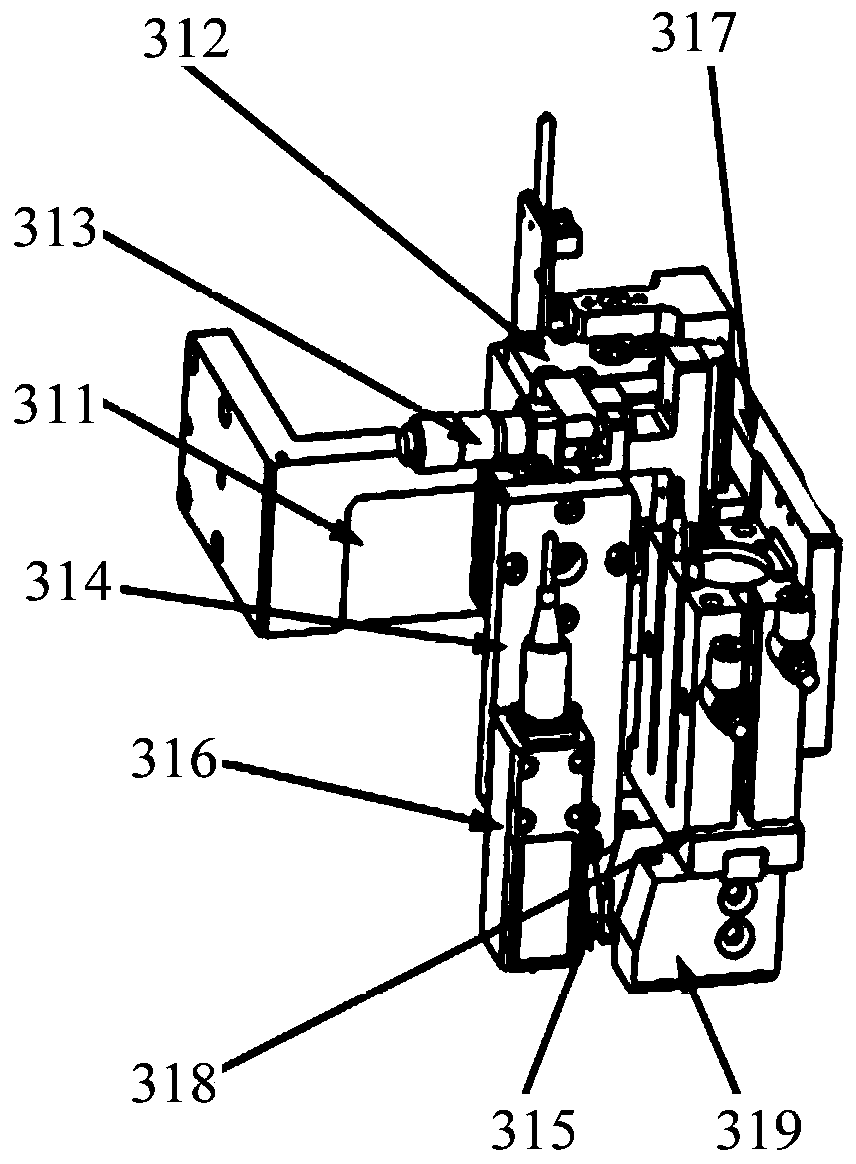

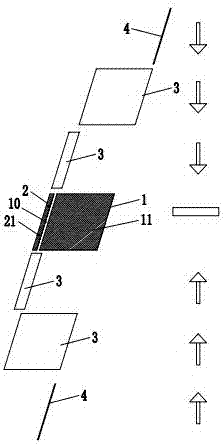

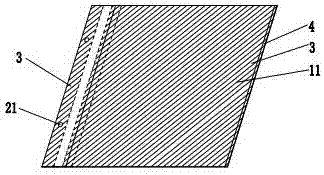

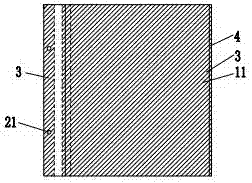

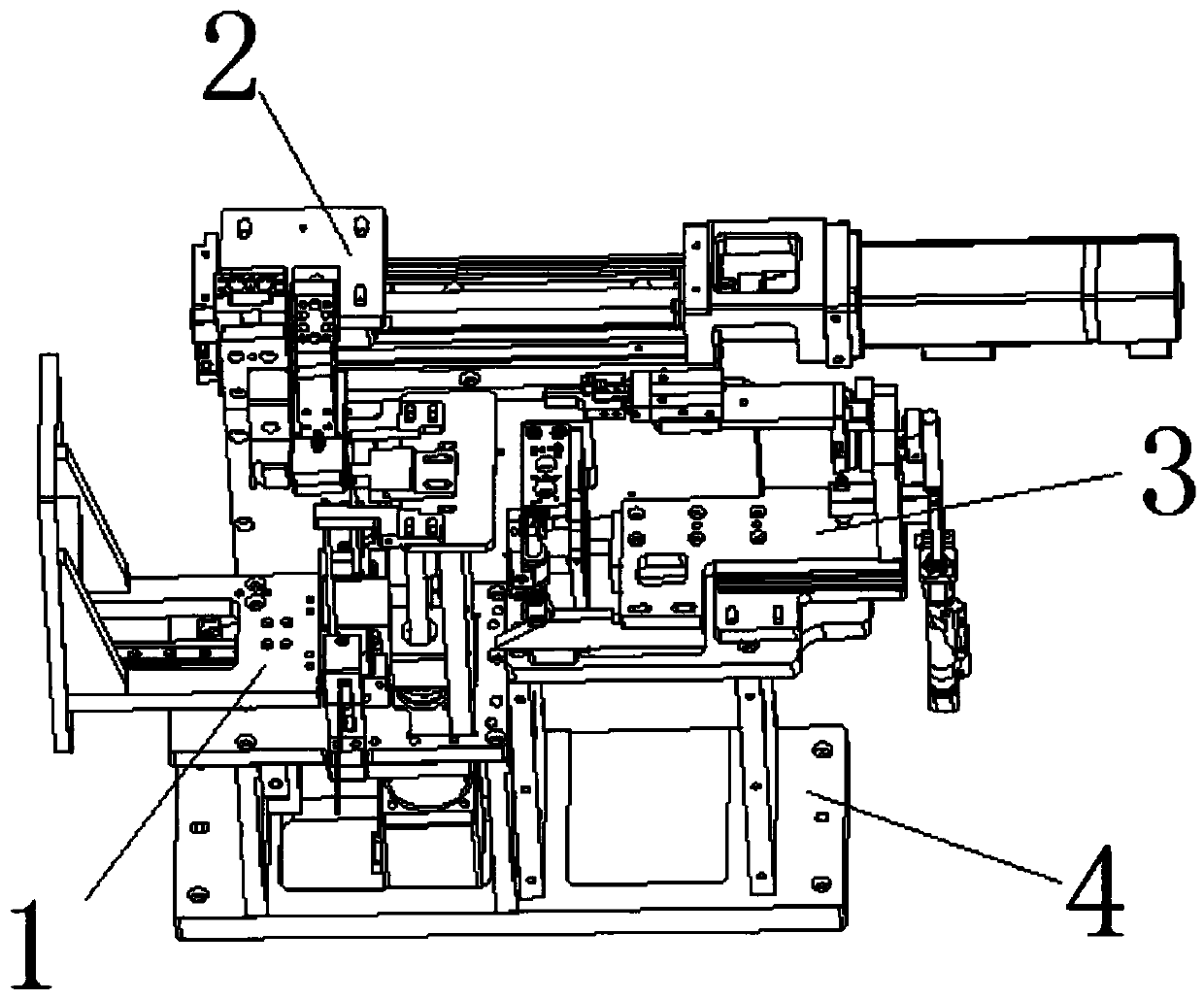

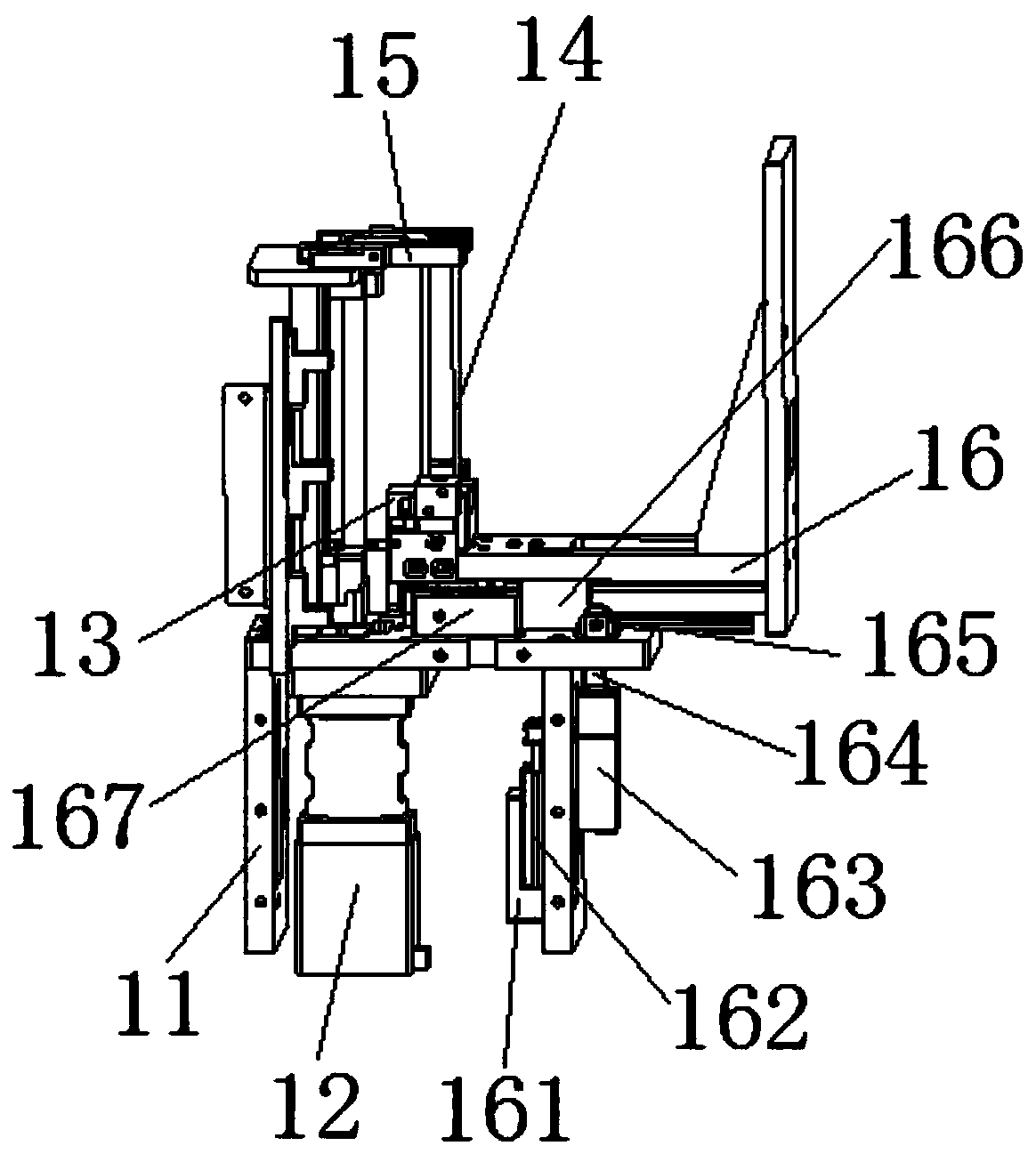

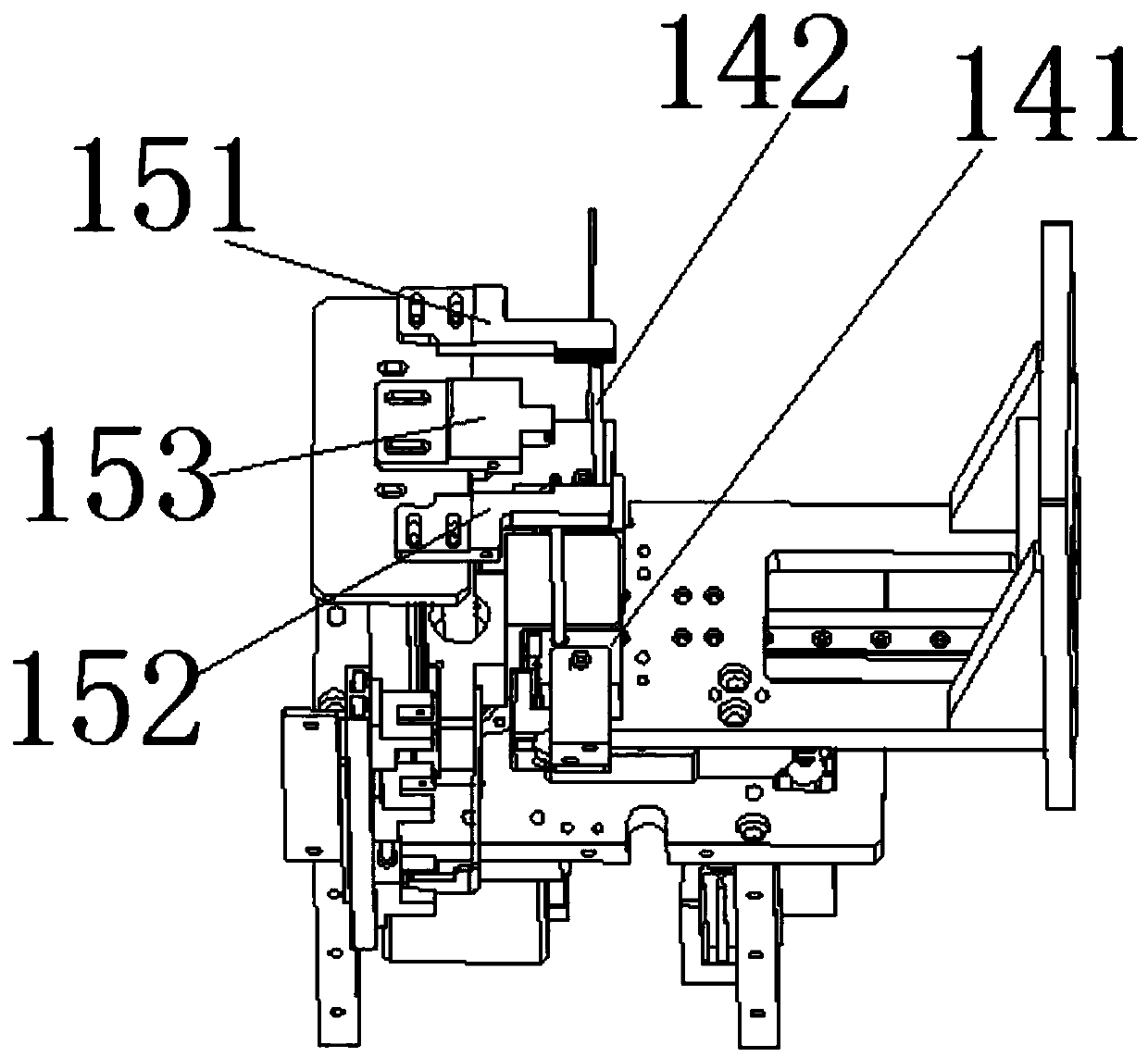

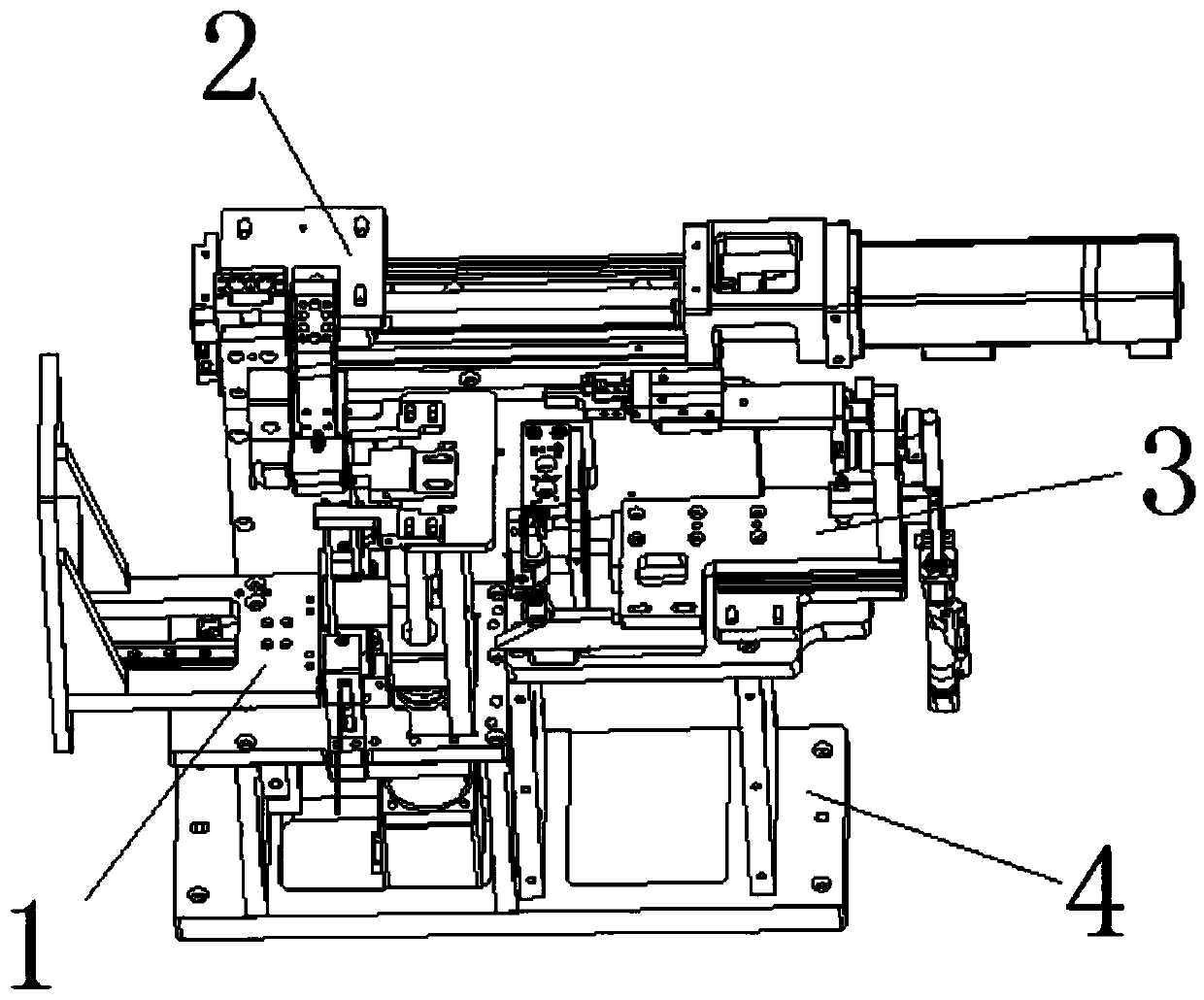

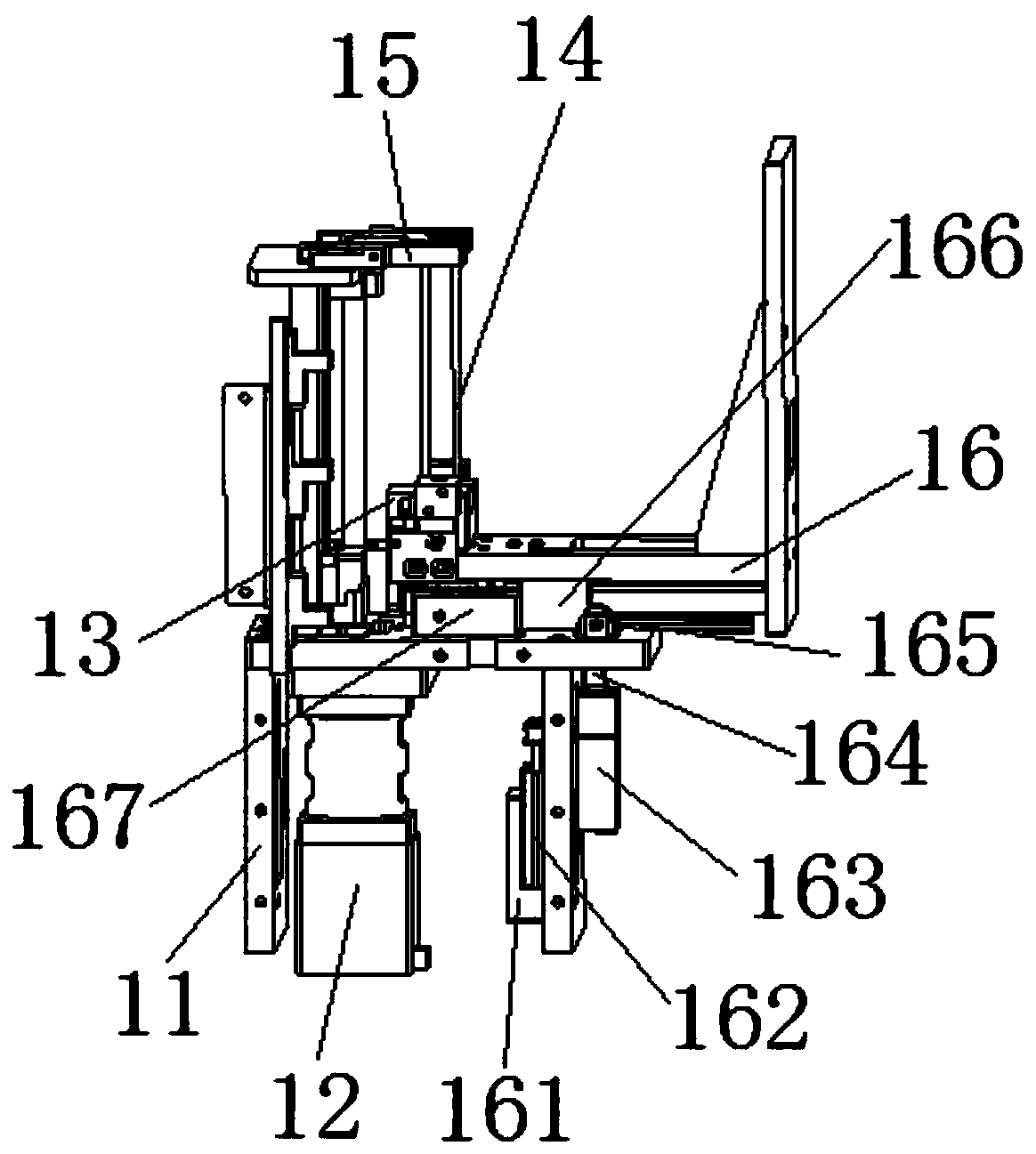

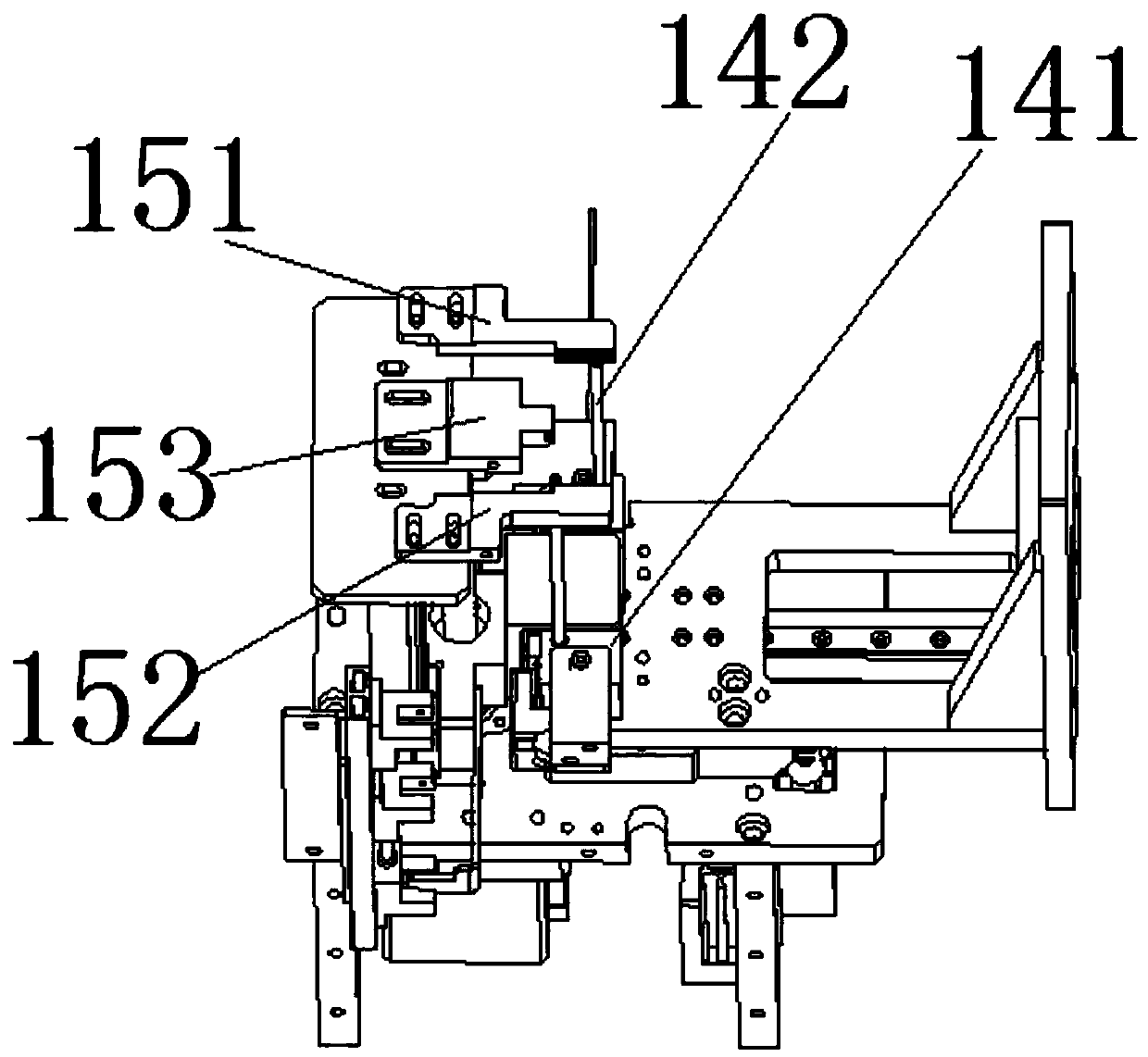

Automatic film tearing device

ActiveCN107187677APrevent product from being taken awayGood tearing effectArticle unpackingElectrical and Electronics engineeringEngineering

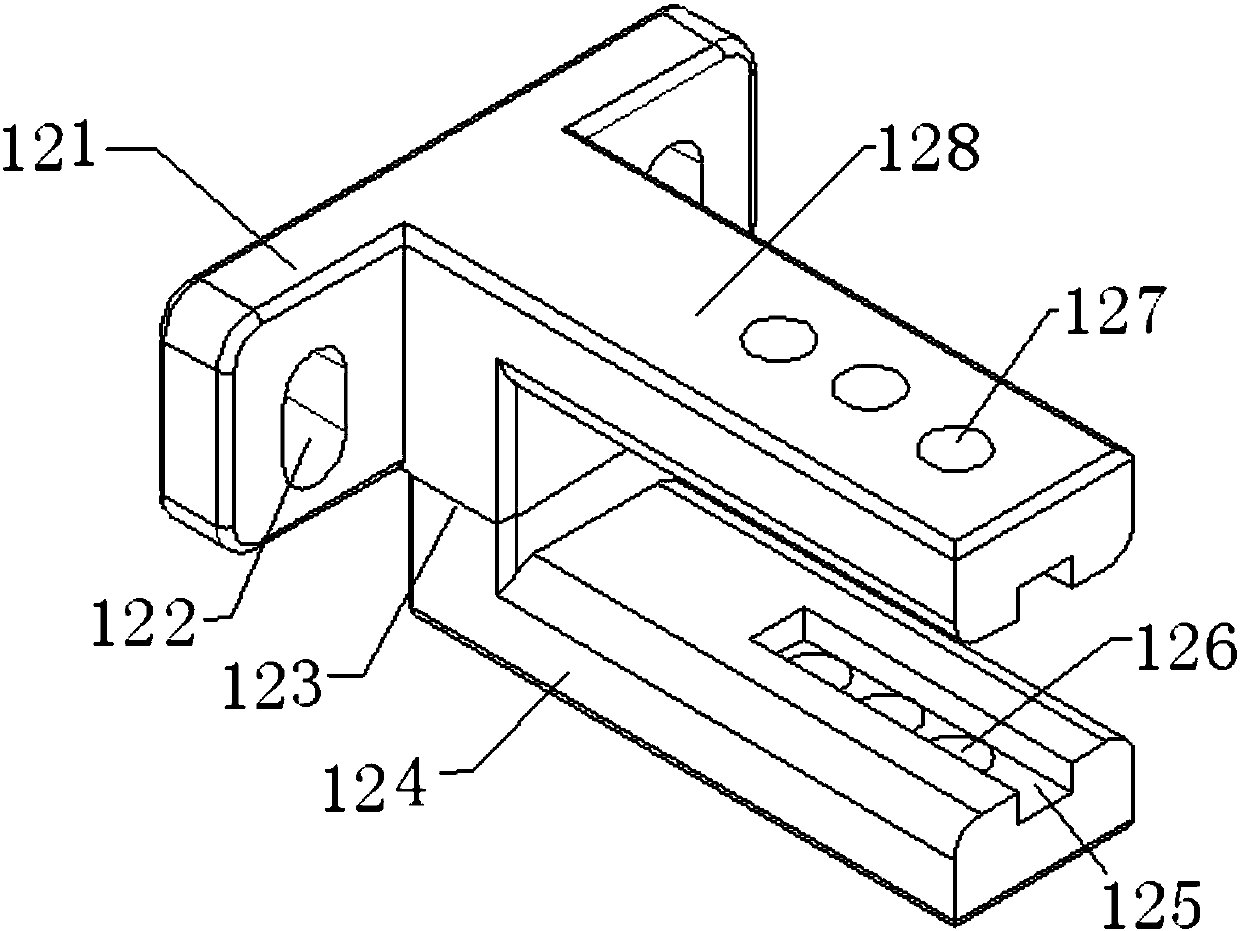

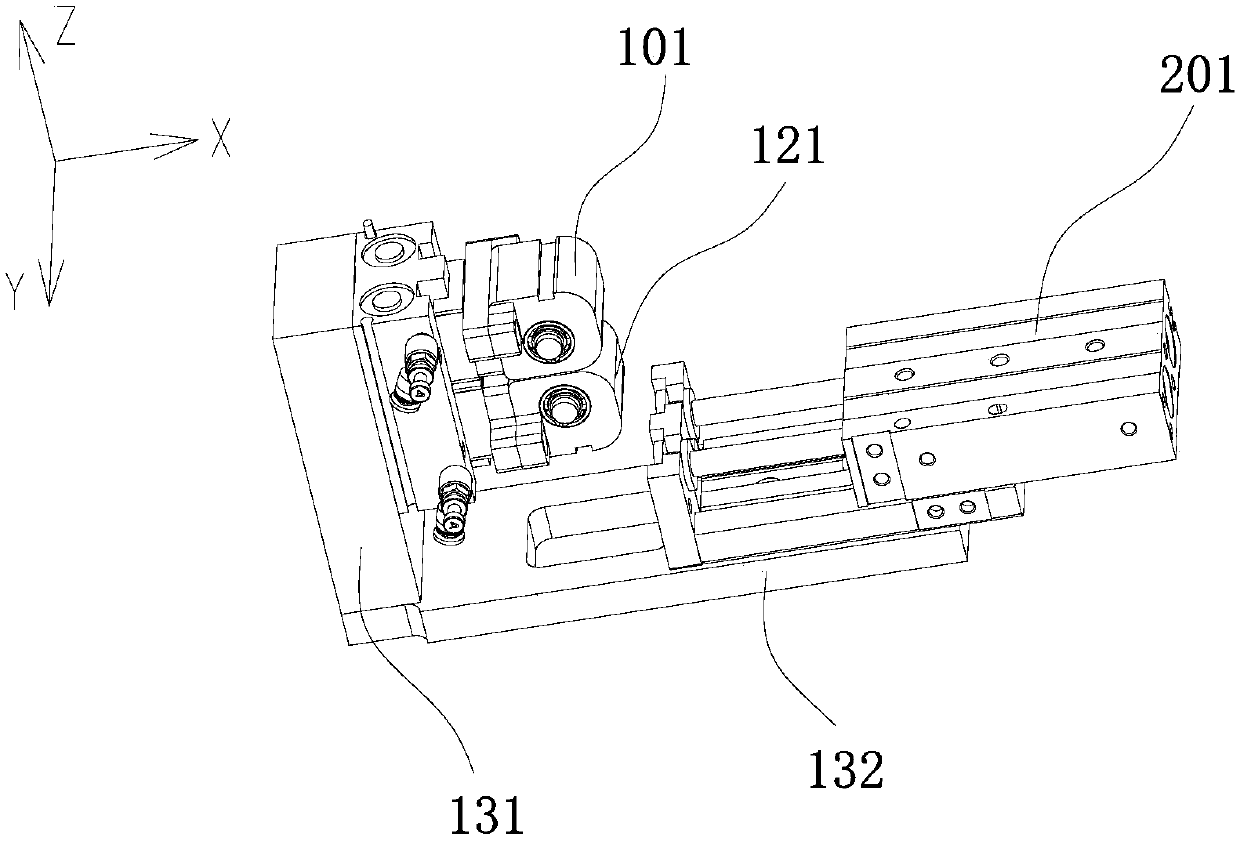

The invention relates to an automatic film tearing device. The automatic film tearing device comprises a third mounting seat, a carrier assembly, a left-right driving assembly and a film tearing assembly, wherein the carrier assembly and the left-right driving assembly are arranged on the third mounting seat, and the film tearing assembly is arranged on the left-right driving assembly and corresponds to the carrier assembly; the film tearing assembly comprises a film-tearing mounting plate, a film-tearing-driving-piece hinged block is arranged on the left side of the film-tearing mounting plate, a film-tearing driving piece is rotatably arranged on the film-tearing-driving-piece hinged block, and a film-tearing-driving-piece connector is connected with the driving end of the film-tearing driving piece; and the film-tearing-driving-piece connector is connected with one end of a rotary arm, the other end of the rotary arm is connected with one end of a rotary shaft, the rotary shaft is arranged on the film-tearing mounting plate in a penetrating mode, the other end of the rotary shaft is connected with a film-tearing swing arm, a film-tearing-clamping-jaw fixing block is arranged on the film-tearing swing arm, and a film-tearing clamping jaw is arranged on the film-tearing-clamping-jaw fixing block. According to the automatic film tearing device, the situation that a product is taken away in the film tearing process can be effectively prevented, and the film tearing effect is good.

Owner:BOZHON PRECISION IND TECH CO LTD

Film tearing device for adhesive tape sticking machine

PendingCN109466966AHigh degree of automationGood tearing effectArticle deliveryReciprocating motionEngineering

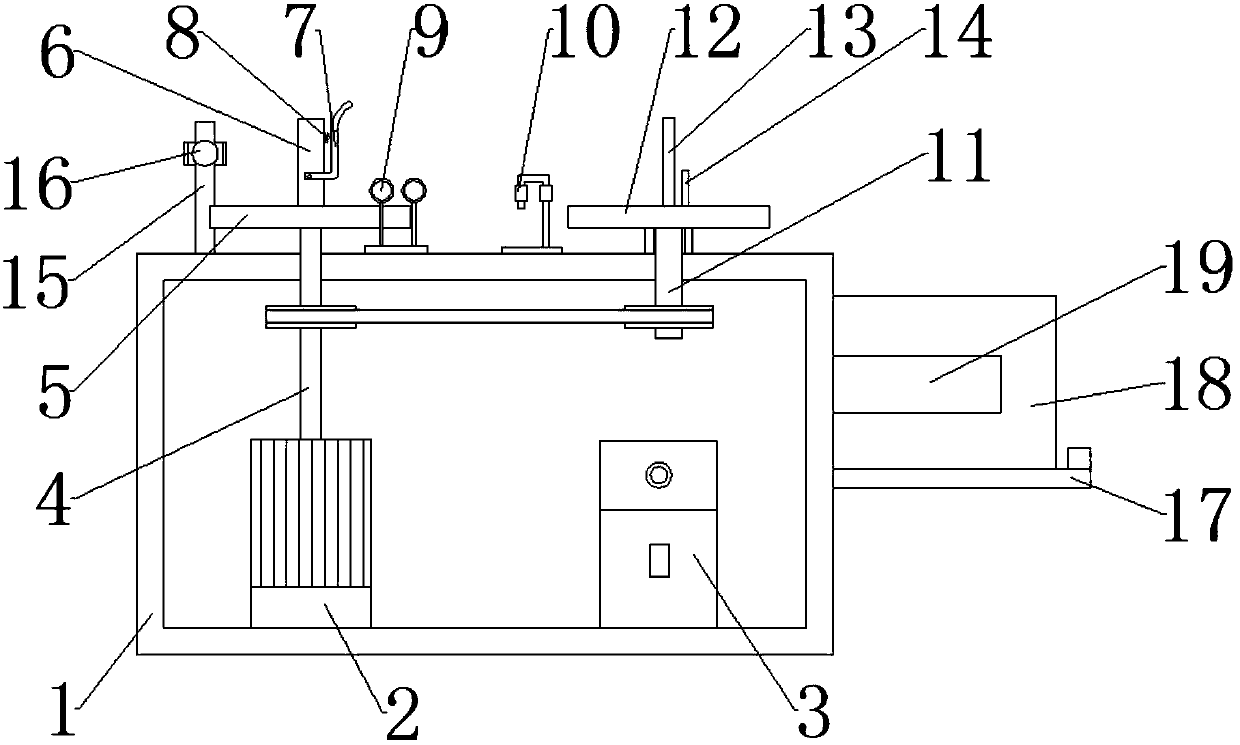

The invention discloses a film tearing device for an adhesive tape sticking machine, and the device comprises a pair of cross beam supports, a cross beam connected between the pair of cross beam supports, a moving plate and a clamping mechanism. An X-axis moving system for driving the moving plate to reciprocate in the horizontal direction is arranged on the cross beam, and a Z-axis moving systemfor driving the clamping mechanism to reciprocate in the Z-axis is arranged on the moving plate. The clamping mechanism comprises a clamping jaw cylinder connected to the Z-axis moving system, a pairof clamping jaws of the jaw cylinder are fixedly connected with mounting rods, and a pair of mutually cooperated first clamping plate and a second clamping plate are respectively fixed on the mountingrod. The jaw cylinder is used for driving the first clamping plates and the second clamping plates to approach each other to clamp the film to be torn off. The film tearing device of the adhesive tape sticking machine has the advantages of high automation degree, good film tearing effect and greatly improved film tearing efficiency.

Owner:SUZHOU JQS INFO TECH CO LTD

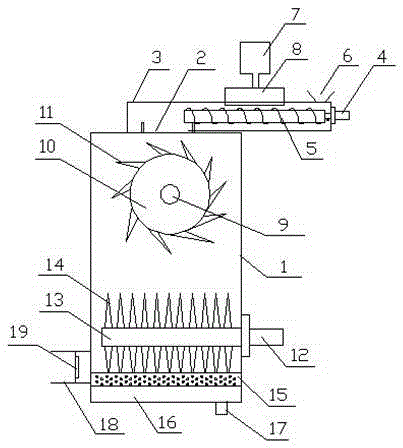

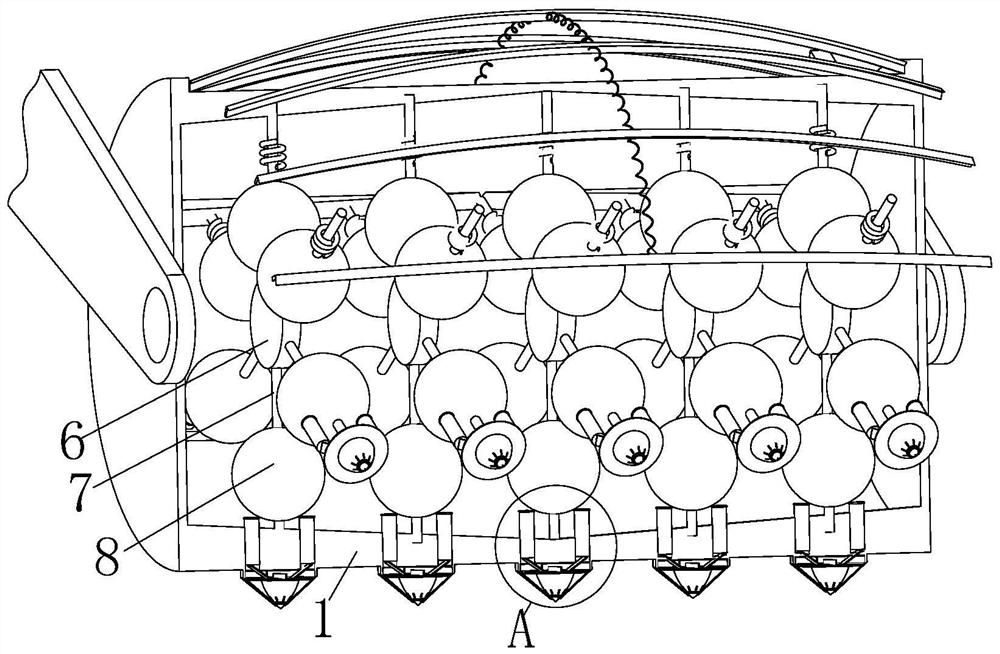

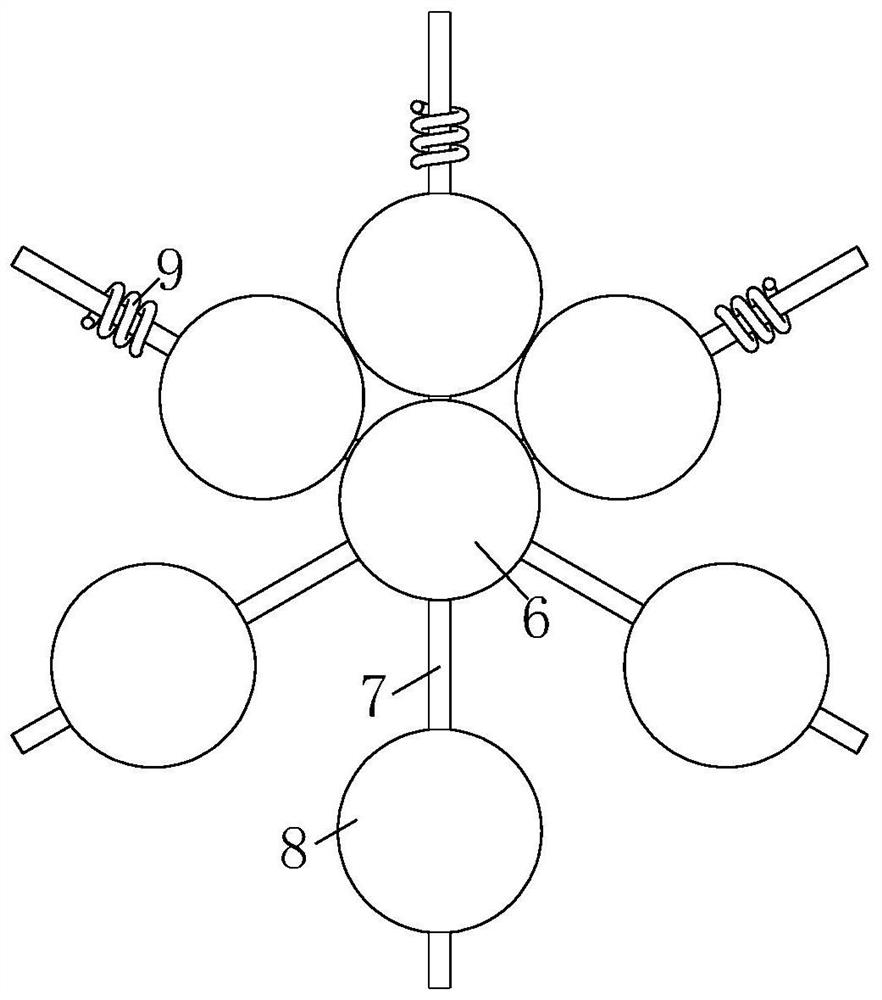

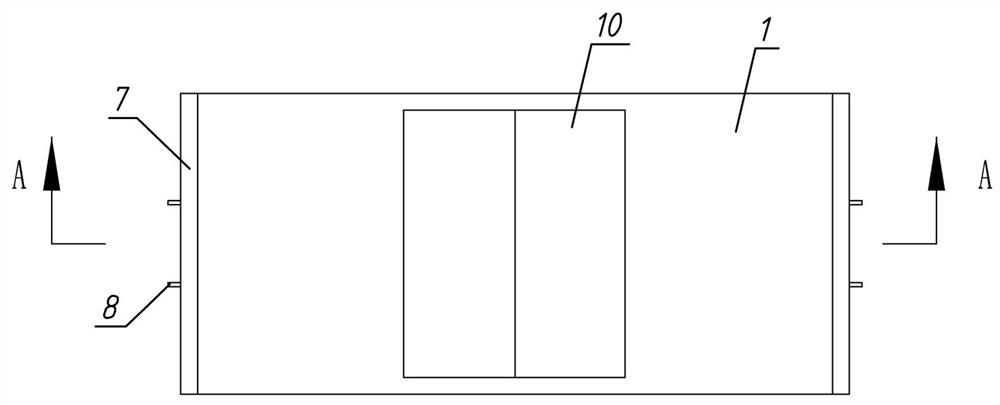

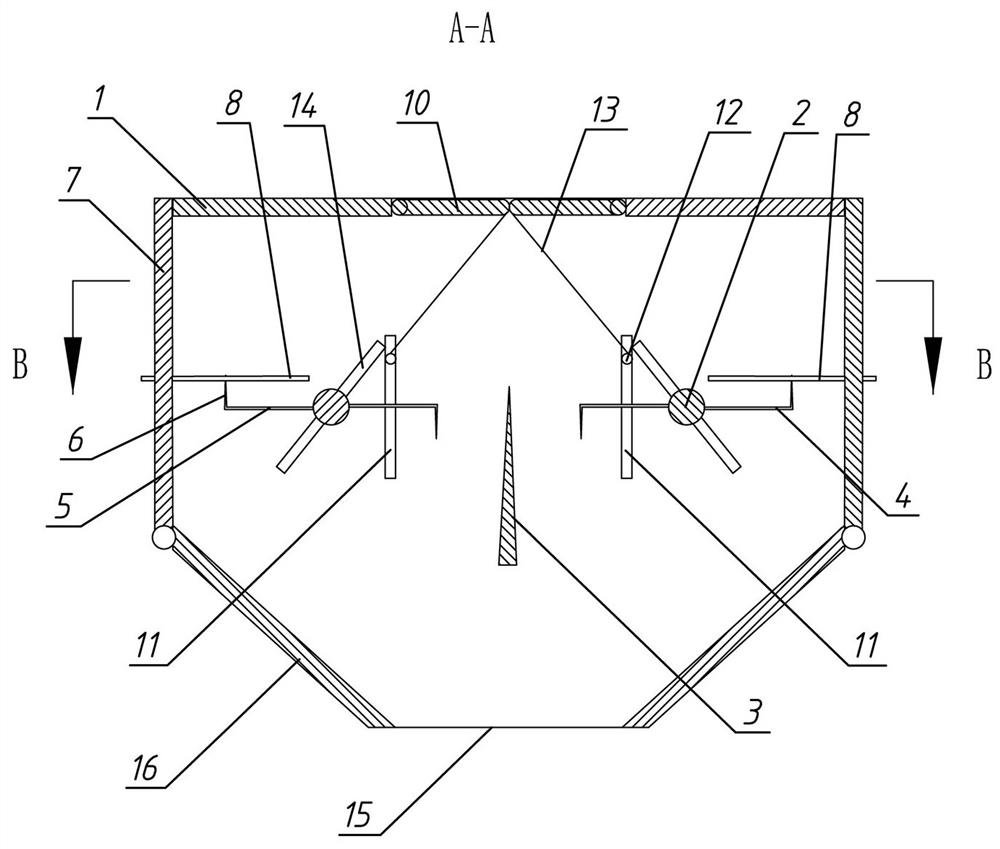

Efficient multi-bin fibrous material tearing machine

ActiveCN105386163AReduce the amount of lumpsIncrease porosityFibre cleaning/opening by toothed membersTextile disintegration and recoveryPulp and paper industryEngineering

The invention discloses an efficient multi-bin fibrous material tearing machine. The machine comprises a box body and an auger conveyer, wherein the interior of the box body is divided into an upper bin and a lower bin, a feeding pipe is arranged on one side of the upper portion of the upper bin, a discharging pipe is arranged on the lower portion of the lower bin, a first cylinder is arranged on the lower portion of the auger conveyer and connected with a baffle, and the upper edge of the baffle is 3-10 mm away from a screw blade; a second cylinder is arranged on the upper portion of the feeding pipe and connected with a fibrous material tearing column, and barbs are arranged on the surface of the fibrous material tearing column; a second motor is arranged on the outer side of the upper bin and connected with a horizontal stirring shaft, and spines are arranged on the horizontal stirring shaft in a stagger mode; fibrous material falling holes are formed in the lower plane of the upper bin, a third motor is arranged at one end of the lower bin and connected with a longitudinal stirring shaft, brads are arranged on the longitudinal stirring shaft in a stagger mode, and a suction fan is arranged in the discharging pipe. According to the machine, multi-bin processing is conducted, materials are torn multiple times in different directions, a product is fluffy, fine and soft, equipment burden is small, service life is long, and production efficiency is high.

Owner:孙习习

High-elasticity rubber composition

The invention discloses a high-elasticity rubber composition which comprises, by weight, 80-85 parts of natural rubber, 20-25 parts of batching rubber, 45-55 parts of fillers, 1-2 parts of accelerators, 1-2 parts of vulcanizing agents, 3-5 parts of zinc oxide, 0.5-1 part of stearic acid, 1-2 parts of anti-aging agents, 4-5 parts of oil and 1-2 parts of paraffin, wherein the batching rubber is mixture of styrene butadiene rubber and butadiene rubber. The rubber composition has high elasticity, high breaking strength and good edge tearing effect, products are stable in size, and white dots and marks cannot be generated when surfaces of the products are scraped by hands.

Owner:ANHUI LIXIN RUBBER TECH CO LTD

High-stability rubber composition and preparation method thereof

The invention relates to the technical field of rubber, in particular to a high-stability rubber composition and a preparation method thereof. According to the invention, the rubber composition is prepared from specific rubber components, fillers and a multifunctional coupling agent, the tensile strength of a vulcanized rubber sheet of the prepared rubber composition is greater than or equal to 35MPa, the elongation at break is greater than or equal to 990%, the 300% stress at definite elongation is greater than or equal to 9MPa, the tearing strength is greater than or equal to 70kN / m, the Akron abrasion volume is less than or equal to 0.2cm<3> / 1.61 km, and the tensile strength reduction rate is less than or equal to 8% and the weight gain rate of the vulcanized rubber sheet is less than or equal to 5% after soaking in 100 DEG C oil for 72 hours. The rubber composition prepared by the invention has high stability and high elasticity, maintains good physical and mechanical properties, also has high wear resistance and hot oil aging resistance, high breaking strength, good edge tearing effect and stable product size, and has a wide application prospect.

Owner:AGRI PRODS PROCESSING RES INST CHINESE ACAD OF TROPICAL AGRI SCI

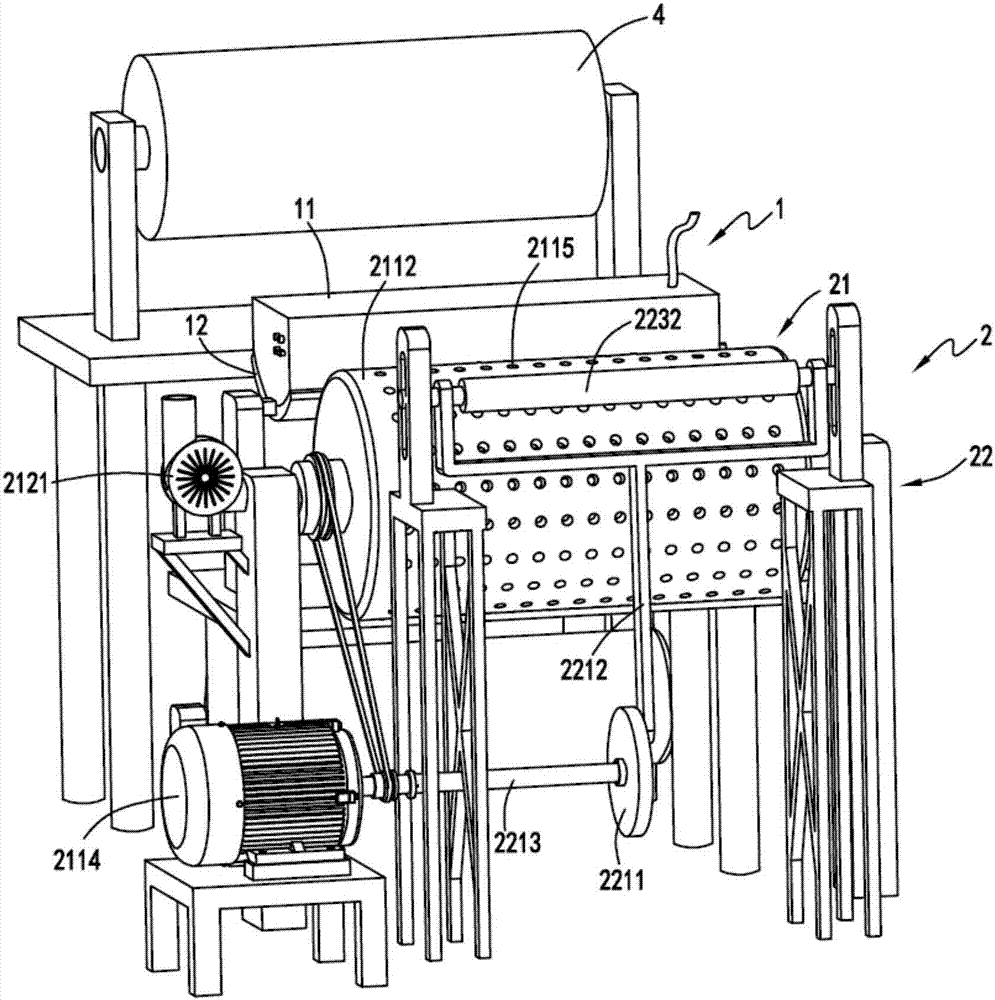

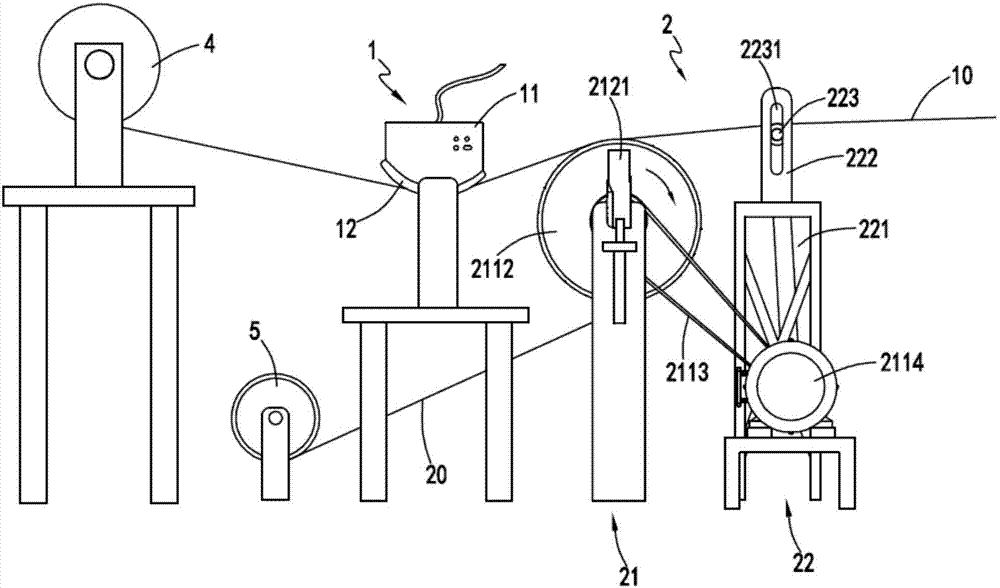

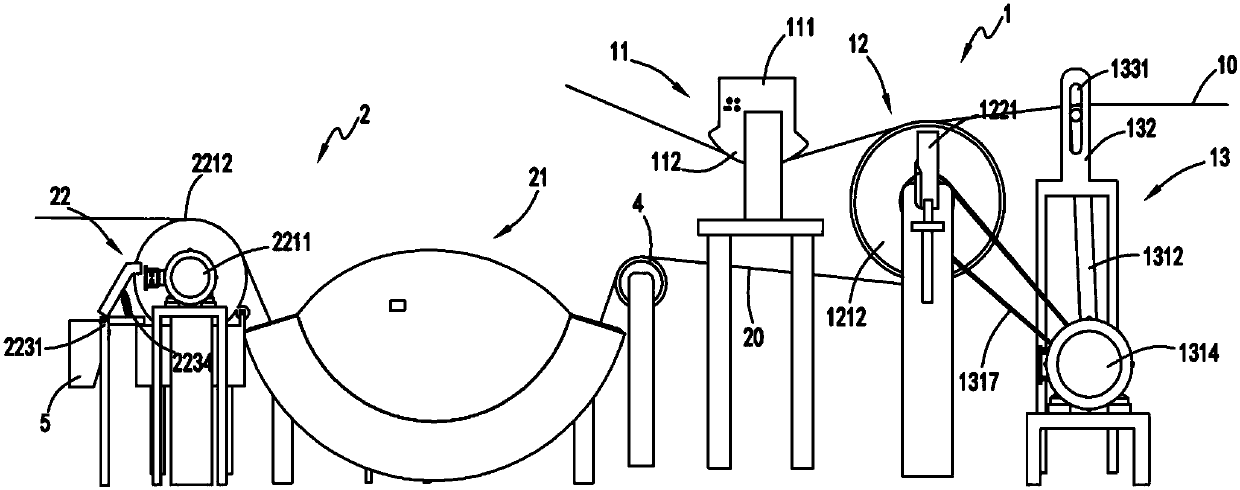

Energy-saving processing equipment used in early-stage production of non-woven cloth

ActiveCN107160822AAvoid damageContinuous and efficient film tearing processLamination ancillary operationsLaminationHigh probabilityEngineering

The invention relates to energy-saving processing equipment used in early-stage production of non-woven cloth. The energy-saving processing equipment comprises a heating part and a cloth and membrane separation part, wherein the heating part is used for heating membrane-carrying cloth to soften glue between the cloth and an isolating membrane; and the cloth and membrane separation part is arranged at the rear end of the heating part and used for separating the cloth from the isolating membrane of the cloth of which the glue is softened, and comprises a membrane adsorption mechanism for adsorbing the membrane and driving the isolating membrane to rotate together to change the transmission direction and a cloth pulling mechanism used for pulling the cloth in the direction opposite to the transmission direction of the isolating membrane. The problems that the single-cloth membrane stripping efficiency of the non-woven cloth is low and the cloth and the membrane have high probability of being damaged due to unstable membrane stripping are solved.

Owner:湖州蓝澳无纬布有限公司

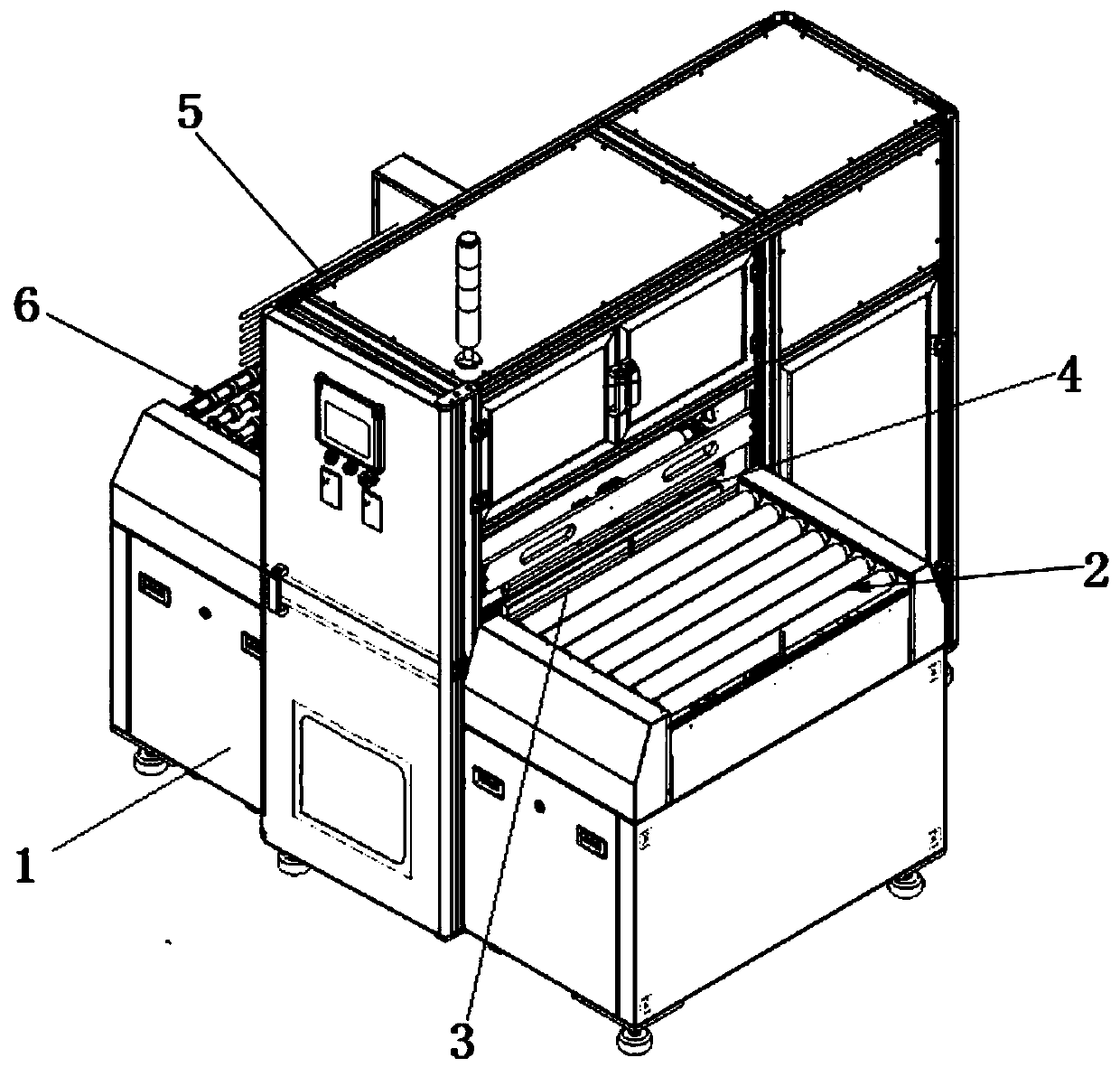

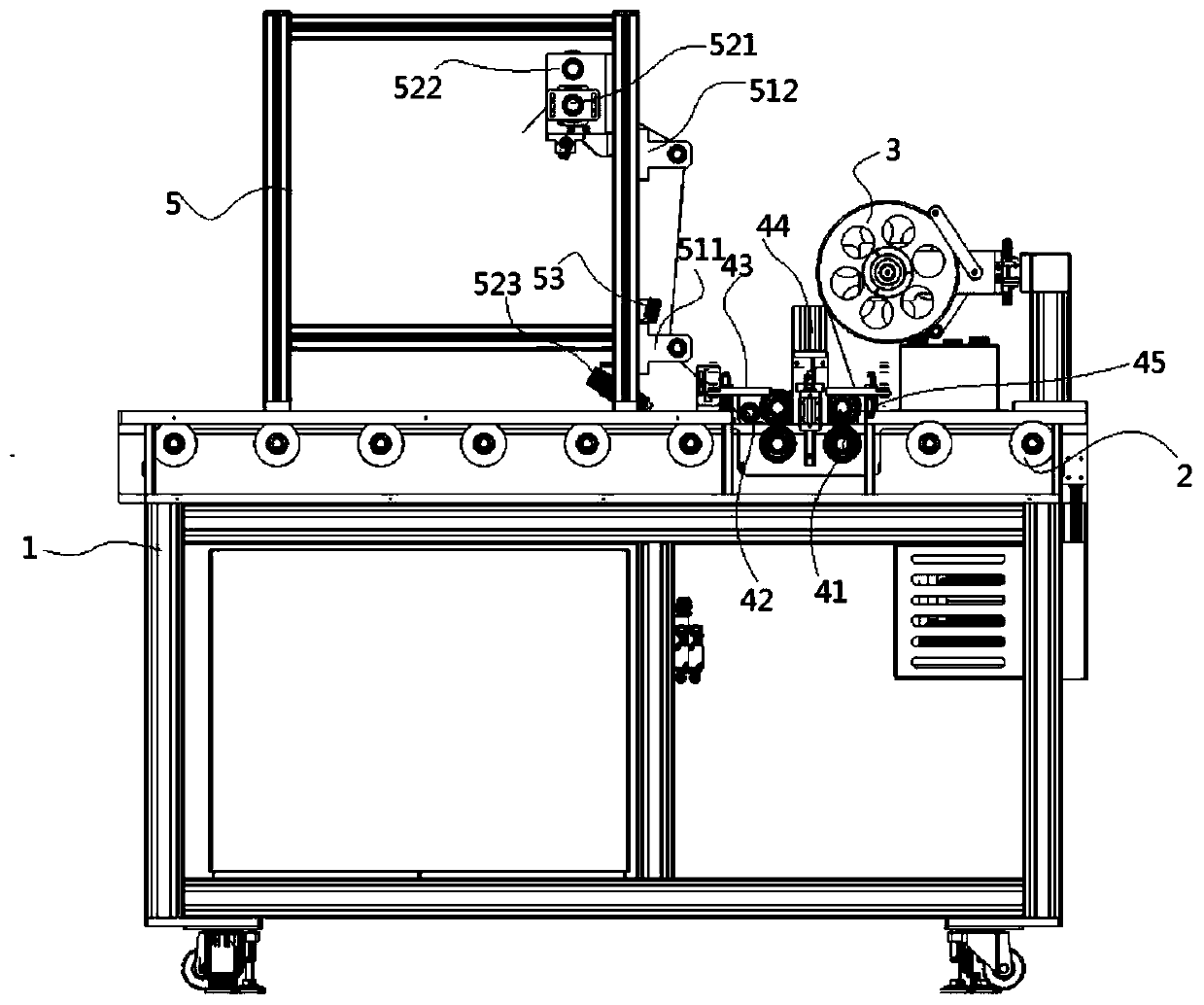

Full-automatic film stripping machine

The invention discloses a full-automatic film stripping machine. The full-automatic film stripping machine comprises a rack and a feeding conveying mechanism, a pressing plate mechanism, a film lifting mechanism, a film stripping conveying mechanism, a film stripping mechanism, a film stripping abnormity lifting mechanism and a discharging conveying mechanism which are arranged on the rack; the feeding conveying mechanism is used for conveying a PCB to the pressing plate mechanism; the pressing plate mechanism is used for pressing the PCB conveyed by the feeding conveying mechanism; the film lifting mechanism is used for carrying out the friction and blowing on the edge of a protection film of the PCB clamped by the pressing plate mechanism, so that the edge of the protection film is lifted; the film stripping conveying mechanism is used for conveying the PCB from the film lifting mechanism to the film stripping mechanism; the film stripping mechanism is used for separating the protection film from the PCB; the film stripping abnormity lifting mechanism is used for detecting whether the PCB after the film stripping is left with the protection film and lifting the PCB with the protection film residual upwards; and the discharging conveying mechanism is used for conveying the PCB without the protection film residual. According to the full-automatic film stripping machine, pluralities of mechanisms are arranged to match with one another, so that the film stripping efficiency of the PCB is improved easily.

Owner:中山市宏唯自动化科技有限公司

High-elasticity rubber and preparation process thereof

Owner:ANHUI LIXIN RUBBER TECH CO LTD

Automatic charging and dyestripping mechanism

ActiveCN107264902ASmooth connectionImprove tearing efficiencyArticle unpackingEngineeringElectrical and Electronics engineering

Owner:BOZHON PRECISION IND TECH CO LTD

Automatic cement bag unpacking device

ActiveCN112193555AGood tearing effectHigh speedBags openingUnpacking by cuttingBilateral symmetryKnife blades

The invention relates to an automatic cement bag unpacking device which effectively solves the problems that cement is prone to remaining in a packing bag, and the packing bag cannot be automaticallyarranged. According to the technical scheme, the automatic cement bag unpacking device comprises a shell, two rotating shafts are inserted into the shell, and the two rotating shafts can synchronouslyand reversely rotate; a blade is arranged between the two rotating shafts, L-shaped rods are arranged on the rotating shafts, each L-shaped rod is composed of a long rod and a short rod, and when thetwo rotating shafts synchronously rotate towards the middle, the short rods on the L-shaped rods can be inserted into the packaging bag; first door plates with the lower ends hinged to the shell arearranged at the left side and the right side of the shell, the two first door plates can rotate outwards respectively, movable rods are inserted into the first door plates, and the movable rods on thetwo first door plates are in bilateral symmetry and can move leftwards and rightwards; and the two movable rods are arranged between the front L-shaped rod and the rear L-shaped rod and are arrangedabove the rotating shafts. The automatic cement bag unpacking device solves the problems that the cement is prone to remaining in the packaging bag and the packaging bag cannot be automatically arranged, the cement in the packaging bag can be completely poured out without residues, and the packaging bag can be collected and arranged.

Owner:益阳宏业建筑劳务有限公司

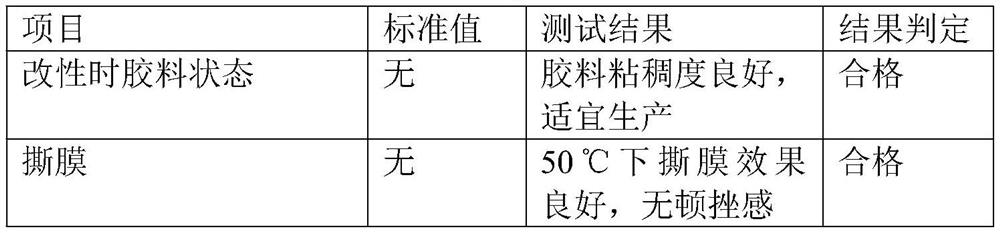

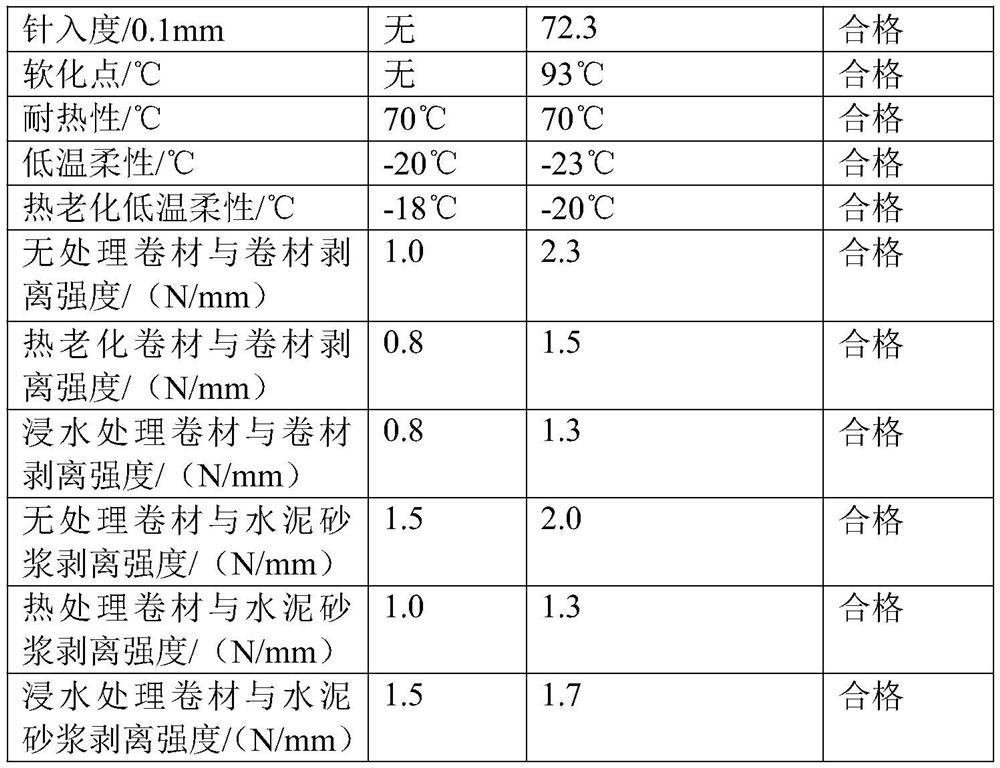

Application of stabilizer for improving film tearing performance of tire-free waterproof coiled material

ActiveCN113604064AImprove cohesionReduce penetrationBuilding insulationsPhysical chemistryEngineering

The invention provides application of a stabilizer for improving the film tearing performance of a tire-free waterproof coiled material, the stabilizer is dissolved in an oil product to form a stabilizer solution, and the mass ratio of the stabilizer to the oil product is 1: (3-5); the stabilizer solution is placed in an independent tank body and is slowly injected when an asphalt sizing material of the tire-free waterproof roll is prepared, and the dosage of the stabilizer is 0.05-0.10% of the total weight of the asphalt sizing material. The adding mode and the adding amount of the stabilizer are optimized, firstly, the stabilizer is pre-dissolved with an oil product, the stabilizer is uniformly dispersed in the oil product to obtain the stabilizer solution, and then the stabilizer solution is slowly injected when the asphalt sizing material of the tire-free waterproof coiled material is prepared. By adding the stabilizer, the cohesion of the modified asphalt sizing material is improved, the penetration of the asphalt sizing material is reduced, the cohesion degree of the asphalt sizing material is improved, the film tearing effect of the tire-free coiled material at high temperature is improved, and the construction applicability is solved.

Owner:苏州卓宝科技有限公司 +1

Self-adaptive bag-connective commodity tearing-off system

The invention discloses a self-adaptive bag-connective commodity tearing-off system. The system comprises a first tooth type belt wheel, a second tooth type belt wheel and a tooth type belt driven bythe first tooth type belt wheel and the second tooth type belt wheel, wherein a second conveying wheel and a first tearing wheel are arranged above the belt; the second conveying wheel and the first tearing wheel are sequentially arranged in the conveying direction of the belt; the position, below the second conveying wheel, of the belt is provided with a first conveying wheel under the belt; theposition, below the first tearing wheel, of the belt is provided with a second tearing wheel under the belt; the speed of a conveying wheel set is smaller than the speed of a tearing wheel set; the starting end of the conveying wheel set is provided with a detection sensor; a counting sensor is arranged at the tail end of the tearing wheel set; gaps are formed between the first tearing wheel and the belt and between the second conveying wheel and the belt; and pressure regulators are arranged on a transmission motor support and a tearing motor support. According to the self-adaptive bag-connective commodity tearing-off system, the conveying wheel set conveys a medicine bag to the tearing wheel set, due to the fact that the speed of the tearing wheel set is larger than the speed of the conveying wheel set, the bag is torn off at a tearing line, thus the cutting is accurate, and the phenomenon of breakage of the medicine bag is avoided; medicine amount is controlled accurately by the counting sensor; and the additionally arranged pressure regulators can automatically adjust the height and pressure between the wheels and the conveying belt according to the thickness of the medicine bag, thus the tearing effect is improved and it is guaranteed that the medicine bag is not broken or clamped.

Owner:天津市润比特斯科技有限公司

Film-tearing equipment based on knurling film-removing mechanism and working method thereof

The invention discloses film-tearing equipment based on a knurling film-removing mechanism and a working method thereof. By using glue paper and using the broken surface of a release film in a knurling film-removing area, the adhesive area of the adhesive paper is increased, the adhesion force to the release film is improved, and the film-tearing effect is good. The film-tearing equipment based onthe knurling film-removing mechanism includes a roller film-removing device and a propulsion device, and the roller film-removing device is installed on the propulsion device, the roller film-removing device is provided with a set of knurl wheels, and the set of the knurl wheels rolls over the release film during forward movement of the propulsion device in the X-axis direction; the roller film-removing device is installed at the movable end of a third power device, the fixed end of the third power device is installed at the movable end of the propulsion device, the fixed end of the propulsion device is installed on a shaping base, and a shaping platform is further arranged on the shaping base; and the shaping base and the film-tearing device are installed on a machine frame, the film-tearing device is provided with a power device moving up and down in the Z-axis direction, and adhesive paper is arranged at the moving end of the power device. The invention relates to the technical field of the film tearing of flexible printed circuit.

Owner:珠海研深科技有限公司

Flexible OLED display screen terminal area automatic ejector-pin film-tearing device

PendingCN110303756AUnique designNovel structureLamination ancillary operationsLaminationInverted-T shapeEngineering

The invention relates to a flexible OLED display screen terminal area automatic ejector-pin film-tearing device. An X-Y-Z axis movement module is mounted on a vertical plate, an ejector-pin film-tearing unit is mounted on the X-Y-Z axis movement module and comprises a first connecting part, an ejector-pin, an air cylinder and a pneumatic clamping claw, a linear movement unit is mounted on the first connecting part, a second connecting part is fixed to the linear movement unit, the ejector-pin is mounted on the second connecting part, the ejector-pin can downwards press along with movement of the X-Y-Z axis movement module, and the ejector-pin pokes up a film on the surface of a display screen to form an inverted-T shape; an electric linear transmission device is fixed to the first connecting part, a third connecting part is arranged on a Y axial sliding rail, and the electric linear transmission device is in driving connection with the third connecting part and drives the third connecting part to move in the Y axial direction in a front-rear linear mode; and the air cylinder is vertically mounted on the third connecting part, the pneumatic clamping claw is mounted on the air cylinder, and the pneumatic clamping claw clamps the protruding film and tears off the remaining film on the display screen. Through full-automatic film-tearing operation with downward-pressing of the ejector-pin and pneumatic film clamping, the efficiency is high.

Owner:SUZHOU DELPHI LASER

Pothole road deicing device for

InactiveCN113605298ASo crackedGood tearing effectSnow cleaningEnvironmental geologyStructural engineering

Owner:王芳秀

Manufacturing method of adhesive type photo album inside pages

InactiveCN107962888AThe preparation method is reasonableImprove product qualityAlbumsSurface layerRolling paper

The invention relates to a manufacturing method of adhesive type photo album inside pages. The manufacturing method comprises the following steps: feeding roll paper; printing a color (dyeing); dryingfor the first time; coating non-setting adhesive glue; pressing to form non-setting adhesive glue cross grains and glue lines; drying for the second time; cutting an engagement region; coating a BOPPprotective film; coating an edge strip; and drilling binder holes. The manufacturing method of the adhesive type photo album inside pages provided by the invention is reasonable and realizes more stable product quality; pictures or photos can be stored for a longer time; the BOPP protective film is good in film stripping effect; the surface layer of the paper is prevented from being torn into pieces; namely the main body of each adhesive type photo album inside page is prevented from being torn into pieces.

Owner:惠州华丰纸品有限公司

Full-automatic water-proof zipper film tearing machine

The invention discloses a full-automatic water-proof zipper film tearing machine, and belongs to the technical field of film tearing machines. The full-automatic water-proof zipper film tearing machine comprises a machine body, a motor and a speed regulator with shiftable gears are fixedly installed in an inner cavity of the machine body, a first rotating shaft and a second rotating shaft are connected with the top of the machine body in a movable and inserted mode, a paper pulling disk is arranged at the top of the first rotating shaft, a paper pulling rod is arranged on the axis of the top of the paper pulling disk, both the first rotating shaft and the second rotating shaft are sleeved with rotating wheels, the rotating wheels are connected through a belt, a separation disk is fixedly arranged on the top of the machine body, a rough separation rod is arranged at the top of the second rotating shaft, and a fine separation rod is arranged on the top of the separation disk. The full-automatic water-proof zipper film tearing machine facilitates film tearing operation, so that human input is reduced, and the film tearing effect is good; speed regulation is conducted, so that the phenomenon of bent corners is reduced; when the paper pulling disk is full, an infrared sensor module conducts sensing, so that halting is convenient, excessive winding is reduced, a zipper film-paper isconvenient to pull out, and the water-proof performance of the whole machine is good.

Owner:江苏大棕科技有限公司

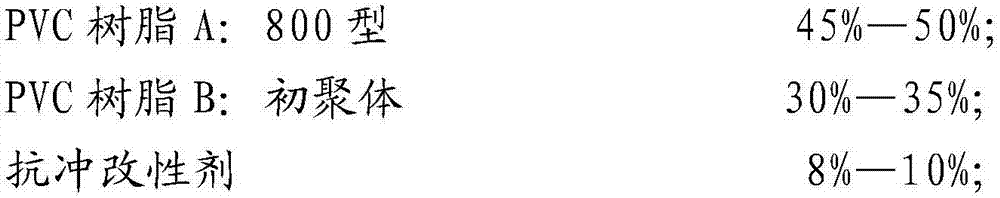

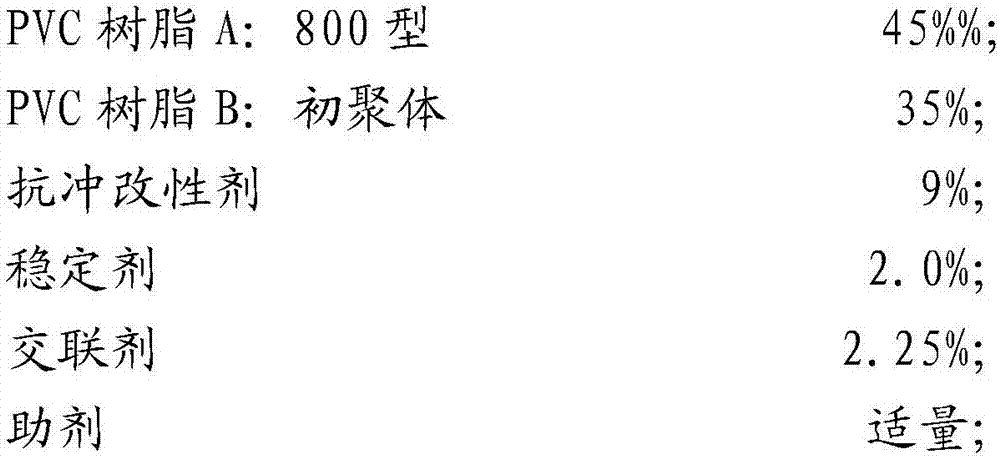

Rolling easy-to-tear hard PVC transparent film

The invention discloses a rolling easy-to-tear hard PVC transparent film. The composition formula comprises 45%-50% of PVC resin A; 30%-35% of PVC resin B; 8%-10% of impact resistance modifier; 1.8%-2.2% of stabilizer; 2.0%-2.5% of crosslinking agent; and an appropriate amount of auxiliary agent; the film production process comprises the steps of burdening, mixing, melting plastifying, mixed refining, distributing, transient high temperature rolling and forming, cooling and shaping, and finished product sheet processing process; the transient high temperature rolling and forming uses a six roll calenders, the rubber material is compressed and formed by the front four roll calenders under the temperature of 110 DEG C-130 DEG C; the temperatures of the later two roll calenders are set as 210 DEG C or above, which creates the high temperature changes of gradient, and the sheets are instantly finished and formed. The optimized composition formula guarantees the softness of the PVC hard film, the transient high temperature sheet rolling process is adopted, the transparency of the film is enhanced; so that the film satisfies the tear-line opening requirement, and the phenomena of mistake tearing, side tearing, torn edges, thorn edges are prevented in the tear-line use process.

Owner:昆山奥瑞航空包装材料有限公司

Self-adhesive anti-corrosion resin bitumen waterproof roll material and preparation method thereof

InactiveCN101979782BHigh bonding strengthImprove toughnessArtificial islandsProtective foundationUltravioletDolomite

The invention relates to a self-adhesive anti-corrosion resin bitumen waterproof roll material and a preparation method thereof. The self-adhesive anti-corrosion resin bitumen waterproof roll material comprises base material cloth, an oil immersion coating layer, an insulating layer and a membrane laminating layer, wherein the oil immersion coating layer comprises the following materials in part by weight: 80 to 120 parts of bitumen, 20 to 30 parts of styrene-butadiene-styrene (SBS) binder, 3 to 7 parts of ethylene / vinyl acetate (EVA) resin, 8 to 12 parts of polypropylene resin, 2 to 5 parts of polytetrafluoroethylene resin, 20 to 40 parts of petroleum resin, 3 to 8 parts of liquid coumarone resin, 6 to 12 parts of mica powder, 8 to 15 parts of dolomite powder, 5 to 10 parts of attapulgite, 10 to 15 parts of nanometer calcium oxide, 1 to 5 parts of ultraviolet absorber UV-9 and 1 to 5 parts of anti-aging agent 4010 Na. The anti-corrosion performance, high and low-temperature resistance and anti-aging performance of the self-adhesive anti-corrosion resin bitumen waterproof roll material are superior to those of the ordinary waterproof roll material, and the self-adhesive anti-corrosion resin bitumen waterproof roll material is mainly used for buildings such as undergrounds, tunnels, bridges, subways, planted roofs and the like which have higher waterproof requirements.

Owner:北京立高科技股份有限公司 +1

An automatic film tearing device

ActiveCN107187677BPrevent taking awayGood tearing effectArticle unpackingEngineeringMechanical engineering

Owner:BOZHON PRECISION IND TECH CO LTD

An automatic unpacking device for cement bags

ActiveCN112193555BGood tearing effectHigh speedBags openingUnpacking by cuttingStructural engineeringKnife blades

The invention relates to an automatic unpacking device for cement bags, which effectively solves the problem that cement is easy to remain in the packaging bag and the packaging bag cannot be automatically sorted; The rotating shafts can rotate in opposite directions synchronously; there is a blade in the middle of the two rotating shafts, and there is an L-shaped rod on the rotating shaft. The L-shaped rod is composed of a long rod and a short rod. On the bag; the left and right sides of the casing are the first door panels whose lower ends are hinged on the casing, the two first door panels can rotate outward respectively, and the first door panels are inserted with movable rods, and the movable rods on the two first door panels are symmetrical And can move left and right; two movable rods are placed between the front and rear L-shaped rods, and placed above the rotating shaft; the invention solves the problem that cement is easy to remain in the packaging bag and the packaging bag cannot be automatically arranged, and the cement in the bag is completely Pour out clean without residue, and can collect and organize the packaging bags.

Owner:益阳宏业建筑劳务有限公司

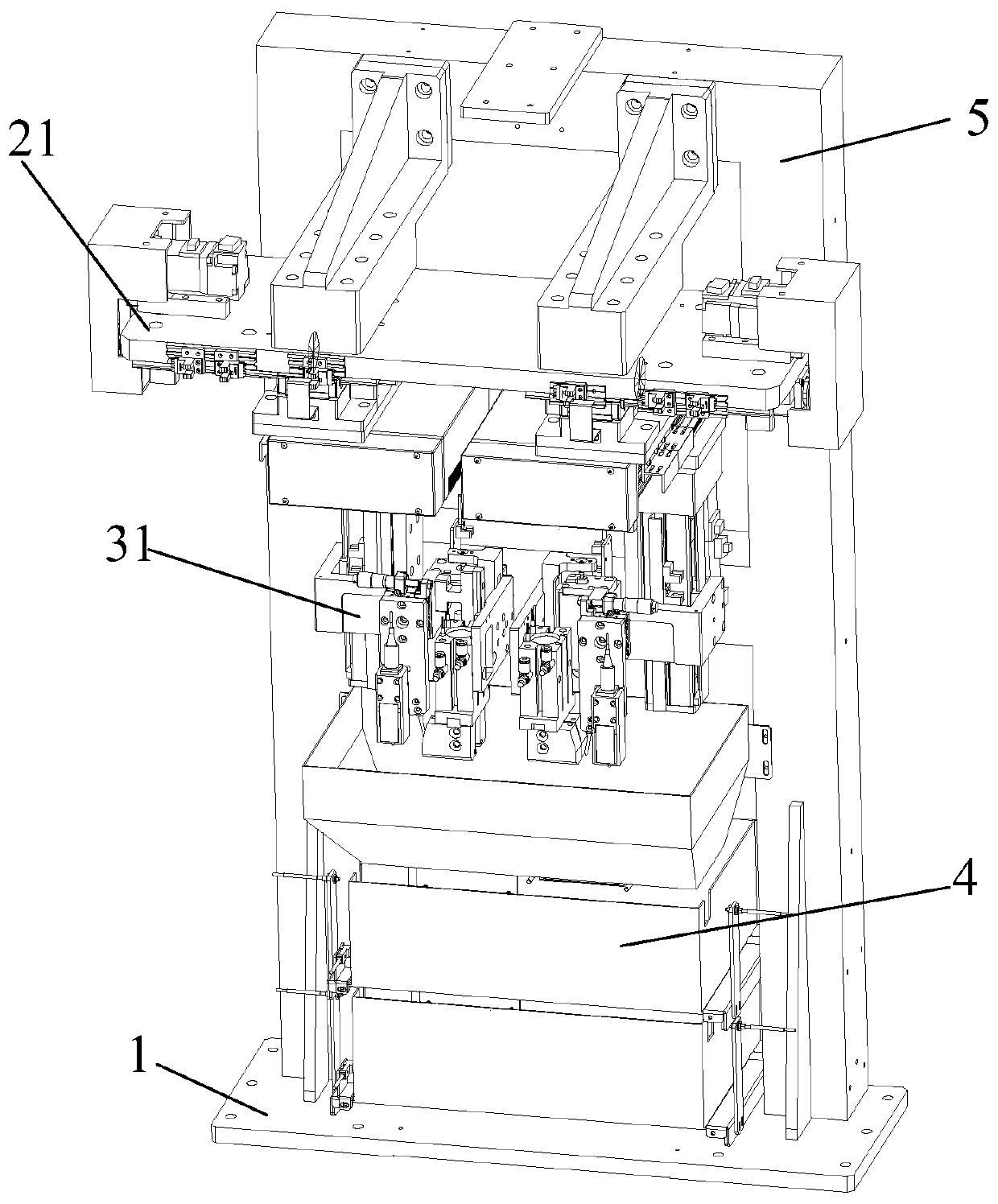

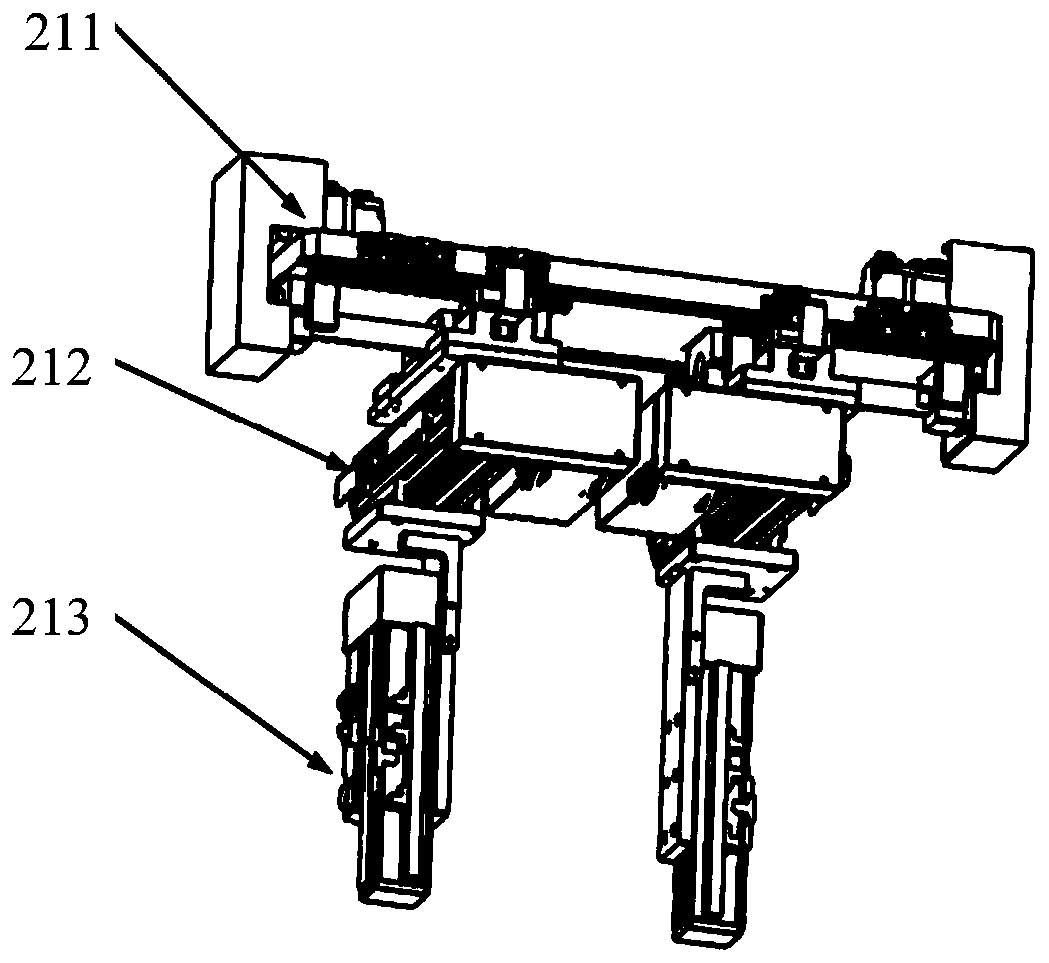

An automatic feeding film tearing mechanism

Owner:BOZHON PRECISION IND TECH CO LTD

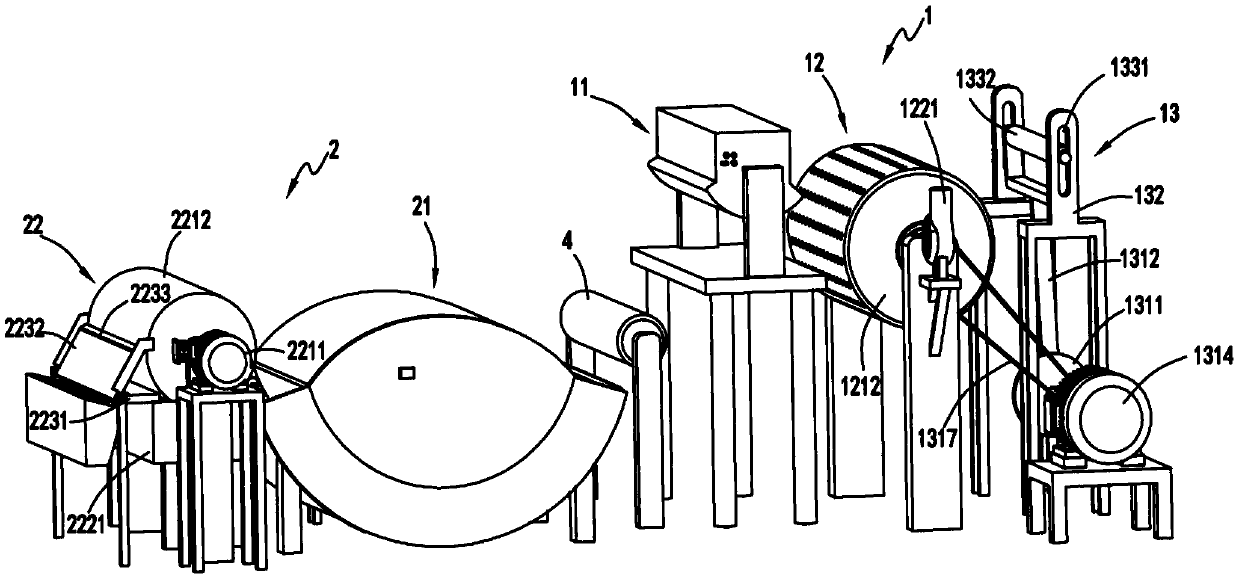

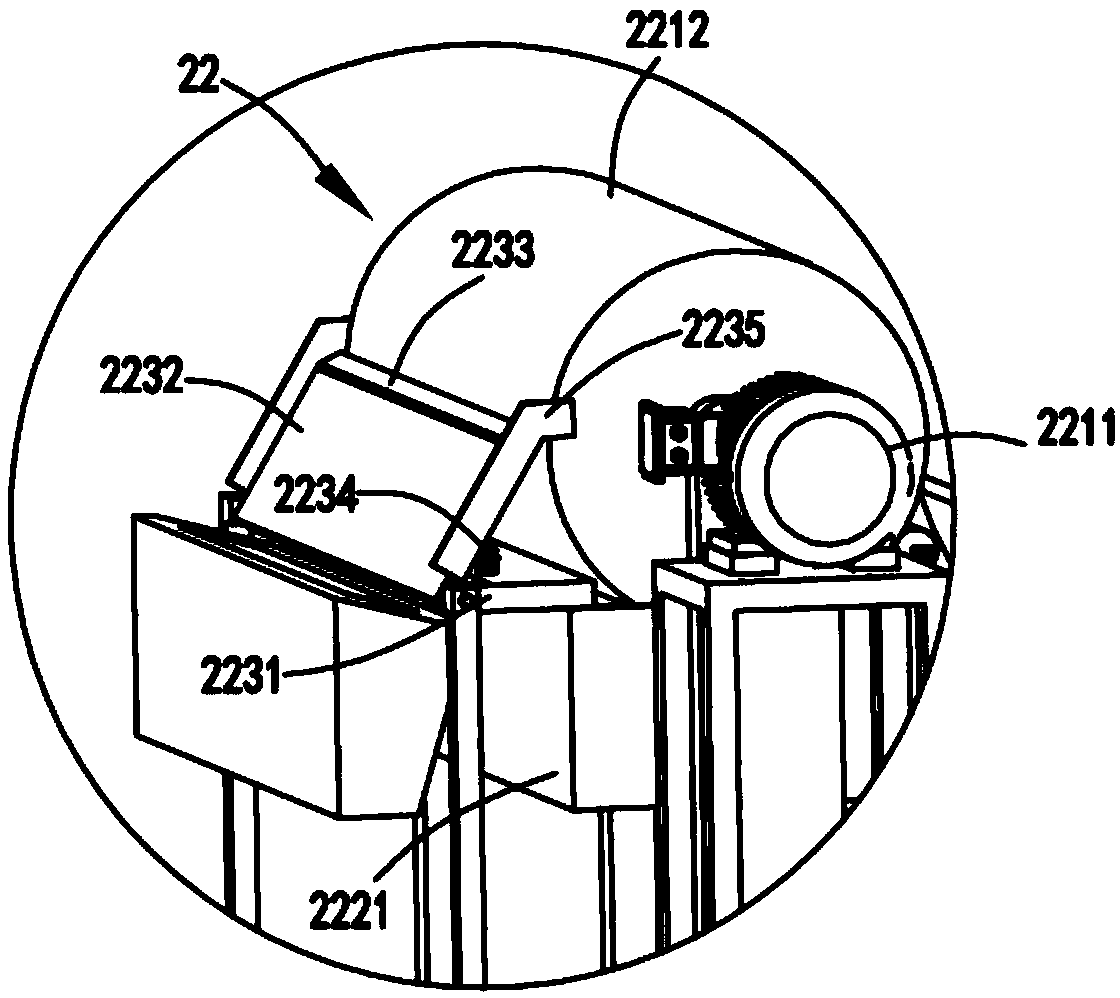

A high-efficiency processing equipment for unidirectional fabric isolation film for non-weft fabric production

ActiveCN107186919BAvoid problems that cannot be exploited againIncrease profitLamination ancillary operationsPlastic recyclingEngineeringMechanical engineering

The invention relates to an efficient processing device for a one-way cloth isolation film for production of weft-free cloth. The efficient processing device comprises a cloth film separating part and a glue removing part; the cloth film separating part is used for performing cloth and film separation on cloth with a film, the cloth film separating part comprises a heating mechanism for heating the cloth with a film to soften glue, a film separating mechanism for adsorbing the film and driving the film to rotate therewith to change a conveying direction and a cloth separating mechanism for pulling the cloth along a direction opposite to the conveying direction of the film; the glue removing part is arranged on the rear end of the cloth film separating part and used for removing residual glue on the film, and the glue removing part comprises a glue softening mechanism for heating the film to soften the glue on the surface and a glue removing mechanism for removing the softened glue from the film. The efficient processing device overcomes the problem that the film cannot be reused caused by a fact that the film is torn off by manual film tearing and the glue residual on the film after the film tearing cannot be cleaned.

Owner:湖州蓝澳无纬布有限公司

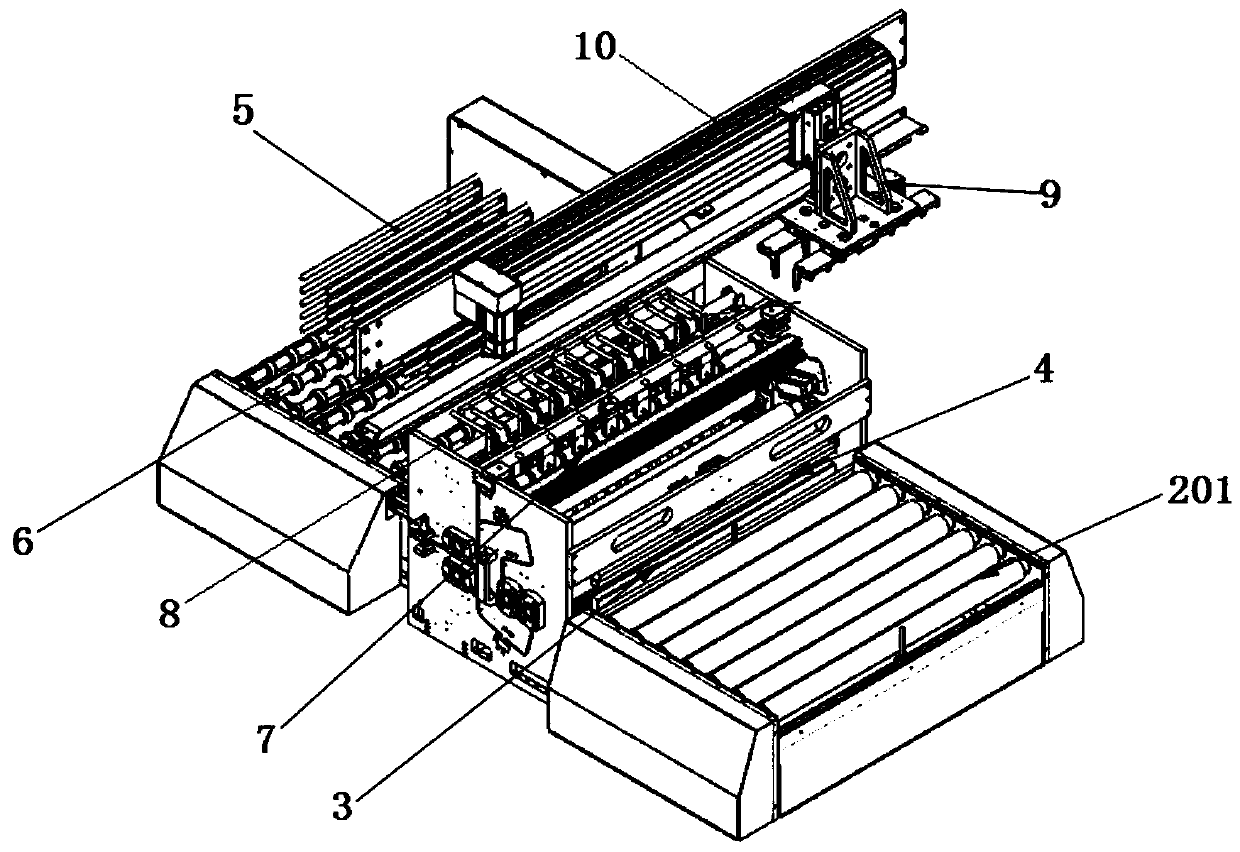

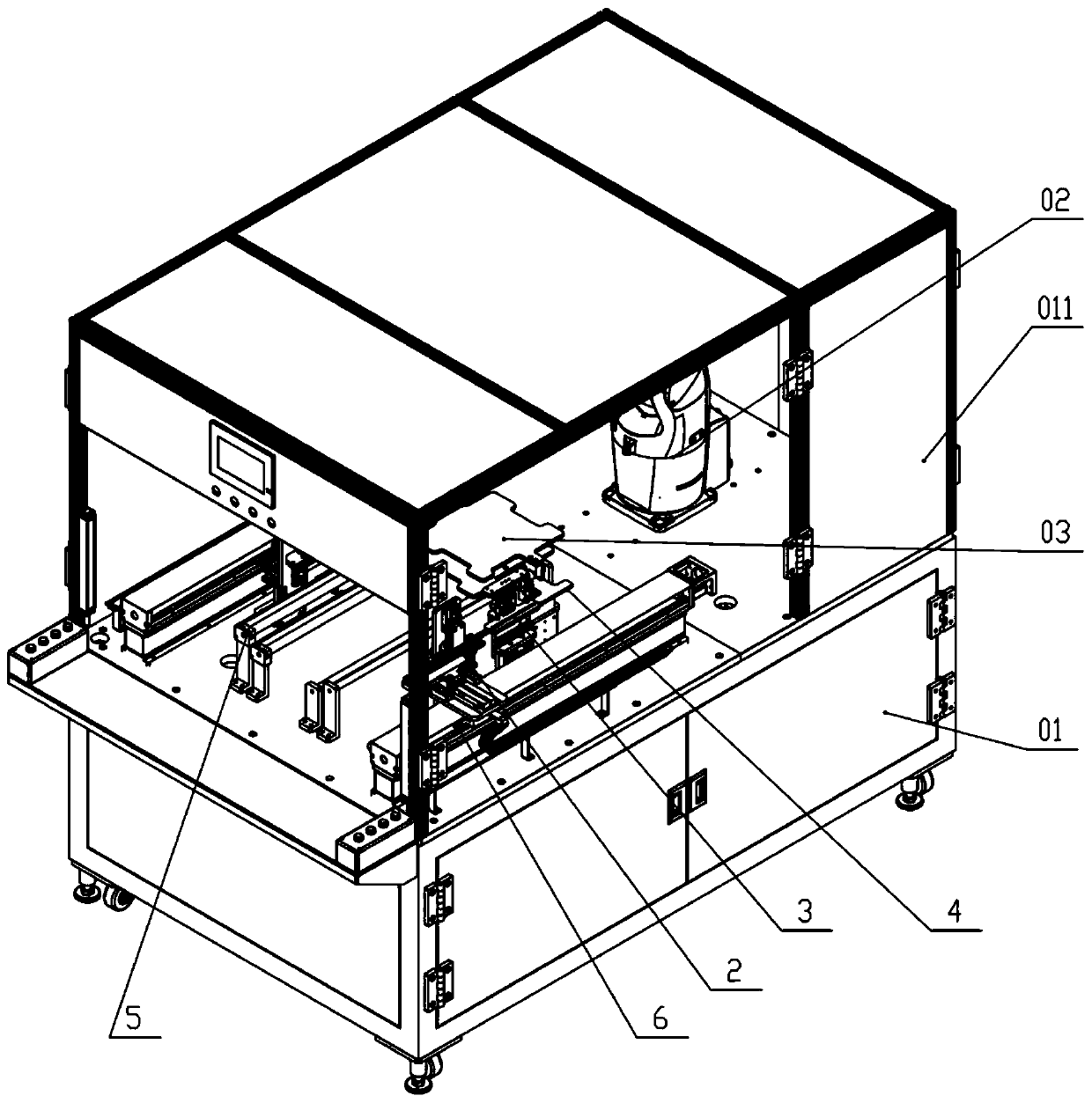

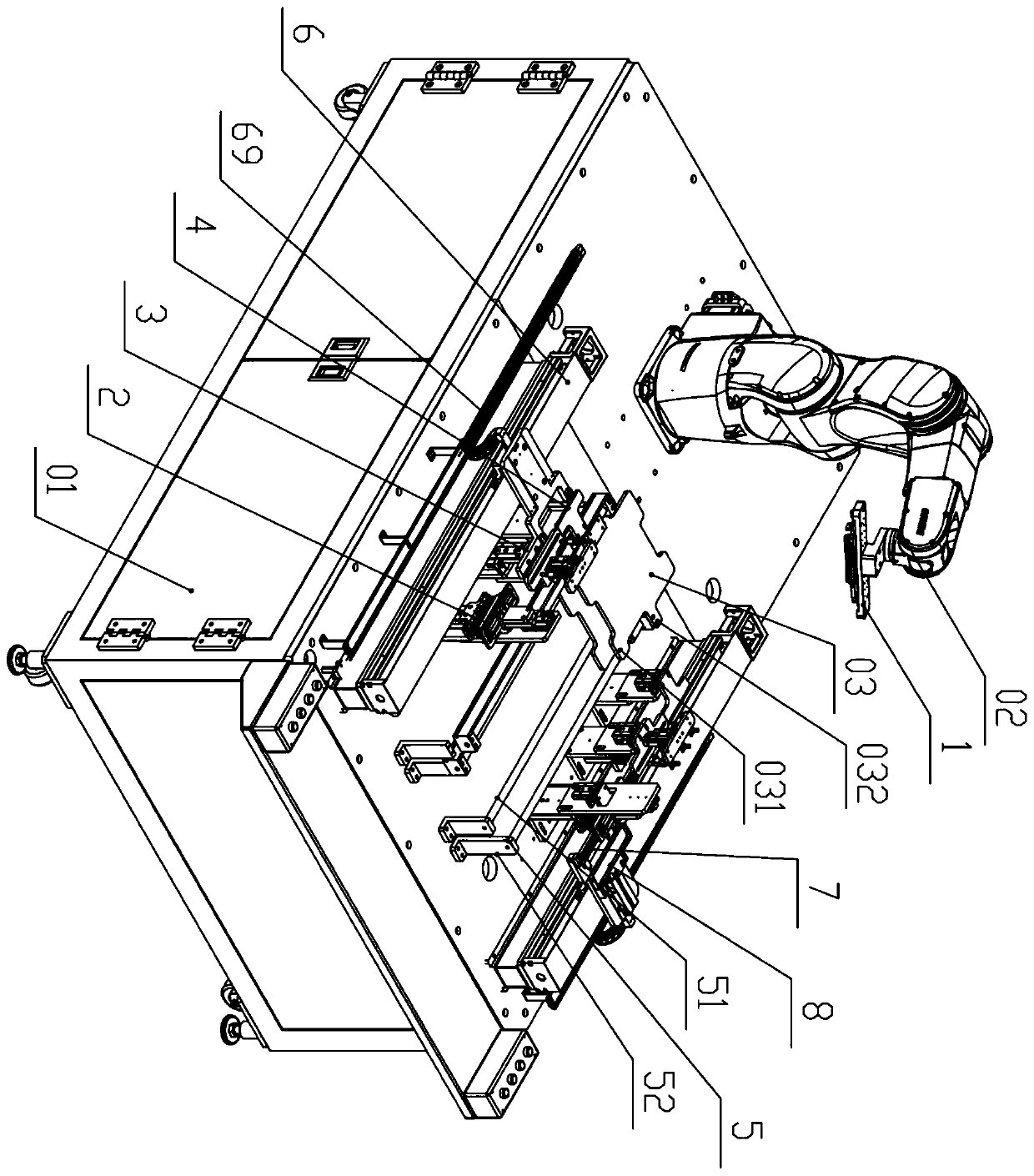

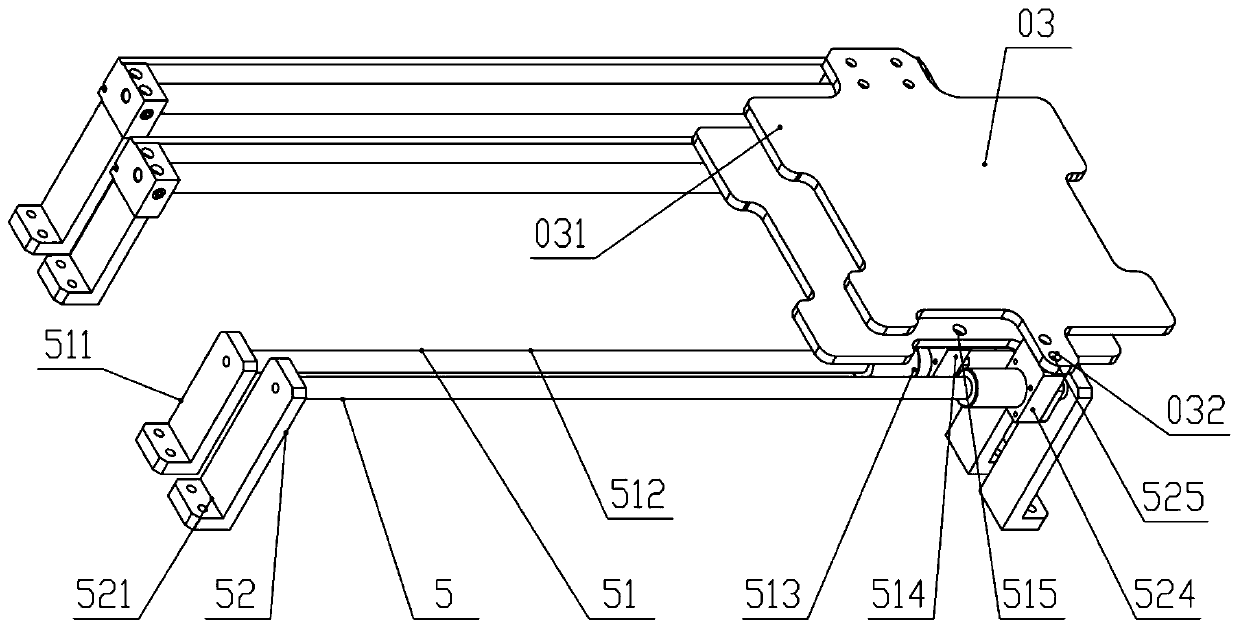

A high-efficiency automatic film tearing machine

The invention discloses a high-efficiency automatic membrane-tearing wobble plate machine. The machine comprises a frame, a manipulator is arranged in the center of a rack table, and a clamping jaw tool is installed on the manipulator, a temporary storage frame is arranged under the manipulator, a material tray can be placed at the temporary storage frame, a moving part is arranged on the side ofthe temporary storage frame, the moving part can drive a material board and a waste film recovery disk to move linearly, one side of the moving part is arranged with a both-side-tearing portion, a middle film-tearing portion and a film-pressing portion in sequence, the both-side-tearing portion includes a first material-pressing fixture, two rows of first nozzles are arranged at the top of the first material-pressing fixture and two rows of side thimbles are arranged on the lower side, the middle film-tearing portion includes a second material-pressing fixture, a plurality of second nozzles are arranged above the second material-pressing fixture and a row of middle thimbles are arranged below the material-pressing fixture, and the first nozzle and the second nozzle are connected to a vacuuming device The high-efficiency automatic membrane-tearing wobble plate machine realizes the mechanized continuous film tearing, the film tearing speed is fast, the production efficiency is high, andthe film tearing precision is high.

Owner:东莞领汇精密制造科技有限公司

A high-efficiency multi-compartment wool tearing machine

ActiveCN105386163BReduce the amount of lumpsIncrease porosityFibre cleaning/opening by toothed membersTextile disintegration and recoveryPulp and paper industry

The invention discloses an efficient multi-bin fibrous material tearing machine. The machine comprises a box body and an auger conveyer, wherein the interior of the box body is divided into an upper bin and a lower bin, a feeding pipe is arranged on one side of the upper portion of the upper bin, a discharging pipe is arranged on the lower portion of the lower bin, a first cylinder is arranged on the lower portion of the auger conveyer and connected with a baffle, and the upper edge of the baffle is 3-10 mm away from a screw blade; a second cylinder is arranged on the upper portion of the feeding pipe and connected with a fibrous material tearing column, and barbs are arranged on the surface of the fibrous material tearing column; a second motor is arranged on the outer side of the upper bin and connected with a horizontal stirring shaft, and spines are arranged on the horizontal stirring shaft in a stagger mode; fibrous material falling holes are formed in the lower plane of the upper bin, a third motor is arranged at one end of the lower bin and connected with a longitudinal stirring shaft, brads are arranged on the longitudinal stirring shaft in a stagger mode, and a suction fan is arranged in the discharging pipe. According to the machine, multi-bin processing is conducted, materials are torn multiple times in different directions, a product is fluffy, fine and soft, equipment burden is small, service life is long, and production efficiency is high.

Owner:孙习习

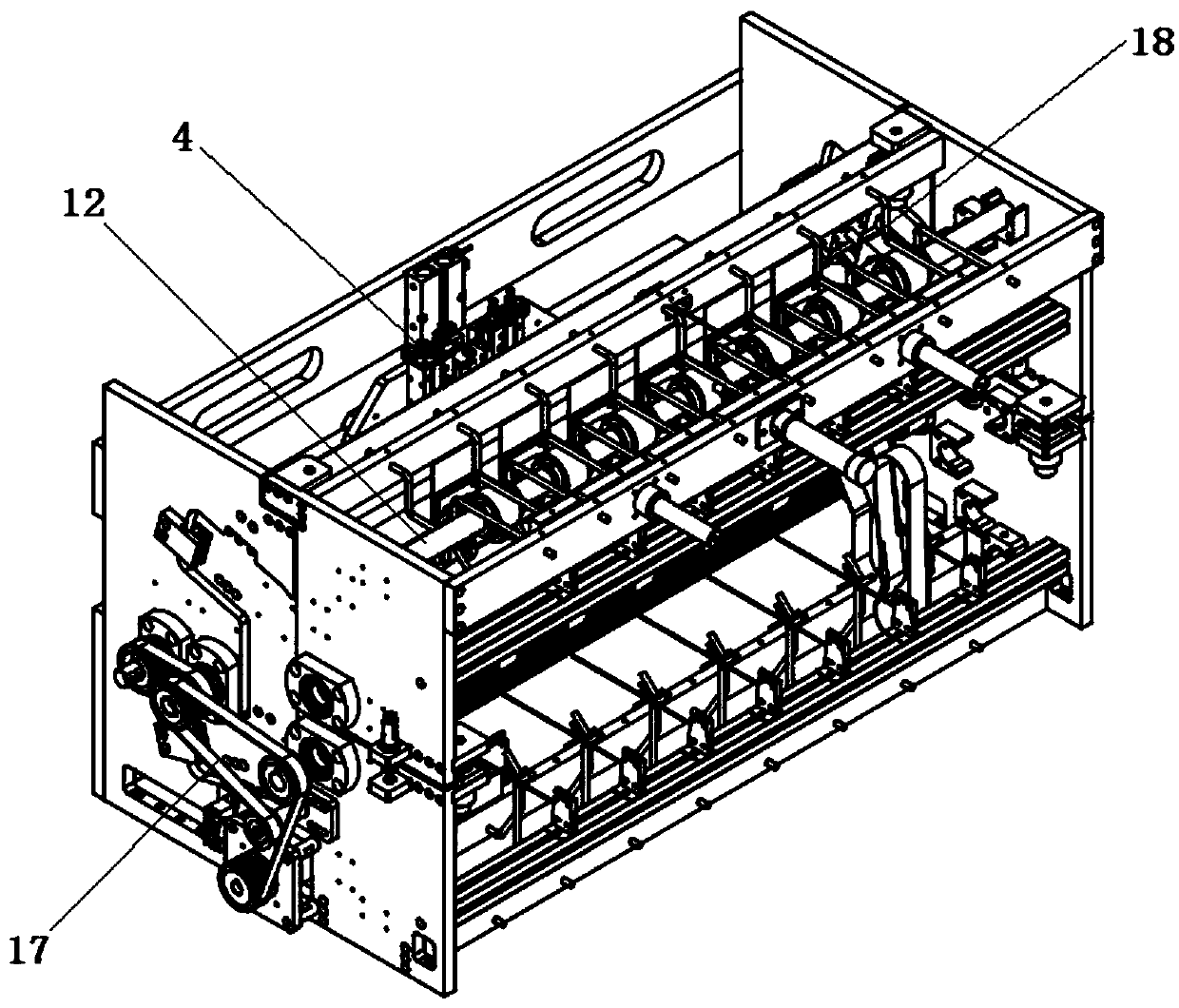

Paper tearing device and method

PendingCN109455563ATear to achieveAchieve single paper outputAuxillary ticket-issuing devicesArticle deliveryPulp and paper industryPower transmission

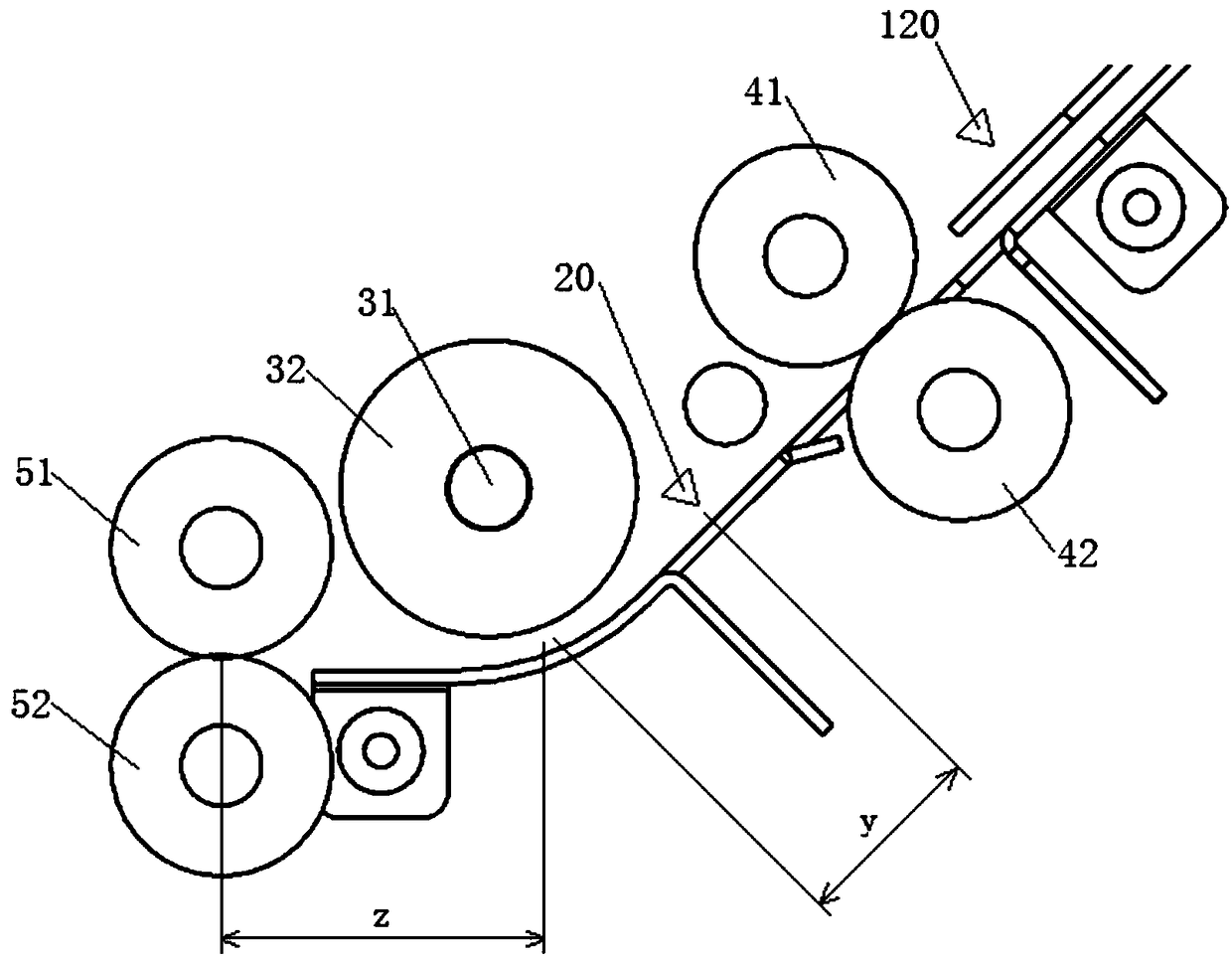

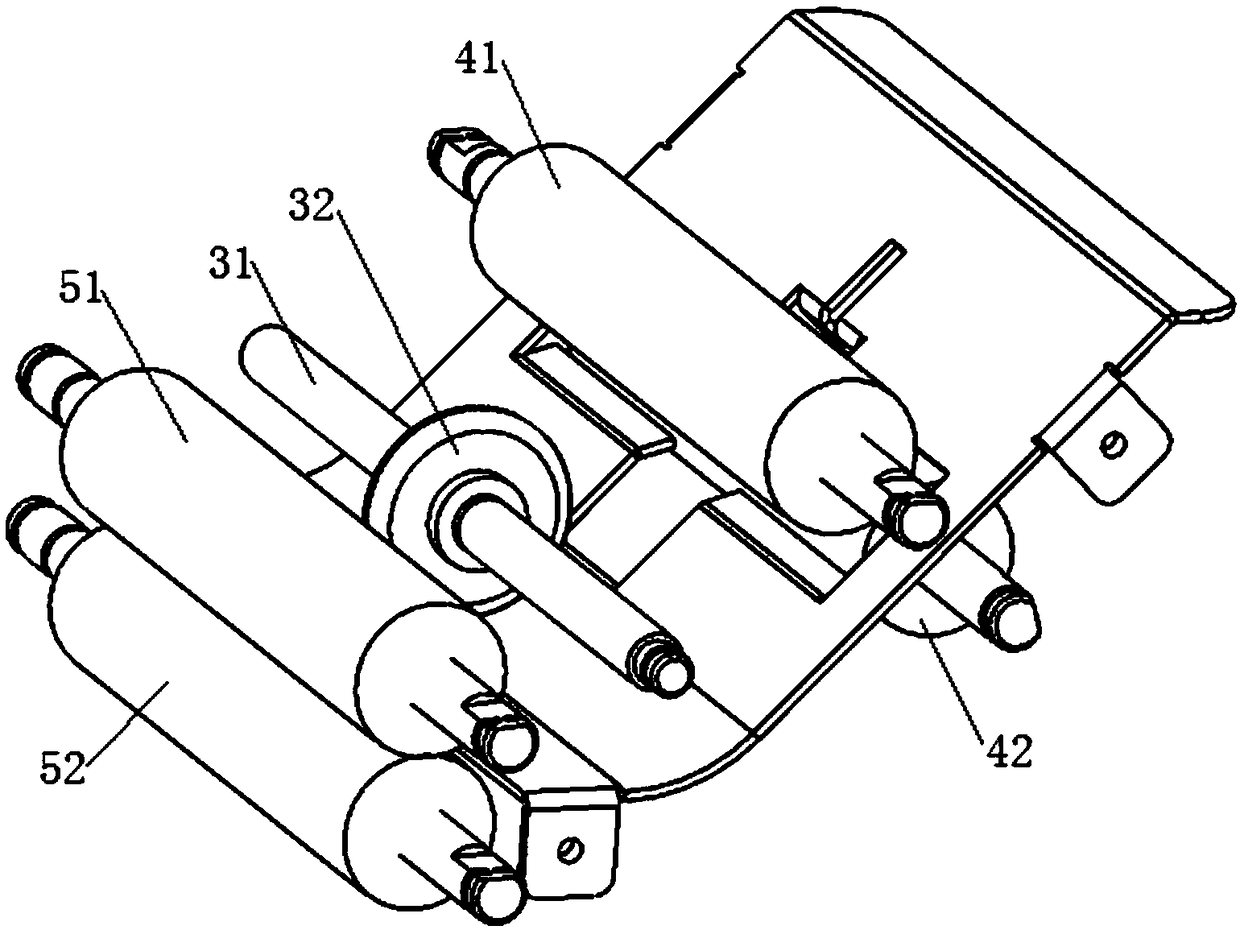

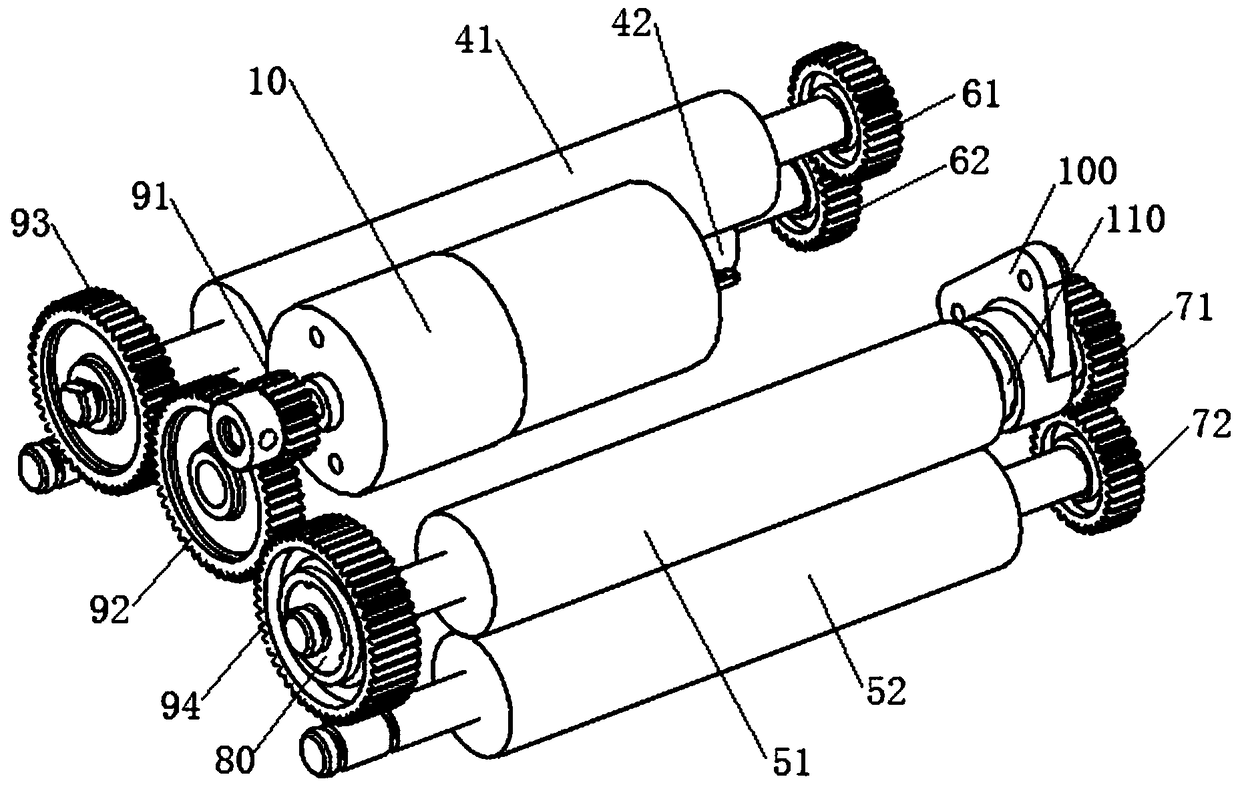

The invention discloses a paper tearing device and method. The paper tearing device comprises a rack, a paper feed roller set, a paper discharge roller set, a power transmission mechanism and a paperejecting opening member; a paper passage is arranged in the rack, and the paper passage is provided with a bending section; the paper feed roller set, the paper ejecting opening member and the paper discharge roller set are sequentially arranged in the paper advancement direction of the paper passage; the paper feed roller set is movably connected to the rack, when the paper feed roller set is driven to move, the paper feed roller set is used for driving paper to move in the paper passage in the paper advancement direction or the paper retreating direction; and the paper discharge roller set is movably connected to the rack, and when the paper discharge roller set is driven to move, the paper discharge roller set is used for driving the paper or torn discharged paper to move in the paper passage in the paper advancement direction. By means of the paper tearing device and method, continuous paper with tear lines can be well torn, single paper output or multi-paper output can be achieved, the structure is compact, the cost is low, the paper can be accurately disconnected at the corresponding tear lines of the paper, and the device is also very convenient to use.

Owner:CHANGZHOU HANS & WILSON ELECTRONICS TECH

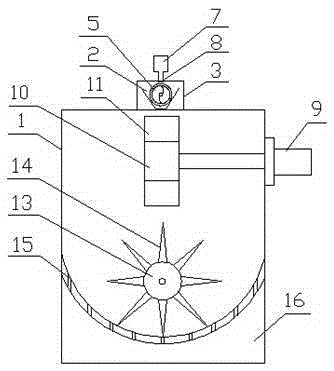

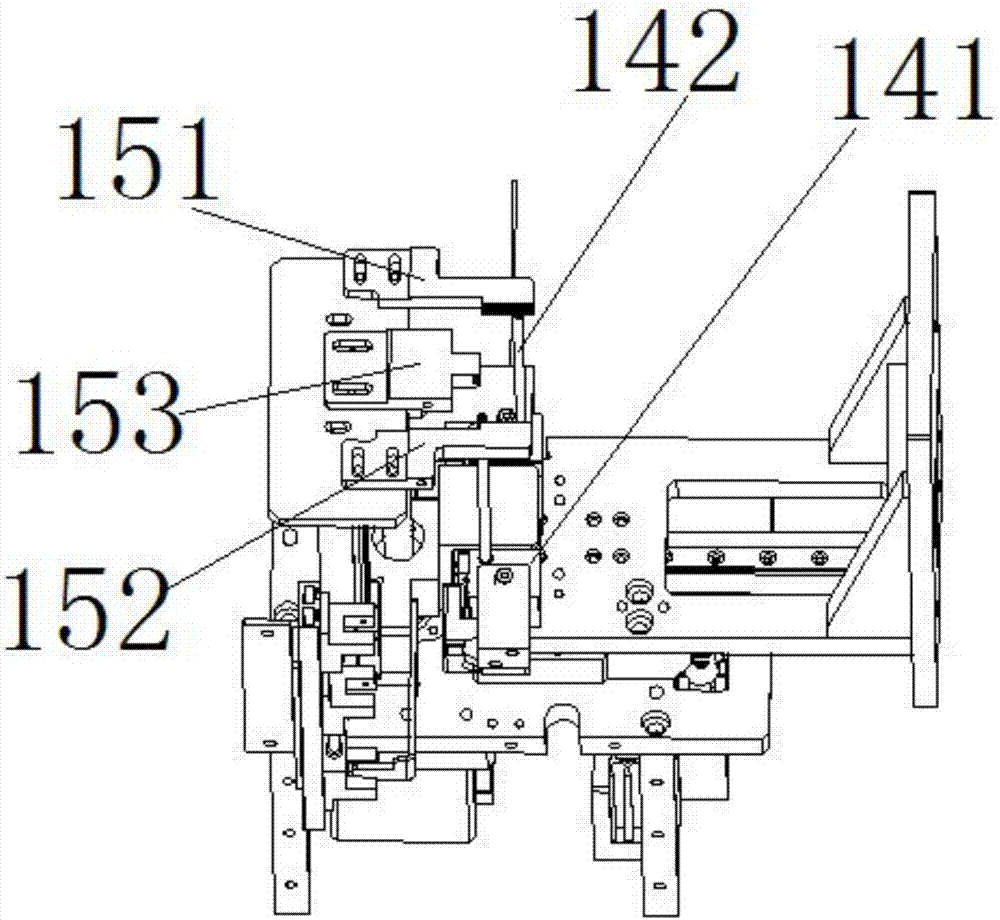

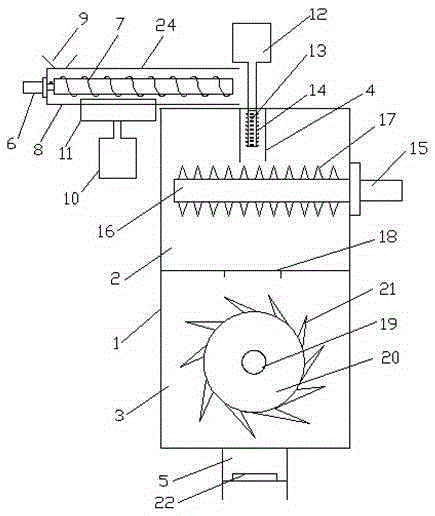

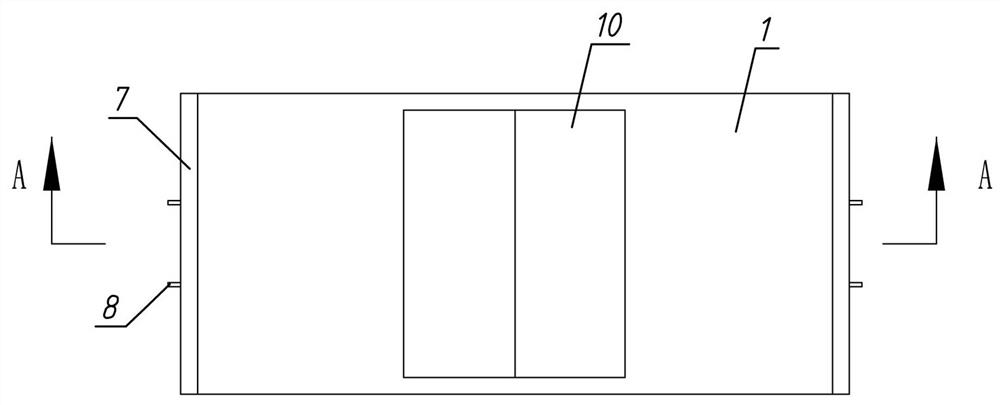

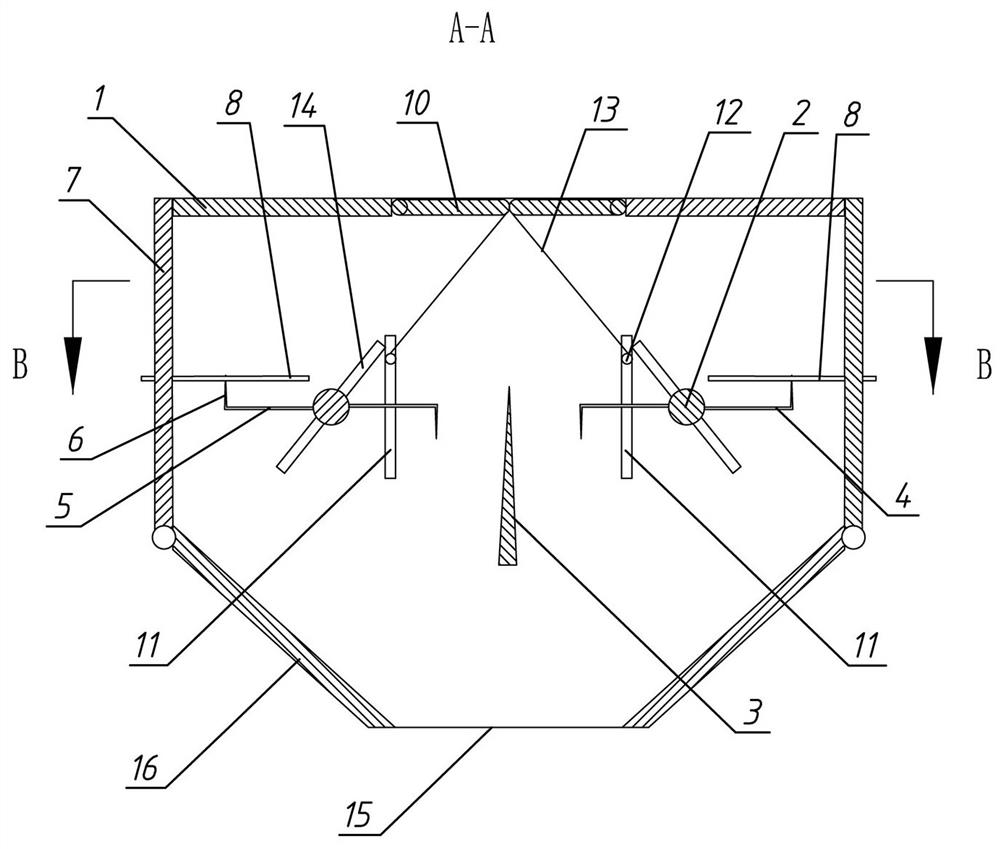

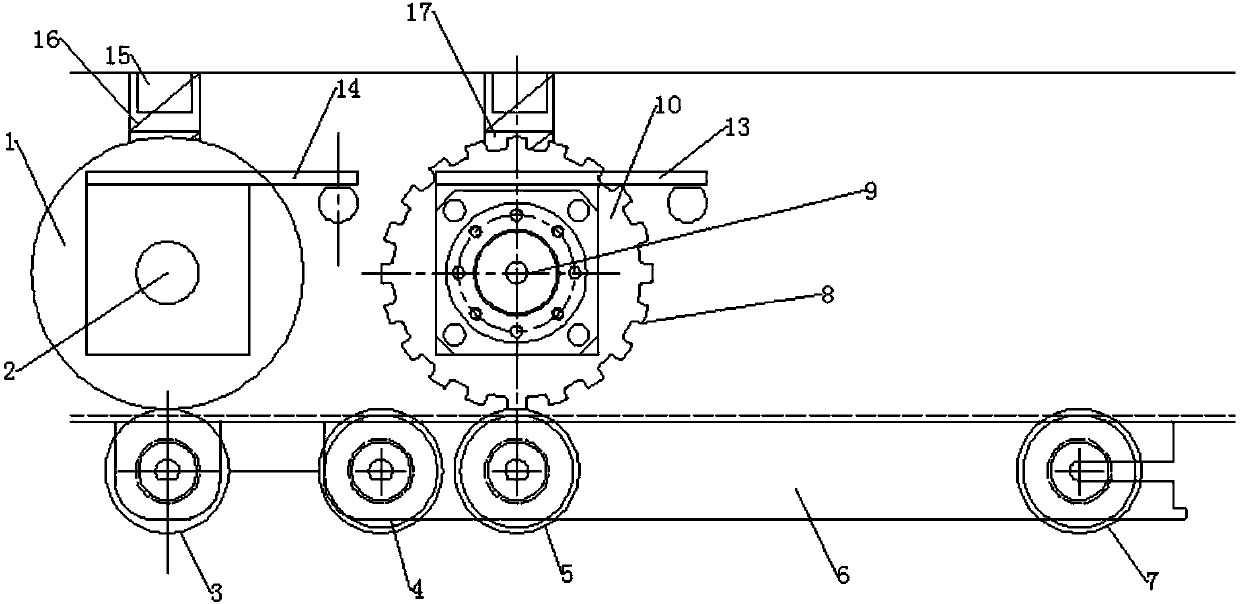

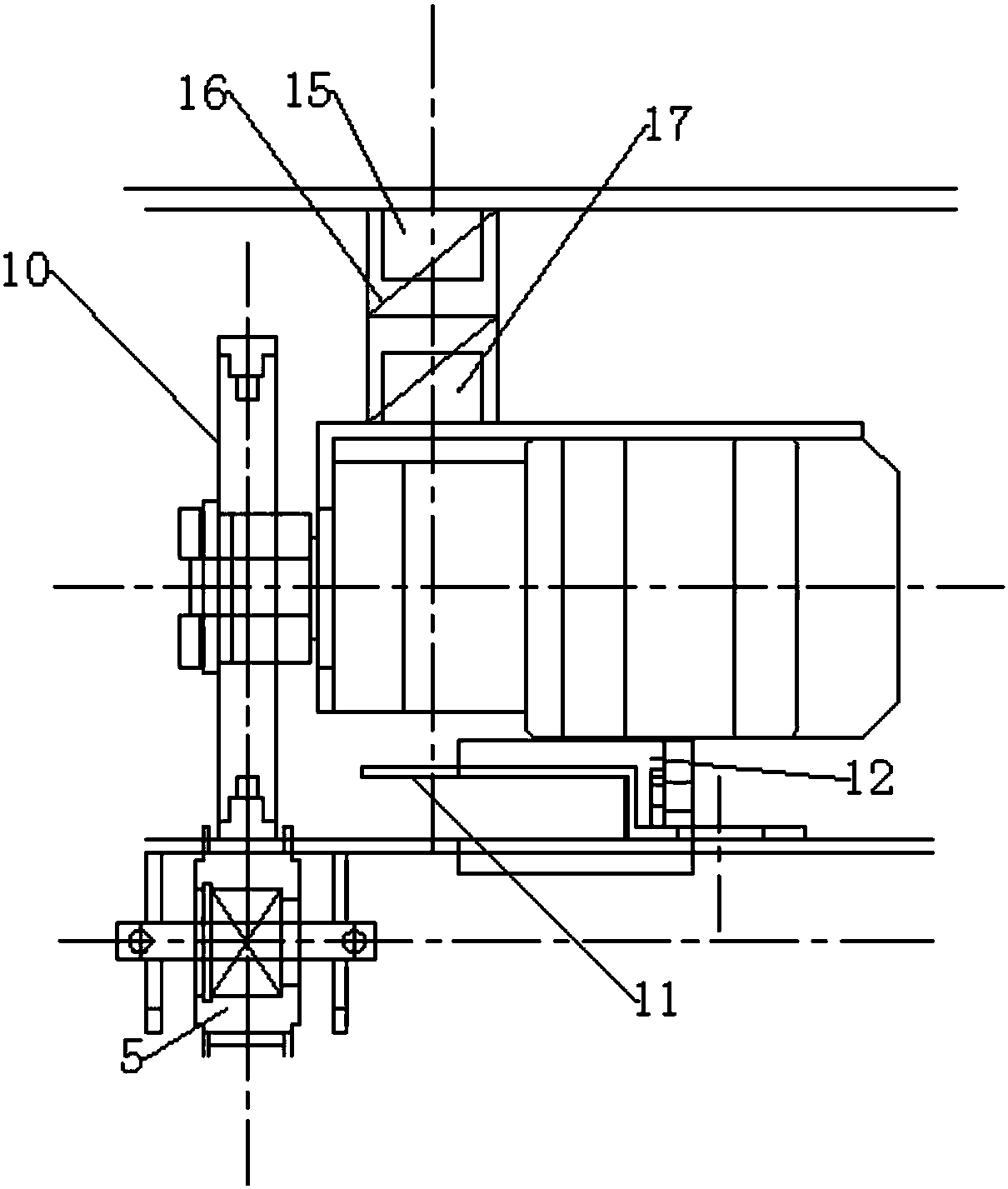

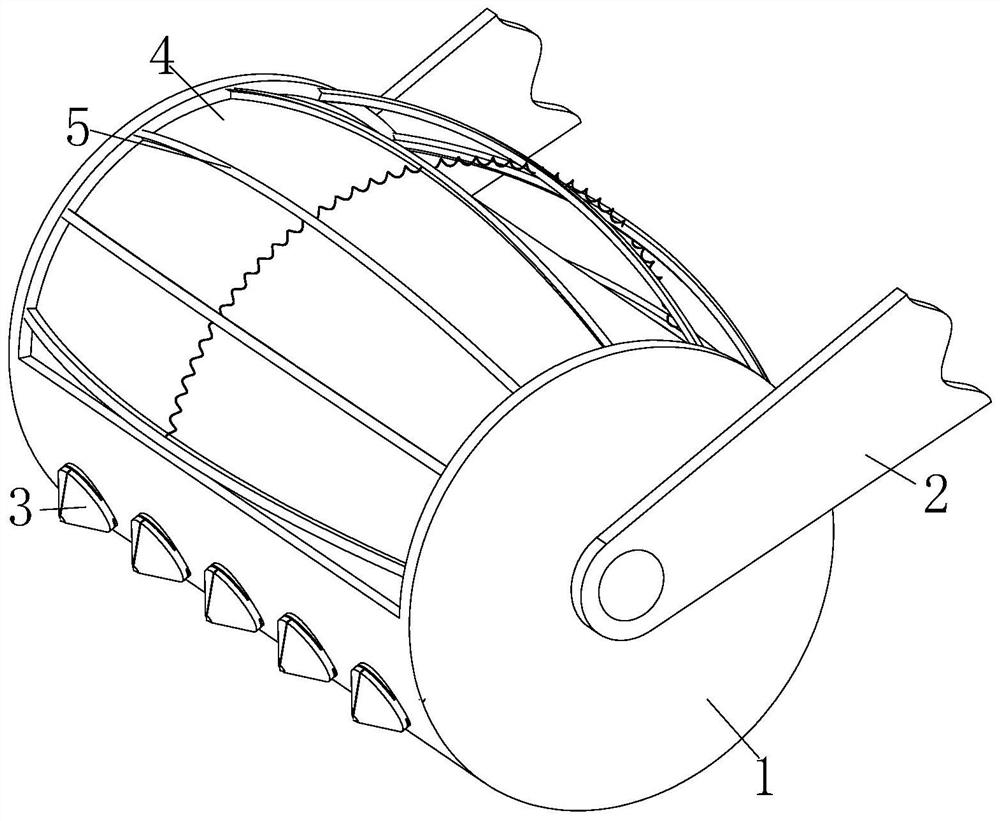

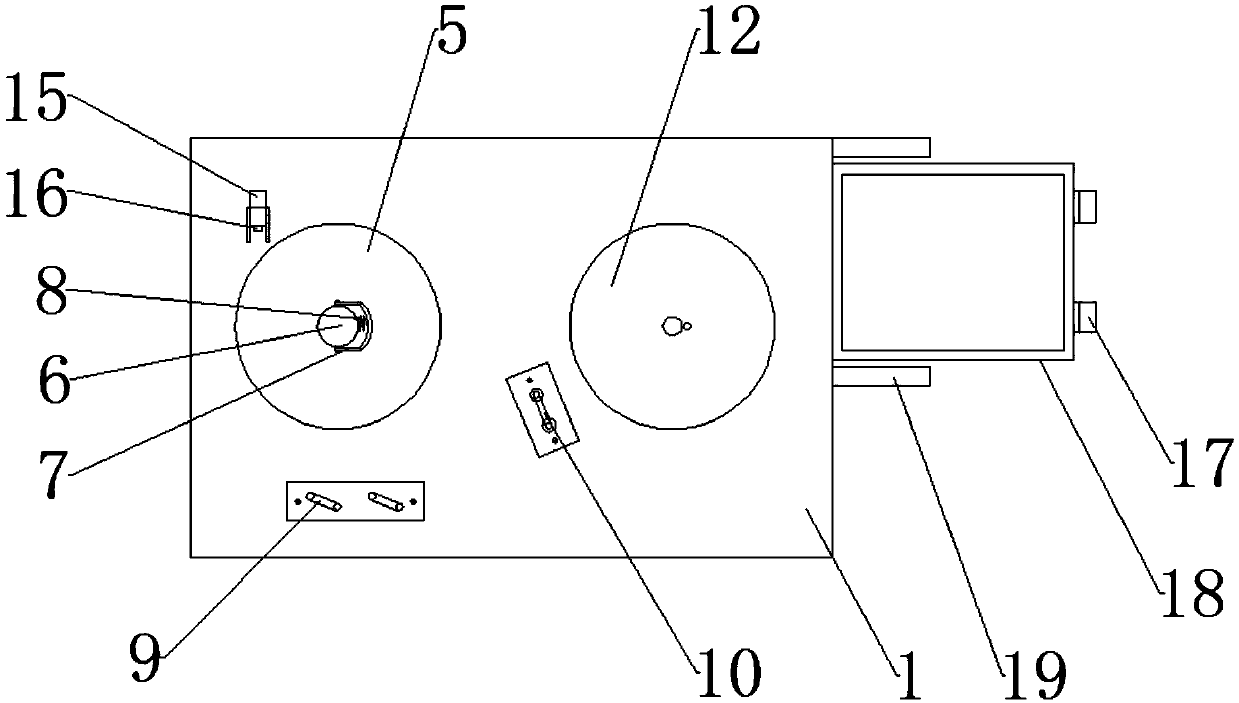

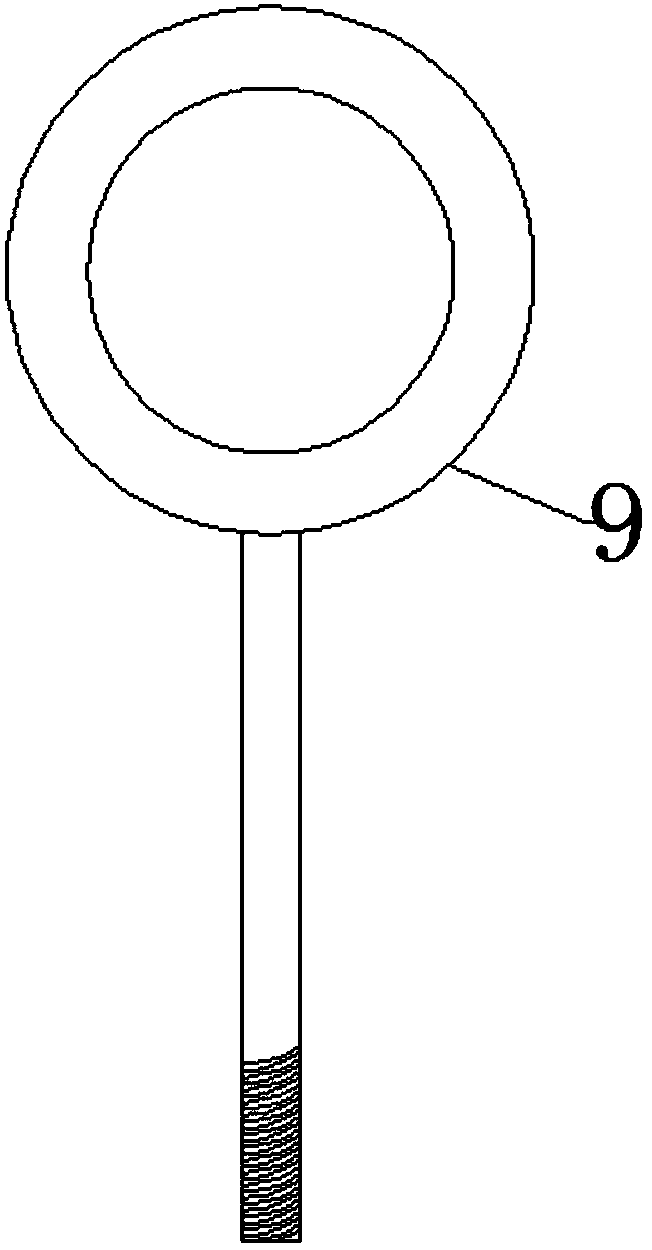

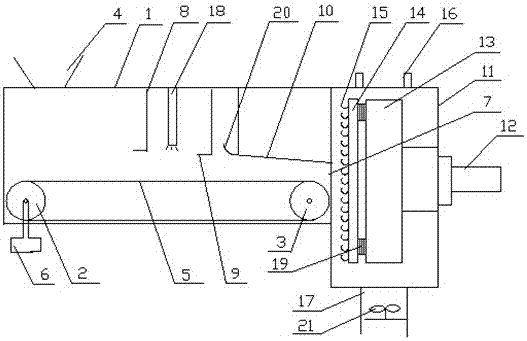

A continuous feed tearing machine

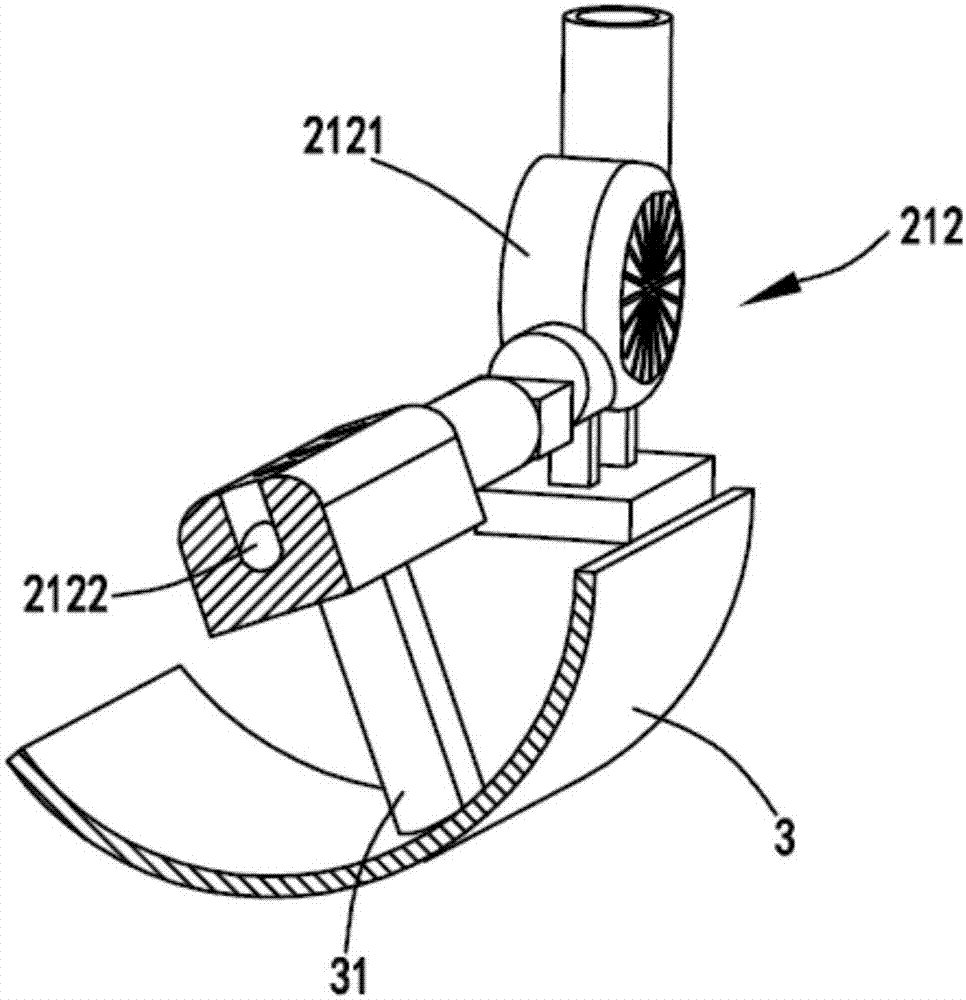

ActiveCN105386160BImprove securityIncrease productivityFibre cleaning/opening machinesFibre cleaning/opening by agitationContinuous feedingNozzle

The invention discloses a wool tearing machine capable of achieving continuous feeding. The wool tearing machine comprises a conveyer roll device and a machine case; the conveyer roll device comprises a support, a drive roll and a driven roll, the support is provided with a feed port, the outer circle of the drive roll and the outer circle of the driven roll are wrapped with a belt, the drive roll is connected with a first motor, a material outlet is formed in the position above the right side of the belt, at least one row of limit pins are arranged above the belt, the lowermost end of each limit pin is provided with a right angle hook, and an inclined limit plate is arranged on the right sides of the limit pins; the machine case is arranged on the right side of the conveyer roll device, the right side of the machine case is provided with a second motor which is connected with a vertical rotary disc arranged in the machine case, the left side of the rotary disc is provided with an adjustable flat plate, the left side of the flat plate is provided with hooks, downward air nozzles are arranged on the machine case, and a discharge pipe is arranged under the machine case. According to the wool tearing machine capable of achieving continuous feeding, tearing is firstly performed for one time in the feeding process to compress the material feeding height, feeding is continuous and ordered, the wool tearing effect is good, and a produced material is fluffy, fine and soft; the structure is simple, use is convenient, the safety is high, the equipment burden is small, and the production efficiency is high.

Owner:徐州天骋智能科技有限公司

Film tearing device

ActiveCN111016403AAchieve separationGood tearing effectLayered productsLaminationAdhesive beltMechanical engineering

The invention provides a film tearing device. The film tearing device comprises a frame and a conveying mechanism arranged on the frame. The conveying mechanism is used for conveying workpieces; a winding drum, a film tearing mechanism and a storing mechanism are mounted on the frame and are sequentially arranged in a workpiece conveying direction of the conveying mechanism; the winding drum is used for releasing and feeding an adhesive tape; the film tearing mechanism comprises a pressing roller and a tearing roller, the pressing roller is used for pressing the adhesive tape and the workpiecetogether, the tearing roller is used for guiding the adhesive tape adhered with a protective film away from the surface of the workpiece, and the diameter of the tearing roller is smaller than the diameter of the pressing roller; the adhesive tape starts from the winding drum, sequentially winds around the pressing roller and the tearing roller and is finally collected into the storing mechanism;and the storing mechanism is used for storing the adhesive tape. The film tearing device provided by the invention can realize automatic stripping of the protective film, and is simple in structure,high in automation degree, capable of saving time and labor, and high in working efficiency.

Owner:HUNAN TENYUM INTELLIGENT EQUIP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com