An automatic film tearing device

A film device and automatic technology, applied in packaging, transportation and packaging, and unsealing of objects, etc., can solve the problems of poor tearing effect and low tearing efficiency, and achieve the effect of preventing products from being taken away and good tearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

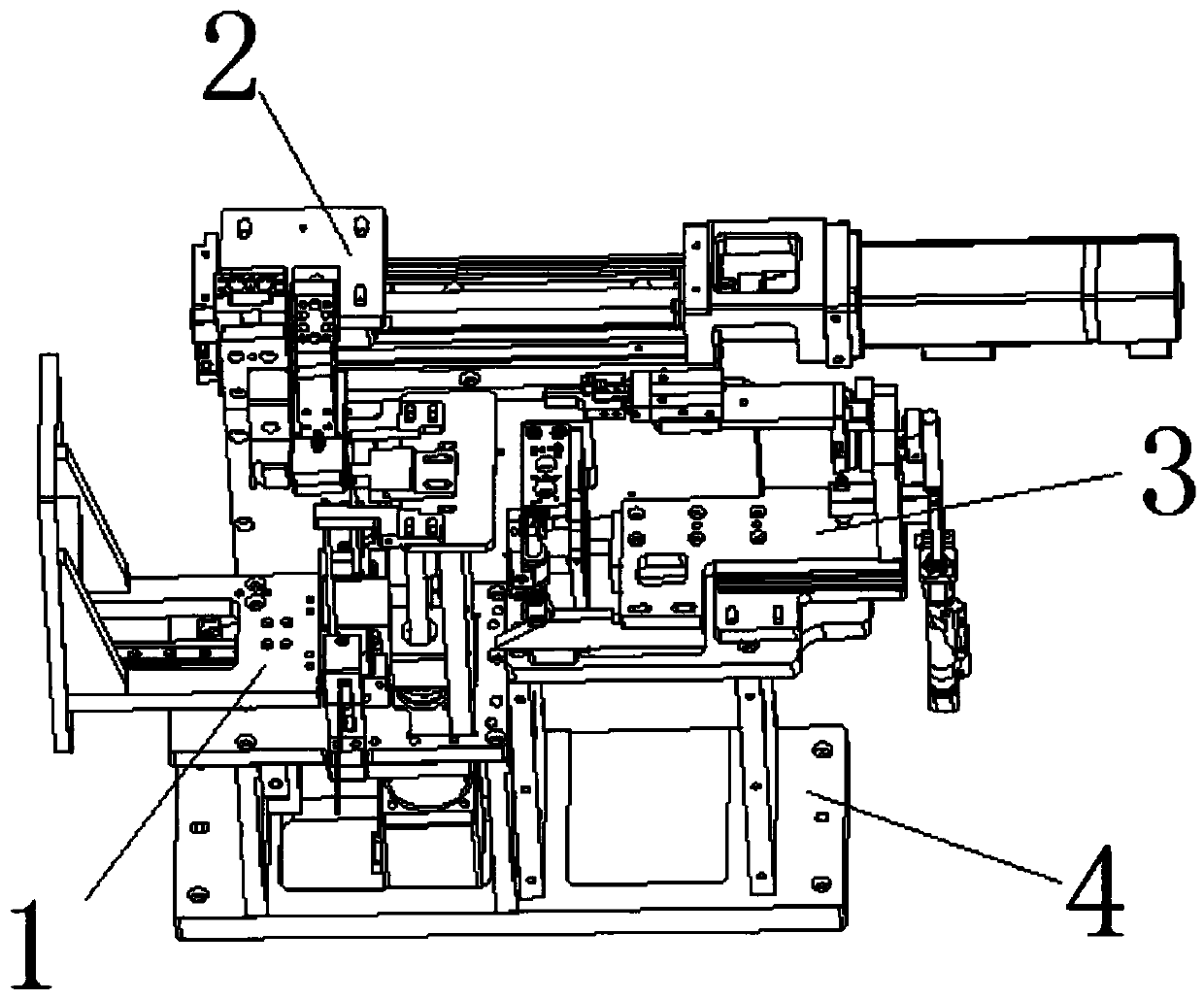

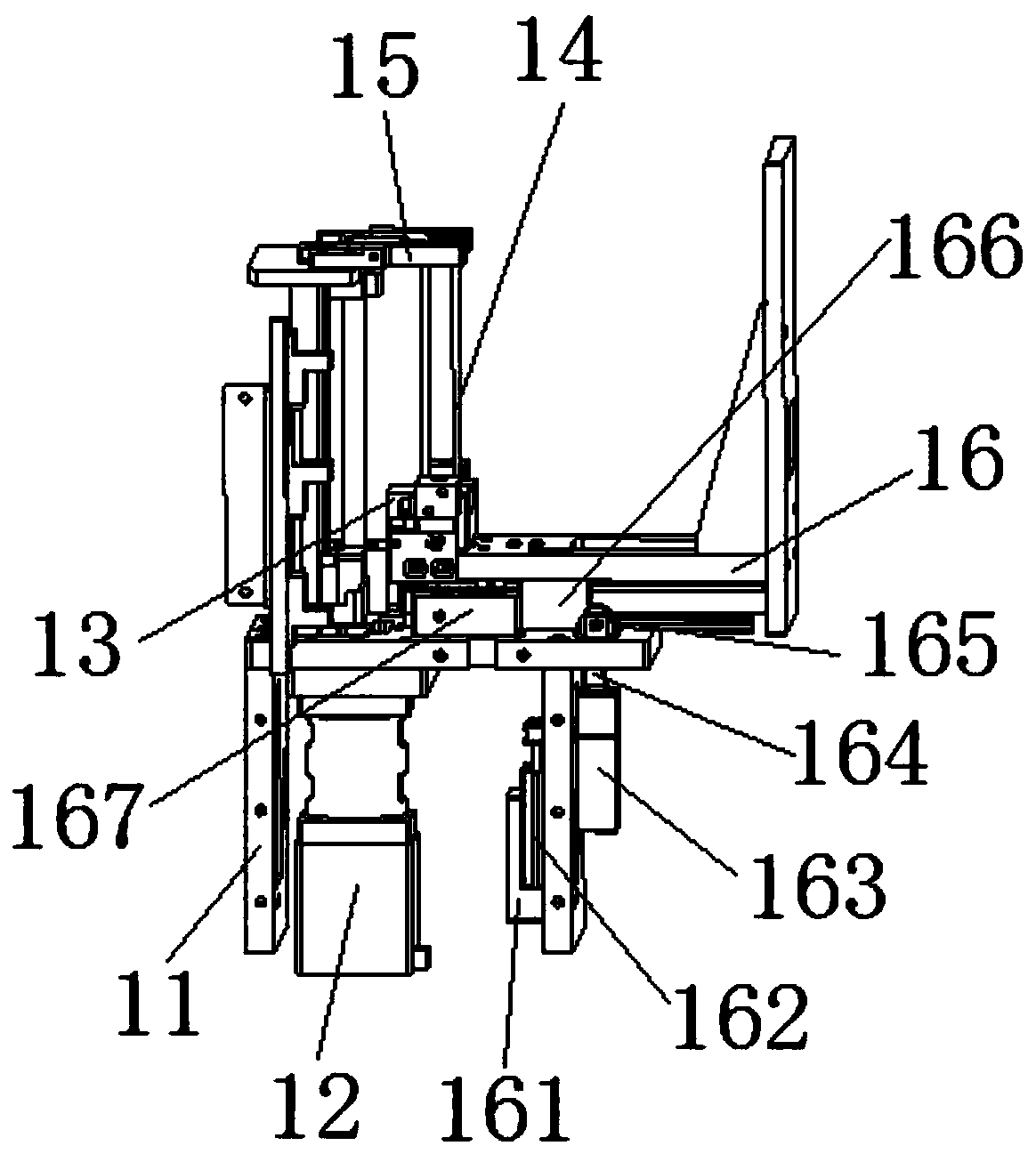

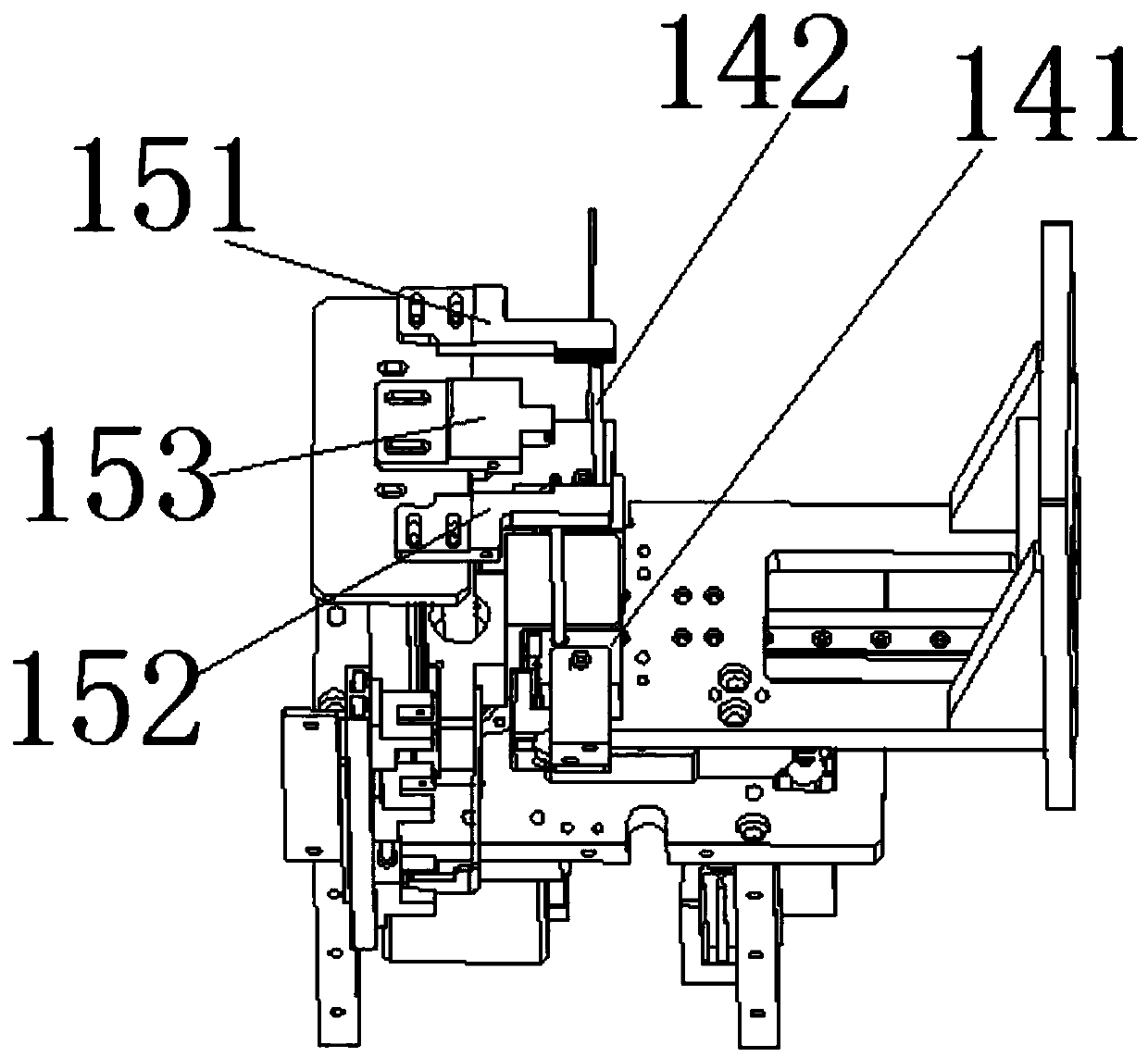

[0028] see Figure 1 to Figure 9 , an automatic feeding and tearing film mechanism, comprising a bottom plate 4 and a feeding device 1, a handling device 2 and a film tearing device 3 that are respectively installed on the left front side, the rear side, and the right front side of the bottom plate 4 and connected in sequence, and the feeding device 1 Continuously supply the product with the upper and lower protective films up to the feeding position, the conveying device 2 transports the product from the feeding position to the tearing film position on the right, and the tearing film device 3 successively removes the upper protective film and the lower part of the product. The protective film is torn off.

[0029] The area above the bin assembly 14 is defined as the feeding position, and the area above the carrier assembly 34 is defined as the film tearing position.

[0030] The feeding device 1 includes a first mounting seat 11, on which a lifting and feeding assembly 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com