Automatic dust removing method for sample preparation and dust removing system thereof

A technology of automatic dust removal and dust removal system, which is applied in the direction of cleaning methods using gas flow, dust removal, chemical instruments and methods, etc., can solve the problem that the dust removal system cannot fully meet the actual needs of the sample preparation process, affect the accuracy of sample preparation and measurement, Unable to guarantee the integrity of material samples and other issues, to achieve a high degree of automation, maintain integrity, and ensure the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

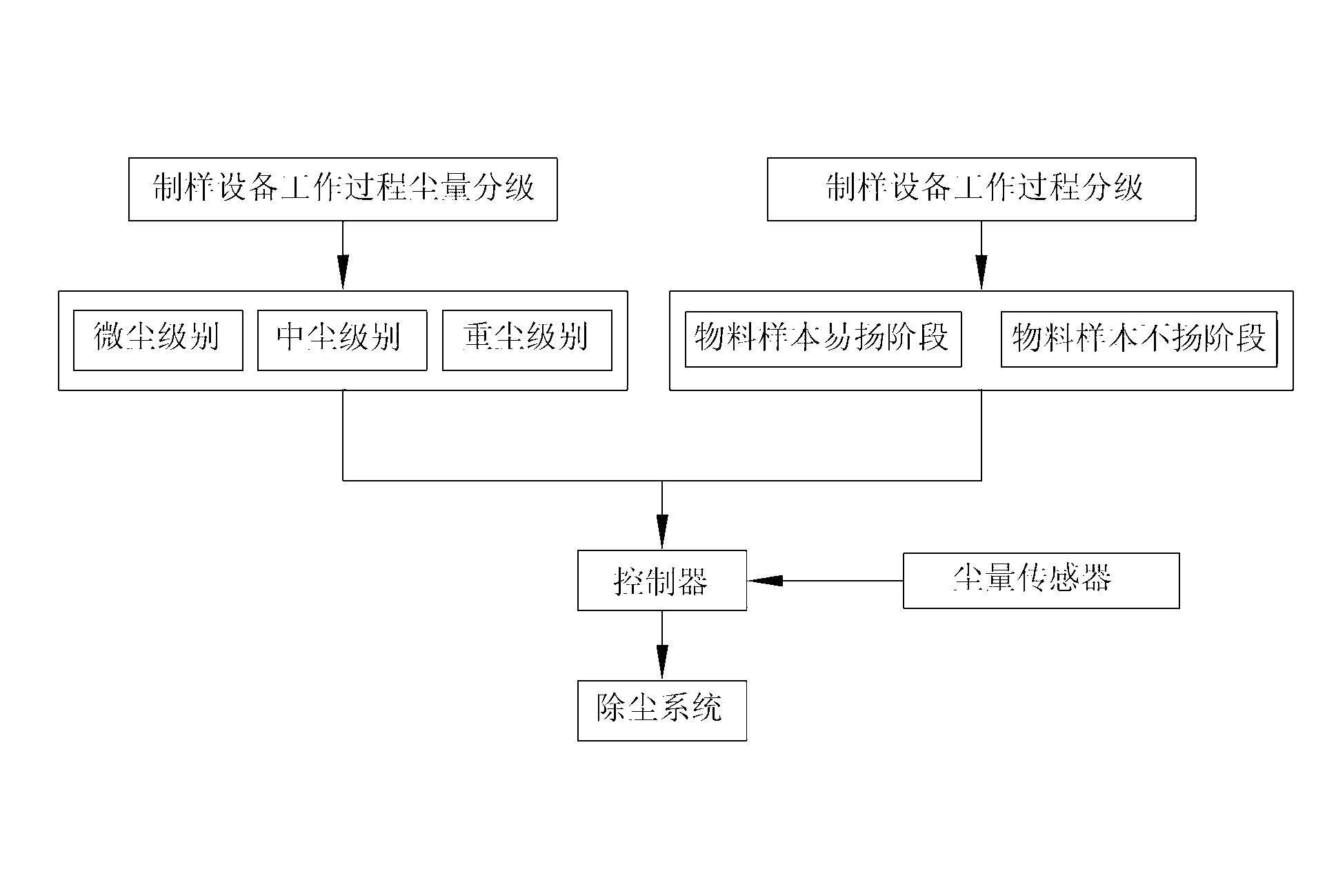

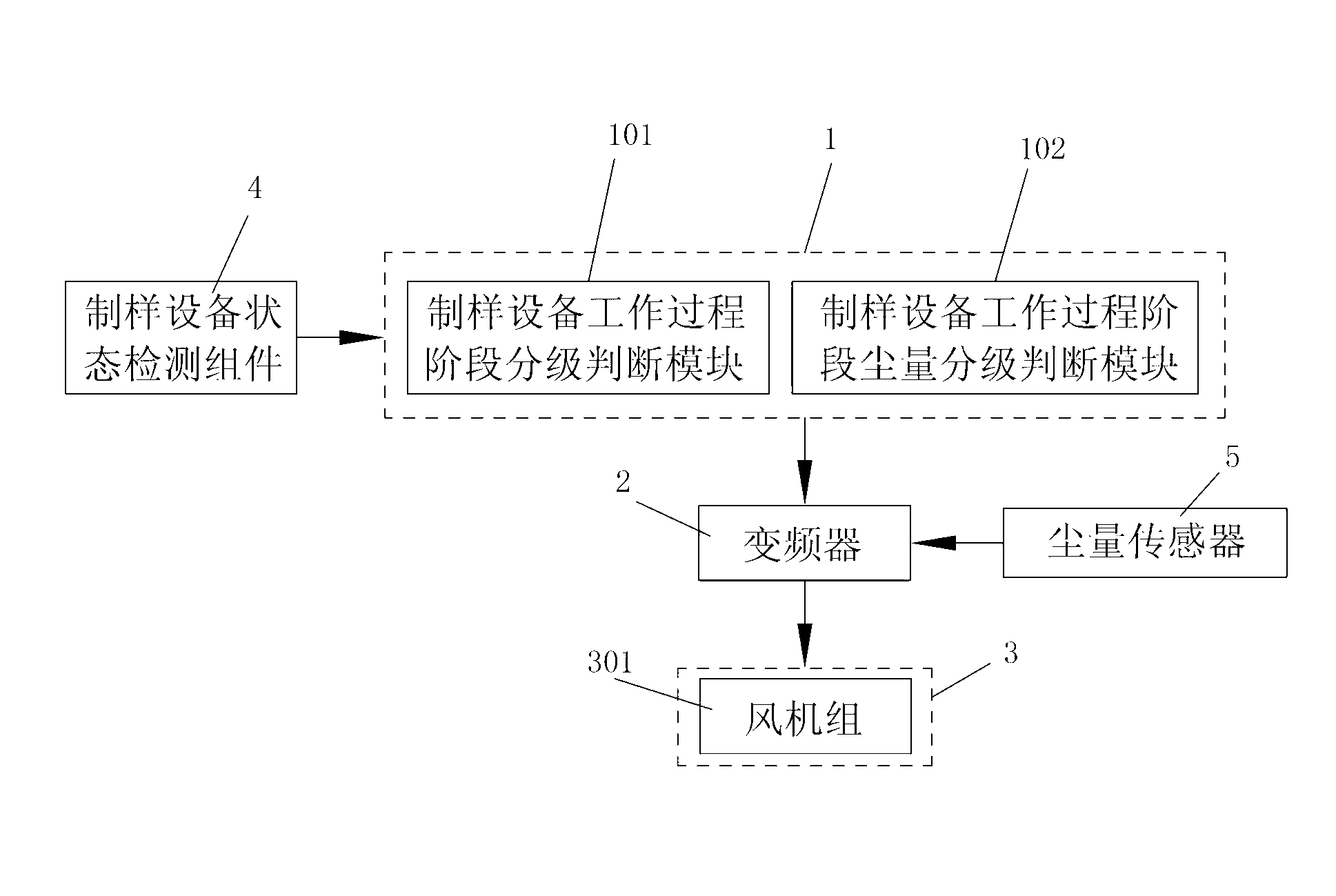

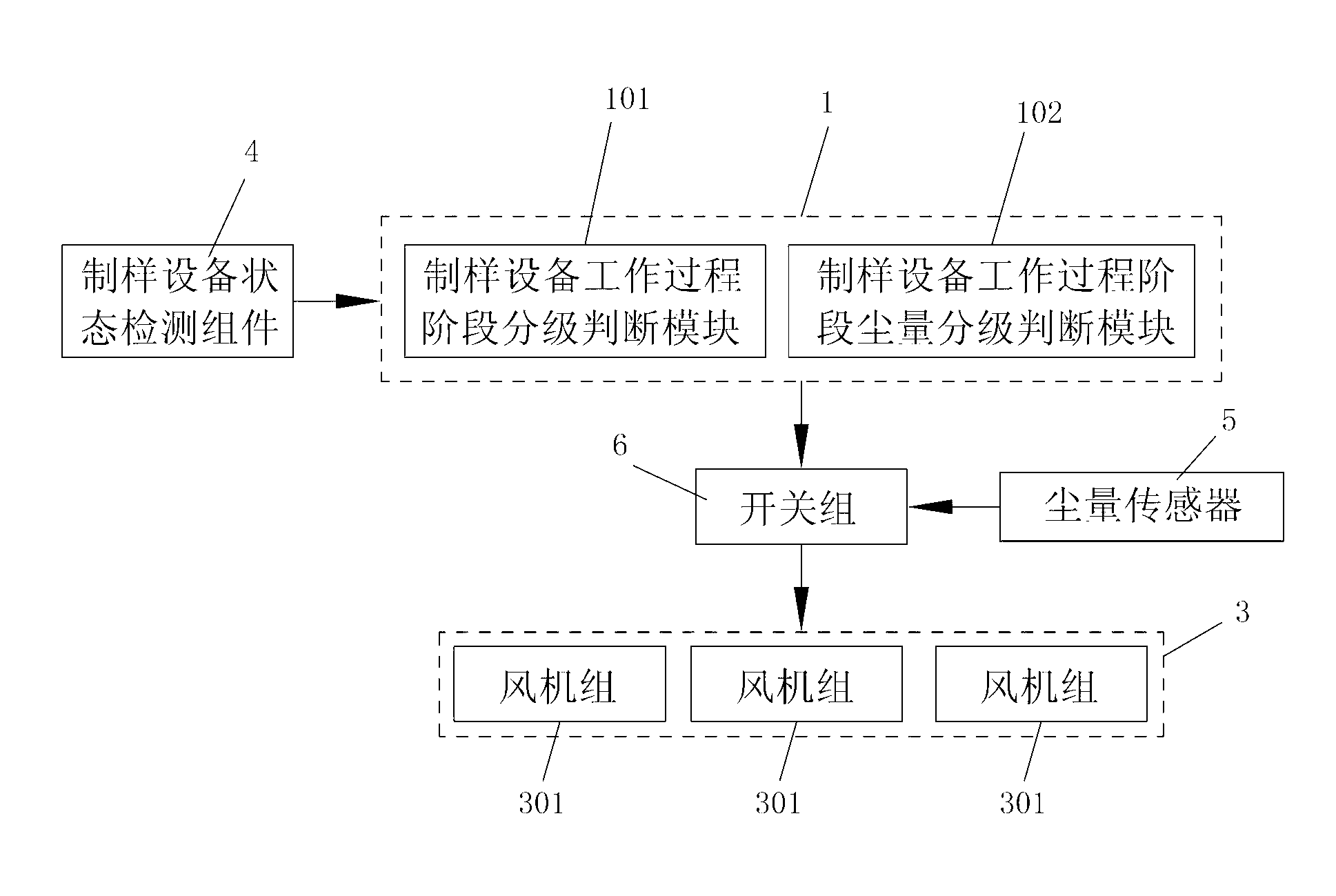

[0029] Such as figure 1 As shown, the automatic dedusting method used for sample preparation in the present invention is: monitor the working state of the sample preparation equipment in real time, judge the level of the dust amount according to the working state of the sample preparation equipment, combine the dust amount of different levels and the location of the sample preparation equipment The working state is used to control the power of the dust removal system.

[0030] There are many kinds of sample preparation equipment, including crushing, abrasive, shrinking and other equipment. All kinds of equipment have different working processes. In their different working processes, the amount of dust generated at each stage is not the same, so the It is very necessary to classify and divide the different dust amounts in the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com