Automatic cement bag unpacking device

An automatic technology for cement bags, applied in the field of automatic unpacking devices for cement bags, can solve problems such as easy residual cement, inability to automatically organize packaging bags, etc., and achieve the effect of high speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

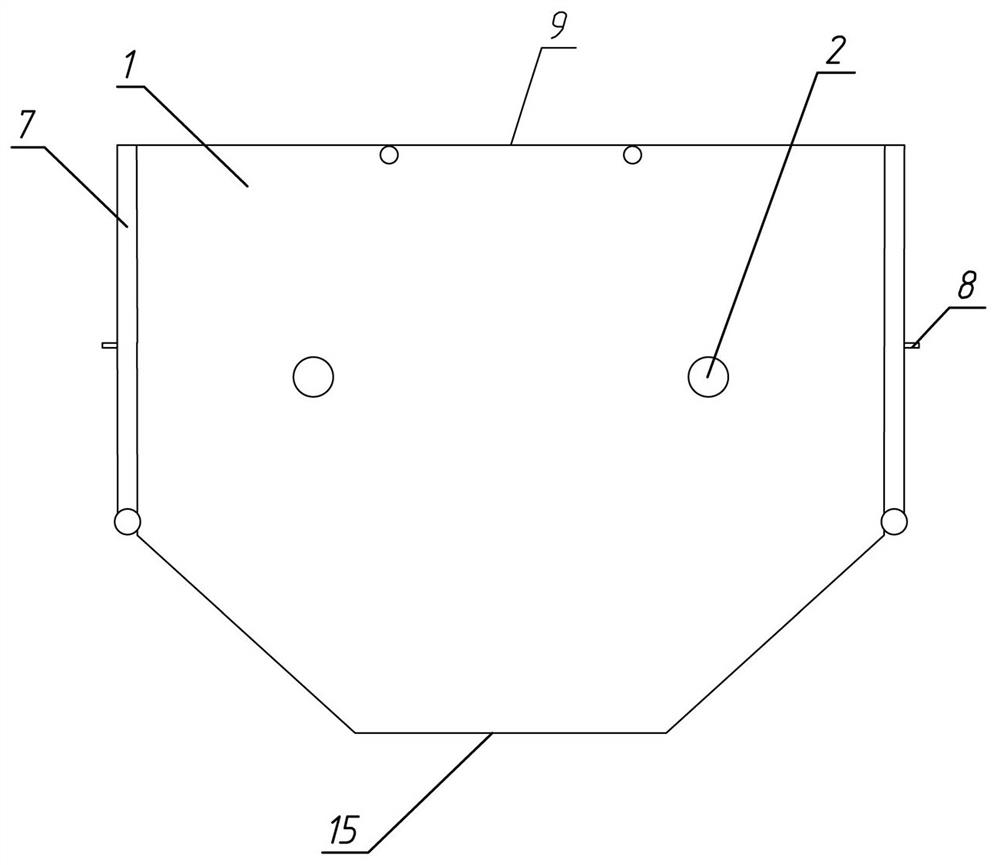

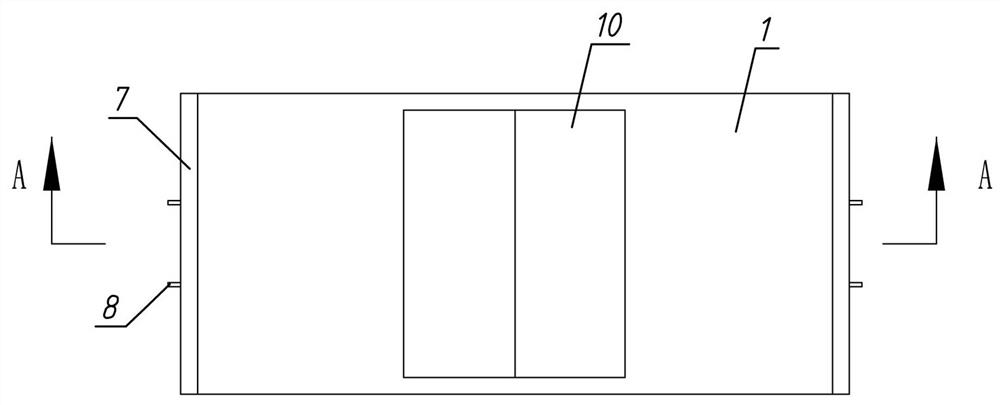

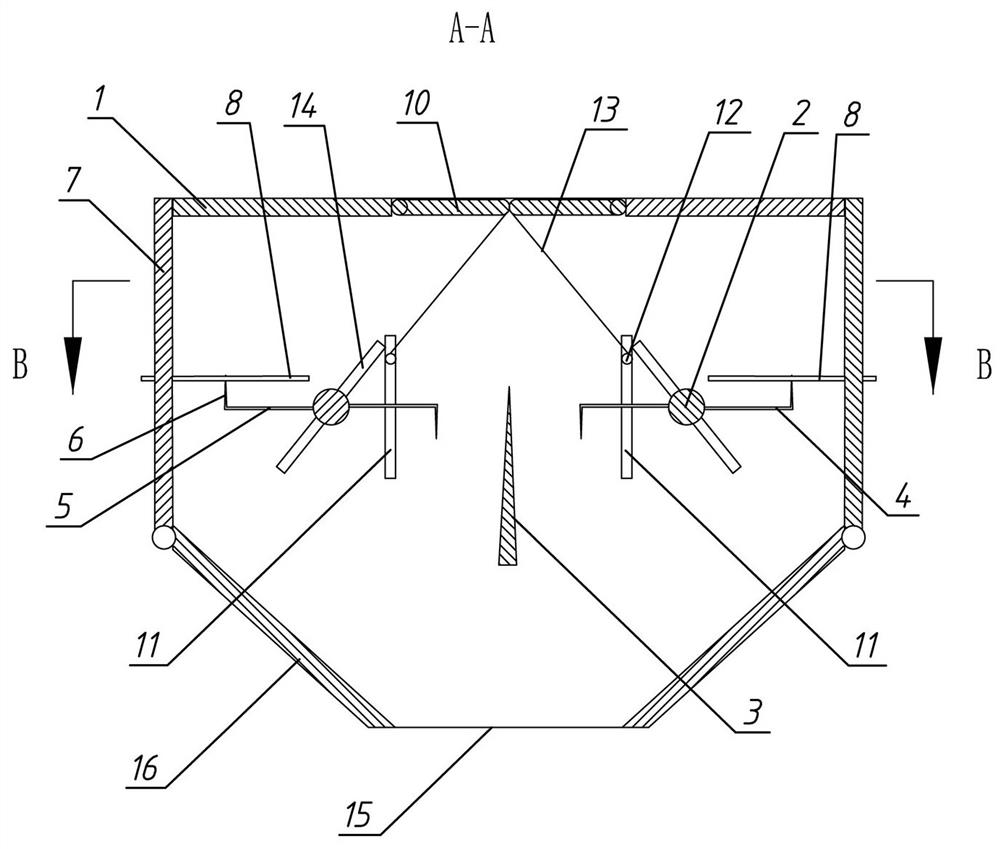

[0011] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] Depend on Figure 1 to Figure 5 Given, the present invention includes a square housing 1, on which two left and right symmetrical rotating shafts 2 are inserted front and rear, and the two rotating shafts 2 can rotate in opposite directions synchronously; The vertical blade 3 of the blade 3 faces upwards; two groups of L-shaped rods 4 are fixed symmetrically front and back on each rotating shaft 2, and each group of L-shaped rods 4 is two and fixed on the rotating shaft 2 symmetrically in the center; the L-shaped Rod 4 is made up of long rod 5 and short rod 6, and one end of long rod 5 is fixed on the rotating shaft 2, and short rod 6 is placed in the vertical plane; 6 is inserted on the packaging bag; the left and right sides of the housing 1 are the first door panels 7 whose lower ends are hinged on the housing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com