Paper tearing device and method

A technology of paper and paper rollers, applied in auxiliary ticket issuing devices, transportation and packaging, instruments, etc., can solve problems such as not easy to tear, large ticket exit space, complex structure, etc., to reduce paper conveying accuracy, tear paper Good effect, good tearing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

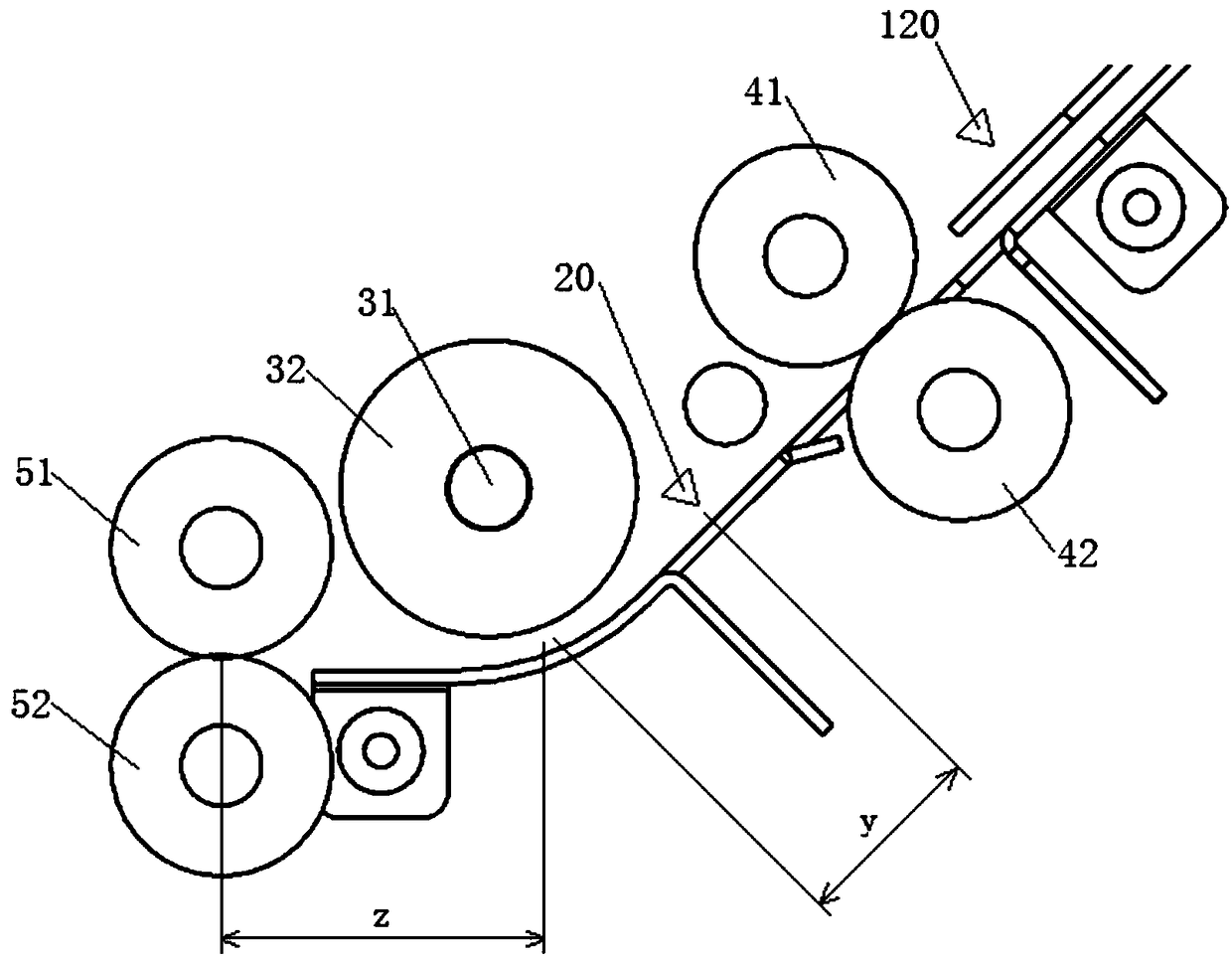

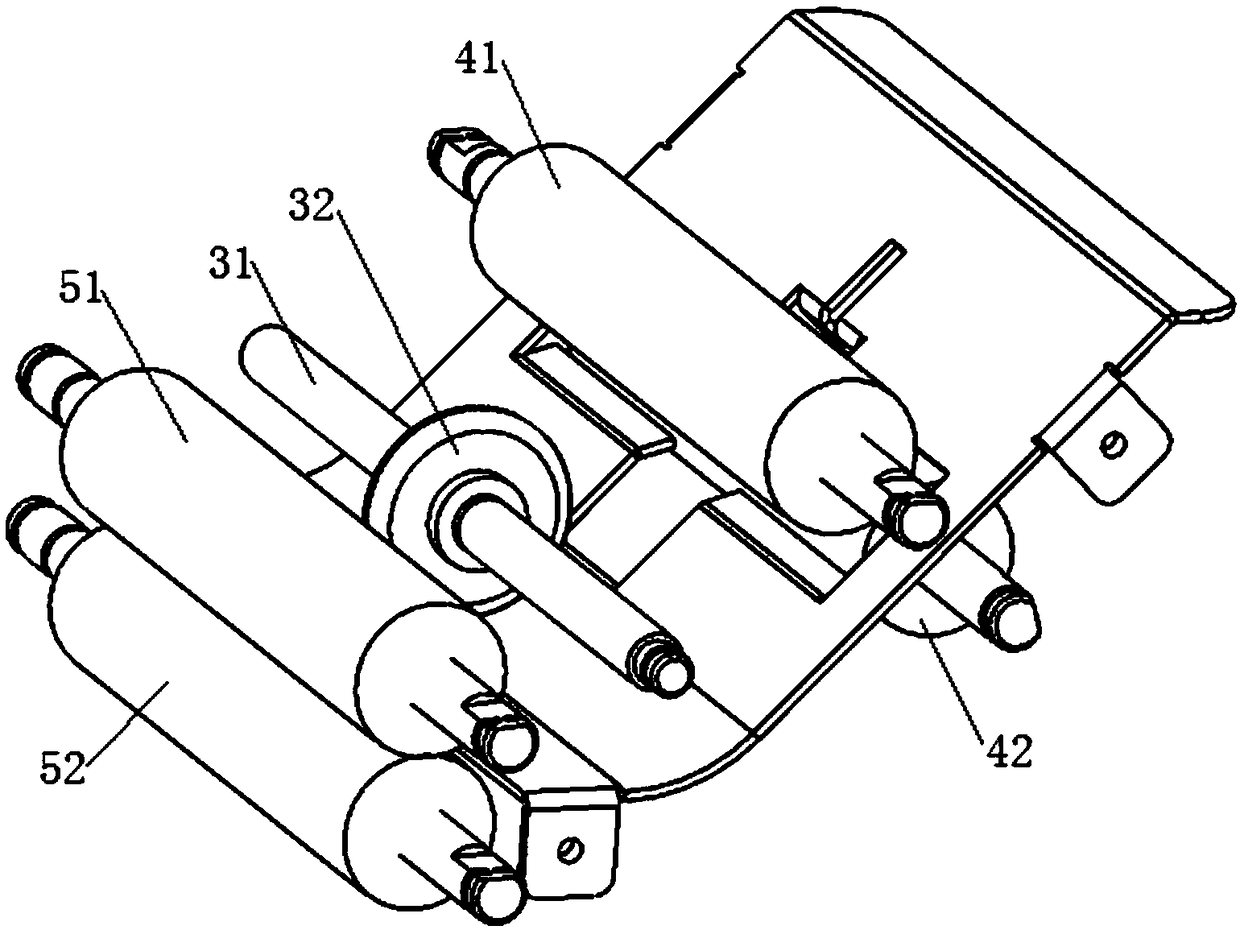

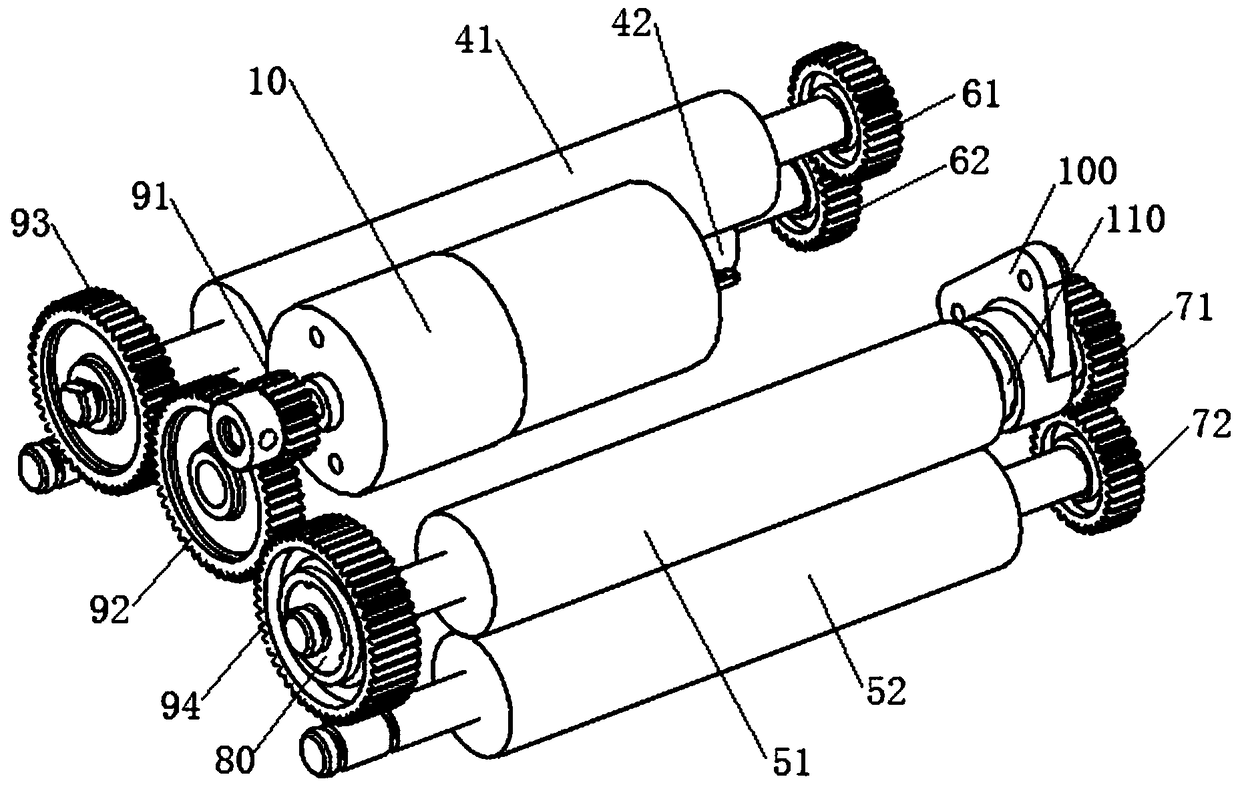

[0045] like Figure 1~4 Shown, a kind of tearing paper device, it is used for tearing to have tearing line and continuous paper, and it comprises frame, paper feeding roller group, paper outlet roller group, power transmission mechanism and paper push-off piece; Wherein,

[0046] A paper passage is arranged in the frame, and the paper passage has a curved section;

[0047] The paper feed roller group, the paper ejector and the paper discharge roller group are arranged in sequence along the paper advance direction of the paper passage;

[0048] The paper feed roller group is movably connected to the frame, and when the paper feed roller group is driven to move, the paper feed roller group is used to drive the paper to move in the paper forward direction or the paper backward direction in the paper passage;

[0049] The paper discharge roller group is movably connected to the frame. When the paper discharge roller group is driven to move, the paper discharge roller group is use...

Embodiment 2

[0073] A method for tearing paper, the method is used for tearing continuous paper with a tear line, the steps of the method include:

[0074] A paper channel with a curved section for conveying paper is provided, and a paper push-off member is arranged corresponding to the curved section of the paper channel. When the paper passes through the curved section in the paper channel and is transported to a predetermined position, the front end of the paper is fixed, and then Feed the paper in the backward direction of the paper, and push away the tear line of the paper through the paper pushing member during the straightening process of the paper.

[0075] The paper tearing method is realized based on the paper tearing device provided with the paper conveying distance control system in the first embodiment, the number of papers required is set to n, the length of a single paper is x, the paper reference position point and the paper breaking piece The distance between the centers o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com