Film-tearing equipment based on knurling film-removing mechanism and working method thereof

A technology of knurling and equipment, which is applied in the field of film tearing equipment based on the knurling film-lifting mechanism, can solve problems such as difficulty in tearing the film, and achieve the effects of increasing the adhesion area, good tearing effect, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

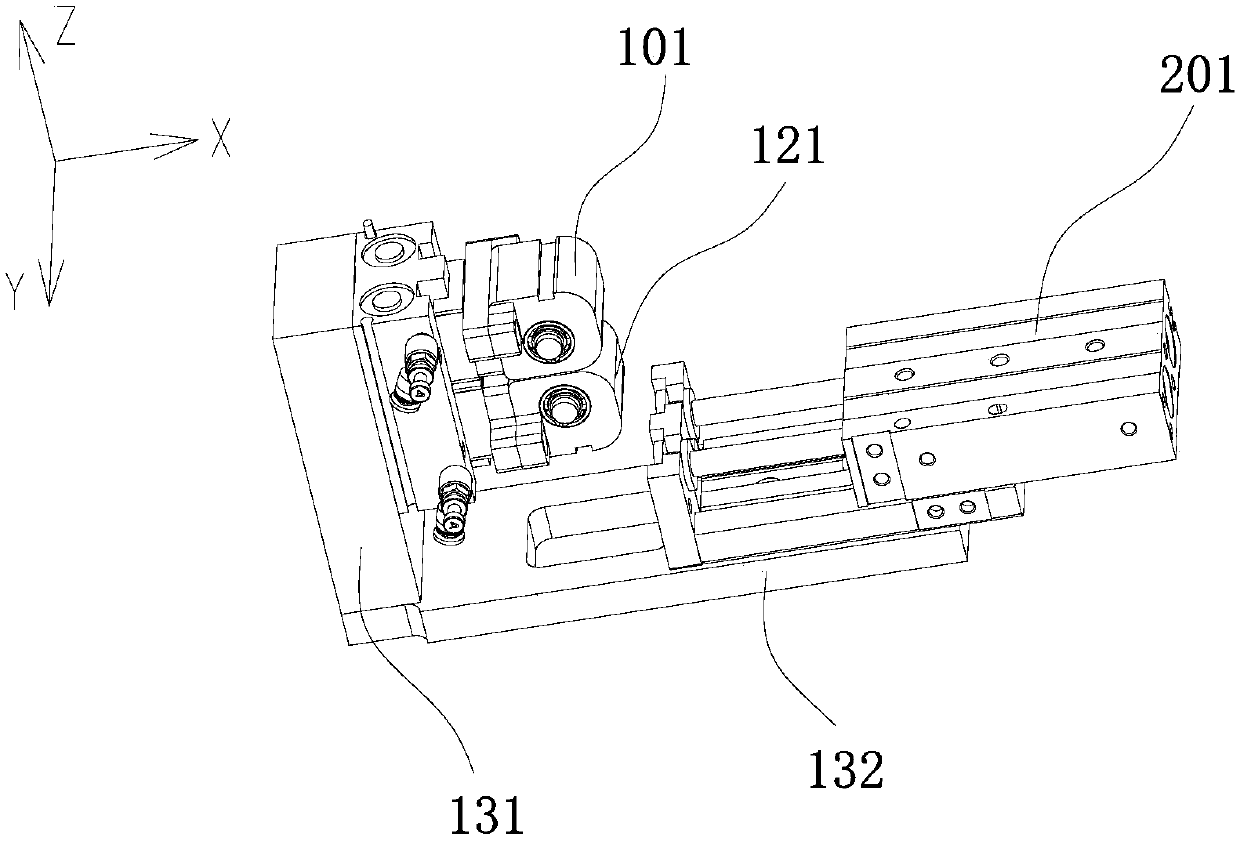

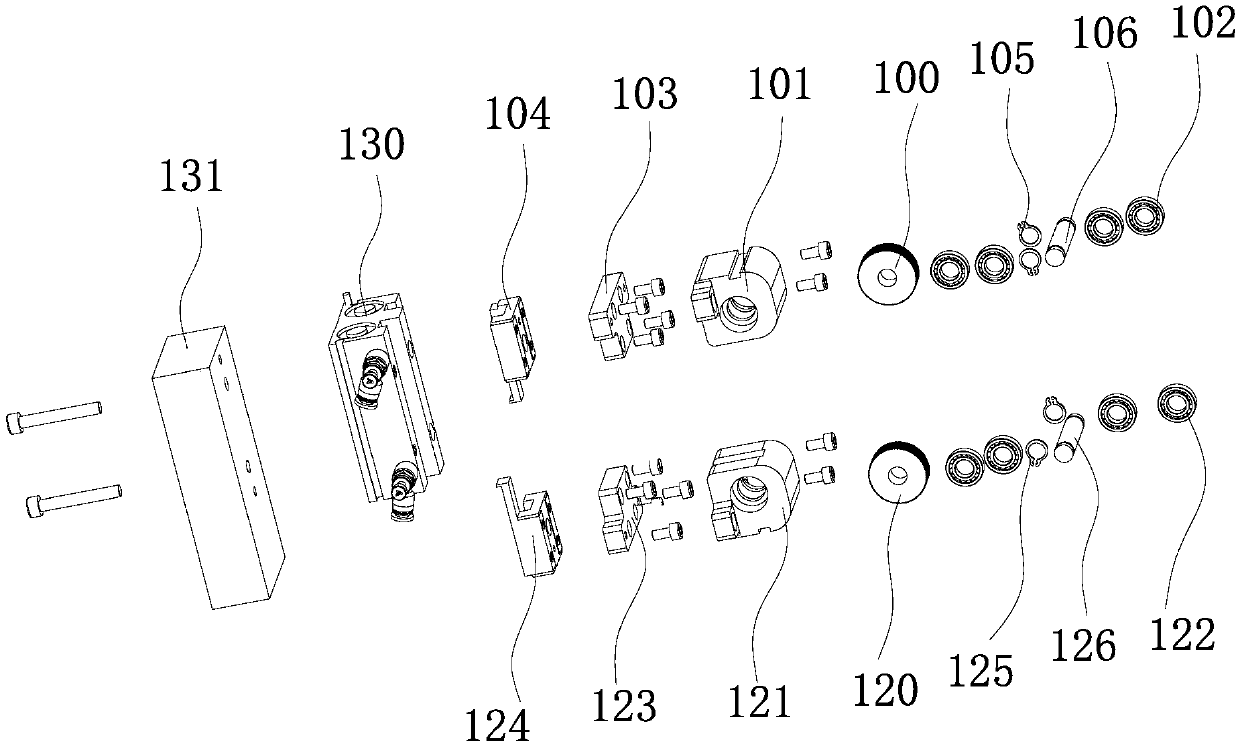

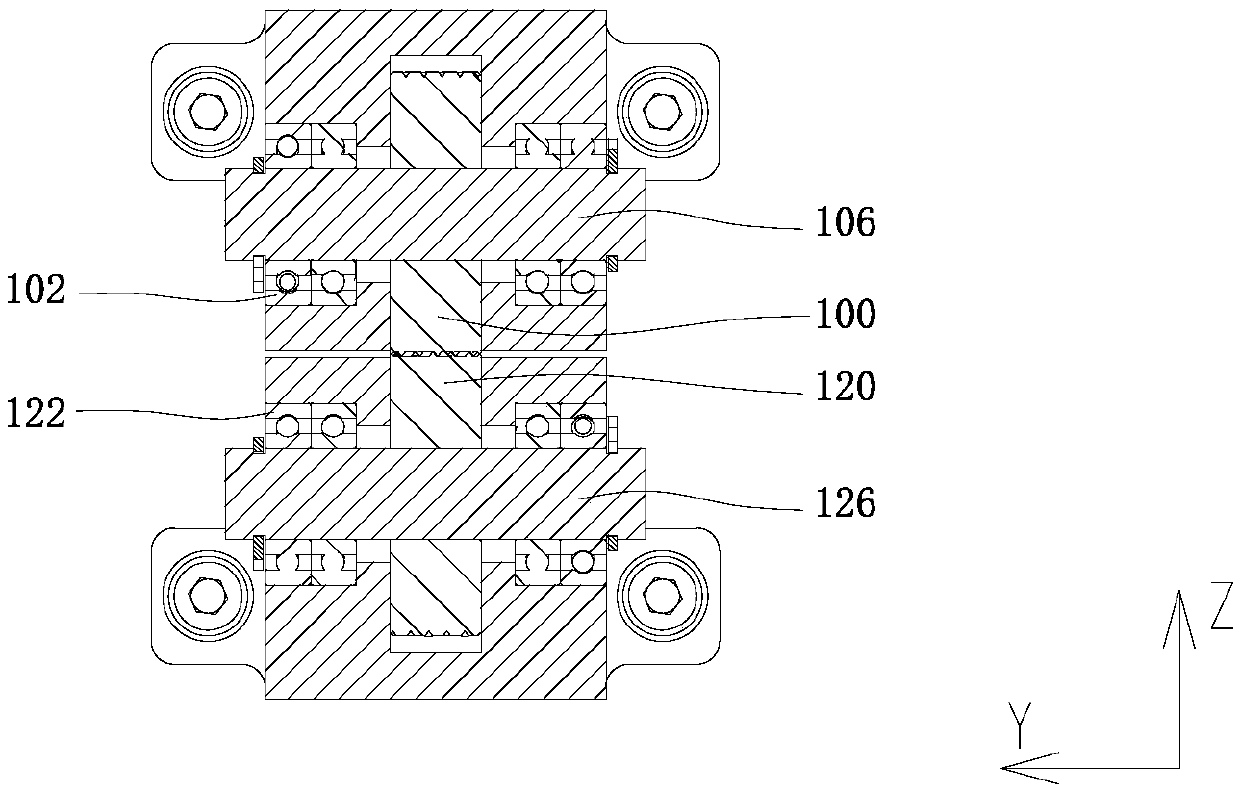

[0049] Preferred embodiment three: the third power device 130 is a double-acting cylinder, the first knurled wheel seat 101 is fixed on the first slider 104 through the first slider connector 103, and the first slider 104 is slidably installed On the upper movable end of the third power device 130, the second knurled wheel seat 121 is fixed on the second slider 124 through the second slider connector 123, and the second slider 124 is slidably installed on the third On the lower movable end of the power unit 130, the fixed end of the third power unit 130 is installed on the movable end of the fourth power unit 201 through an L-shaped connector; the first slider 104 is provided with a first gap for moving up and down, The second sliding block 124 is provided with a second gap for moving up and down, which is convenient for adjusting the Z-axis coordinates of the first knurled wheel seat 101 and the second knurled wheel seat 121 .

[0050] Preferred Embodiment 4: As a further ste...

Embodiment 7

[0059] Preferred Embodiment 7: Between the second film tearing mechanism 305 and the frame 300, there is also a fifteenth power device 321 that moves linearly along the X-axis direction, and the fifteenth power device 321 can adjust the second adhesive tape 307 and the The distance in the X-axis direction between the film-forming regions of the two release films 112, the fifteenth power device 321 is a cylinder or an electric screw.

[0060] A working method of a film tearing device based on a knurling film raising mechanism, comprising the following steps:

[0061] Step 1. Place the FPC 110 provided with the first release film 111 and / or the second release film 112 on the shaping platform 202;

[0062] Step 2, adjust the position of the first positioning plate 203 through the X-axis electric screw 208, adjust the position of the second positioning plate 204 through the Y-axis electric screw 209, and position the FPC 110 in the XY plane;

[0063] Step 3, start the vacuum gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com