A food waste disposer

A technology for food waste treatment and food waste, which is applied in grain treatment and other directions, can solve the problems of small space for improvement of pulverization performance, wear of upper pulverization cavity, blockage of sewer pipes, etc., and achieves the effect of simple structure, improved pulverization fineness, and prolonged life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

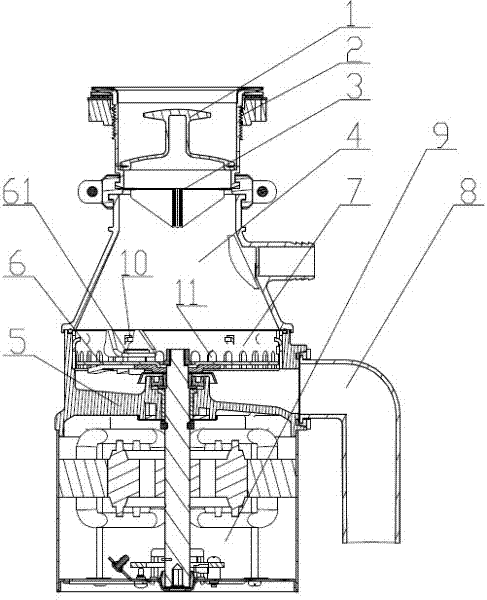

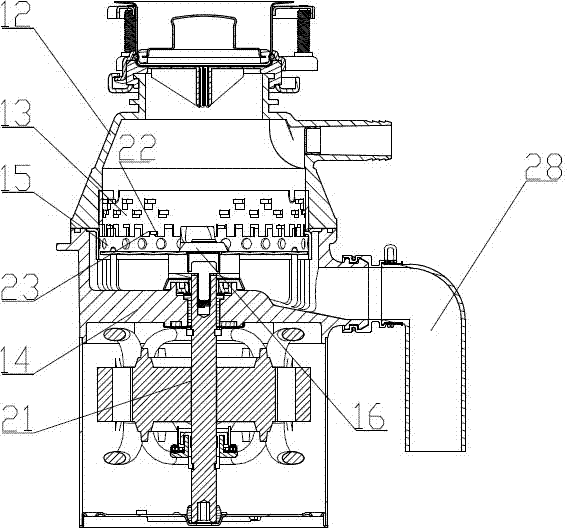

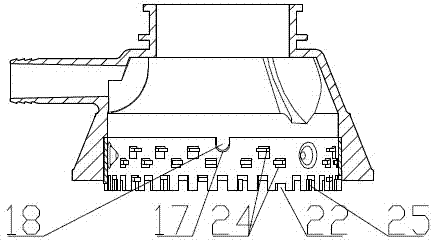

[0024] The structure diagram of the present invention is as figure 2 , 3 , 4, the food waste disposer of the present invention includes a housing 29, an upper crushing chamber 12, a lower crushing chamber 14, a cutter head assembly 16, and a motor assembly 21, wherein the upper crushing chamber 12 for holding food waste Set on the upper part of the housing 29, the lower crushing chamber 14 is arranged under the bottom of the upper crushing chamber 12, the upper grinding ring 13 is installed in the upper crushing chamber 12, and the cutter head assembly 16 is placed in the lower crushing chamber 14 to drive the cutter head The motor assembly 21 for the rotation of the assembly 16 is installed in the lower part of the housing 29 , wherein the lower grinding ring 15 is installed in the lower crushing chamber 14 .

[0025] The upper grinding ring 13 is fastened together with the positioning protrusion 23 provided on the lower grinding ring 15 through the positioning groove 22 pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com