Patents

Literature

56results about How to "Increase the speed of crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency crushing treatment device for construction waste

InactiveCN110000968AEvenly distributedImprove crushing effectUsing liquid separation agentPlastic recyclingArchitectural engineeringConstruction waste

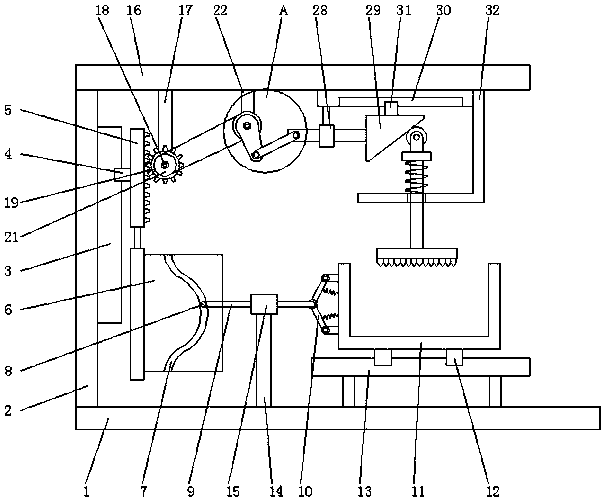

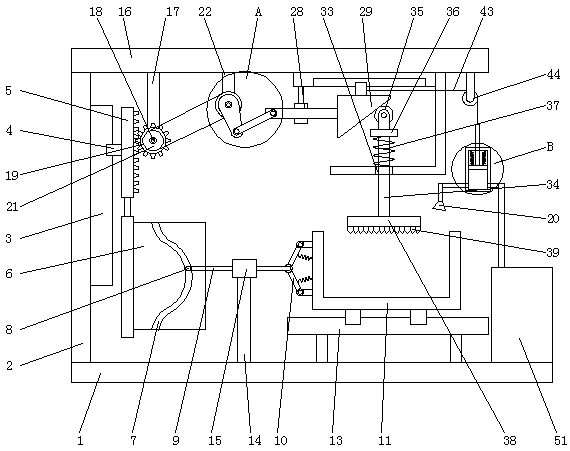

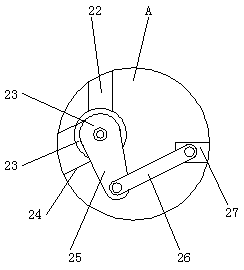

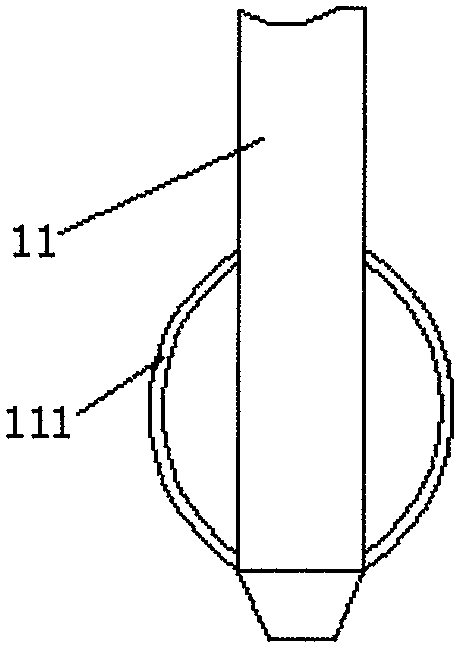

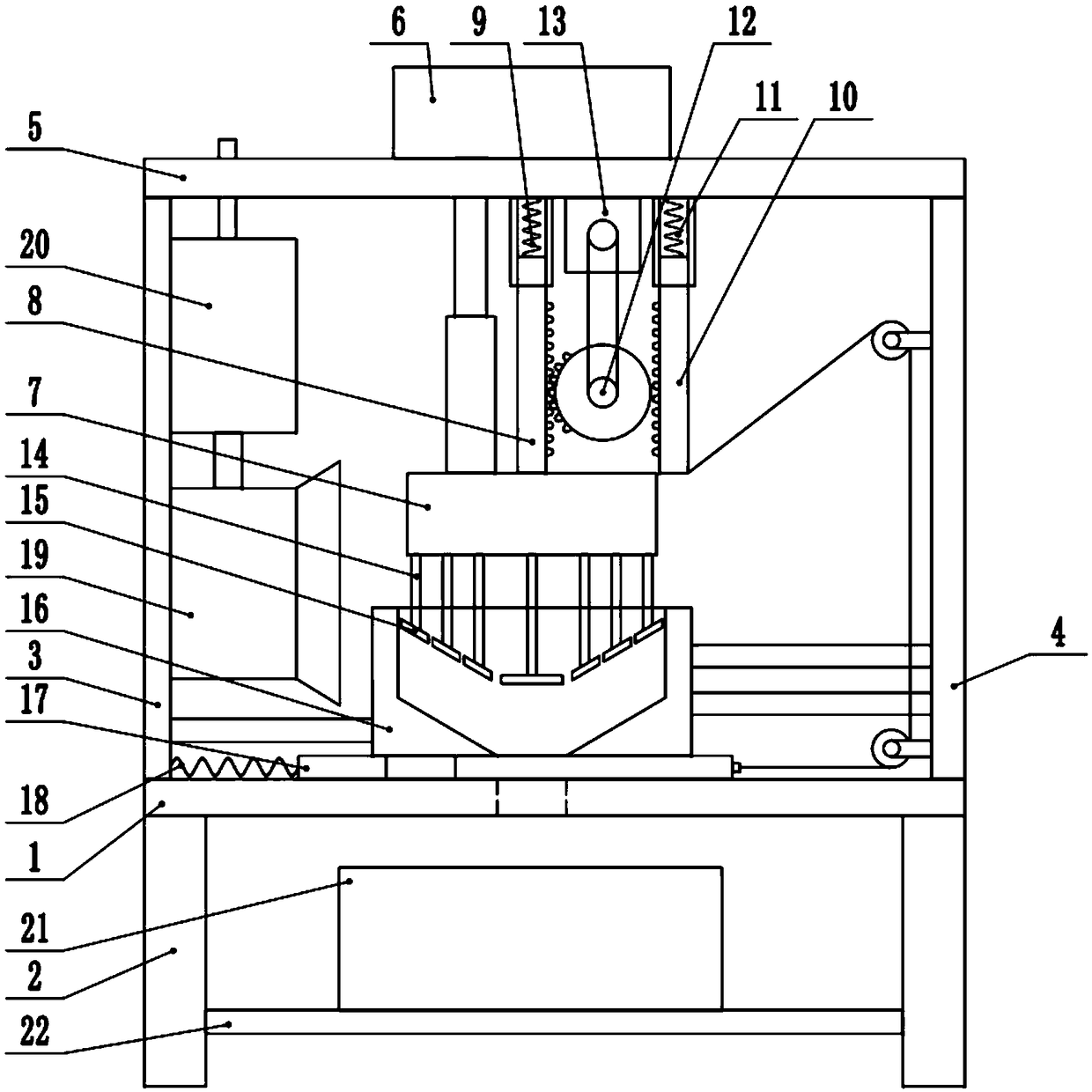

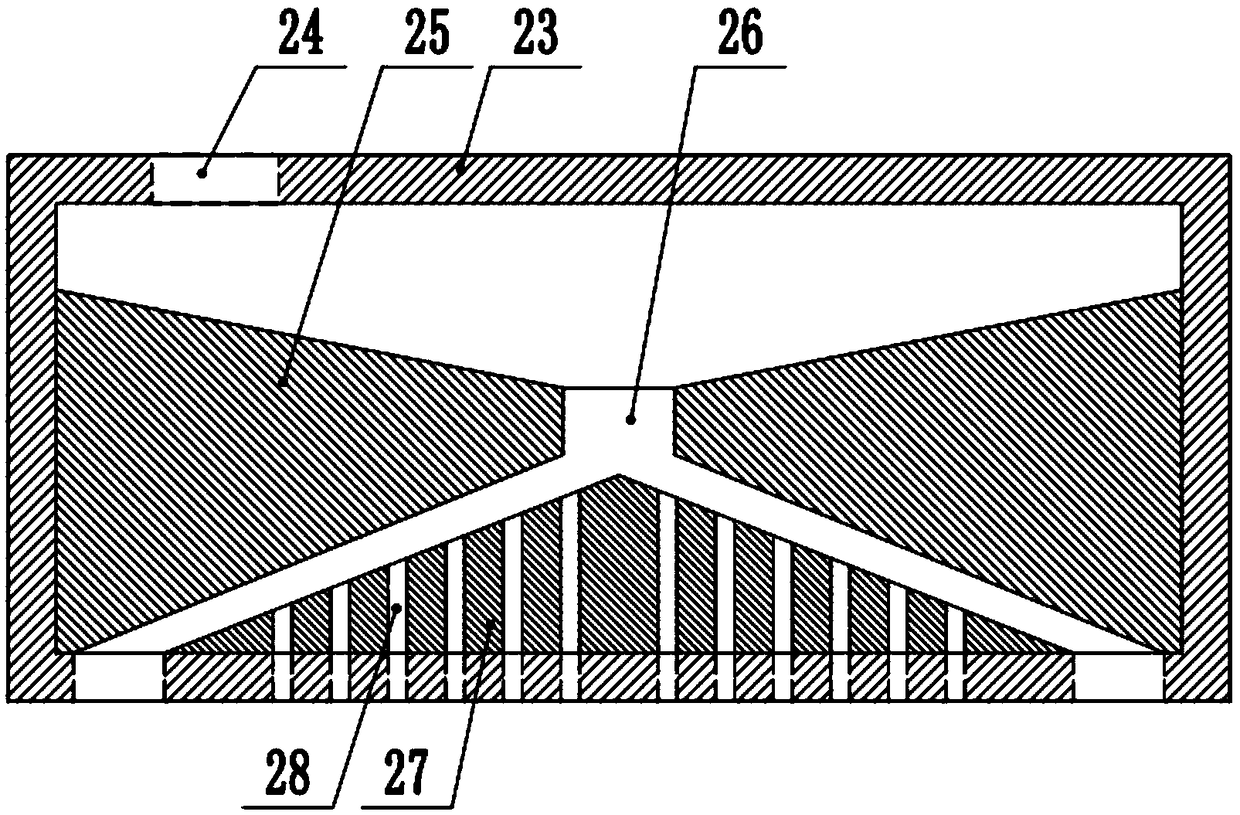

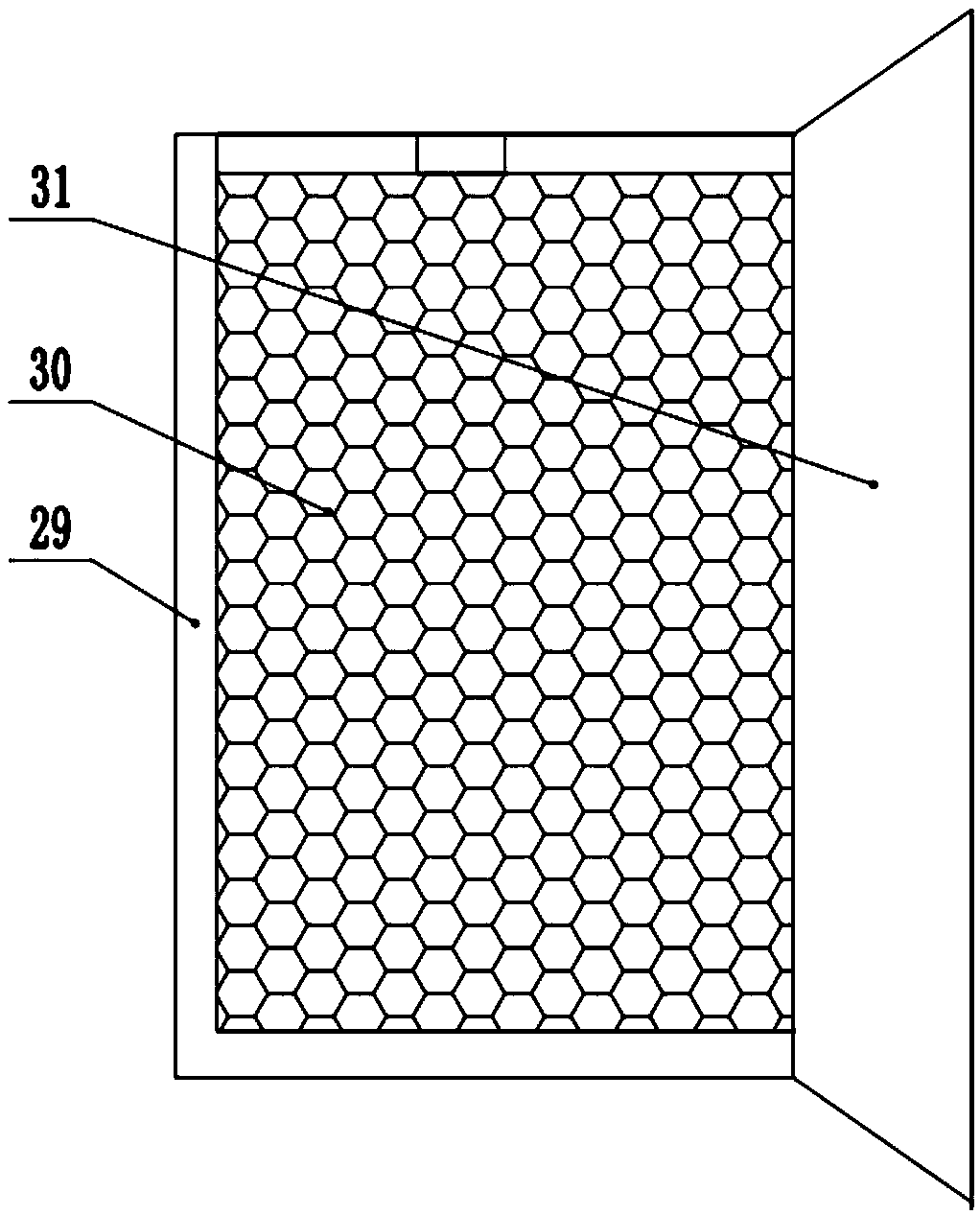

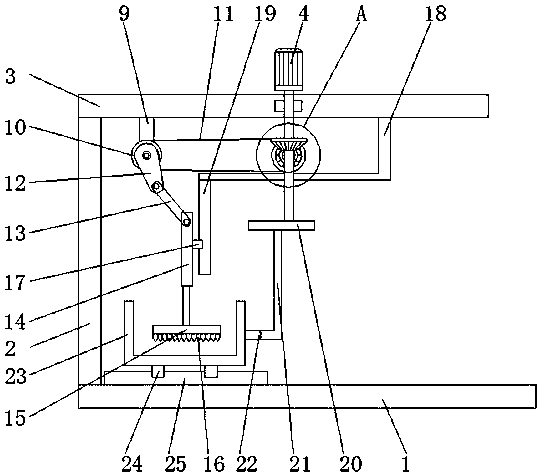

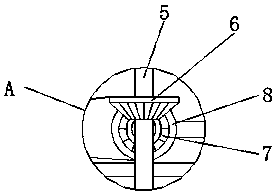

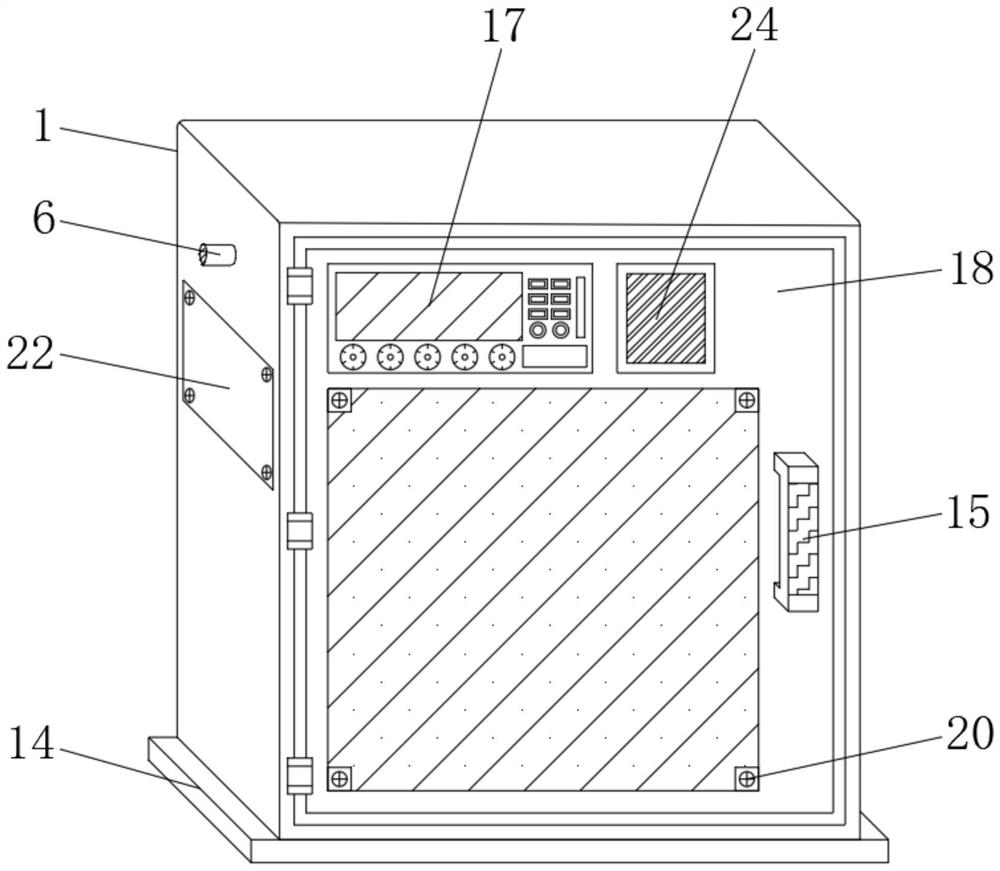

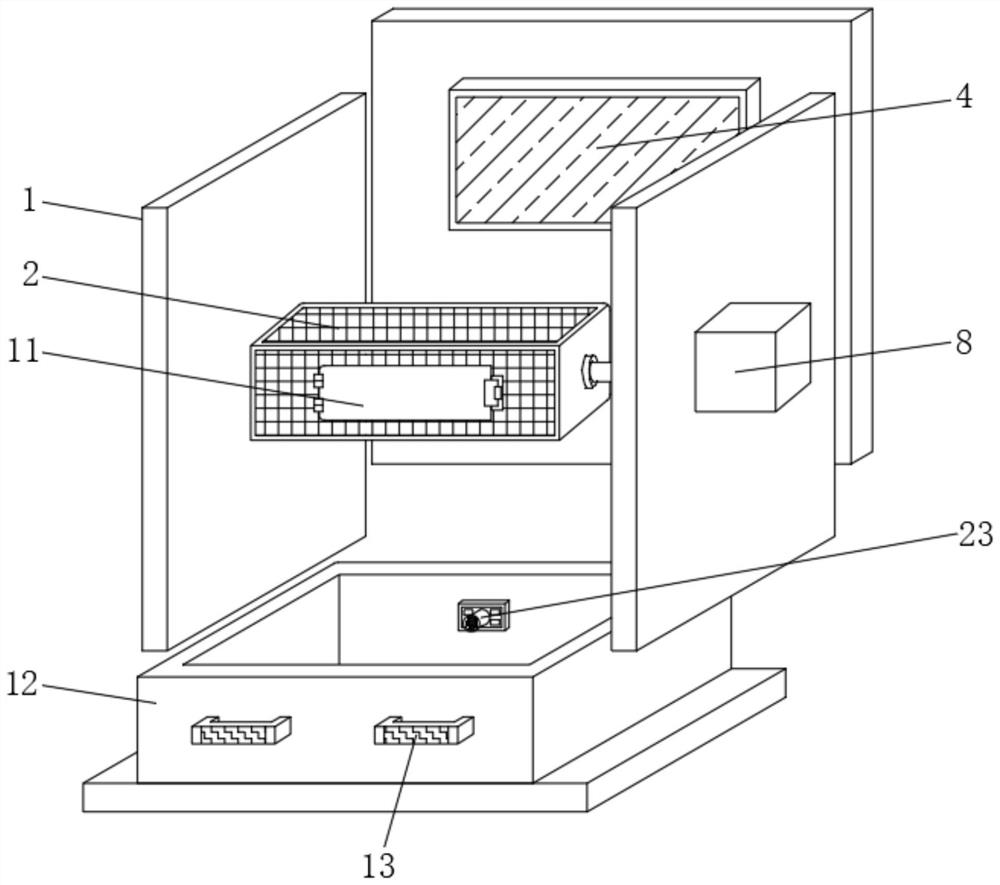

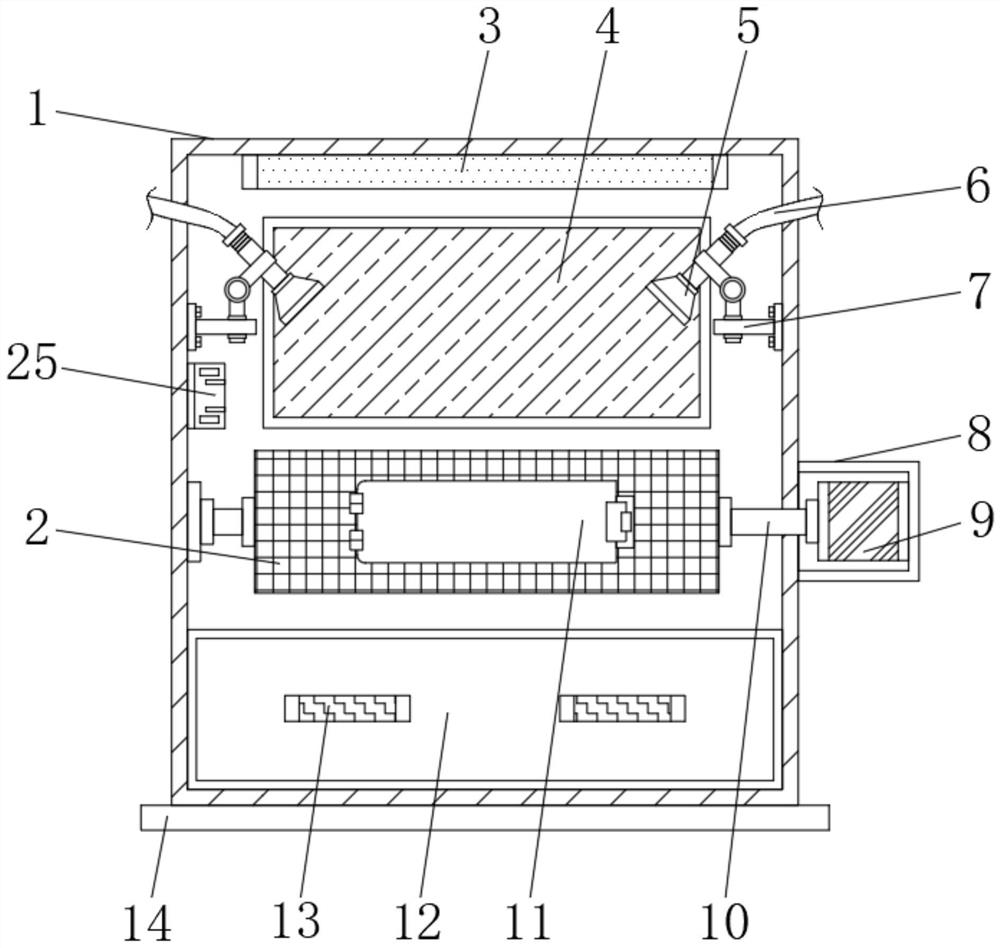

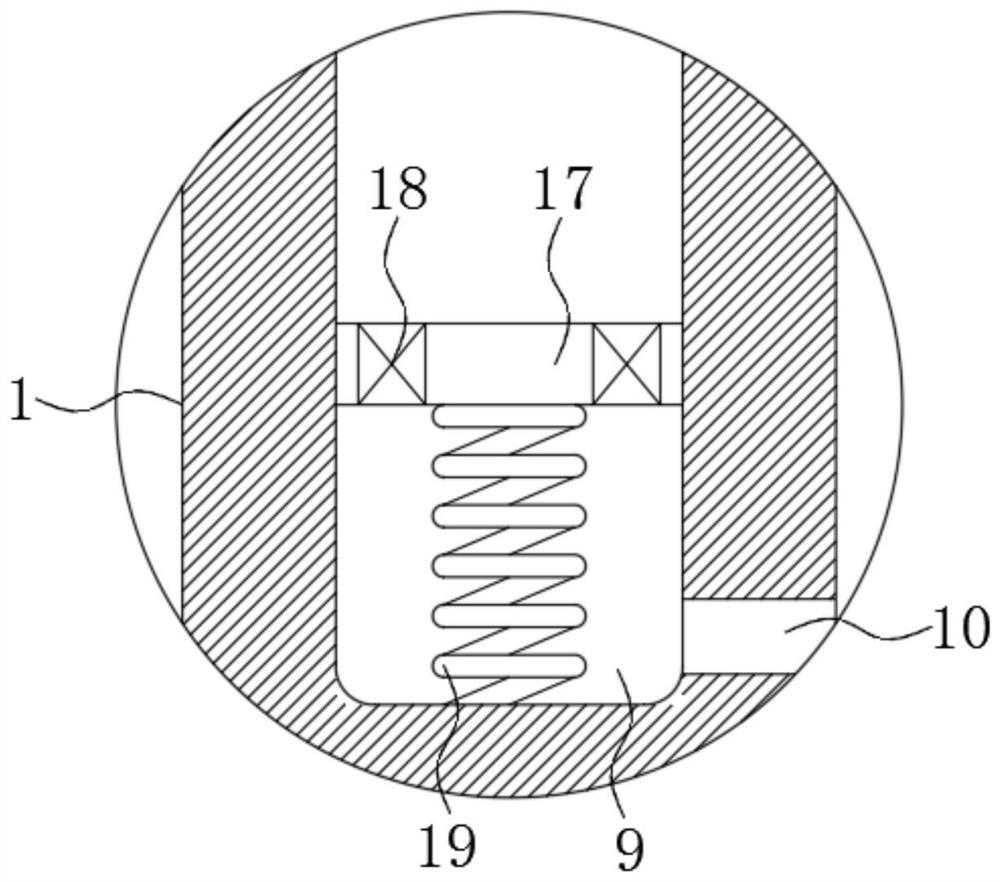

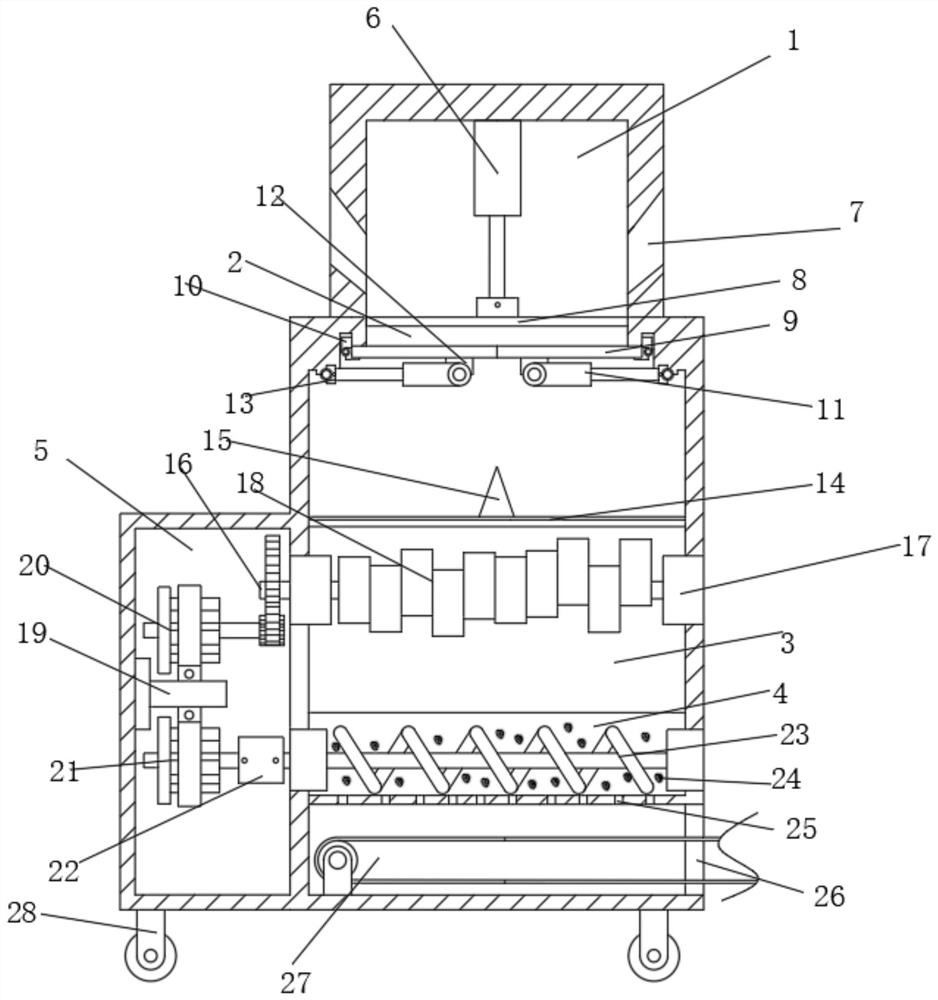

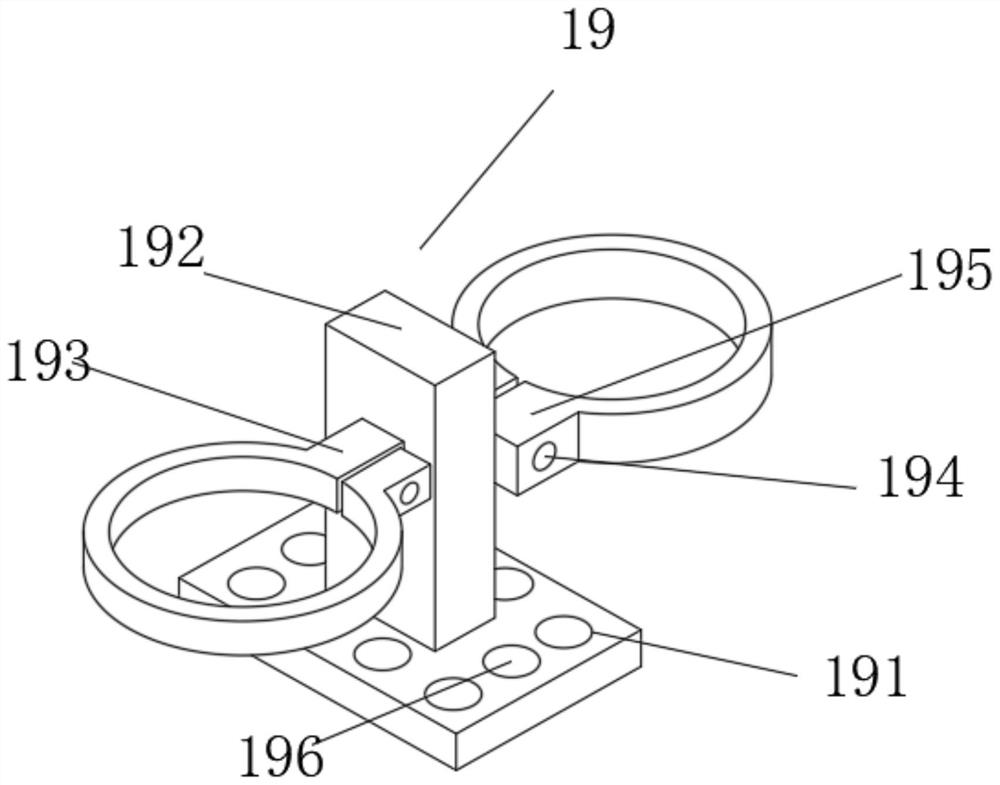

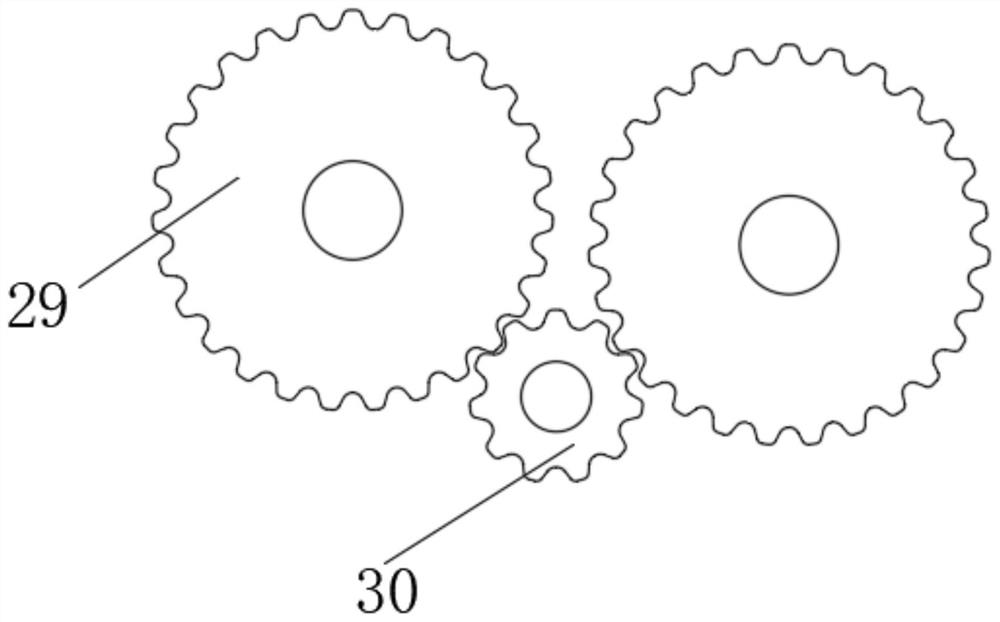

The invention discloses a high-efficiency crushing treatment device for construction waste. The high-efficiency crushing treatment device comprises a bottom plate, one side of the bottom plate is provided with a side plate, the side plate is provided with a first sliding rail, the first sliding rail is provided with a first sliding block in a matched manner, a rack is fixed on one side of the first sliding block, a moving block is connected to the bottom of the rack, an S-shaped through hole is formed inside the moving block, a sliding shaft is arranged inside the S-shaped through hole, a first moving rod is hinged to the sliding shaft, and an elastic mechanism is connected to the tail end of the first moving rod; a crushing frame is connected to one side of the elastic mechanism, a secondsliding block is arranged at the bottom of the crushing frame, a second sliding rail is arranged on the bottom plate, and the second sliding block is connected to the surface of the second sliding rail in a sliding manner; and the bottom plate is provided with a support rod, the top of the support rod is provided with a first guide sleeve matched with the first moving rod, the top of the side plate is fixedly provided with a top plate, the bottom end of the top plate is fixedly provided with a first support rod, and the bottom of the first support rod is provided with a servo motor. The high-efficiency crushing treatment device achieves the effects of the good crushing effect, the high crushing speed and effective dust removal.

Owner:卢李娜

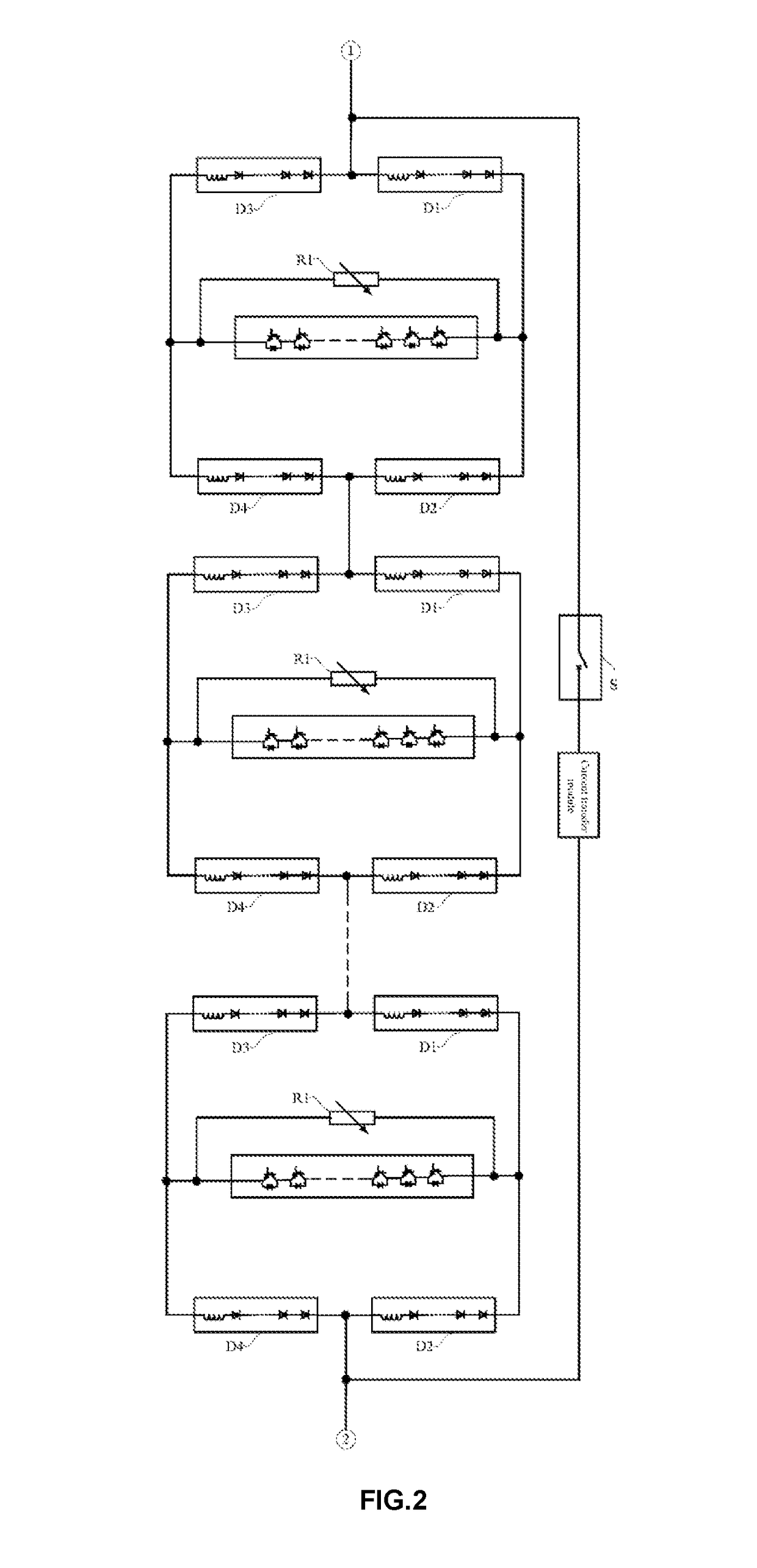

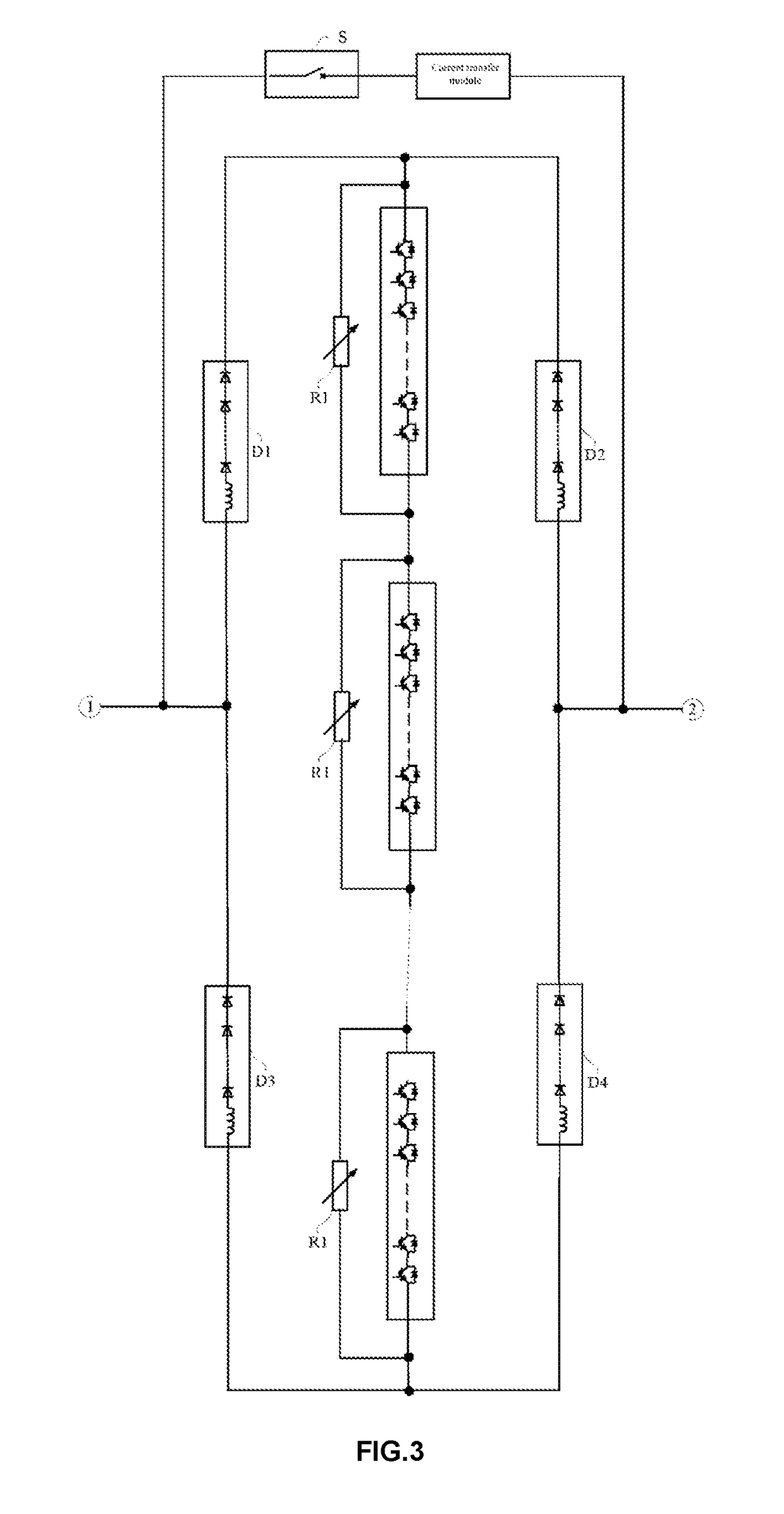

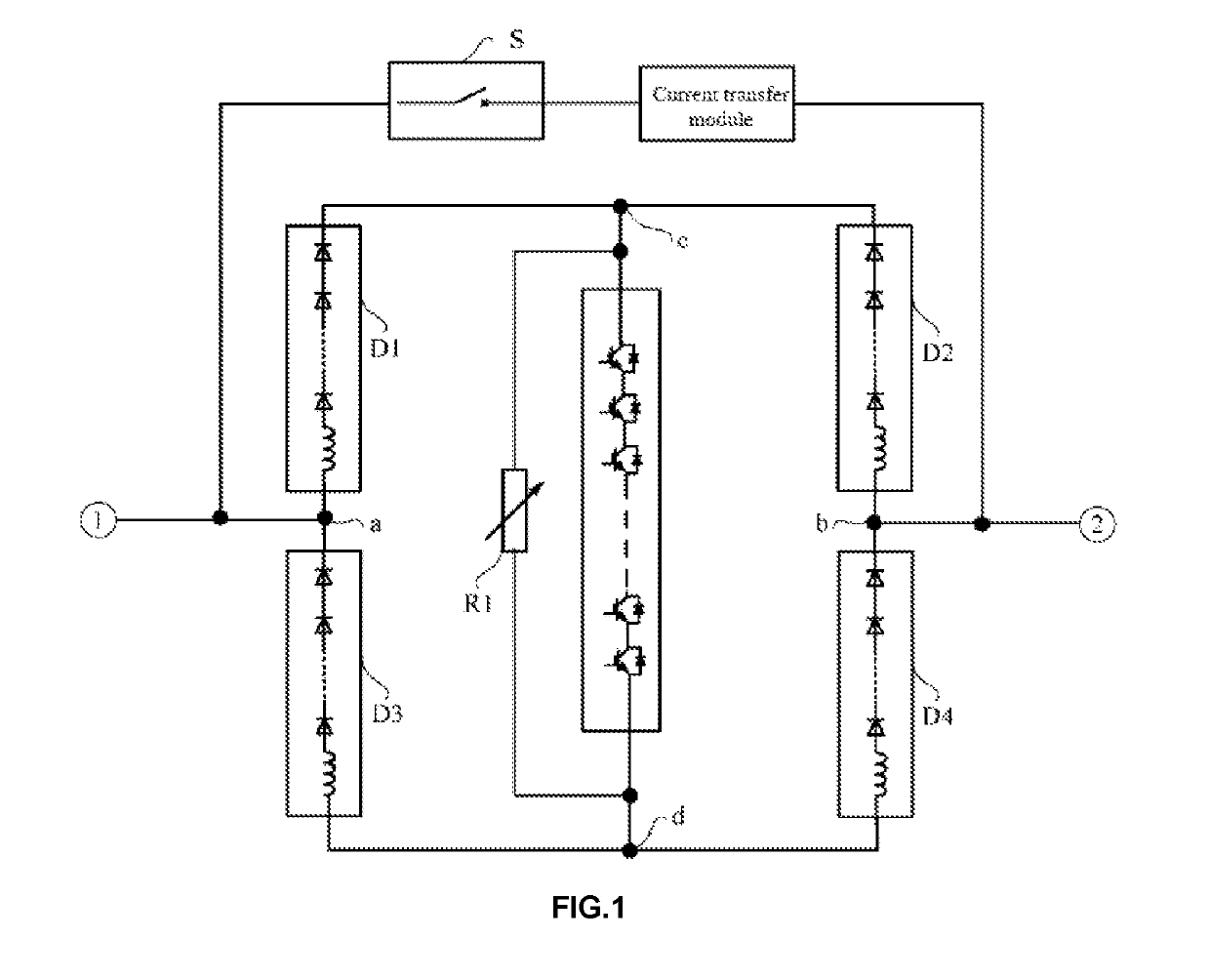

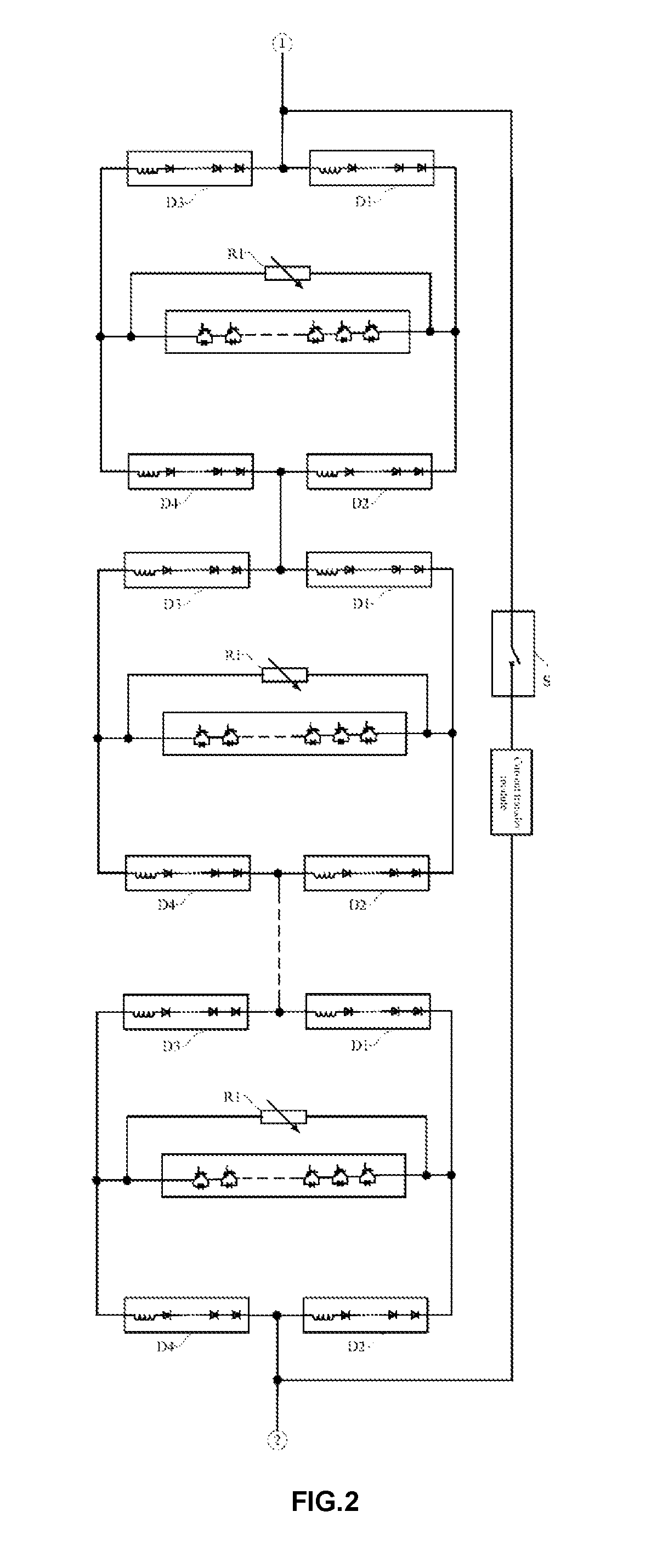

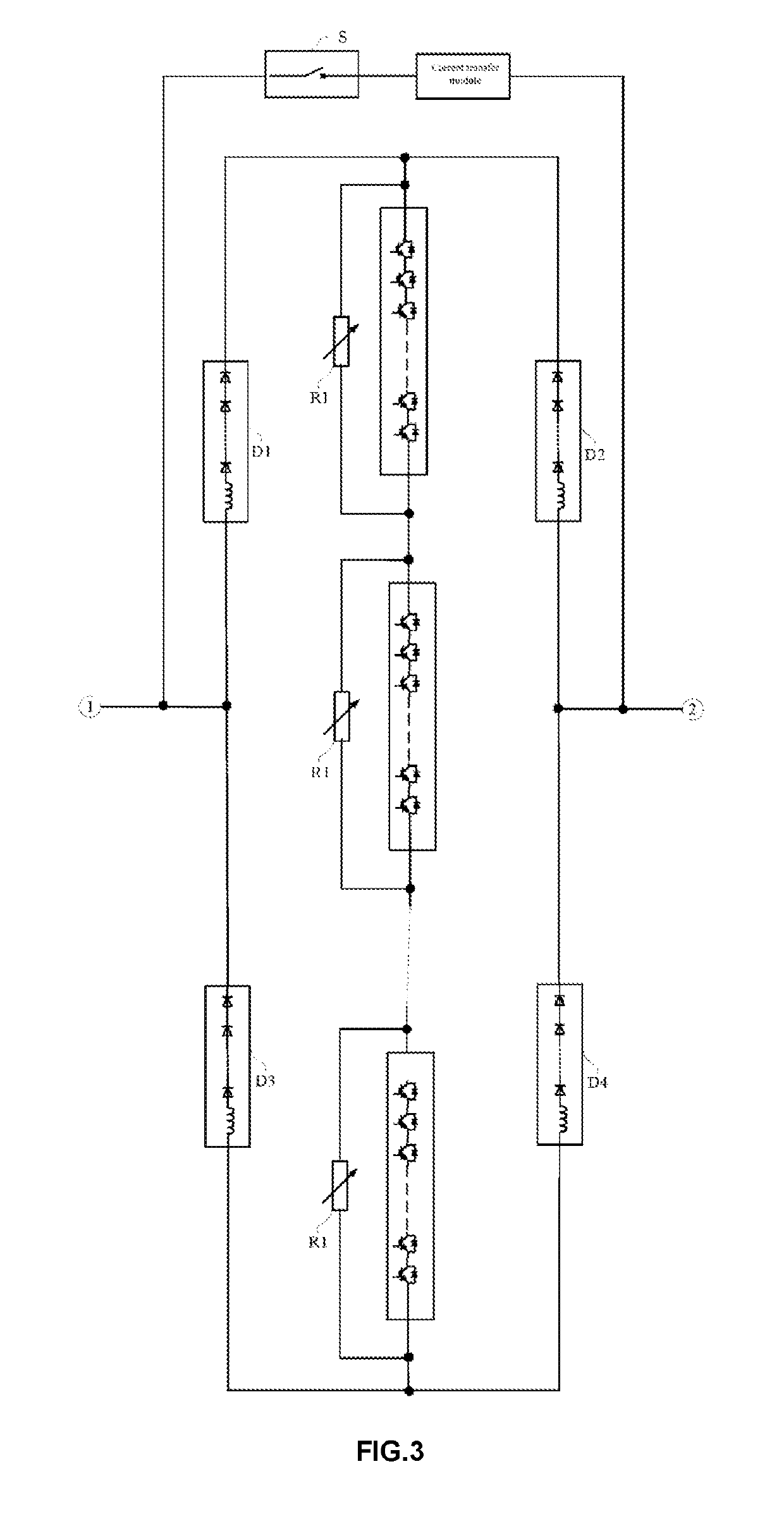

Direct Current Switch-Off Device And Control Method Thereof

ActiveUS20190020193A1Reduce equipment costsImprove scalabilityEmergency protective arrangements for automatic disconnectionHigh-tension/heavy-dress switchesNonlinear resistorElectrical resistance and conductance

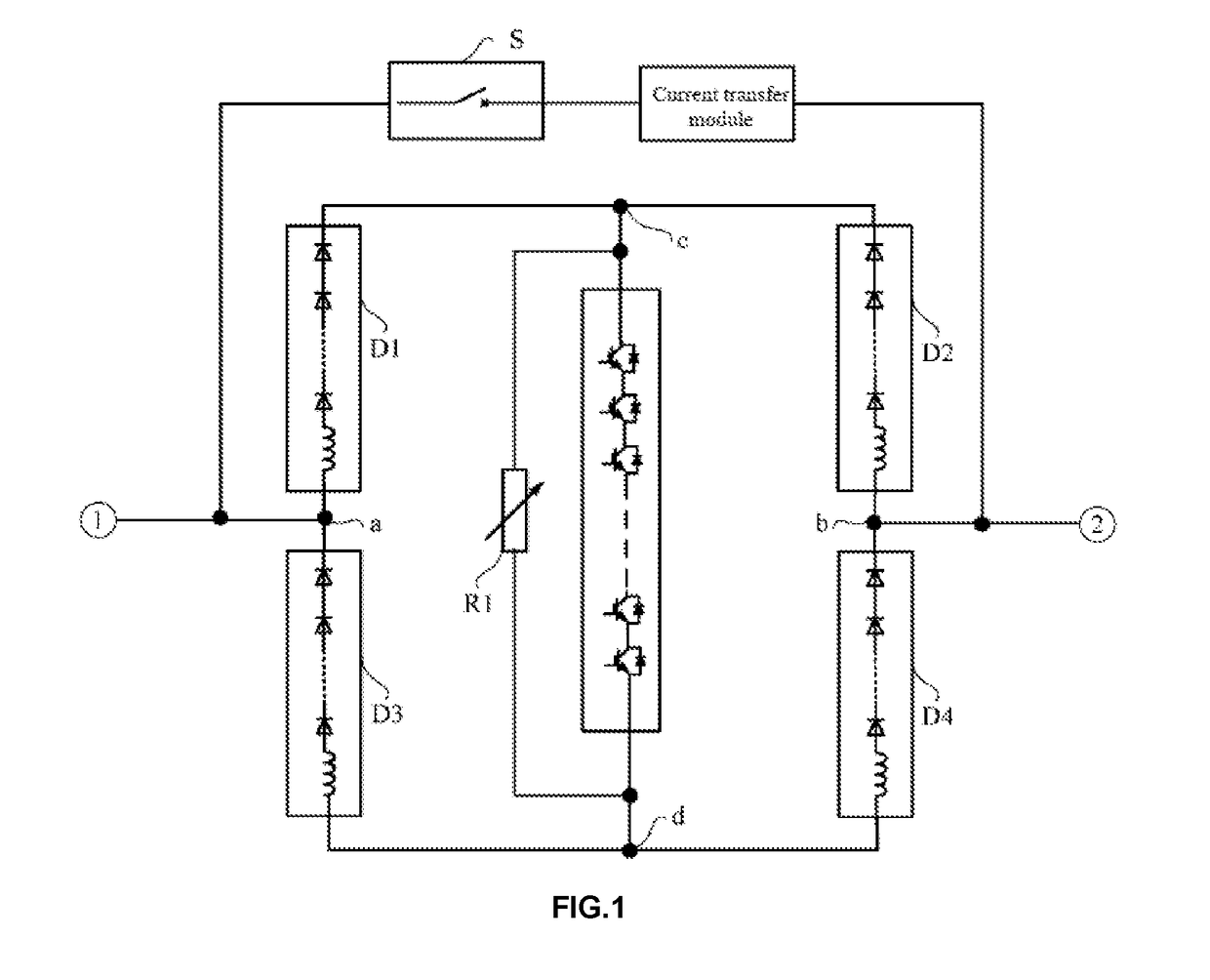

A direct current switch-off device comprises an on-state current branch circuit and a current commutating and breaking unit which are connected in parallel. The on-state current branch circuit has a mechanical switch (S) and a current transfer module which are connected in series. The current commutating and breaking unit comprises a bridge-type branch circuit and a current-breaking branch circuit. The current-breaking branch circuit and two bridge arms of the bridge-type branch circuit are connected in parallel. The current-breaking branch circuit comprises a nonlinear resistor (RI) and a valve group consisting of fully-controlled devices connected in series. The nonlinear resistor (RI) and the valve group are connected in parallel. Two ends of each fully-controlled device in the valve group are connected in parallel with a buffering and reclosing circuit.

Owner:NR ELECTRIC CO LTD +1

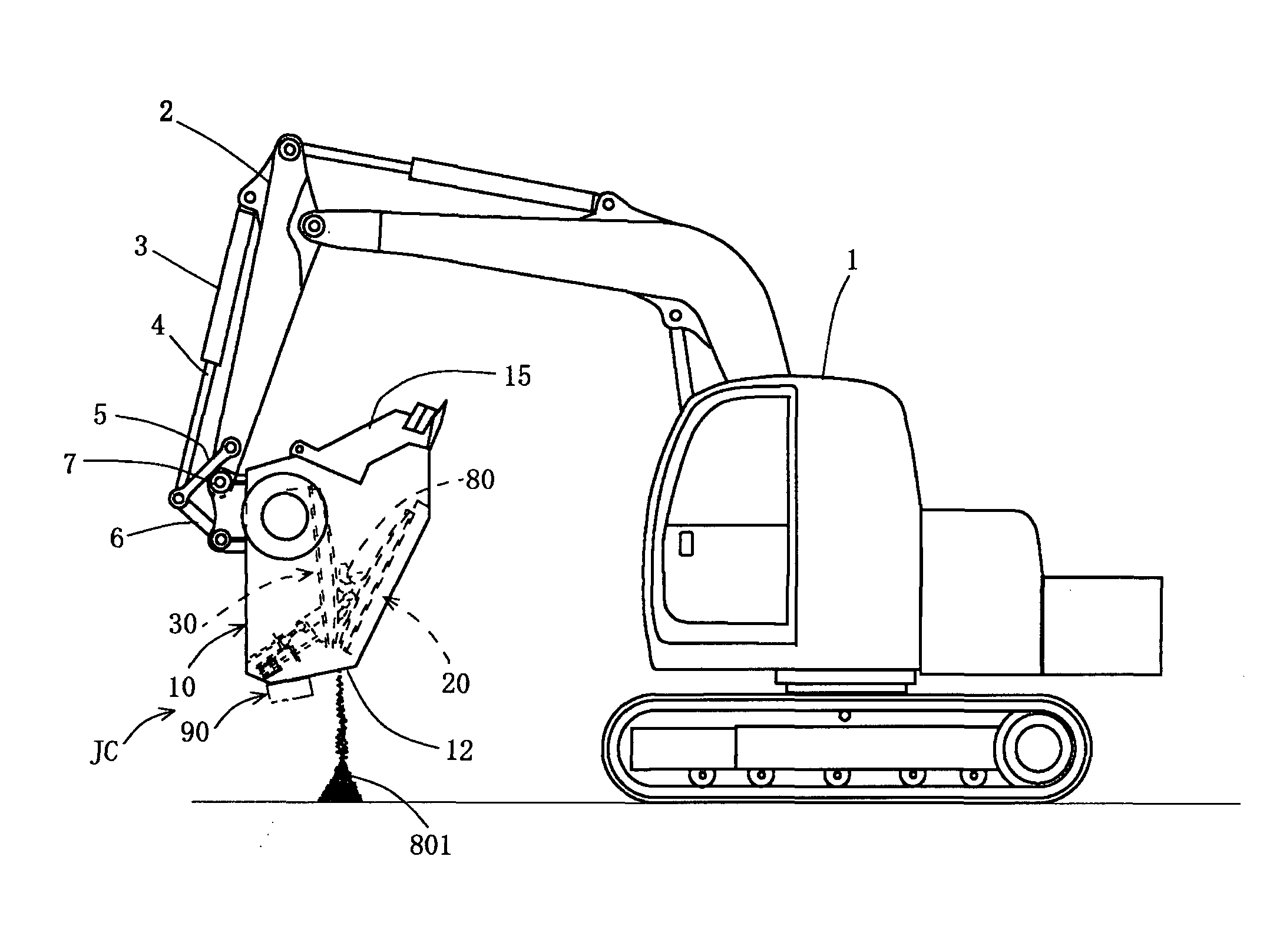

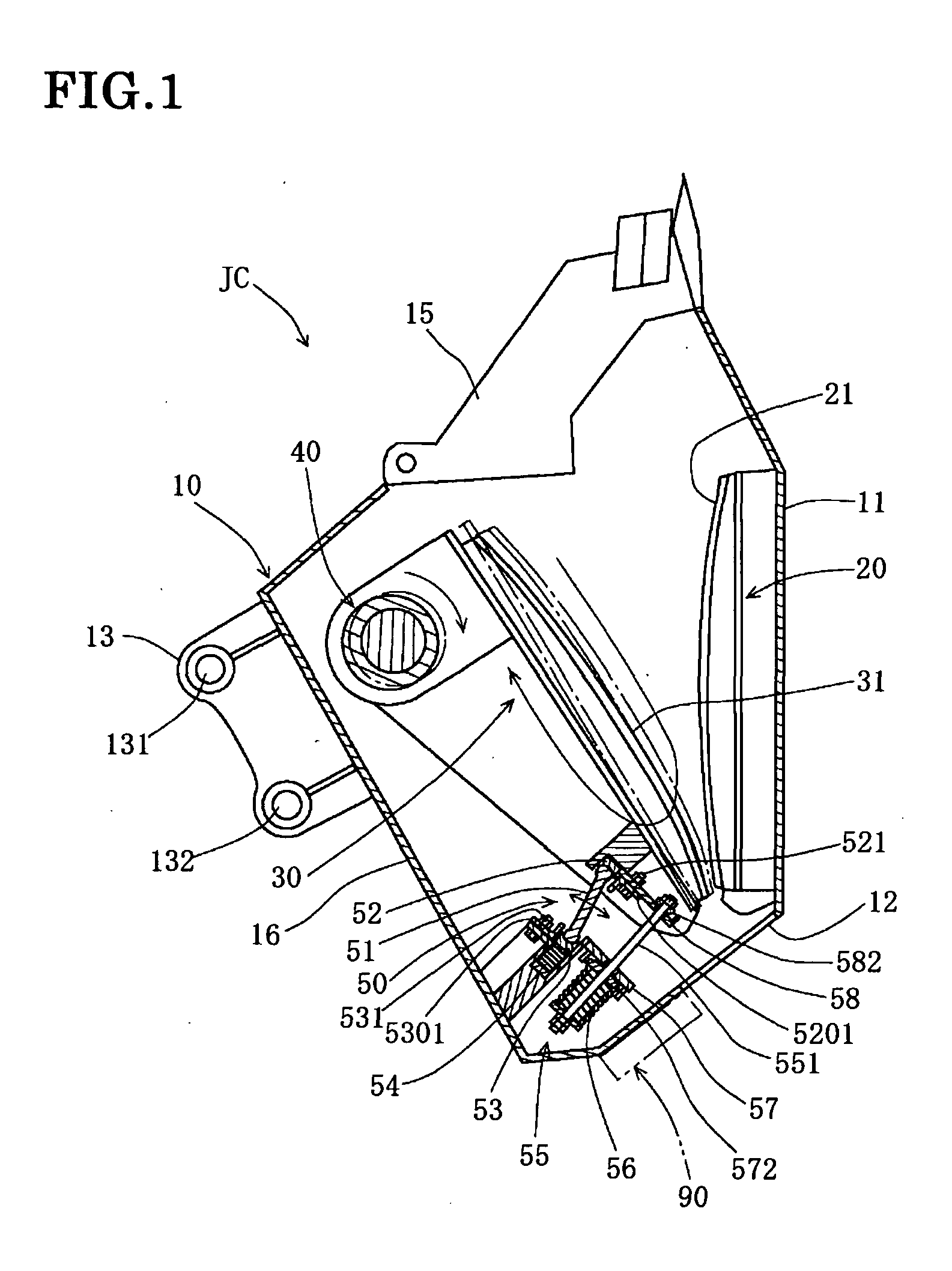

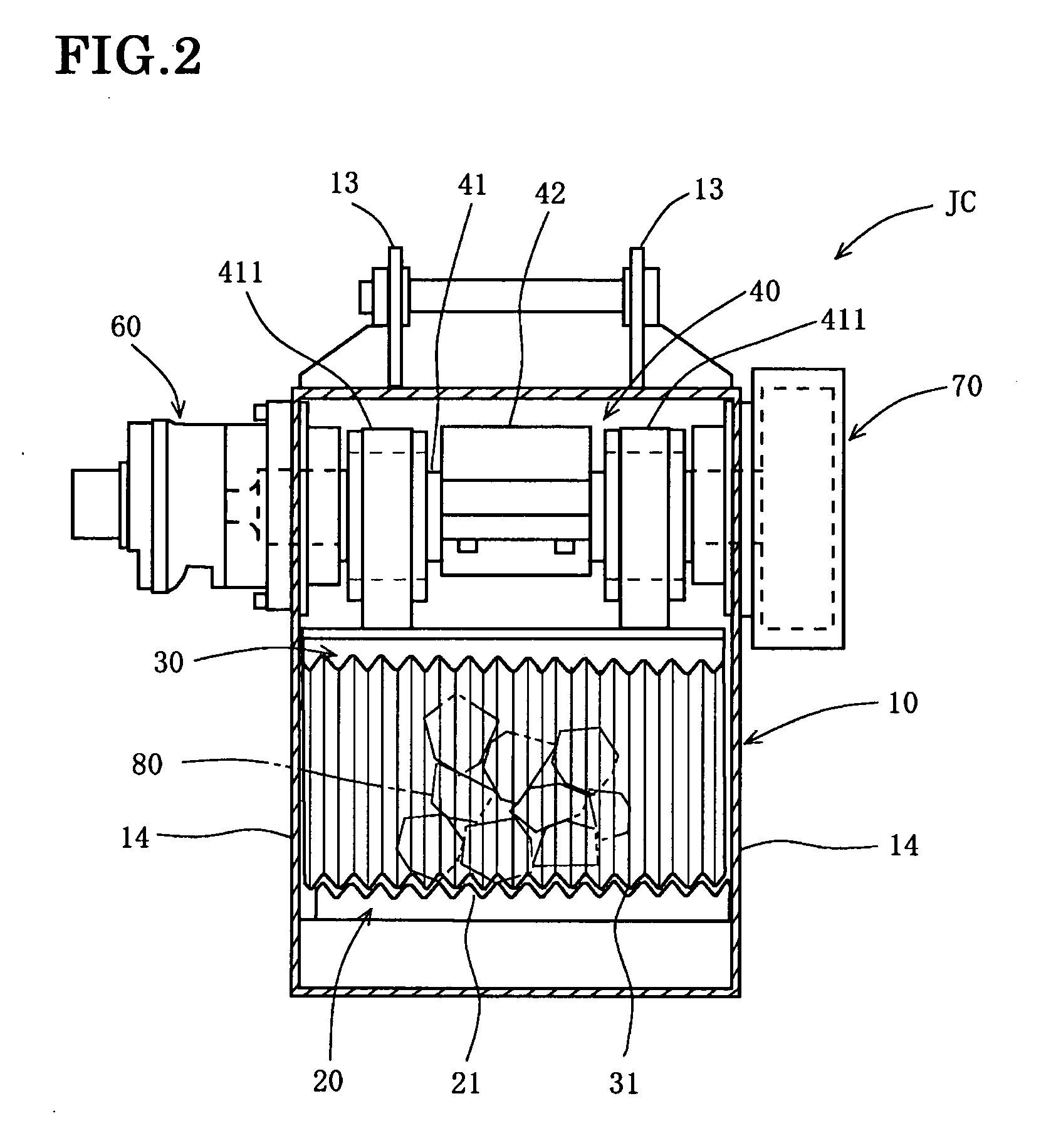

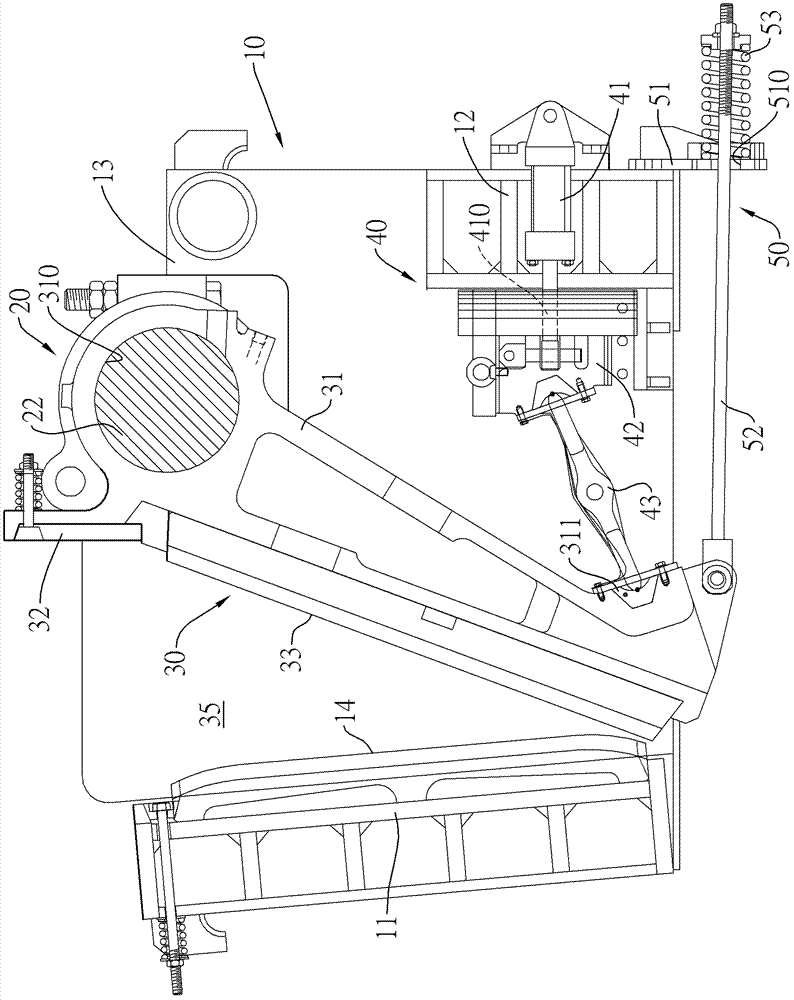

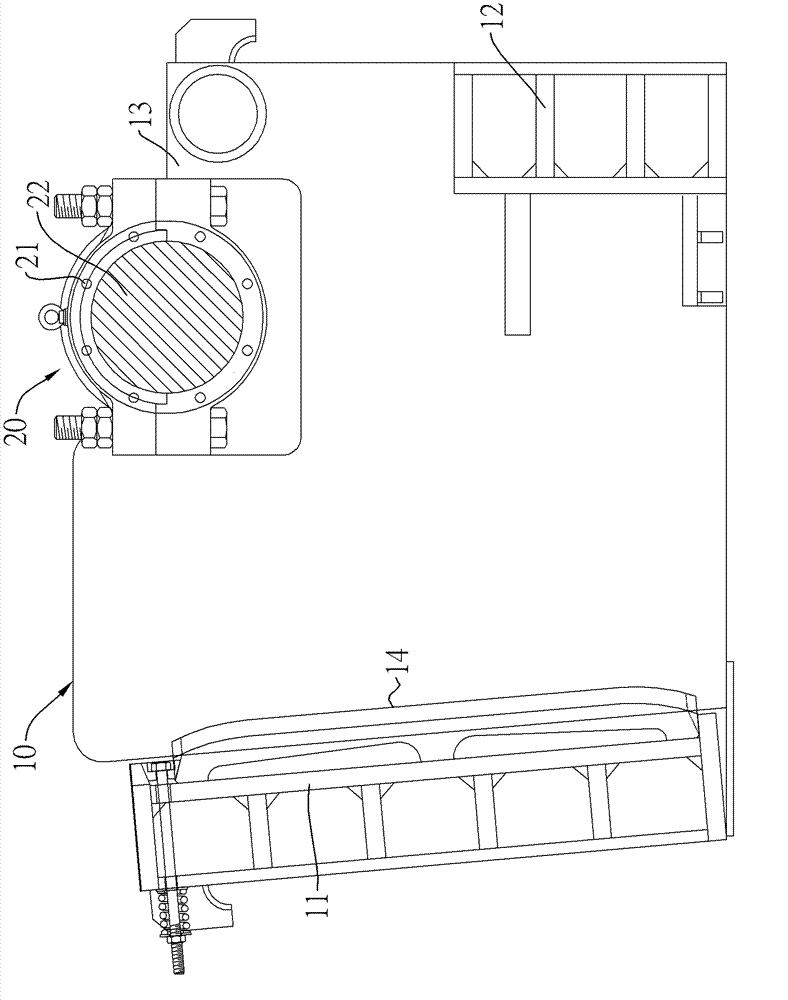

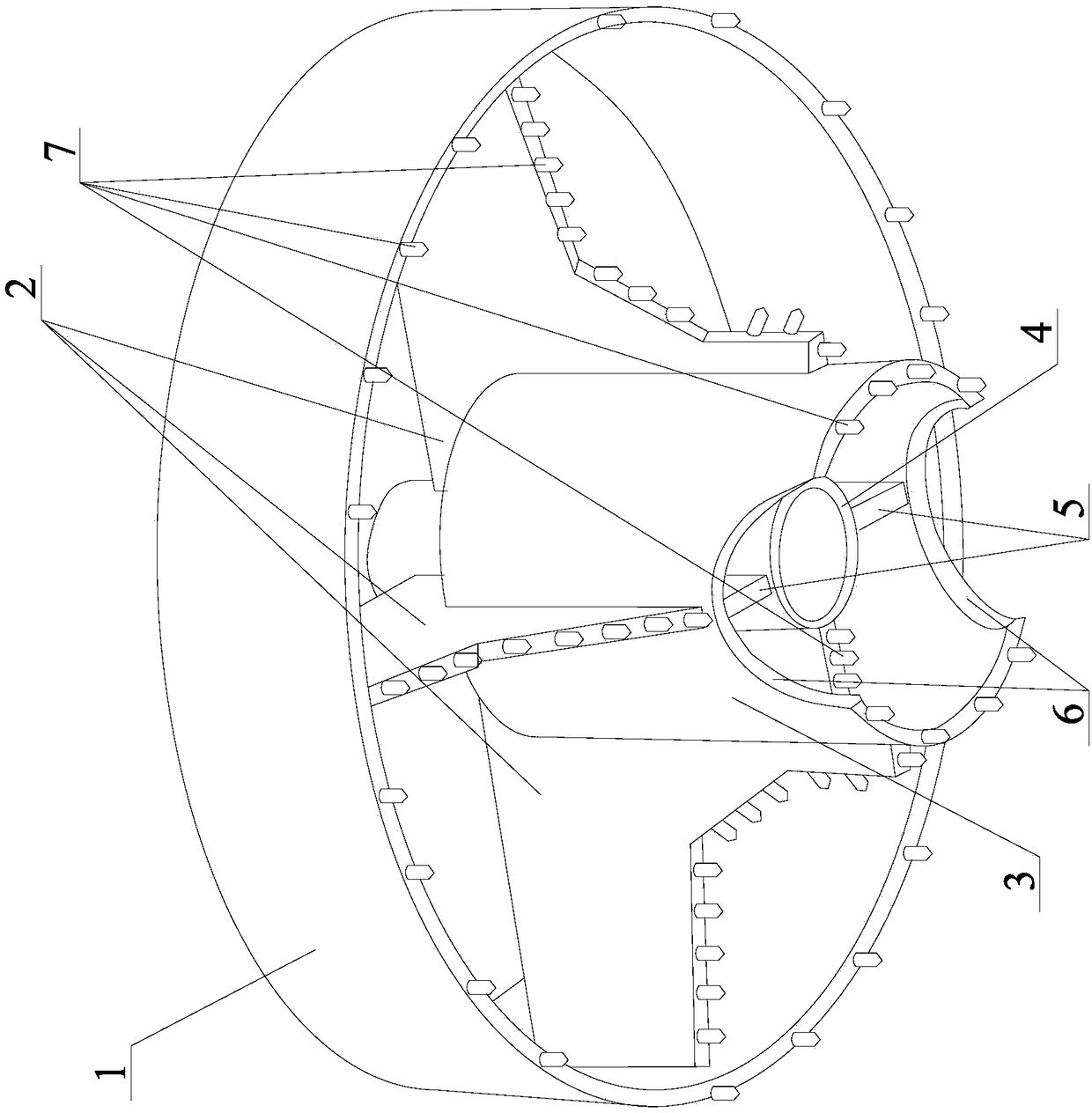

Bucket type jaw crusher

ActiveUS20100206975A1Short timeFor quick replacementMowersSoil-shifting machines/dredgersHydraulic motorReciprocating motion

A bucket type jaw crusher comprises a hydraulic motor connected to one end of an eccentric main shaft, a flywheel connected to the other end of the eccentric main shaft, and a counterweight for balance adjustment fitted at an intermediate section of the eccentric main shaft between the hydraulic motor and the flywheel. A movable jaw teeth side load receiving section of a toggle plate is placed at an upper position than a bucket side load receiving section of the toggle plate, and while movable jaw teeth are reciprocated by rotation of the eccentric shaft, an object to be crushed is pressed against stationary jaw teeth by the movable jaw teeth via rocking motion of the toggle plate.

Owner:UEDA IND

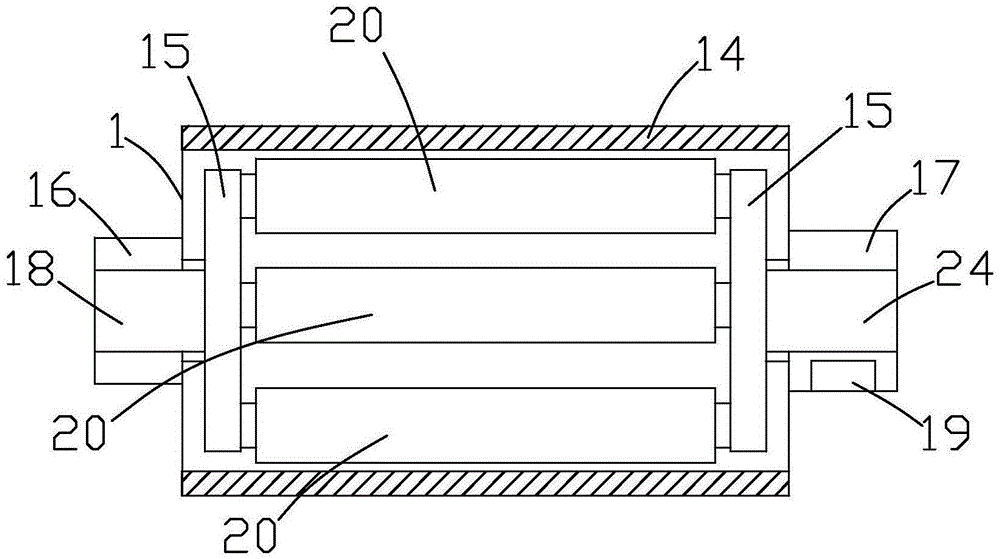

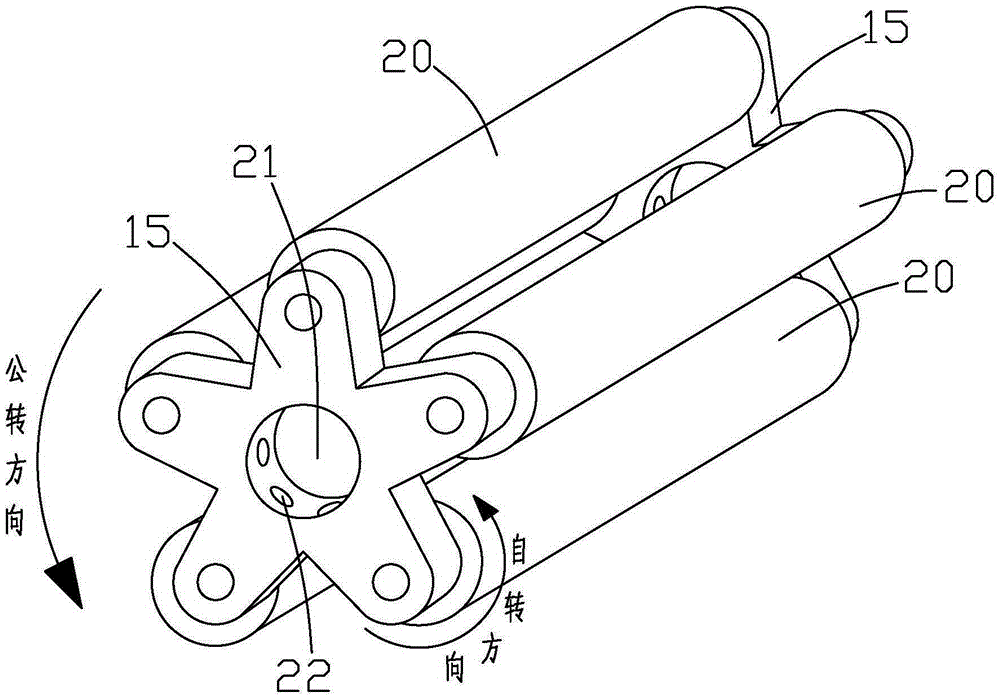

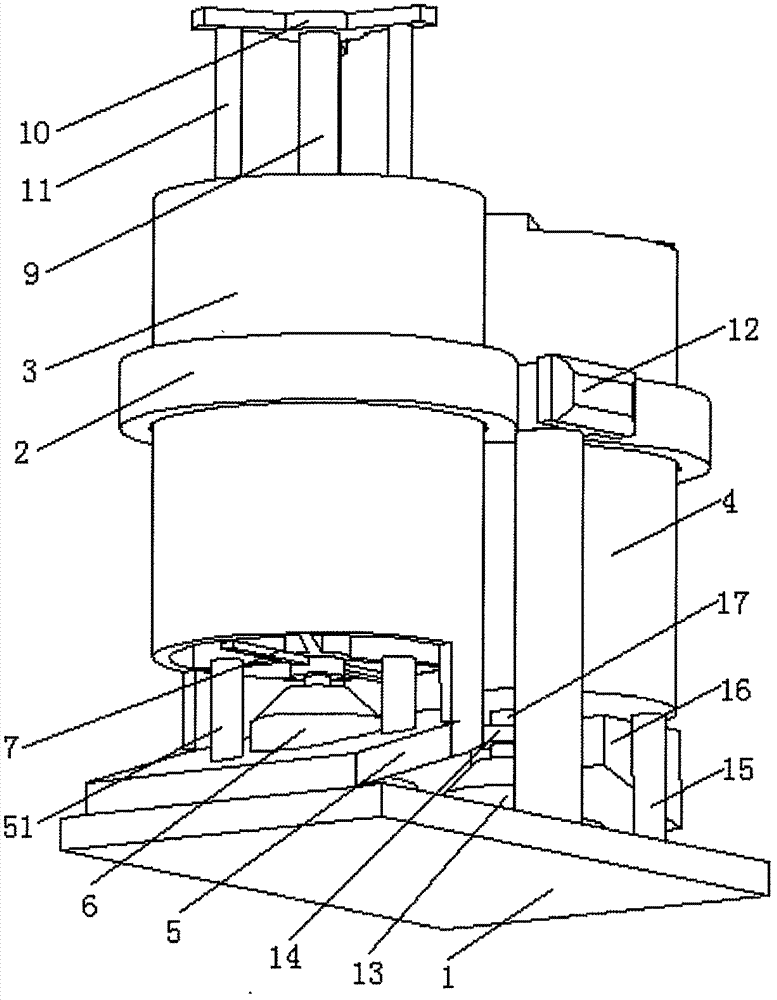

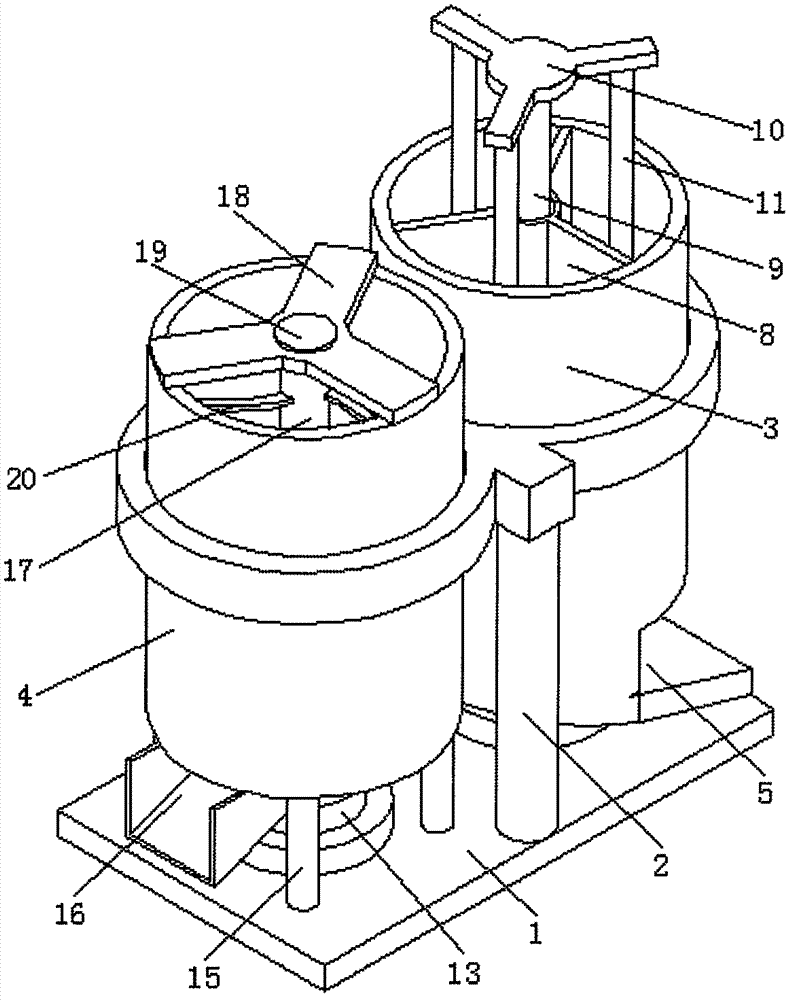

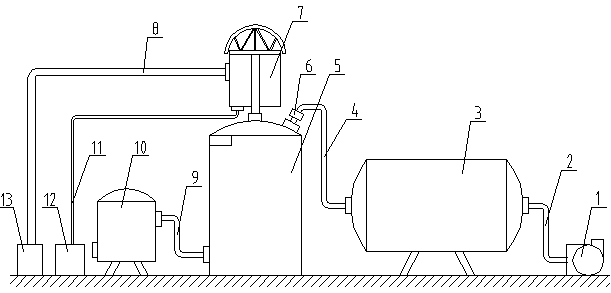

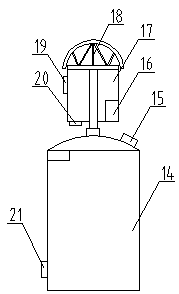

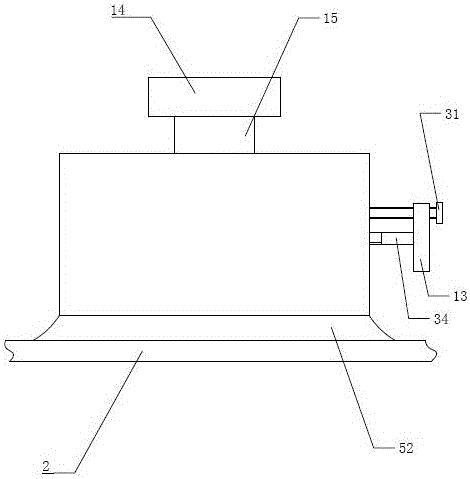

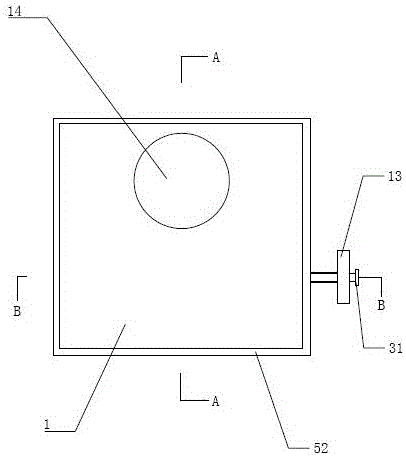

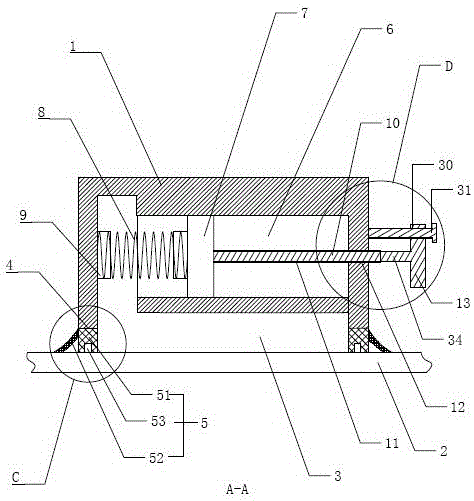

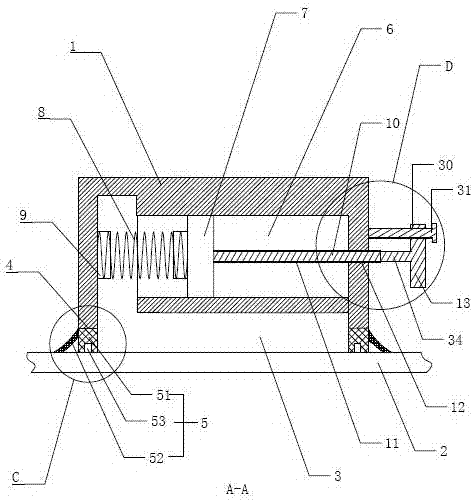

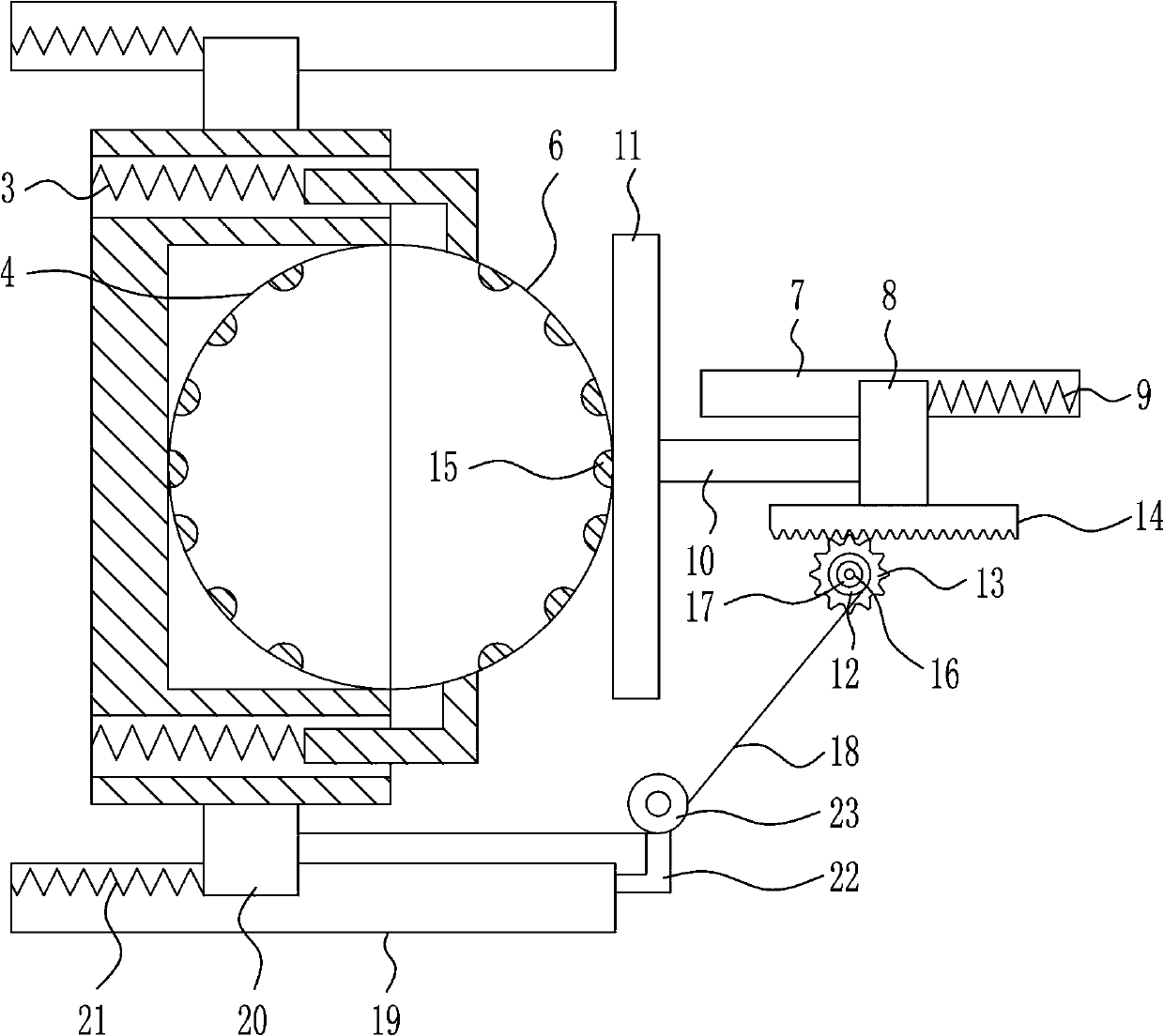

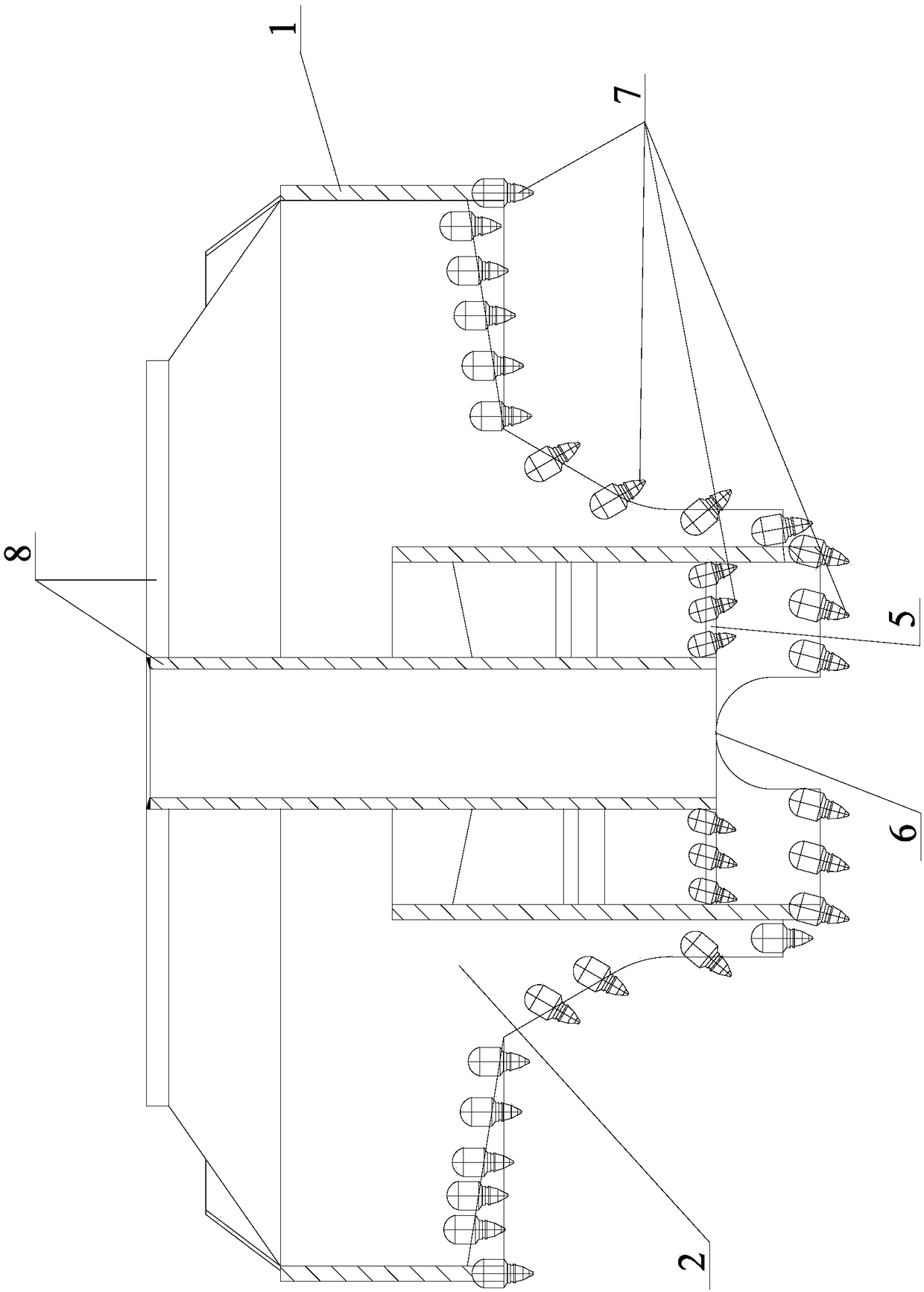

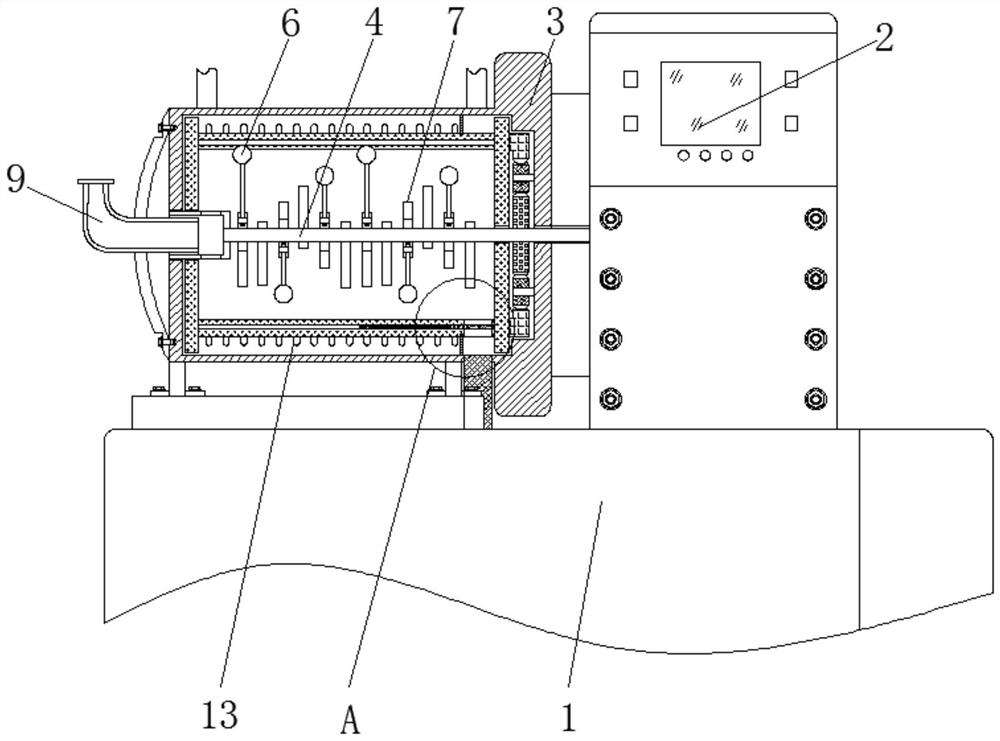

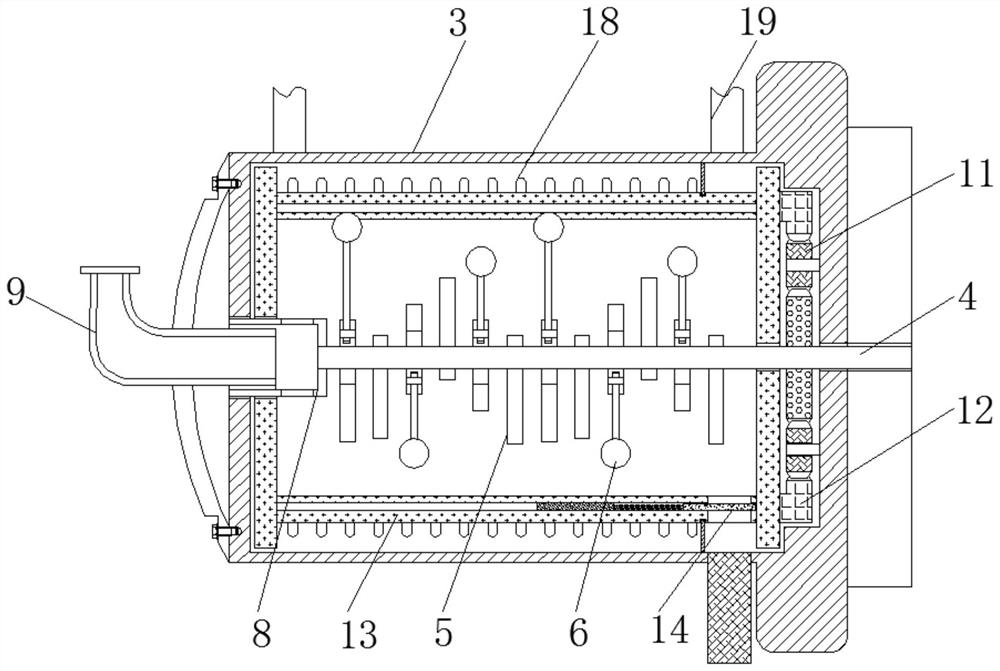

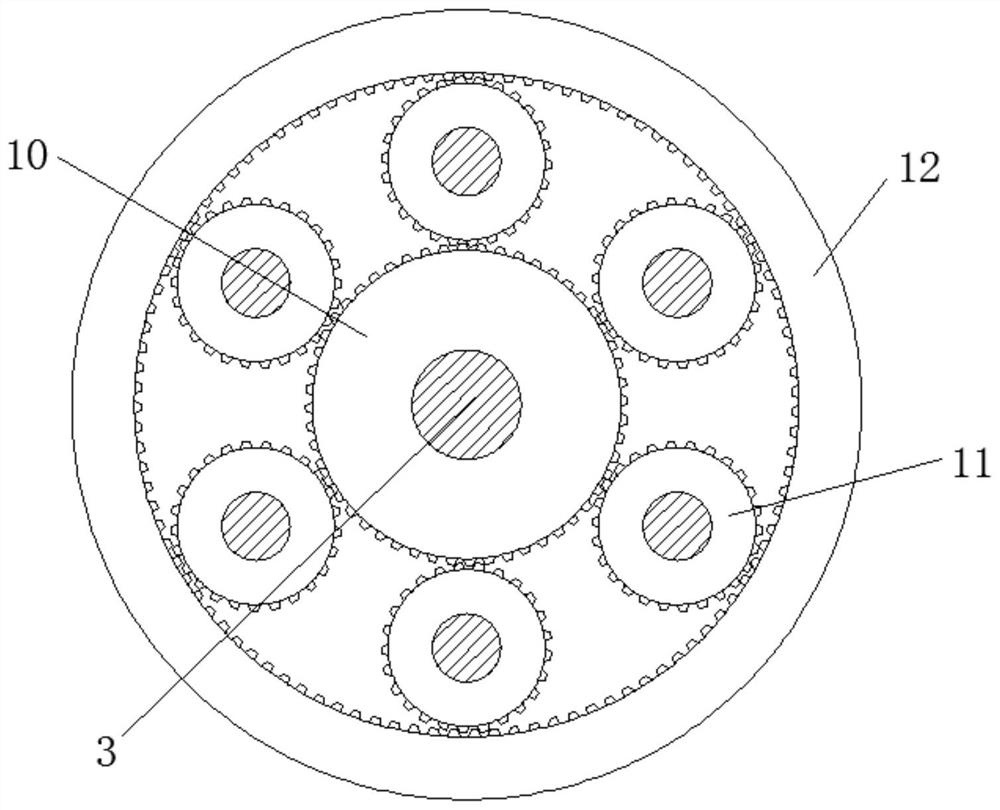

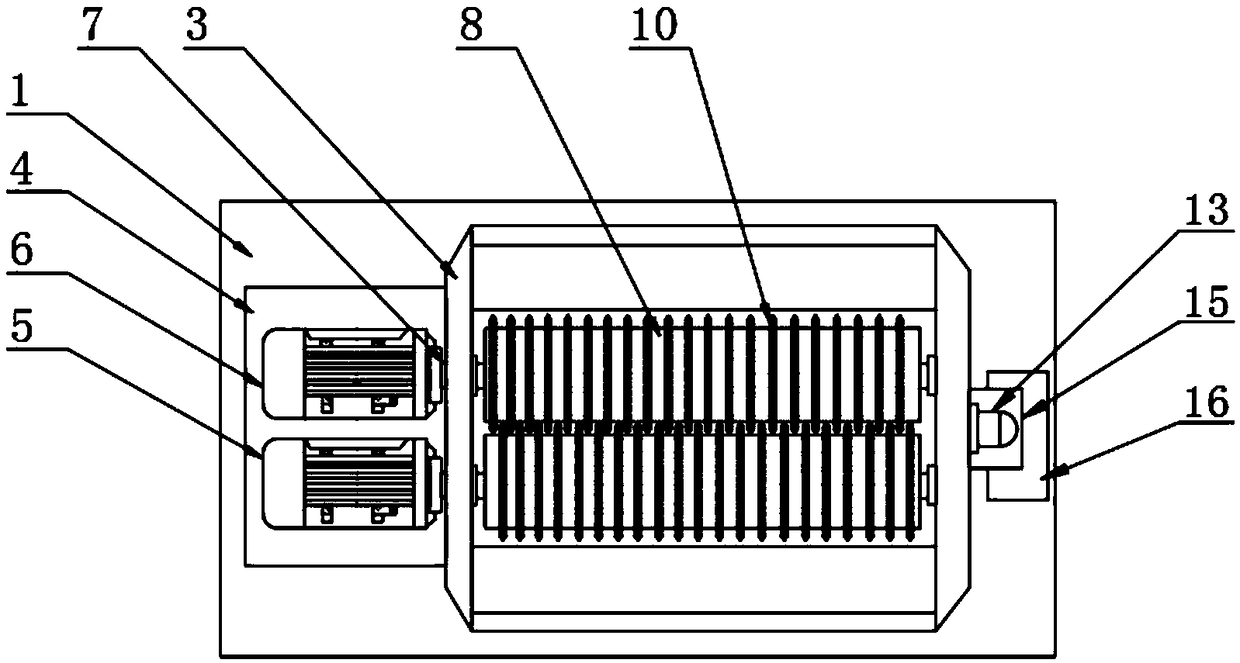

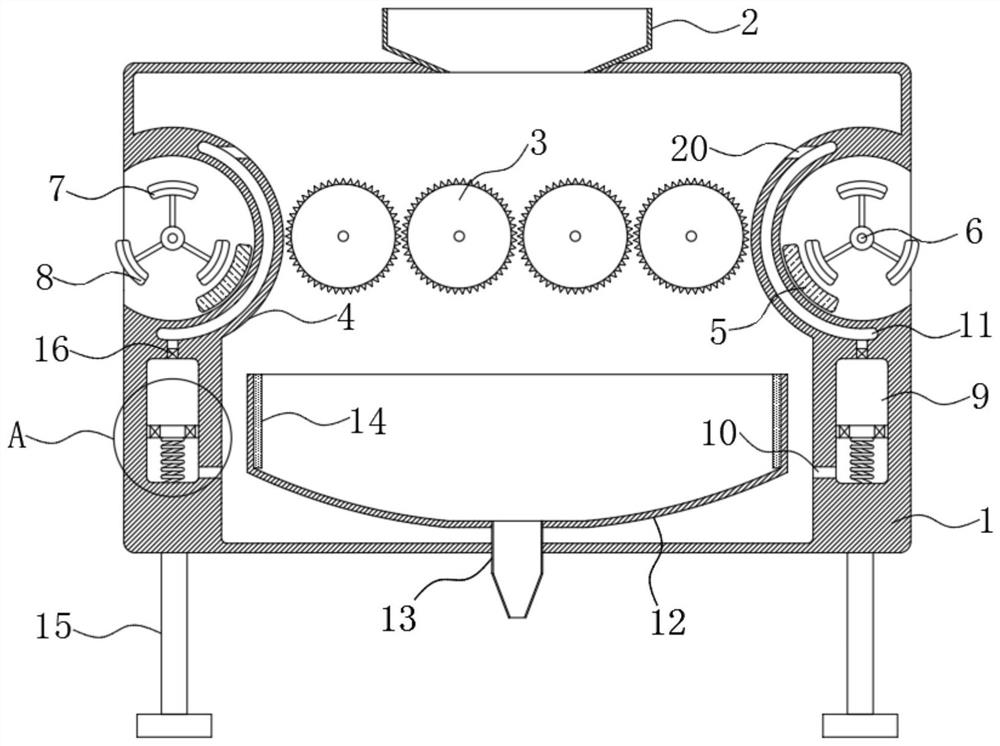

Ball mill used for producing graphite powder

InactiveCN105413813AExcellent crushing speedReduce crushing timeGrain treatmentsSynchronous motorGraphite

The invention discloses a ball mill used for producing graphite powder. The ball mill comprises a roller, a power drive device, a feeder and a dumping device, wherein two star brackets which are parallel to each other are arranged on the inner part of the roller; material distributing tubes are uniformly arranged on the inner parts of the star brackets; five cylindrical ball-milling tanks which are parallel to each other are uniformly distributed between the two star brackets; the two ends of each cylindrical ball-milling tank are provided with supporting tube racks; a synchronous motor is arranged on the inner parts of the star brackets; the cylindrical ball-milling tanks realize autoroatation around the star brackets; the two ends of the roller are respectively provided with a front positioning bearing and a rear positioning bearing; and the cylindrical ball-milling tanks realize rotation around the front positioning bearing and the rear positioning bearing. The ball mill is simple in structure, high in practicability, not only can realize autoroatation and rotation of the cylindrical ball-milling tanks and improve material crushing efficiency and material crushing quality, but also can pre-heat and crush materials, so that the materials are guaranteed to have certain temperature while being output, and therefore, crushing requirements of different materials are met.

Owner:SHENGZHOU SIGMA TECH

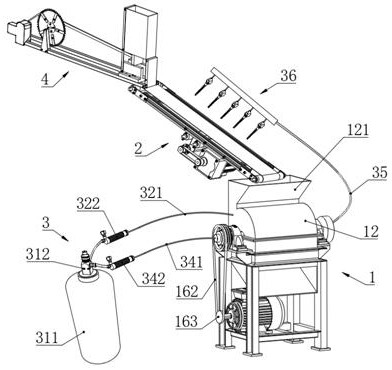

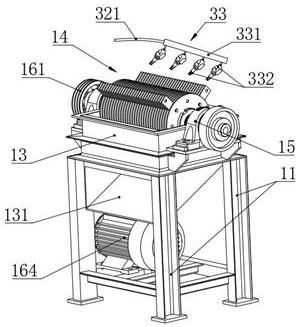

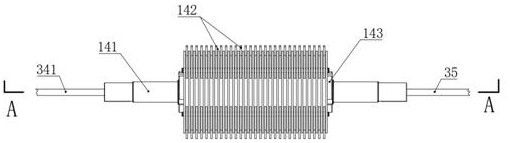

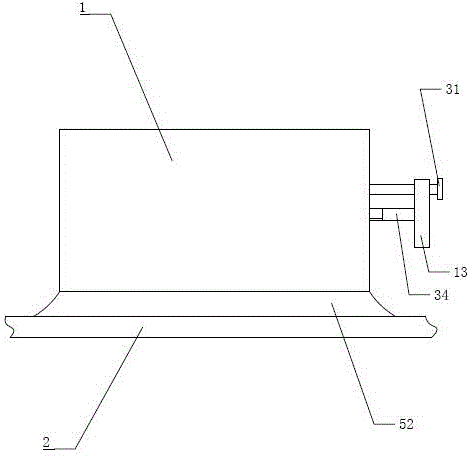

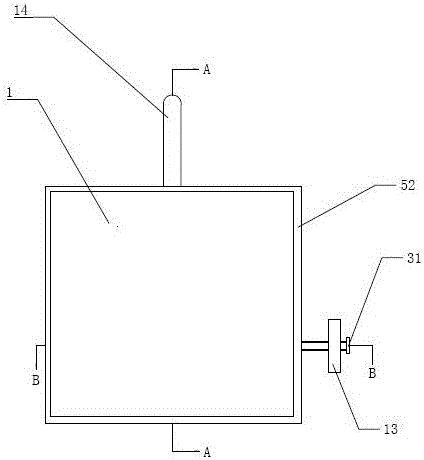

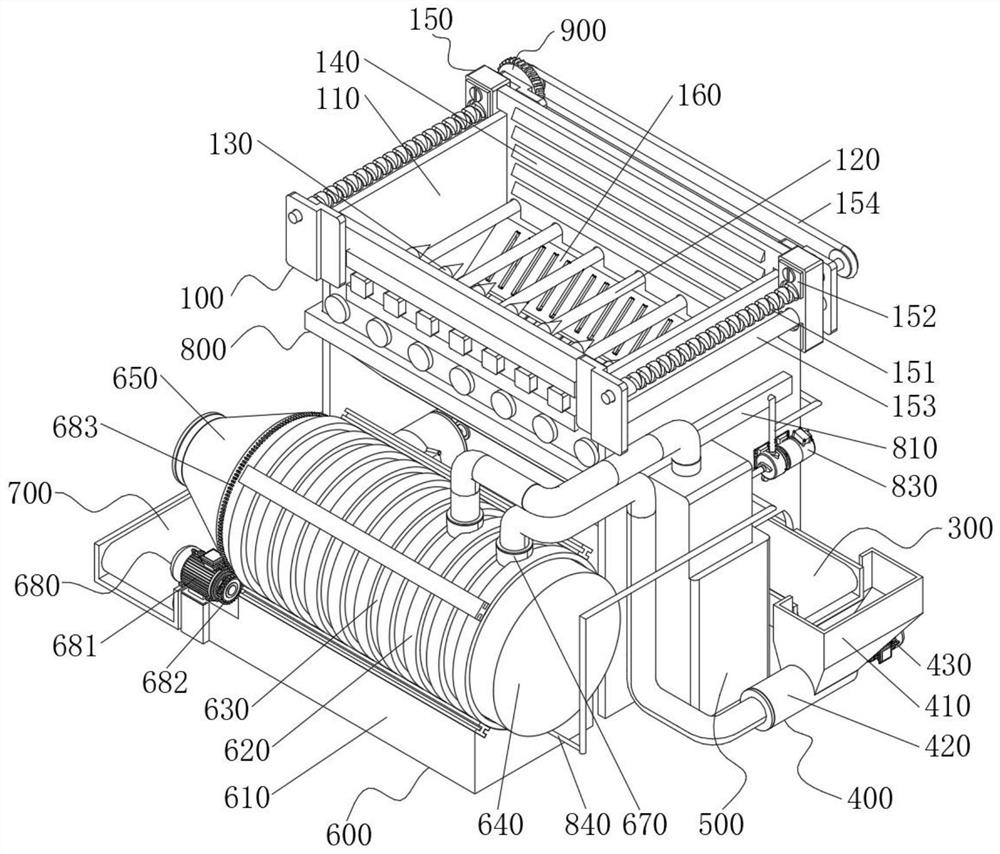

Brown sugar processing equipment and use method

ActiveCN112169948AIncrease temperatureIncrease the speed of crushingDomestic cooling apparatusLighting and heating apparatusEngineeringProcess engineering

The invention belongs to the technical field of brown sugar processing, and particularly relates to brown sugar processing equipment. The brown sugar processing equipment comprises a pulverizer, a conveying device and a cooling device, wherein the pulverizer is arranged on the back end of the conveying device, and a high-pressure tank of the cooling device is located on one side of the pulverizer.After the brown sugar processing equipment is operated for a long time, the temperature of cutters can be prevented from being increased, and brown sugar powder cannot be melted into blocks; and additionally, moisture in the brown sugar powder is condensed into ice crystals before processing, the brown sugar powder cannot be caked due to cooling of the cooling device, the crushing speed and the crushing quality are increased, and the influence on the processing efficiency is reduced. The invention further provides a use method of the equipment. The use method comprises the steps of preprocessing brown sugar blocks, cooling the brown sugar blocks, cooling the interiors of the cutters, and crushing the brown sugar blocks. According to the use method, the crushing operation can be performedwhen the water content of brown sugar is lower than 7%, the processing range is large, dehydration treatment is not needed, and the cost is reduced; and additionally, the use method has the advantagesof high degree of mechanization and high processing efficiency and processing quality and is suitable for large-scale processing.

Owner:湛江市金丰糖业有限公司

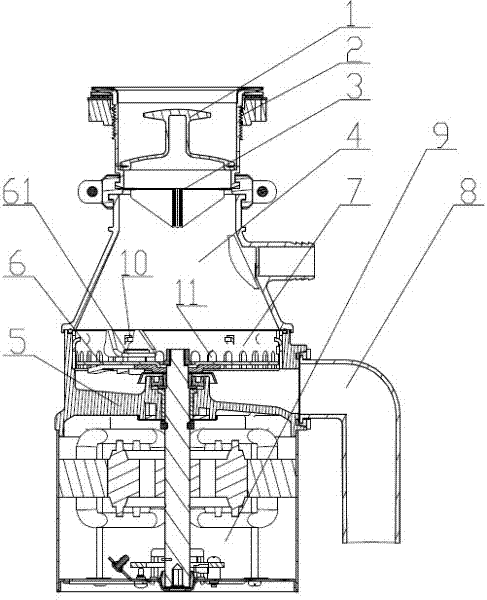

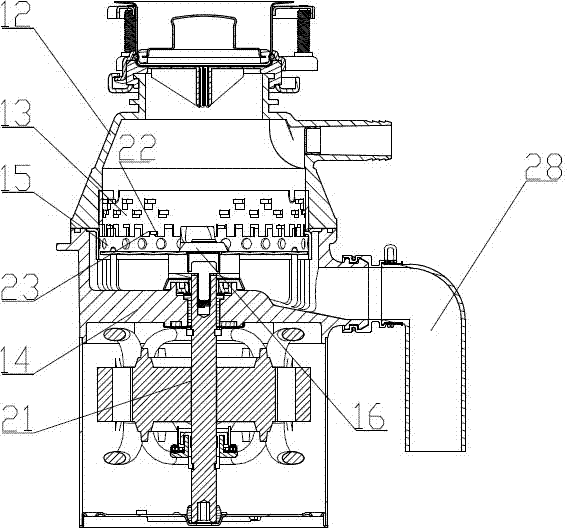

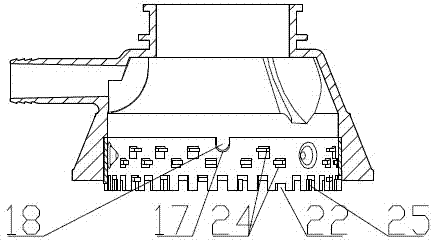

A food waste disposer

The invention is a food waste disposer. It includes a casing, an upper crushing chamber, a lower crushing chamber, a cutter head assembly, and a motor assembly, wherein the upper crushing chamber for holding food waste is arranged on the upper part of the casing, and the lower crushing chamber is arranged under the bottom of the upper crushing chamber. The upper grinding ring is installed in the upper crushing chamber, the cutter head assembly is placed in the lower crushing chamber, the motor assembly that drives the cutter head assembly to rotate is installed in the lower part of the housing, and the lower grinding ring is installed in the lower crushing chamber. In the present invention, a coaxial connecting ring is formed between the upper grinding ring and the lower grinding ring, and this structure can gather a certain amount of food waste, especially fibrous food waste. In addition, since the upper grinding ring is provided with staggered grinding grooves and transverse protrusions, the grinding fineness and grinding speed of food can be effectively improved, the impact of bone food waste on the upper grinding chamber can be avoided, and the upper grinding chamber can be extended. The service life of the crushing chamber; the invention is easy to assemble and has excellent performance.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

Traditional Chinese medicine circulating and extracting pre-processing device

InactiveCN107097277AImprove slicing efficiencyEasy to sliceGrain treatmentsMetal working apparatusMaterial resourcesEngineering

The invention discloses a traditional Chinese medicine circulating and extracting pre-processing device which comprises a bottom plate. A supporting frame is arranged in the middle of the upper surface of the bottom plate. The upper end of the supporting frame is fixedly connected with a slicing bucket and the middle of the side face of a crushing bucket. A control switch unit is arranged at the upper end of the side face of the supporting frame and electrically connected with an external power source. A partition plate frame is arranged inside the slicing bucket, and the interior of the slicing bucket is divided into three feeding grooves through the partition plate frame. A first motor is arranged on the lower side of the slicing bucket. The bottom of the first motor is fixedly connected with the upper surface of the bottom plate. An output shaft of the first motor is sleeved with a first cutting tool. A discharging chute is arranged at the right end of the bottom of the crushing bucket. The traditional Chinese medicine circulating and extracting pre-processing device is simple in structure, capable of conducting crushing or uniform slicing treatment on various kinds of traditional Chinese medicine, easy to operate, and capable of effectively preventing blockage of the interior of the slicing bucket, meanwhile, manpower and material resources are reduced, the working efficiency is improved, and cost is reduced.

Owner:朱玉波

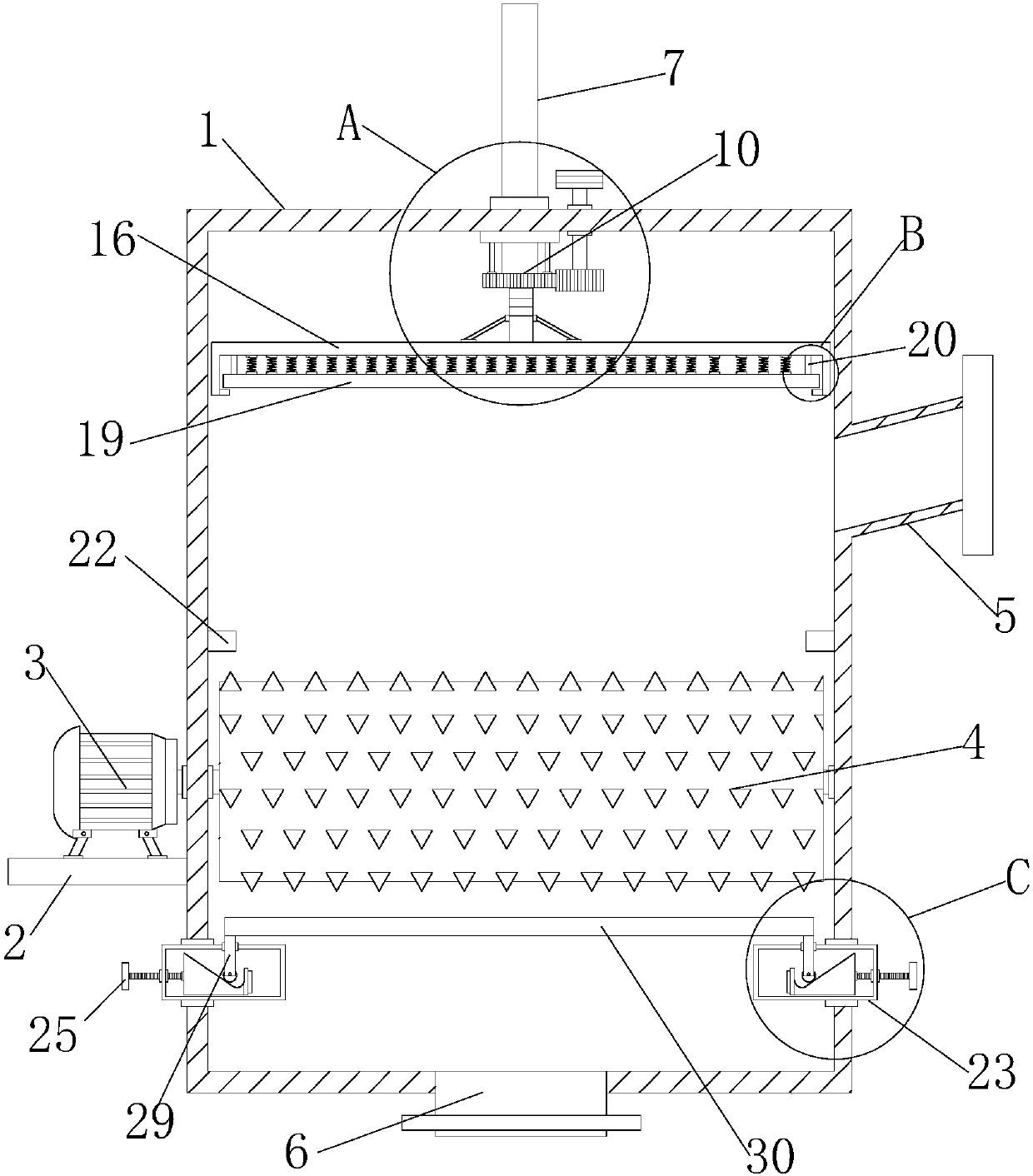

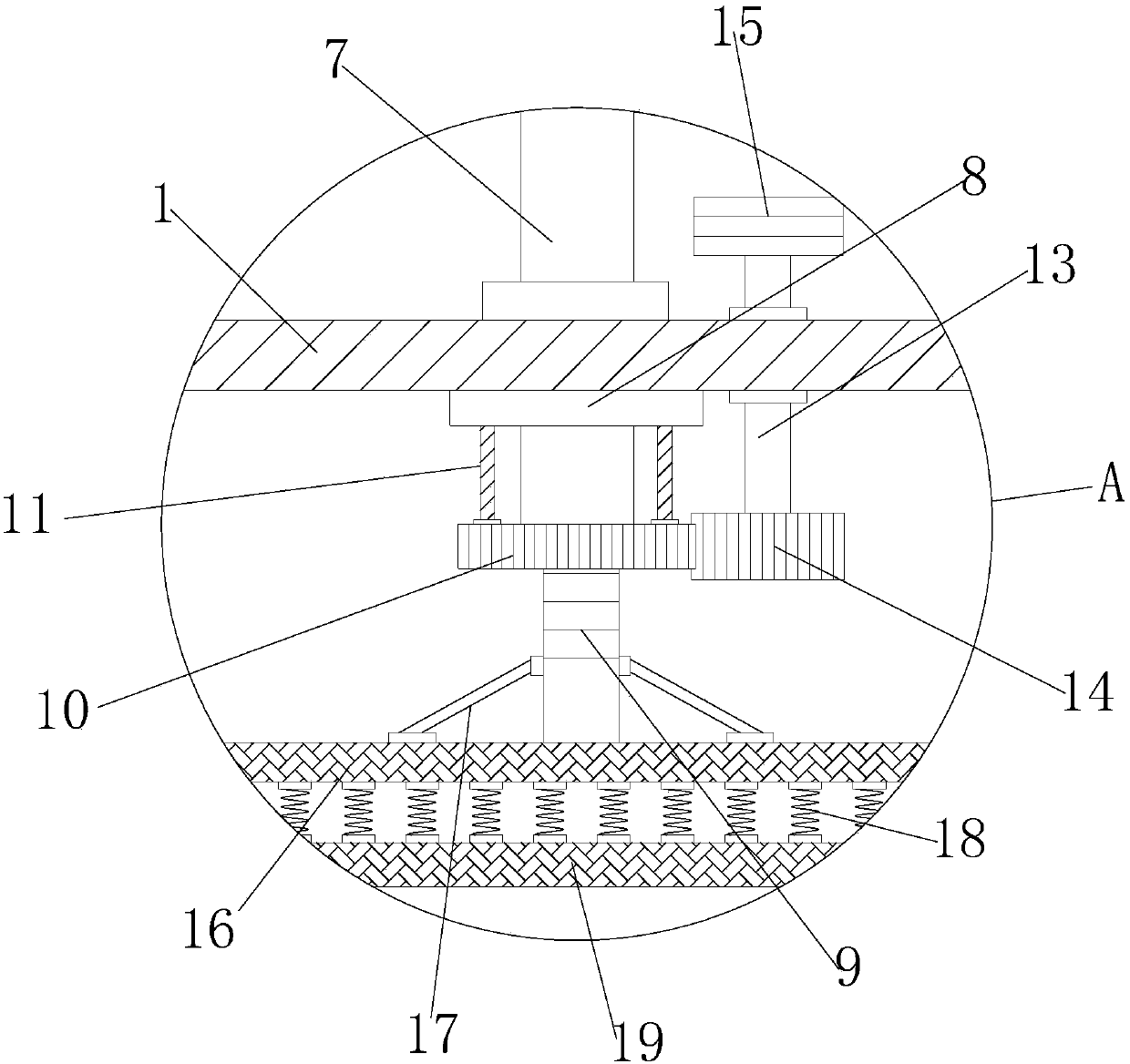

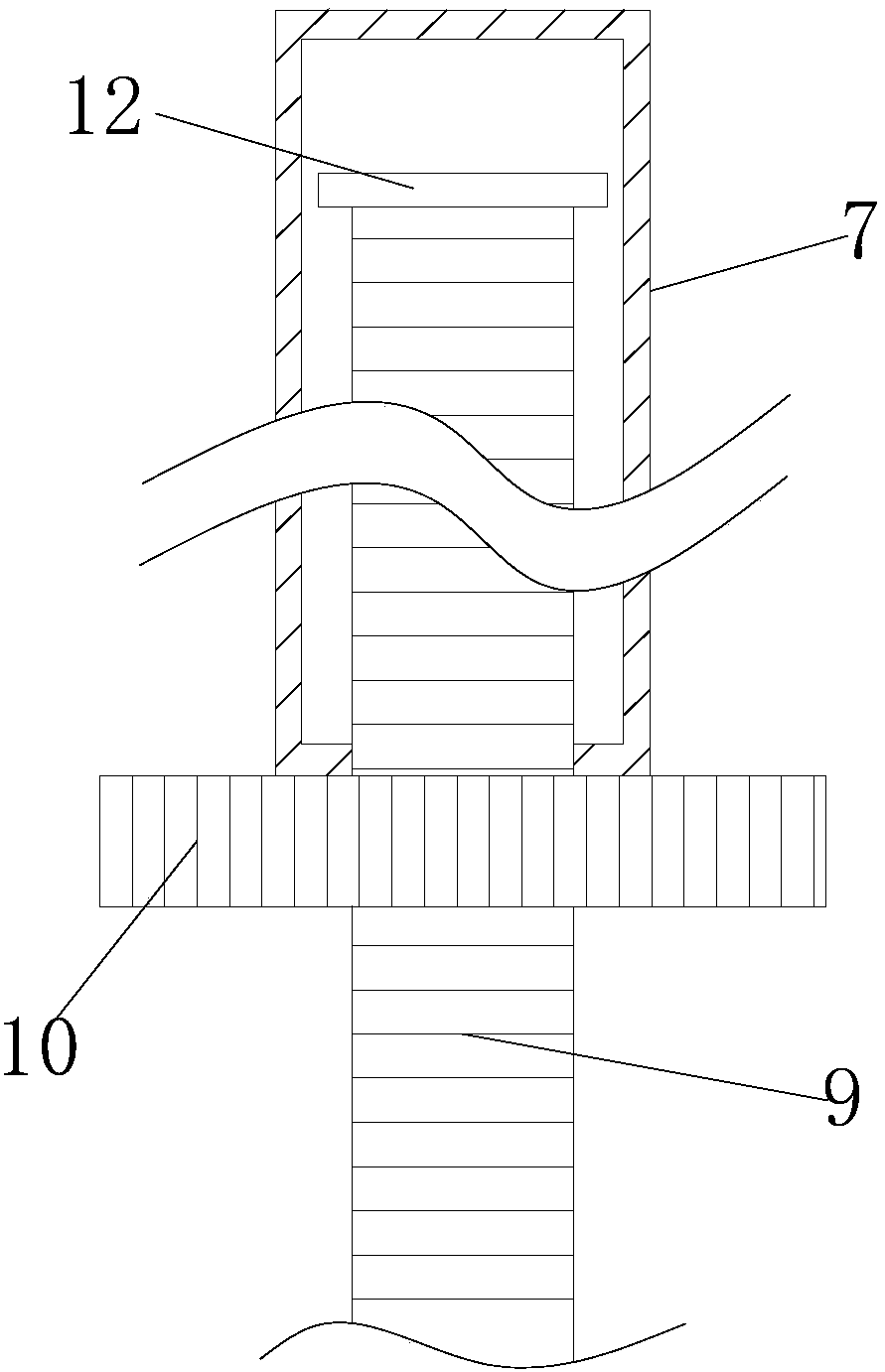

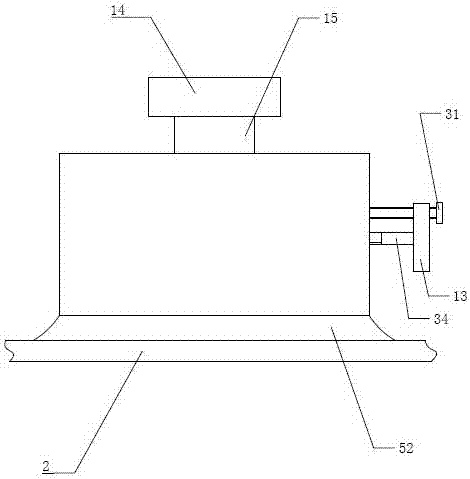

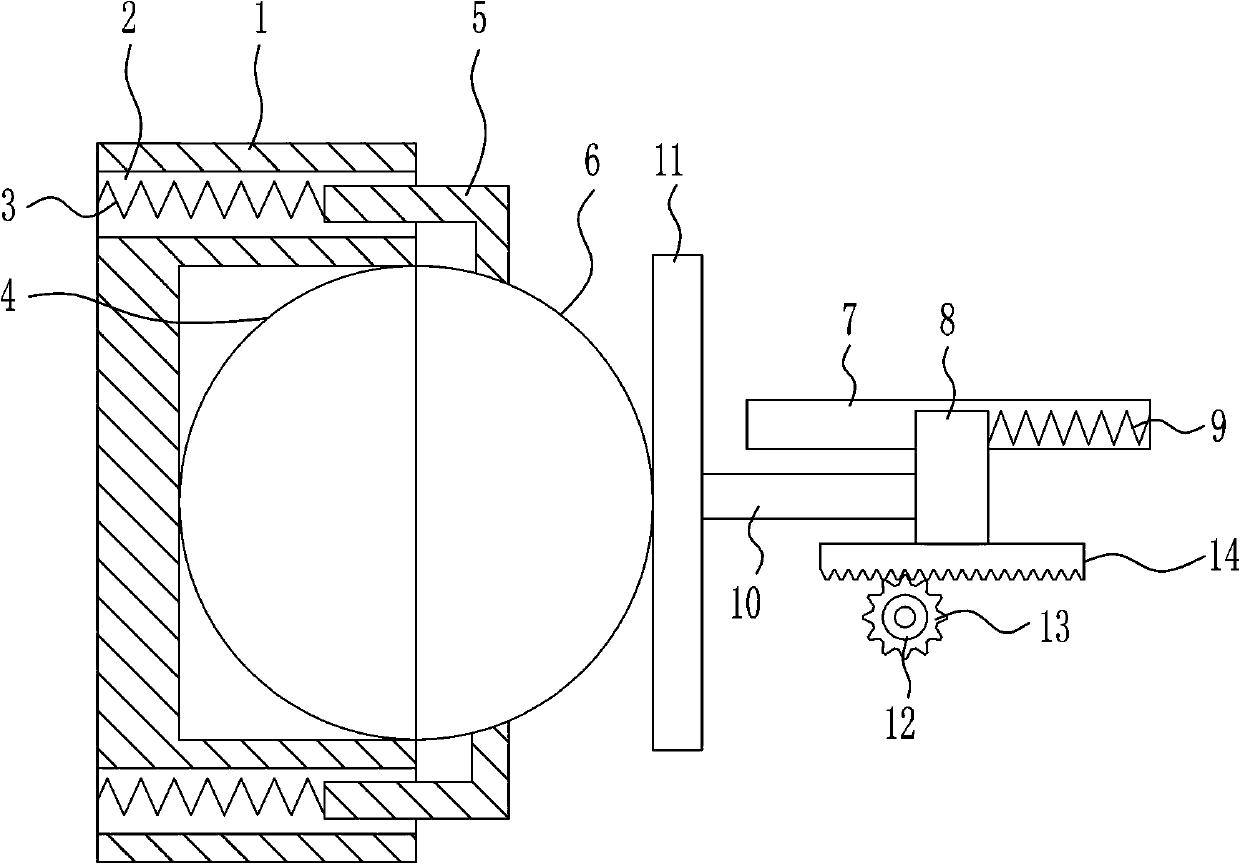

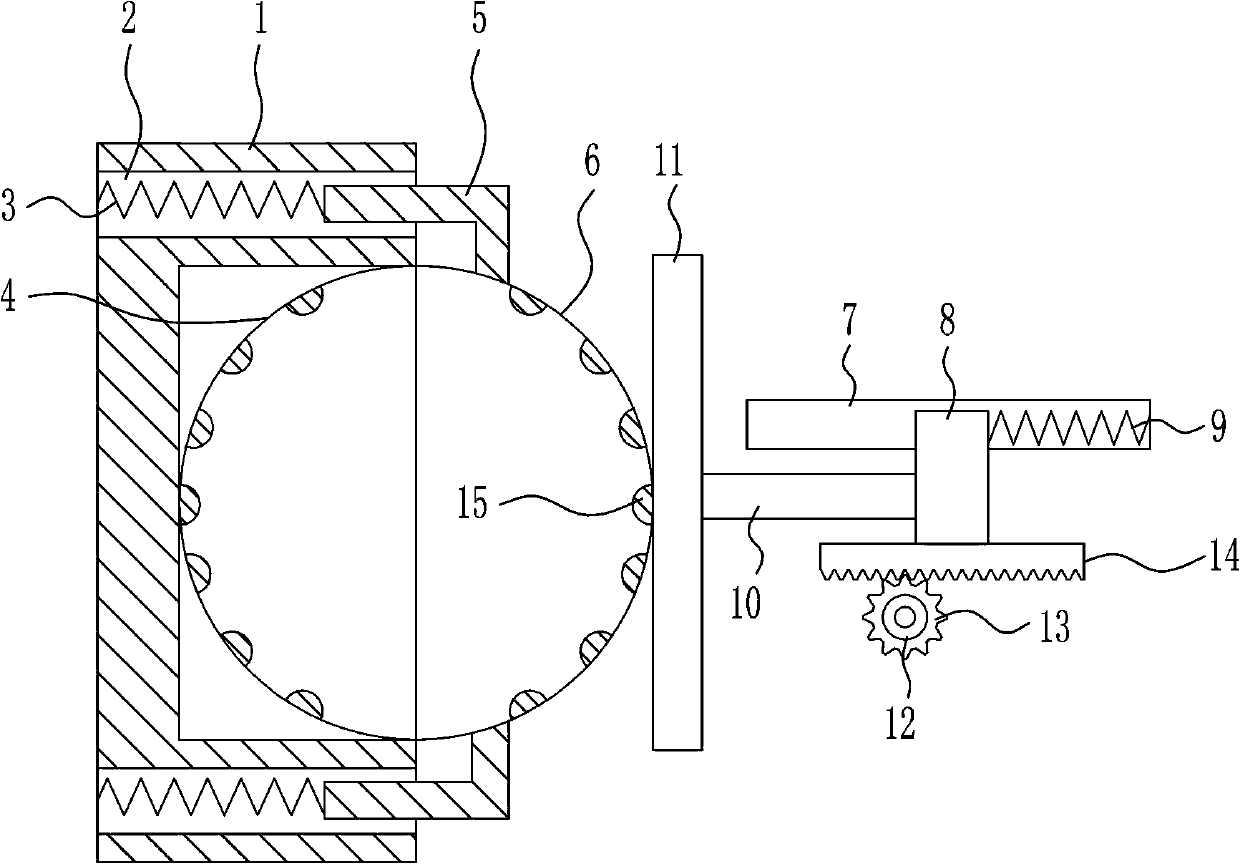

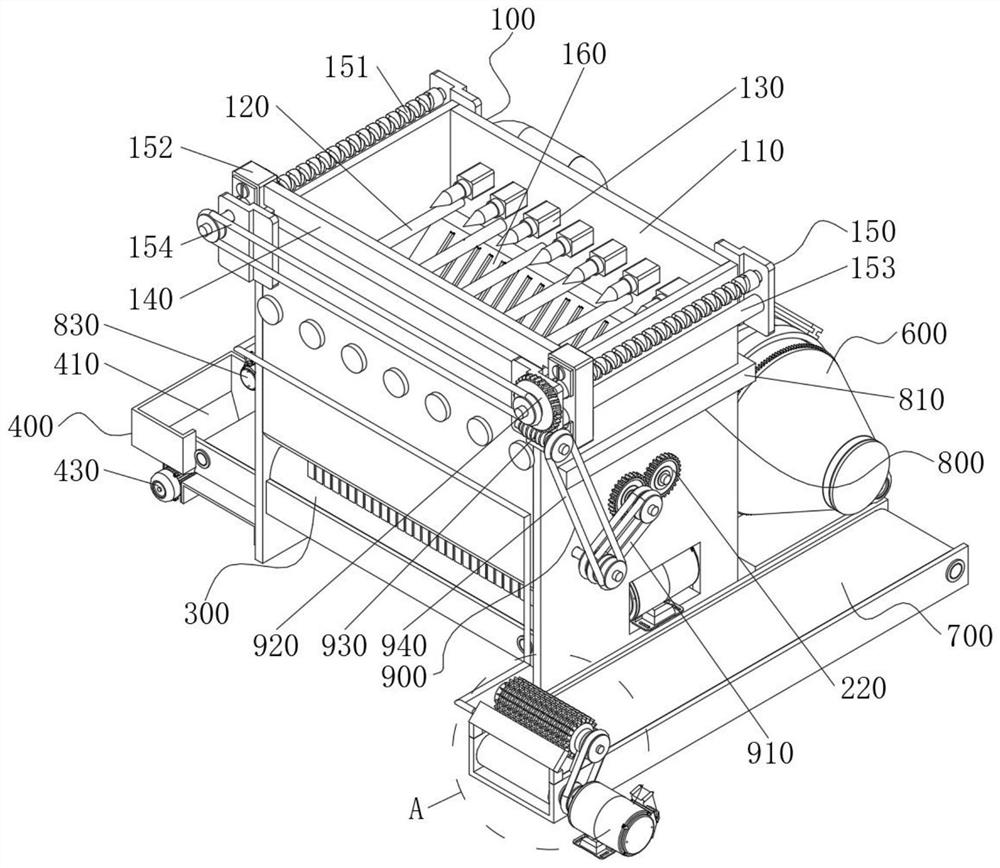

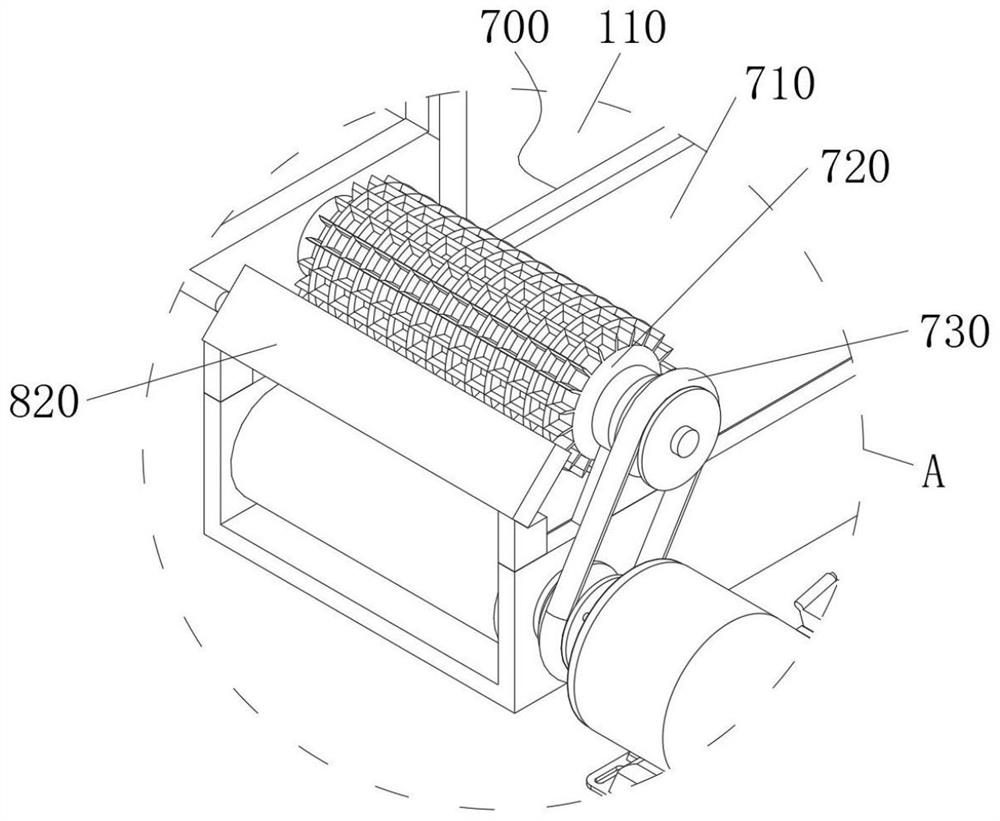

Animal husbandry continuous feed crushing device

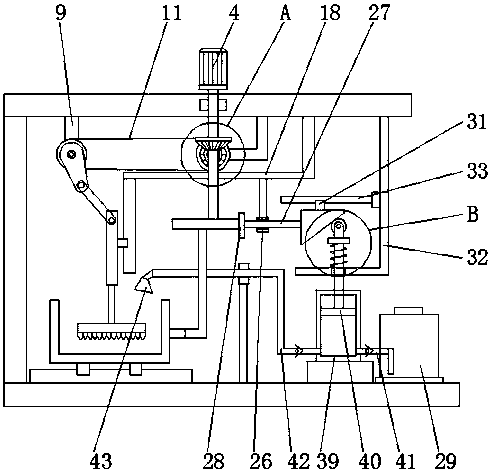

PendingCN109126953AIncrease the speed of crushingFeeding-stuffGrain treatmentsEngineeringDrive motor

The invention discloses an animal husbandry continuous feed crushing device which comprises a support table. Support legs are fixedly connected with the bottom of the support table, a first side frameand a second side frame are fixedly connected with two sides of the top surface of the support table, a top frame is fixedly connected with the top of the first side frame and the top of the second side frame, a feed hopper is fixedly arranged on the top of the top frame, a distributing device is arranged between the first side frame and the second side frame, a driving motor is fixedly arrangedat the bottom of the top frame, a first lifting rod and a second lifting rod are arranged on two sides of the driving motor, an incomplete gear is in transmission connection with the driving motor, racks which mesh with the incomplete gear are arranged on the first lifting rod and the second lifting rod, a slide plate is slidably connected with the top of the support table, a crushing table is arranged on the slide plate, and crushing grooves are formed in the crushing table. The animal husbandry continuous feed crushing device has the advantages that continuous feed feeding, crushing and discharging can be integrated with one another, and accordingly the feed crushing speeds can be greatly increased.

Owner:莱西市辉道装备技术中心

Plastic waste efficient processing device for decoration

InactiveCN110124771AEvenly distributedQuality is not affectedUsing liquid separation agentGrain treatmentsPlastic wasteEngineering

The invention discloses a plastic waste efficient processing device for decoration. The plastic waste efficient processing device comprises a bottom plate, one side of the bottom plate is provided with a side plate, the top of the side plate is provided with a top plate, and the top of the top plate is provided with a servo motor; an output shaft of the servo motor penetrates through the top plateto be connected with a rotary rod; the rotary rod is sleeved with a first bevel gear, the rear side of the first bevel gear is provided with a second bevel gear, and the rear side of the second bevelgear is connected with a first belt wheel; the bottom of the top plate is provided with a strut, the bottom of the strut is rotationally connected with a second belt wheel, and the second belt wheeland the first belt wheel are sleeved with the same belt; the front side of the second belt wheel is connected with a first cam; a first connection rod is hinged to the front side of the first cam, a first moving rod is hinged to the end of the first connection rod, a pressing block is connected to the bottom of the first moving rod, and conical teeth are uniformly distributed at the bottom of thepressing block; and the end of a transmission block is connected with an elastic mechanism, and the end of the elastic mechanism is connected with a breaking frame. The plastic waste efficient processing device for decoration achieves the effects of being good in breaking effect, high in breaking speed and capable of removing dust effectively.

Owner:翁宇彬

Steam explosion pulping equipment

The invention relates to the field of mechanical equipment, and in particular relates to steam explosion pulping equipment. The equipment comprises a vacuum pump, a negative-pressure emptying tank andan explosion tank; and one end of the negative-pressure emptying tank is connected with the vacuum pump, a material outlet of the negative-pressure emptying tank is connected with a material inlet ofthe explosion tank, the upper part of the explosion tank is provided with a chimney device, the material outlet end opening of the explosion tank is connected with a slurry collecting tank, the upperpart of the chimney device is connected with a dust discharging pipe, the dust discharging pipe is connected with a dust collecting box, the lower part of the chimney device is connected with a sewage pipeline, and the sewage pipeline is connected with a sewage collecting box. The equipment provided by the invention has the characteristics of a simple structure, high explosion efficiency, stableproduction quality, environmental protection, sanitation and the like.

Owner:广西洋荣科技有限公司

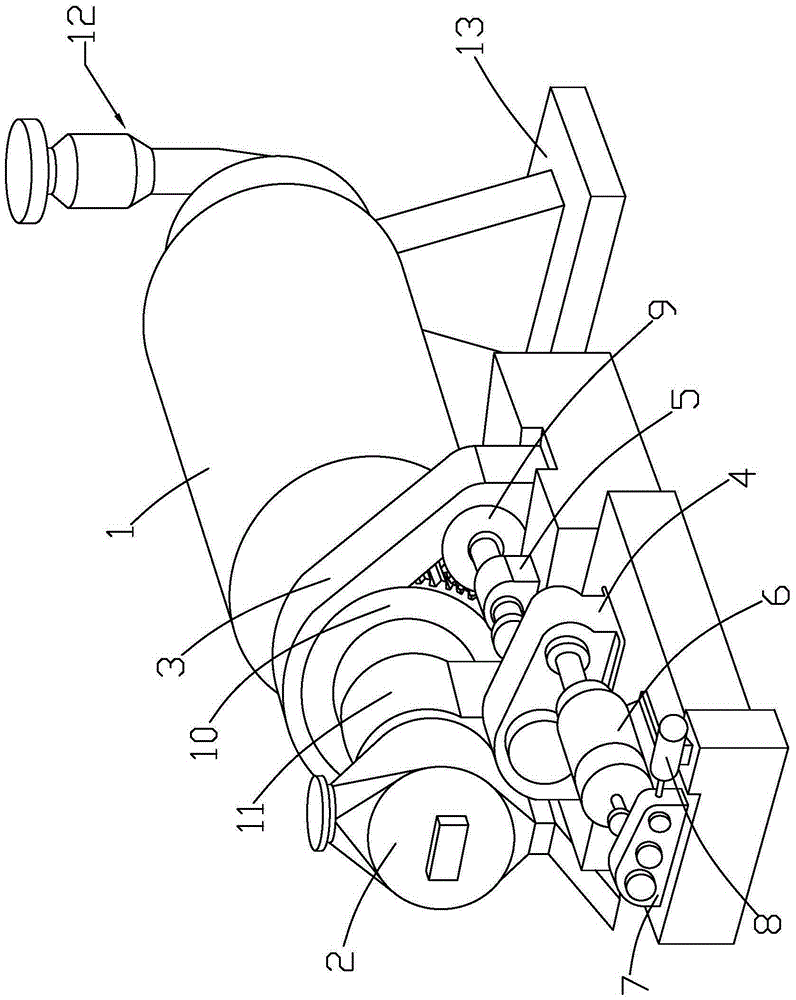

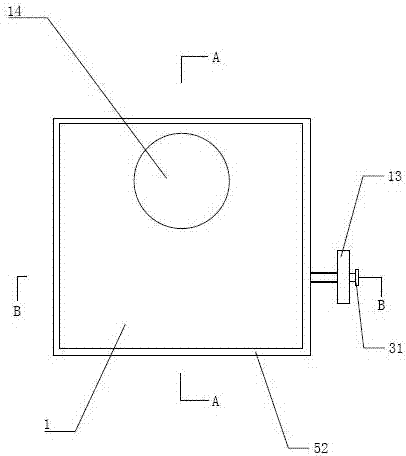

Active car window knapper

InactiveCN106740640AEasy to operateEasy to installPedestrian/occupant safety arrangementBuilding rescueEngineeringPiston

The invention discloses an active car window knapper. The active car window knapper is characterized in that the knapper is preliminarily fixed through a spring and a piston by means of hard rubber edges and soft rubber sealing edges of a vacuum cavity, then a rotary disc is rotated to drive the piston to move so as to further conduct vacuum supply, and accordingly the car window knapper is conveniently fixed to a car window; meanwhile, a crushing device is arranged, wherein the crushing device comprises a crushing mechanism and a trigger mechanism, and when a user presses the trigger mechanism, the trigger mechanism can convert force into kinetic energy of a firing pin; after possessing the kinetic energy, the firing pin collides with a primer so that an explosive in an explosive cavity is triggered to cause explosion, the explosion energy can generate sufficient pressure to a crushing piston so that the piston on the top can obtain sufficient energy, and a diamond at the top compresses the car window, so that the car window is crushed. The active car window knapper can quickly and conveniently break up the car window when the car window needs to be broken up, and then the life safety of passengers and the life safety of drivers are guaranteed.

Owner:CHANGSHU INTEREST SHARING INFORMATION TECH CO LTD

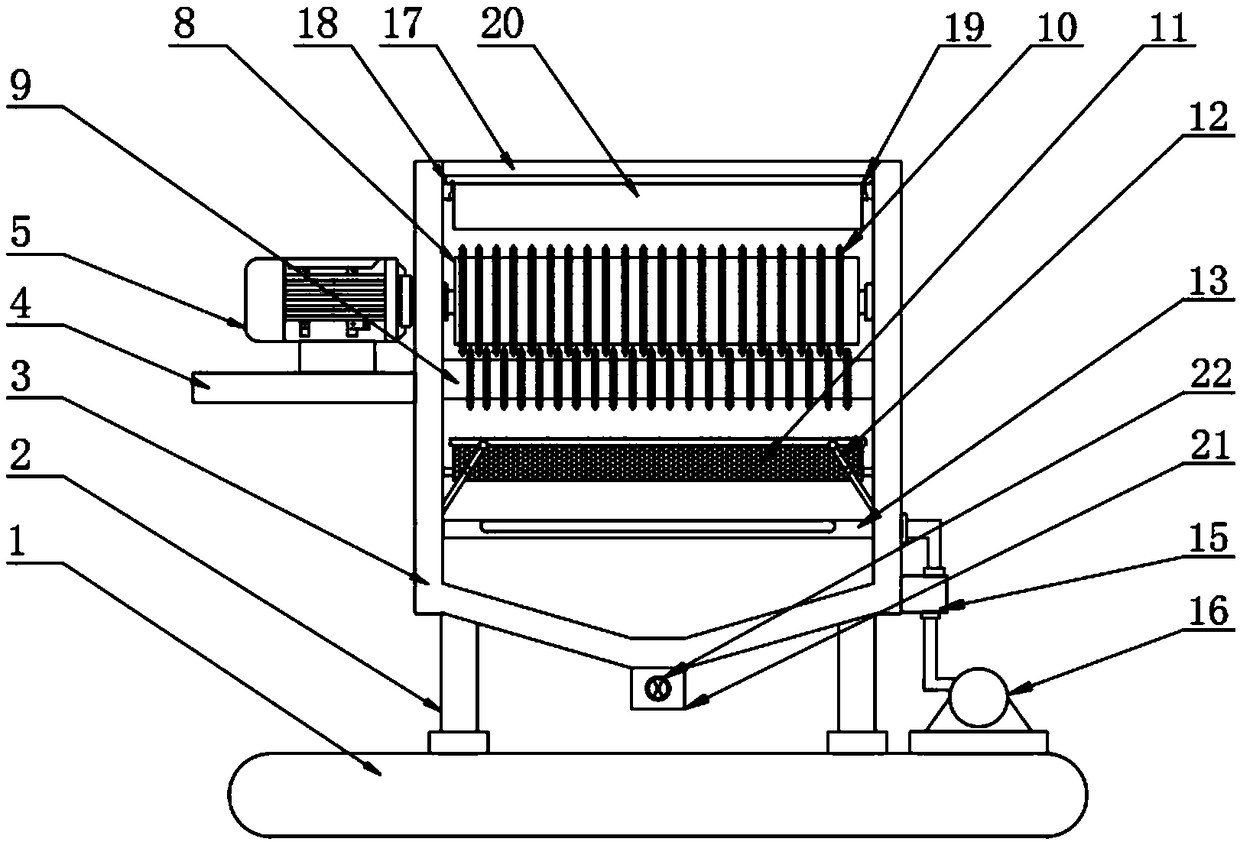

Closed type foam crusher

InactiveCN109834871ASmash thoroughlyIncrease the speed of crushingPlastic recyclingMechanical material recoveryDecompositionArchitectural engineering

The invention discloses a closed type foam crusher. The closed type foam crusher comprises a machine body, wherein a supporting plate is fixedly connected to the left side of the machine body, and a rotating motor is fixedly arranged at the top of the supporting plate. According to the closed type foam crusher, a fixing sleeve and a fixing block are arranged, a first bearing, a first threaded rod,a threaded ring, a fixed rod, a rotating rod, a gear disc, a twisting cap, a pushing plate, a compression plate, a second threaded rod, a second bearing, a sliding block, a baffle plate, a supportingrod and a steel wire mesh plate are used in a cooperative mode, so that fully-closed decomposition is achieved in the process of crushing foam, through rotation of the gear disc and on the basis of the thread pushing principle and extrusion of the threaded ring and the fixing sleeve, the first threaded rod moves downwards, so that the crushing speed and the crushing degree are increased by extruding foam blocks and through a crushing roller, the height of a steel wire mesh plate is adjusted, so that the foam blocks with different sizes can be decomposed, and the foam is thoroughly crushed.

Owner:芜湖市新京桥包装科技有限公司

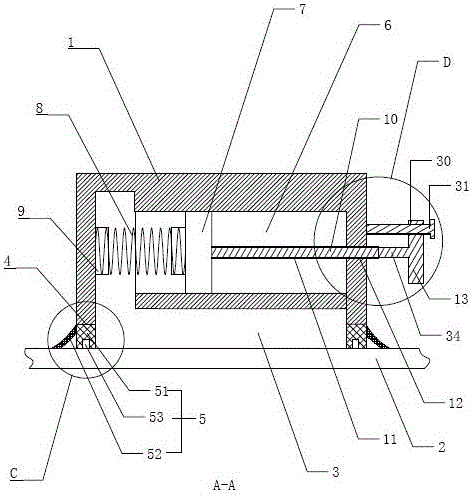

Active-type car window breaker

The invention discloses an active-type car window breaker. According to the technical scheme, the active-type car window breaker is characterized in that the car window breaker can be preliminarily fixed through a hard rubber edge and a soft rubber sealing edge of a vacuum cavity together with springs and a piston body, and then the piston body is driven to make displacement for further vacuum pumping by rotating a rotating plate, so that the car window breaker is fixedly installed on car window glass conveniently; meanwhile, a breaking device is arranged and comprises a breaking mechanism and a trigger mechanism, and the trigger mechanism can convert energy into kinetic energy of a firing pin by means of pressing by a user; and the firing pin can impact on a primer after obtaining the kinetic energy so that explosive in an explosive cavity can be detonated, explosion energy can generate sufficient pressure for a breaking piston, the piston on a center can have sufficient energy to press the glass through diamond on the center, and thus the glass can be broken. By means of the active-type car window breaker, a car window can be broken quickly and conveniently when the car window needs to be broken, and hence the life safety of passengers and drivers can be guaranteed.

Owner:CHANGSHU INTEREST SHARING INFORMATION TECH CO LTD

LED lamp tube recovering equipment

InactiveCN109909037AIncrease the speed of crushingImprove the extrusion effectGrain treatmentsLight pipeElectric machinery

The invention relates to recovering equipment, in particular to LED lamp tube recovering equipment. The LED lamp tube recovering equipment aims to achieve the technical effects that residues cannot besplashed out when an LED lamp tube is recovered. In order to achieve the technical effect, the LED lamp tube recovering equipment comprises a machine frame, a fixing plate, a first spring, a clampingplate, a moving rod, a rubber plate, a first sliding rail, a first sliding block, a second spring, a connecting rod, a pressing plate, a motor and the like, the fixing plate is welded to the machineframe, small holes are symmetrically formed in the rear portion and the front portion of the fixing plate, the movable rod is arranged in the small holes, and the first spring is connected between themovable rod and the left side of the fixing plate in a hook connecting mode. According to the LED lamp tube recovering equipment, the effect that the residue cannot be splashed out when the LED lamptube is recovered is achieved.

Owner:惠州巨能科技有限公司

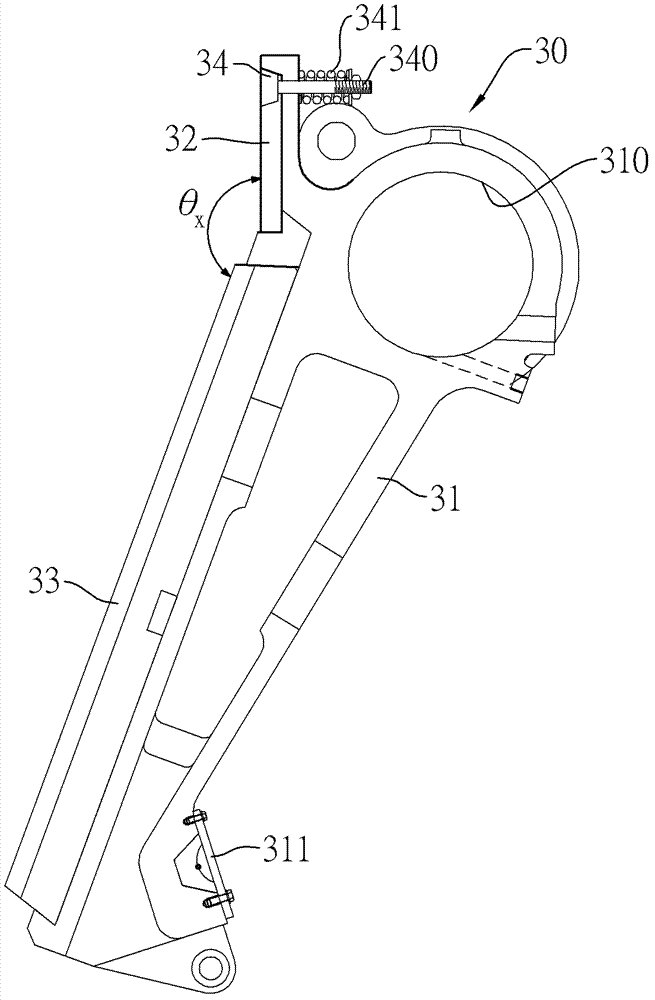

Improved jaw breaker

InactiveCN103191799ANot easy to damageExtended service lifeGrain treatmentsEngineeringMechanical engineering

The invention relates to an improved jaw breaker. The improved jaw breaker comprises a frame, a fixed jaw board, a transmission mechanism, a movable jaw assembly and a gap adjusting mechanism; and the transmission mechanism has an eccentric shaft, the top of the movable jaw assembly is sleeved on the eccentric shaft to pivot the movable jaw assembly to the eccentric shaft, the press block of the movable jaw assembly is positioned at the top of a movable jaw protection board, the fastening bolt of the movable jaw assembly is positioned above the eccentric shaft, and there is an angle of below 180DEG between the movable jaw protection board and the movable jaw board of the movable jaw assembly, so the motion locus of the bottom end of the movable jaw board can be improved, the production capability of the jaw breaker is raised, the fine powder proportion is reduced, the service life of the movable jaw board is prolonged, and the integral weight of the jaw breaker is reduced.

Owner:范公奇

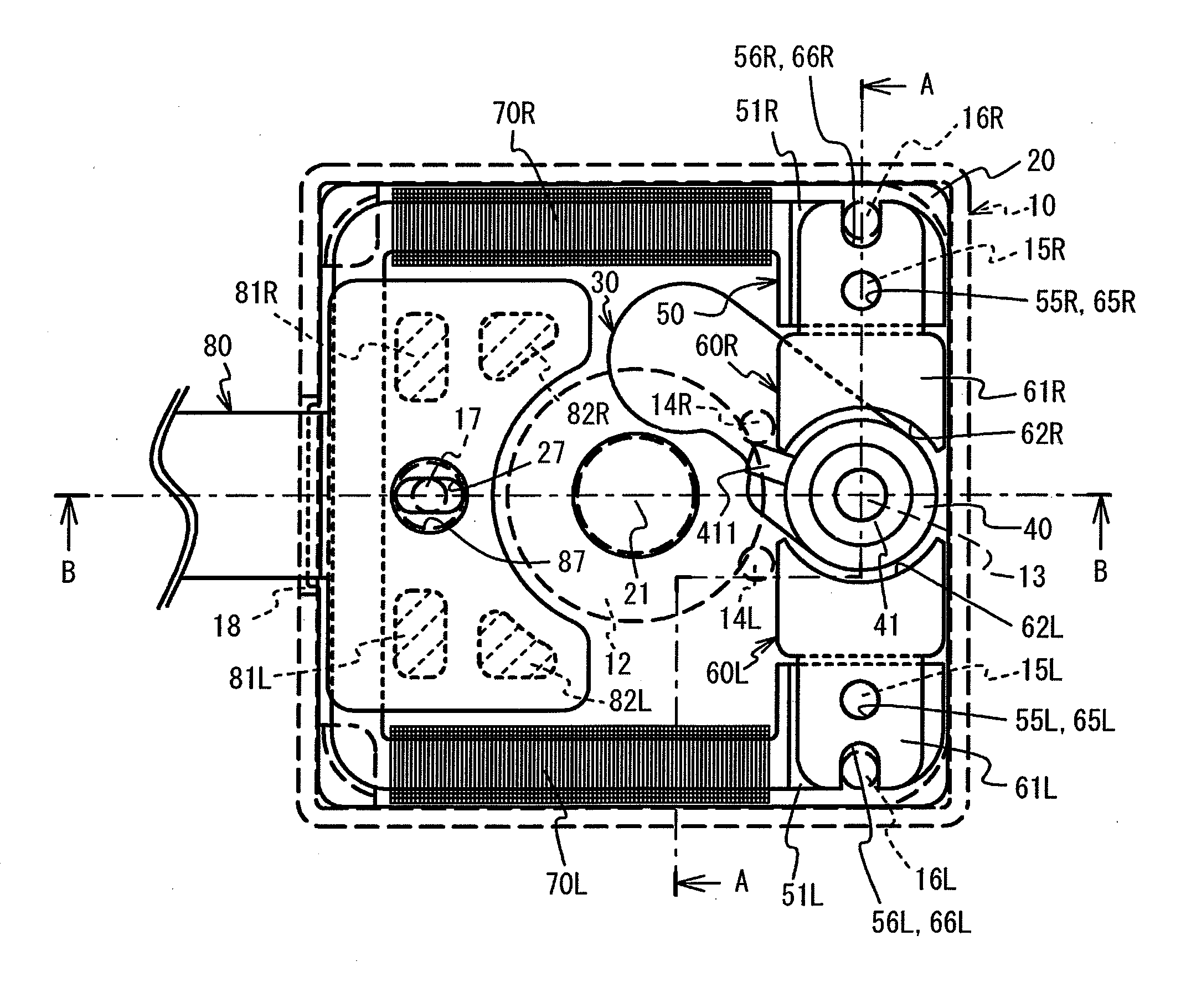

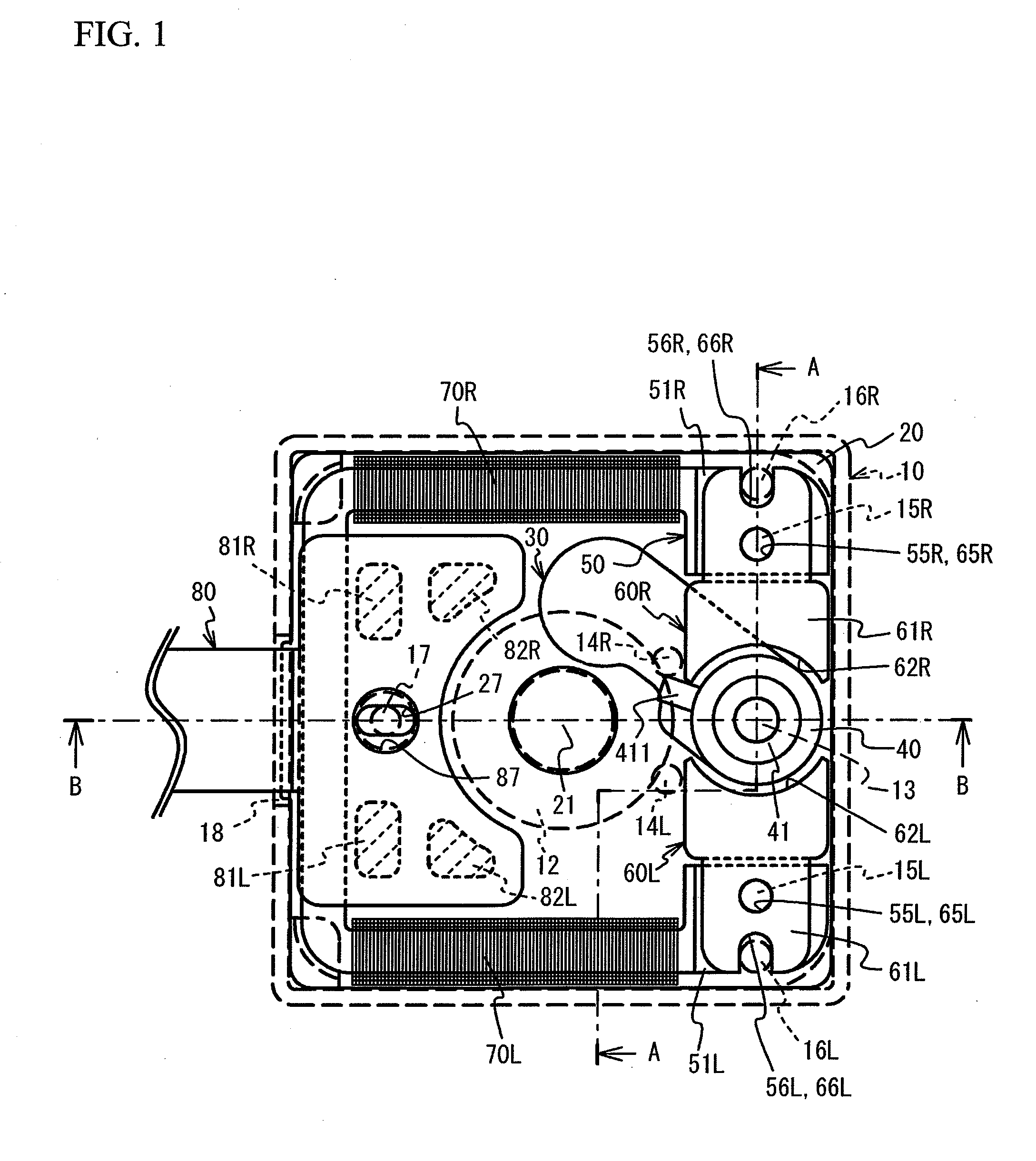

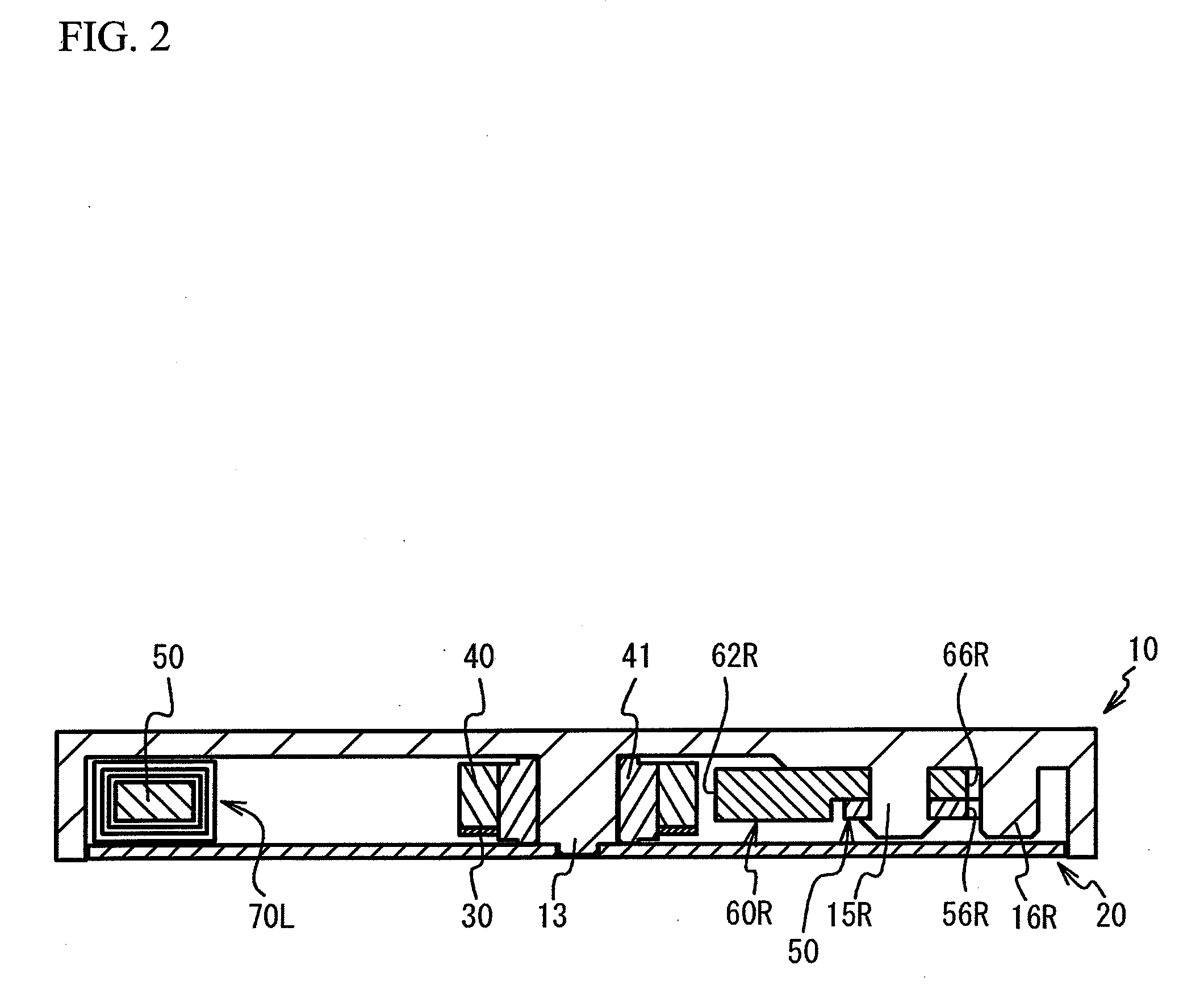

Blade drive device

ActiveUS20100046939A1Reduce sizeImproved shatter speedMagnetic circuit stationary partsShuttersStatorEngineering

A blade drive device includes: a blade; a drive source that drives the blade; and a chassis that has an opening opened and closed by the blade and that houses the blade and the drive source. The drive source includes: a rotor that is rotatably supported; a stator around which a coil for excitation is wound and which applies a rotational force to the rotor. The stator is arranged to surround a periphery of the opening and has a rectangular shape.

Owner:SEIKO HLDG KK TRADING AS SEIKO HLDG CORP

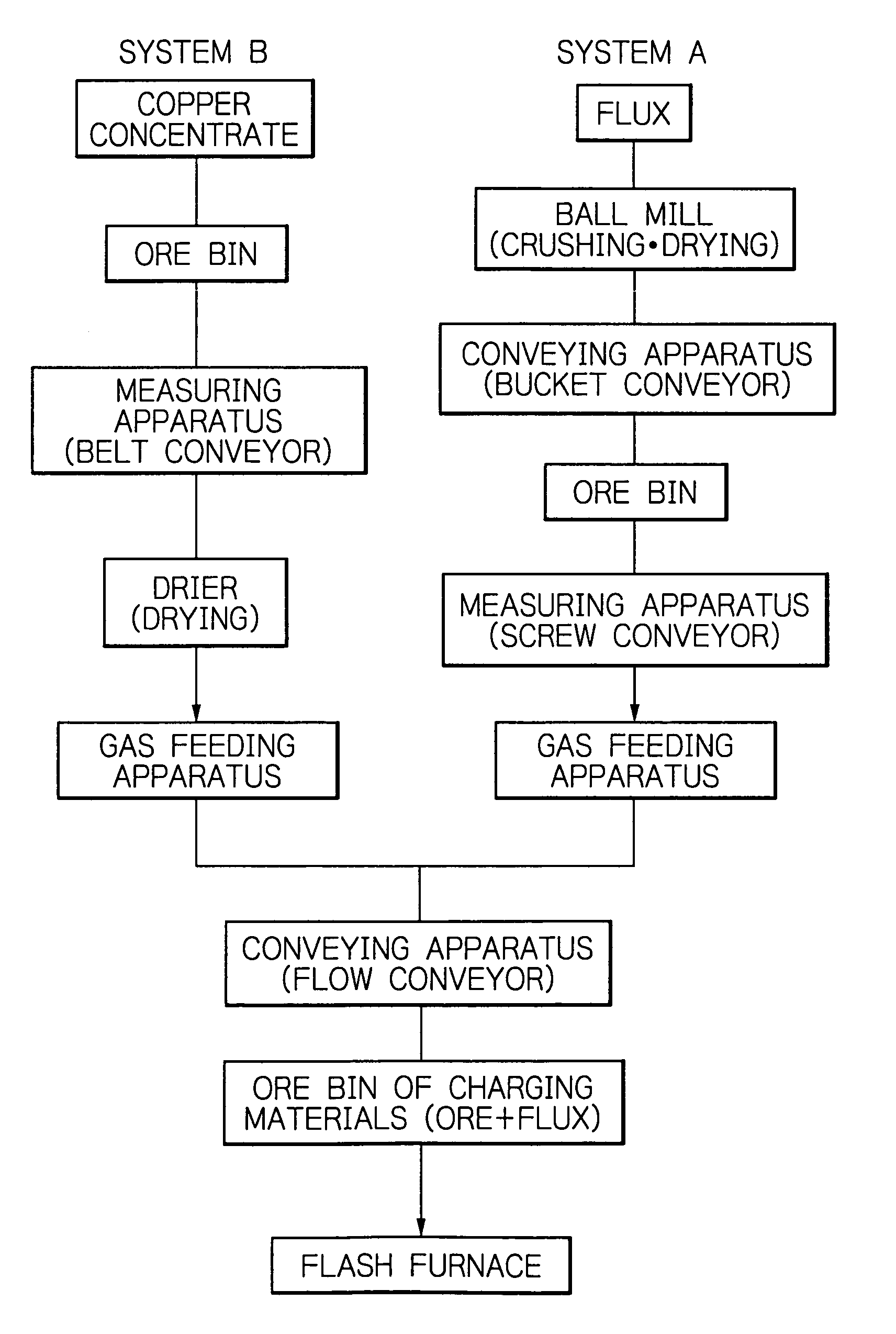

Method of operating non-ferrous smelting plant

ActiveUS7776133B2Increase productionIncrease volumeReverberatory furnaceGrain treatmentsNon-ferrous extractive metallurgyCopper

Owner:JX NIPPON MINING & METALS CORP

Method for operating non-ferrous smelting plant

ActiveUS20090064820A1Increase productionIncrease volumeGrain treatmentsNon-ferrous extractive metallurgyCopper

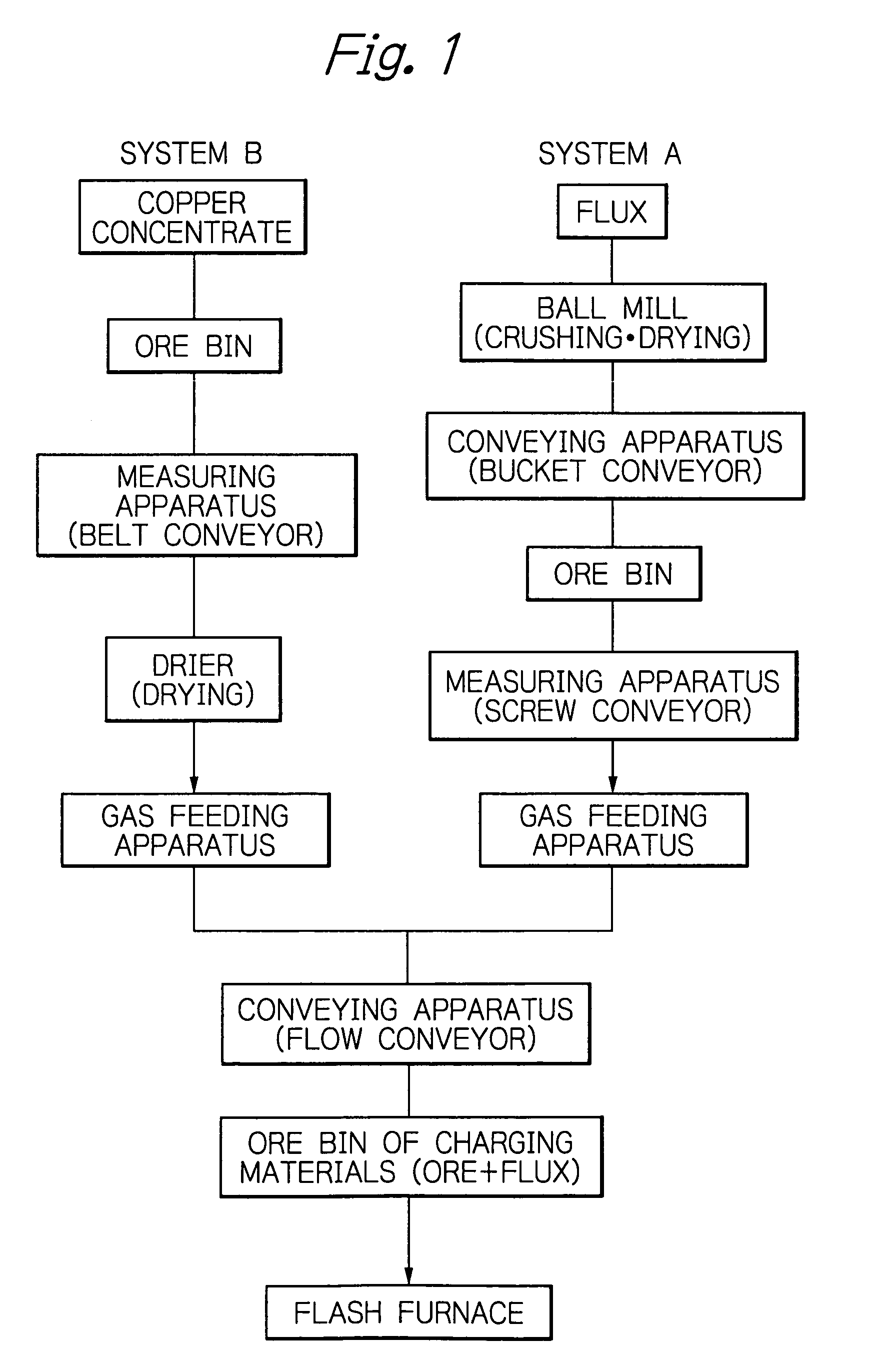

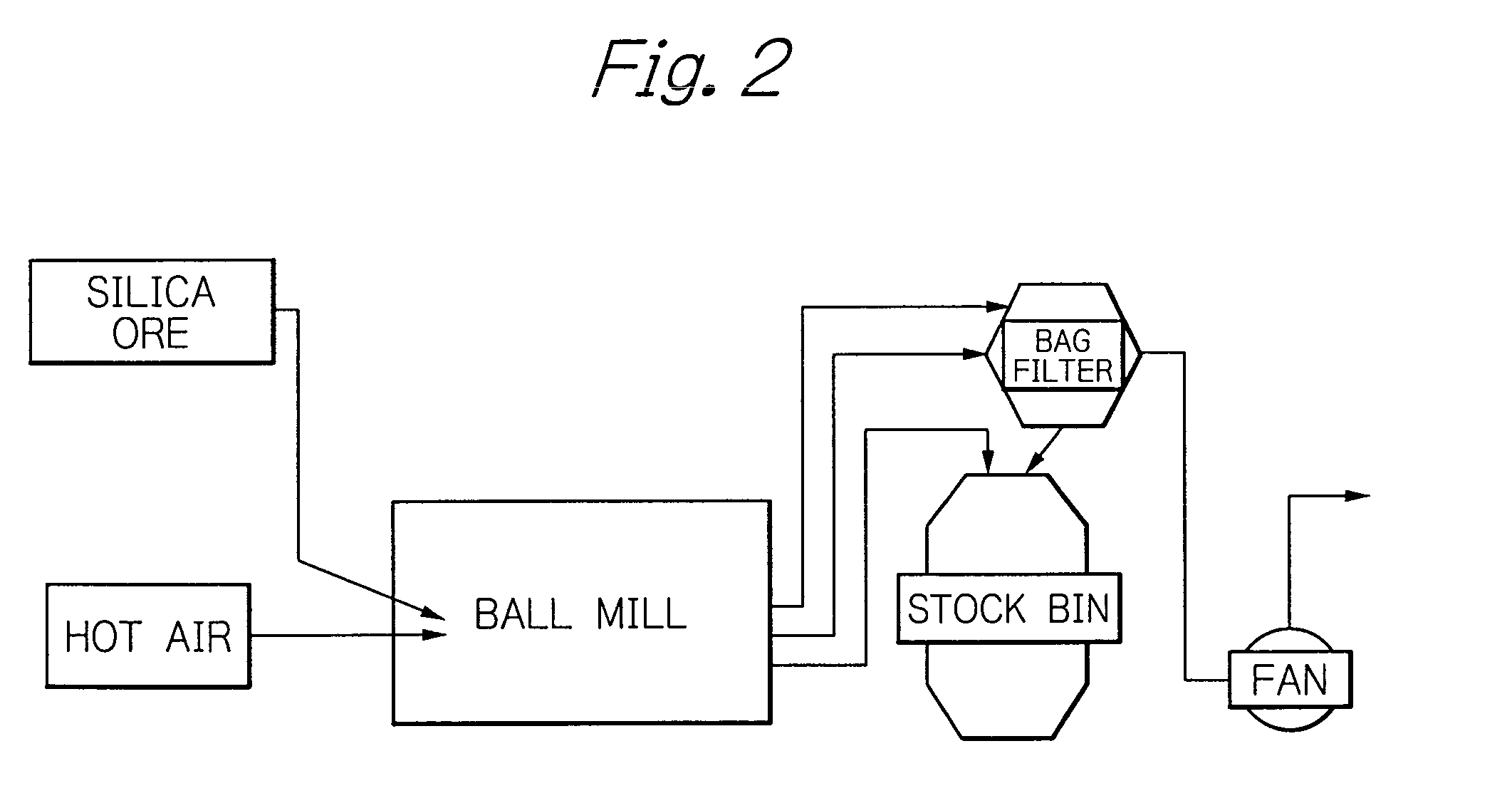

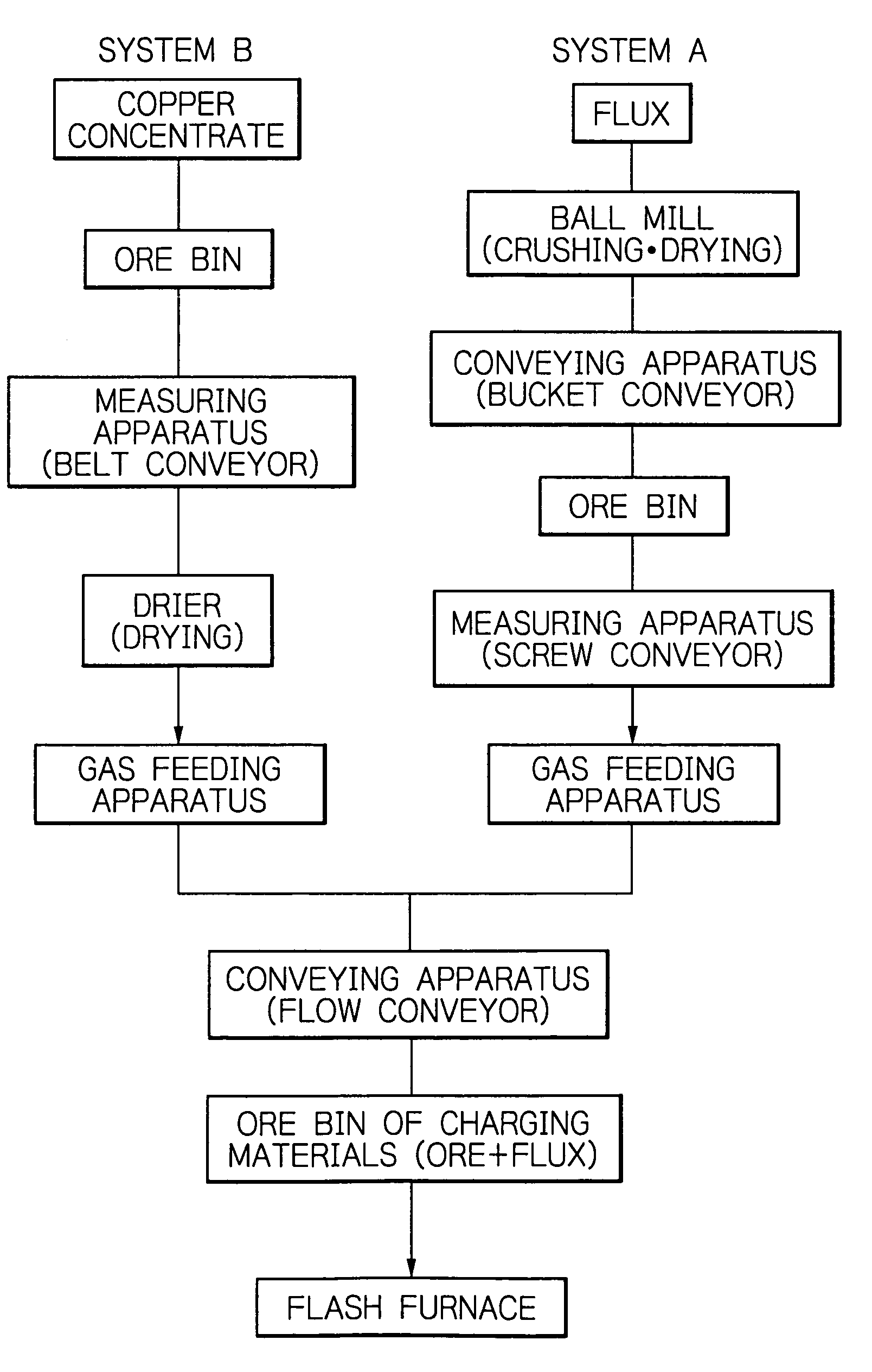

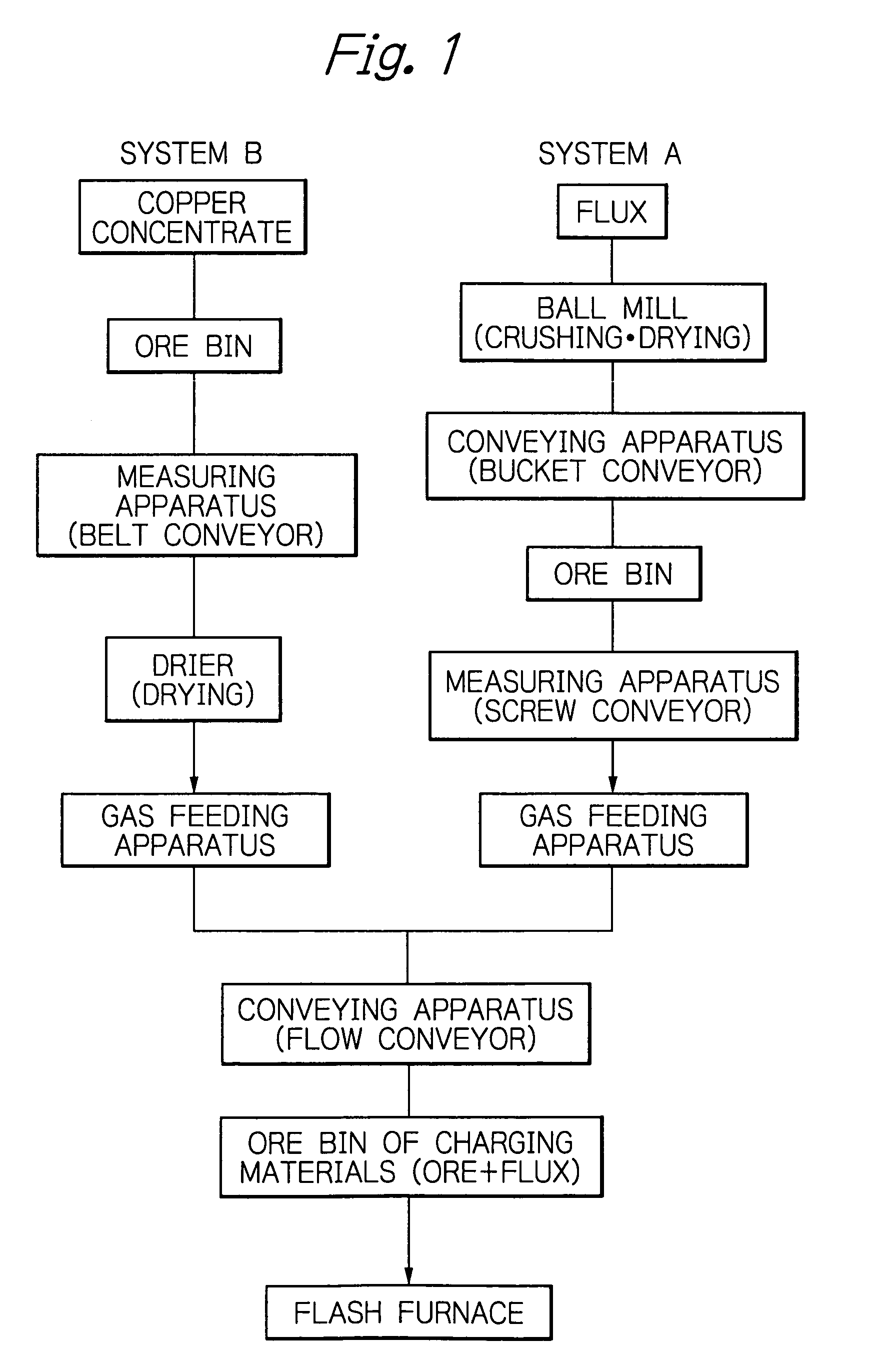

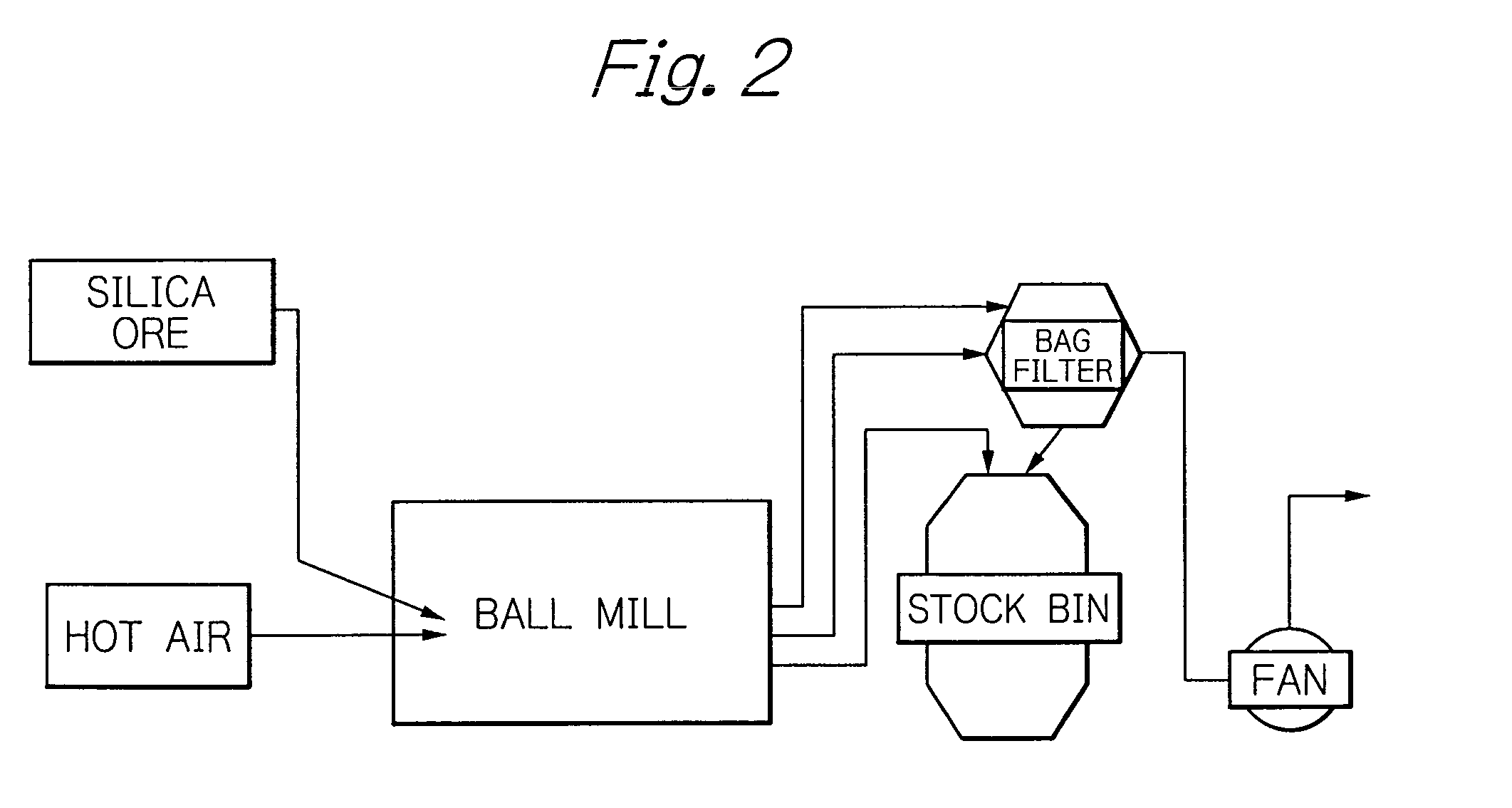

In the operation, a flux mainly composed of silica ore and a non-ferrous metal-ore raw-material are charged into a smelting furnace via a conveying system.In order to increase the production amount of the metal, the flux is conveyed and treated through a first system, in which the flux is crushed in a ball mill and dried in the ball mill while hot air is blown into the ball mill, and the crushed and dried flux is conveyed directly before the smelting furnace. In the drier of copper concentrate, the flux is not dried at all.

Owner:JX NIPPON MINING& METALS CORP

Energy-saving efficient aquatic product thawing device

PendingCN114027353AEvenly heatedImprove defrosting effectFood processingMeat/fish preservation by freezing/coolingFisheryUltraviolet lights

The invention relates to the technical field of aquatic products, in particular to an energy-saving efficient aquatic product unfreezing device. The technical scheme is that the device comprises a box body, a grid box and a base; a motor is installed in the tool box, a rotating rod is installed on the other side of the motor and penetrates through the box body, the grid box is installed on the other side of the rotating rod in the box body, a baffle is installed on the surface of the grid box, a collecting box is arranged at the bottom of the grid box in the box body, and a heating plate is installed at the other end in the box body; nozzles are mounted on the two sides of the top of the grid box through mounting frames, and an ultraviolet lamp panel is mounted on the top in the box body. According to the aquatic product unfreezing device disclosed by the invention, the spray head is aligned with the grid box to spray clean water to clean the grid box, and ultraviolet light irradiates the grid box to sterilize, sterilize and remove peculiar smell of the grid box, so that the problems of odor tainting and bacterium breeding are avoided, the subsequent unfreezing work of aquatic products is facilitated, and the use process is optimized.

Owner:ZHEJIANG OCEAN UNIV

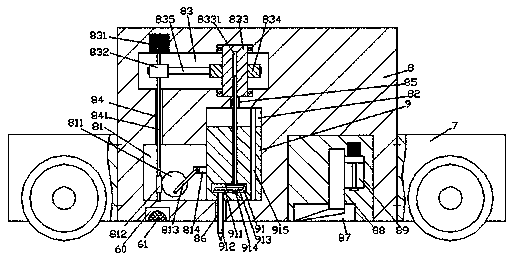

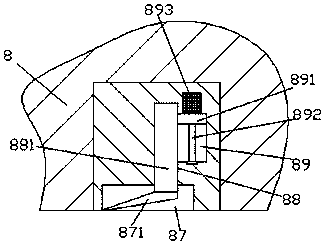

Improved construction device for road repairing

InactiveCN108221623ASimple structureEasy to operateRoads maintainenceArchitectural engineeringBuilding construction

The invention discloses an improved construction device for road repairing. The improved construction device comprises a loading vehicle body and a construction machine body, wherein the constructionmachine body is fixedly arranged in the loading vehicle body; a transmission cavity is formed in the construction machine body; the tail end of the right side of the transmission cavity is communicated with a sliding guiding cavity stretching upwards; a driving cavity stretching leftwards is formed in an inner wall body of the construction machine body arranged at the upper side of the sliding guiding cavity; a stretching section of the left side of the driving cavity is located in the construction machine body above the top part of the transmission cavity; a first through hole is formed in the inner wall body of the construction machine body between the transmission cavity and the driving cavity in a penetrating way; the first through hole is internally in transition fit connection with arotating shaft stretching up and down; a stretching section of the top part of the rotating shaft stretches into the driving cavity, and a stretching tail end is in power fit connection with a firstmotor; the outer surface of the first motor is embedded in and fixedly connected with the inner top wall of the driving cavity; a stretching tail end of the bottom part of the rotating shaft stretchesinto the transmission cavity and is in rotational fit connection with the inner bottom wall of the transmission cavity. The improved construction device disclosed by the invention is simple in structure, convenient to operate and high in safety, and the crushing speed and the crushing quality are increased.

Owner:广州曙迅自动化设备有限公司

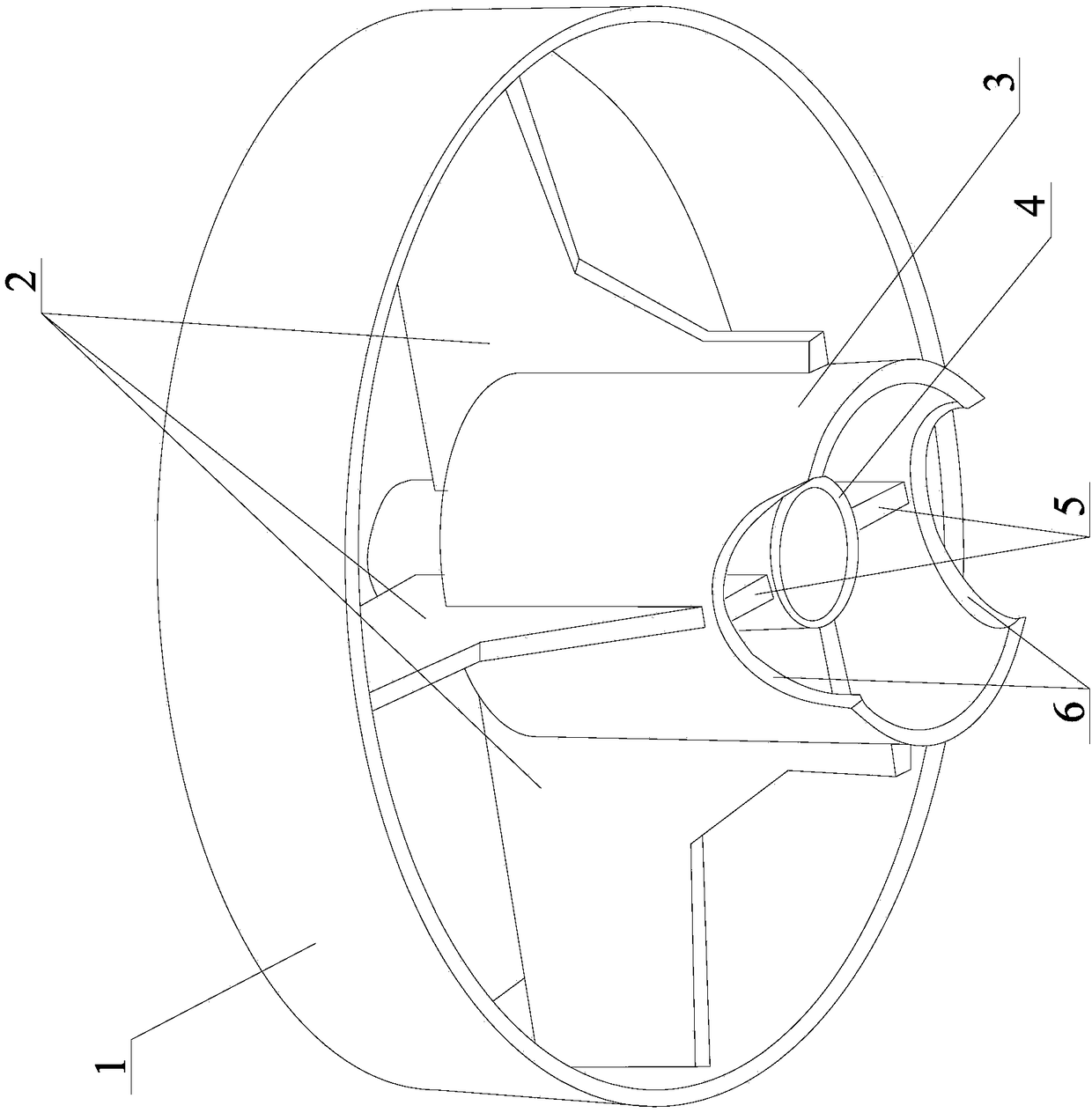

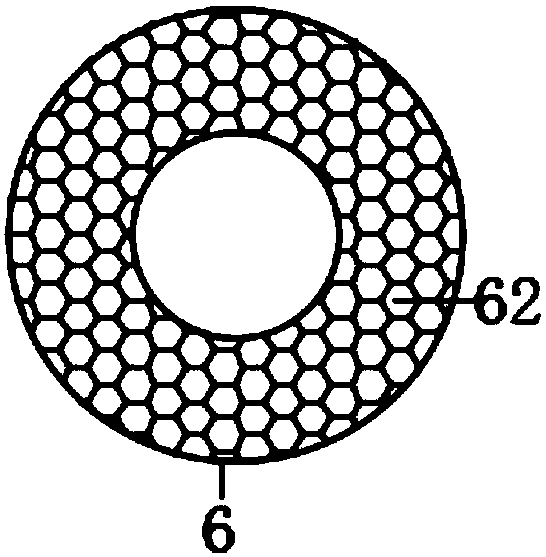

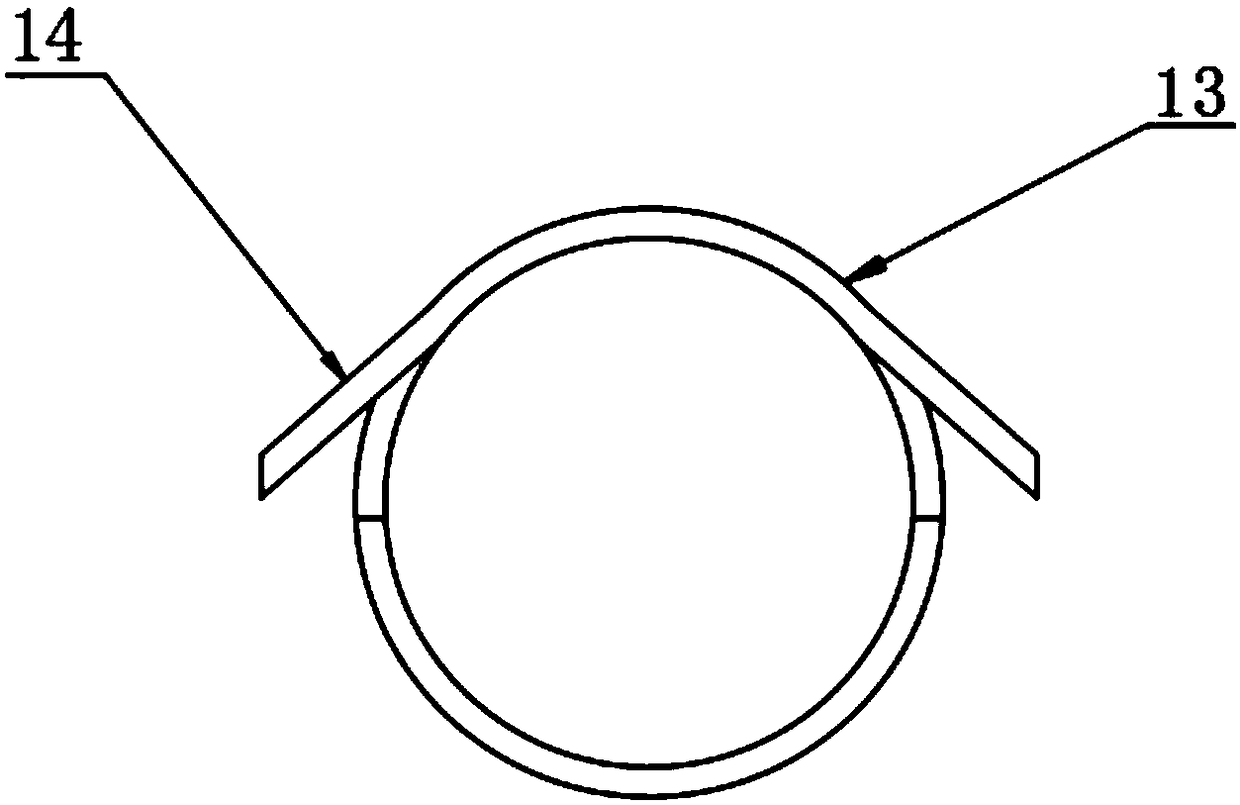

Drill bit for construction of cast-in-situ bored pile

PendingCN108590533APrevent deviationAvoid drill bit slipping and other phenomenaConstructionsDirectional drillingStructural engineeringSoil horizon

The invention discloses a drill bit for construction of a cast-in-situ bored pile. The drill bit comprises a hollow foundation rod, a connecting part positioned at the top end of the hollow foundationrod and used for being connected with a drill stem of a drilling machine, a retainer ring concentric with the hollow foundation rod, a plurality of connecting plates used for being connected with theretainer ring and a plurality of first scraper plates used for being connected with the retainer ring and provided with cutting teeth. A concentric guide drill sleeve is arranged outside the hollow foundation rod; the bottom end face of the guide drill sleeve is arranged to be a plane and the multiple cutting teeth are arranged on the bottom end face in the circumferential direction; the guide drill sleeve extends to the position below the bottom end face of the hollow foundation rod in the axial direction; a plurality of second scraper plates are arranged between the guide drill sleeve and the hollow foundation rod, wherein a plurality of cutting teeth are arranged at the bottom faces of at least two second scraper plates; all the connecting plates connected with the retainer ring and all the first scraper plates connected with the retainer ring at the same plumb line are arranged to be integrated type connecting plates and first scraper plates; and a plurality of cutting teeth are arranged on the bottom end face of the retainer ring. Drill holes, namely formed holes, of the drill bit in slop rock on the interface between soil and soft rock have good perpendicularity.

Owner:浙江易通特种基础工程股份有限公司

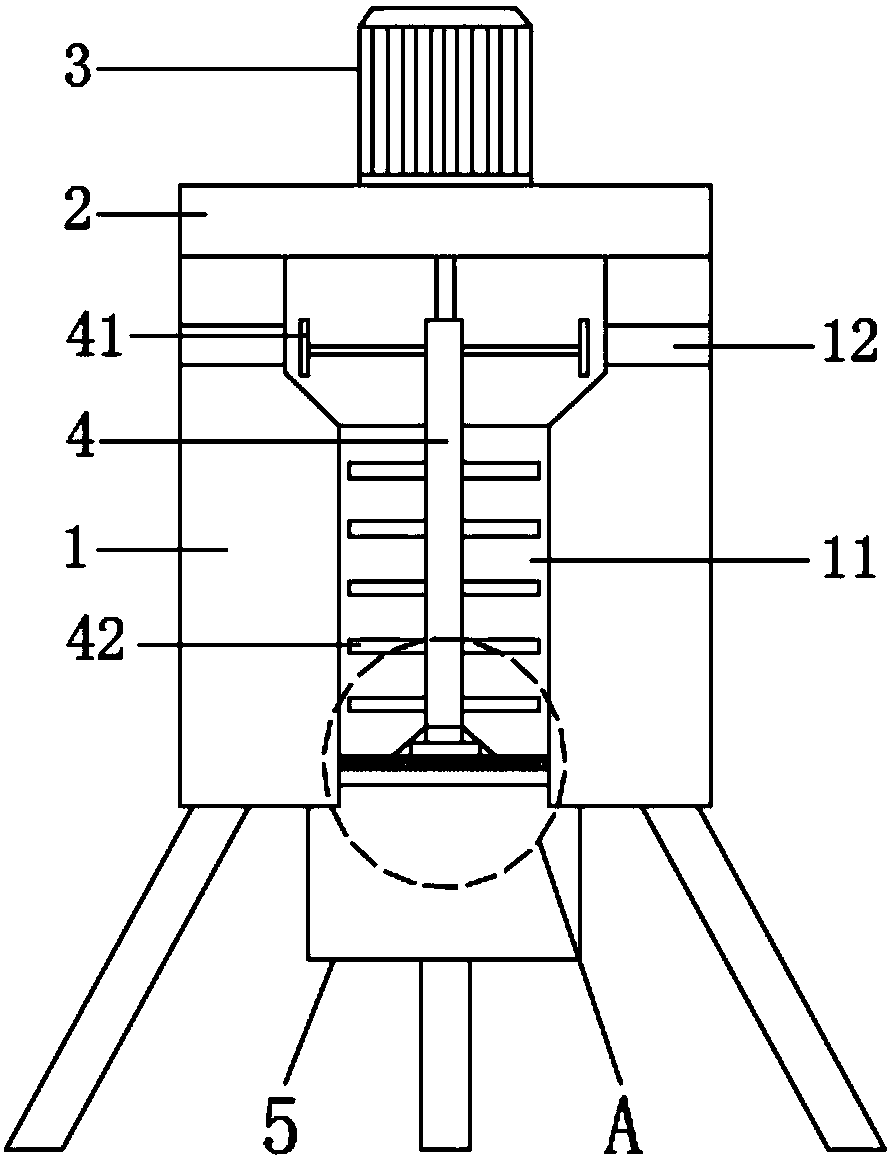

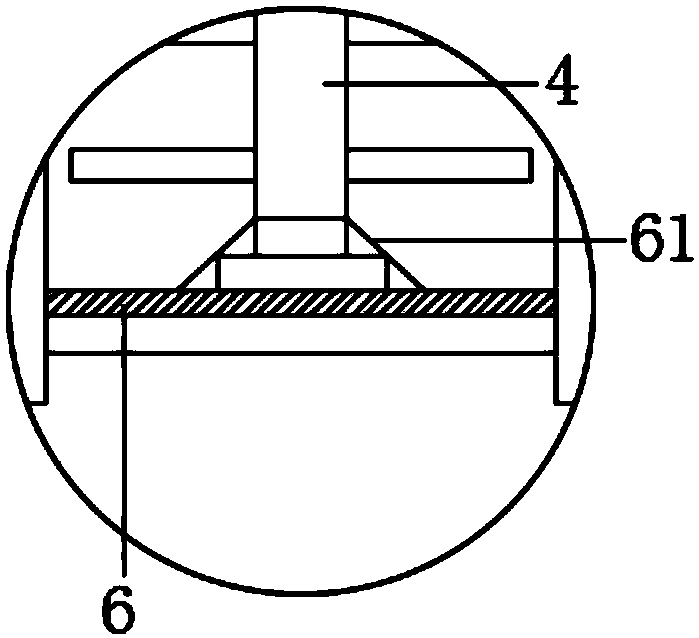

Plant sample crusher for plant inspection

PendingCN107930798AEasy to feedWell mixedPreparing sample for investigationGrain treatmentsElectric machineryAgricultural engineering

The invention provides a plant sample crusher for plant inspection. The plant sample crusher for plant inspection comprises a cutter, a crushing knife, a screen and a conical cover; a crushing channelis formed in middle in the machine body; the screen is fixedly mounted at the bottom of the inner side of the crushing channel; a rotating shaft of a crushing motor penetrates through a top cover toconnect into a cross connecting hole at the top of the rotating shaft; the top end side of the rotating shaft is connected with the cutter; the crushing knife is welded on the lower end side of the rotating shaft; the bottom of the rotating shaft penetrates through the conical cover on the screen to embed in a bearing; screen holes are formed in an annular structure on the outer side of the screen; a material barrel is connected to the bottom of the crushing channel through a thread; and five sets of feeding channels are annularly arranged on the upper end side of the crushing channel. Througharrangement of the arc cutter, materials fed in the crushing channel through the feeding channels can be sliced, and the crushing speed of samples in the crusher can be accelerated; and through arrangement of the multiple feeding channels, multiple materials can be crushed at the same times.

Owner:新昌县七星街道新伟机械厂

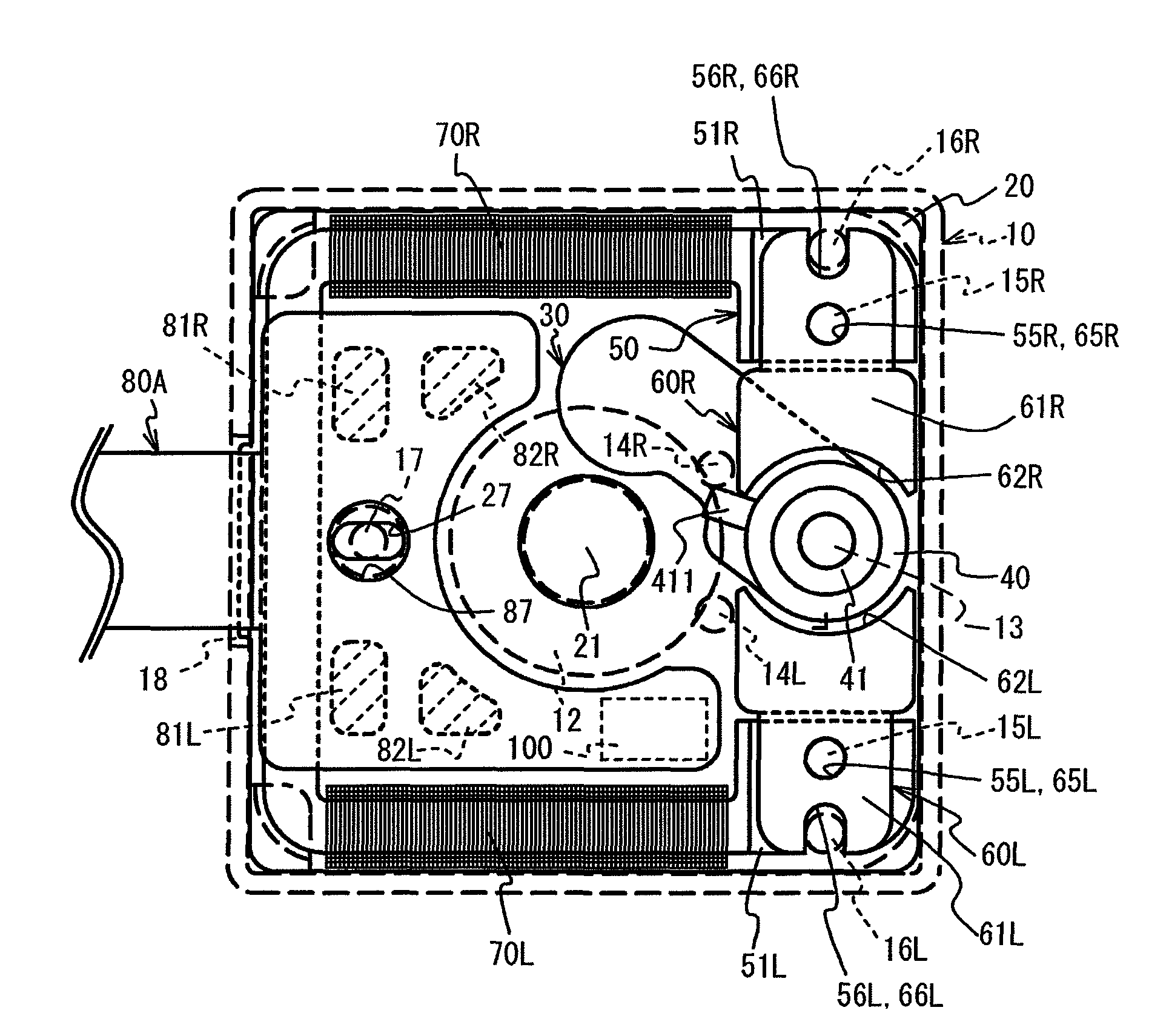

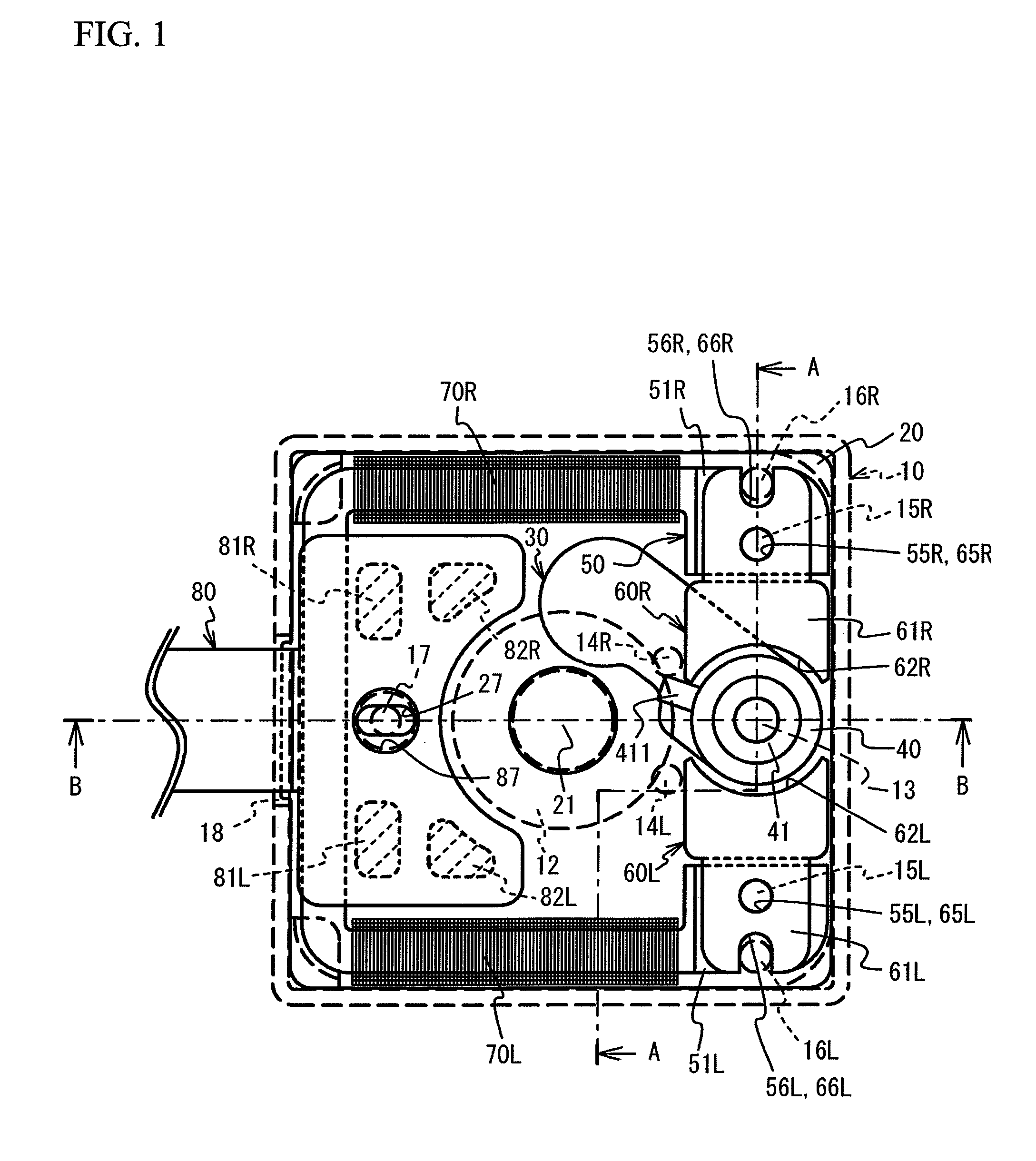

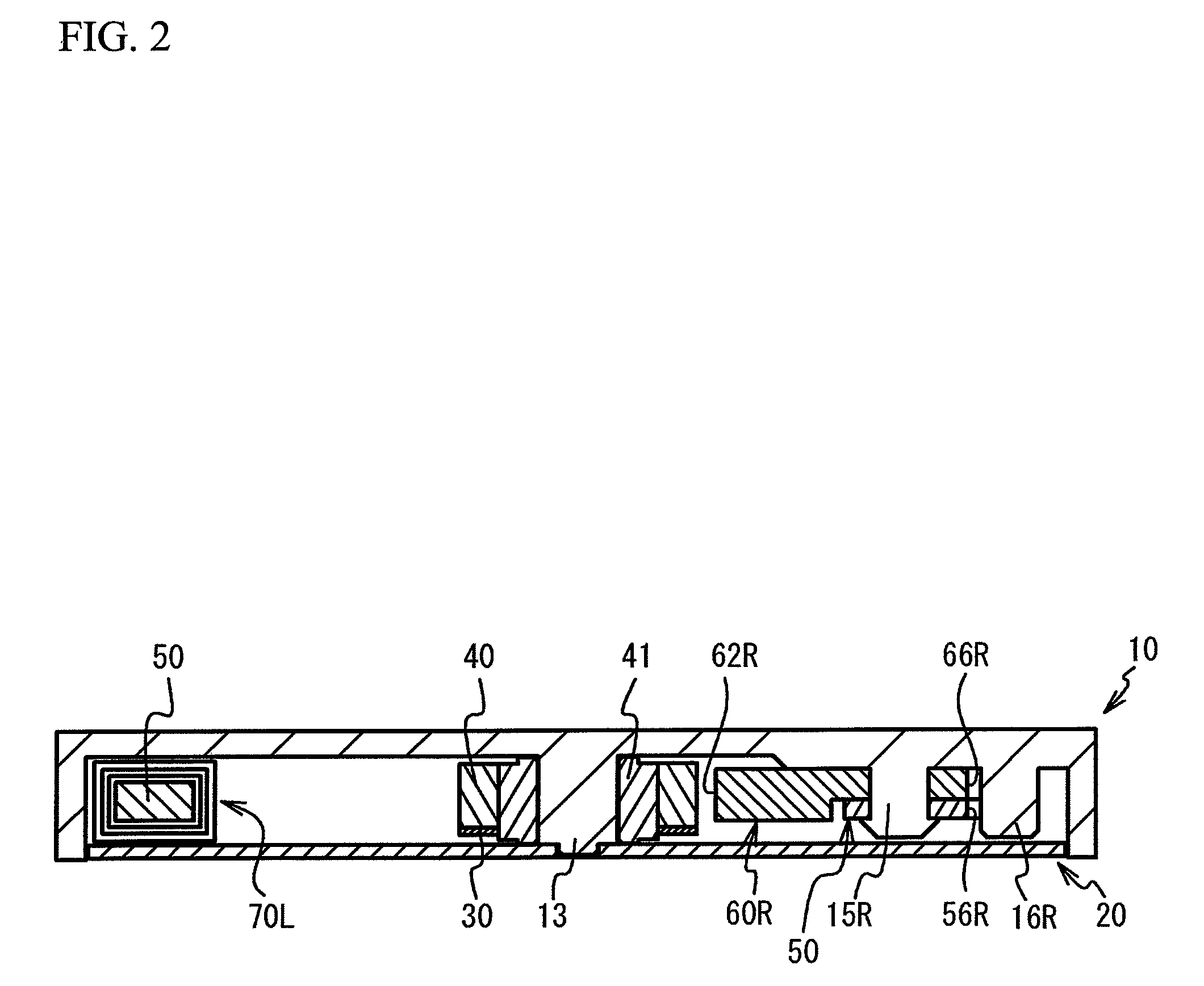

Blade drive device

ActiveUS8540439B2Small sizeIncrease the speed of crushingMagnetic circuit stationary partsShuttersEngineeringChassis

A blade drive device includes: a blade; a drive source that drives the blade; and a chassis that has an opening opened and closed by the blade and that houses the blade and the drive source. The drive source includes: a rotor that is rotatably supported; a stator around which a coil for excitation is wound and which applies a rotational force to the rotor. The stator is arranged to surround a periphery of the opening and has a rectangular shape.

Owner:SEIKO HLDG KK TRADING AS SEIKO HLDG CORP

Combined multi-stage rotary paint powder sanding device

ActiveCN111672581AIncrease collisionFast crushingGrain treatmentsManufacturing engineeringSupport plane

The invention relates to the technical field of paint, and discloses a combined multi-stage rotary paint powder sanding device. The combined multi-stage rotary paint powder sanding device comprises abase, a control console is fixedly connected to the top of the base, a supporting frame is fixedly connected to the top of the base, a main shaft is movably connected into the supporting frame, the outside of the main shaft is fixedly connected with a knock out pin, the outside of the main shaft is fixedly connected with a crushing ball, the outside of the crushing ball is fixedly connected with acounterweight, the right end of the main shaft is fixedly connected with a sleeve shaft, and a feeding inlet is movably connected into the sleeve shaft. Thorough cooperative use of the supporting frame, the main shaft, the knock out pin rod, the crushing ball, the counterweight and an inner shell, the effect of increasing collision is achieved, the efficiency of the movement of a medium inside the inner shell is improved, a collision mechanism and a collision method of the medium inside the inner shell are effectively increased, the crushing speed and crushing effect of the paint powder are improved, and the efficiency and quality of the paint powder grinding are effectively improved.

Owner:山东鸿粤新材料有限公司

Direct current switch-off device and control method thereof

ActiveUS10418803B2Reduce equipment costsImprove scalabilityEmergency protective arrangements for automatic disconnectionHigh-tension/heavy-dress switchesNonlinear resistorElectrical resistance and conductance

A direct current switch-off device comprises an on-state current branch circuit and a current commutating and breaking unit which are connected in parallel. The on-state current branch circuit has a mechanical switch (S) and a current transfer module which are connected in series. The current commutating and breaking unit comprises a bridge-type branch circuit and a current-breaking branch circuit. The current-breaking branch circuit and two bridge arms of the bridge-type branch circuit are connected in parallel. The current-breaking branch circuit comprises a nonlinear resistor (RI) and a valve group consisting of fully-controlled devices connected in series. The nonlinear resistor (RI) and the valve group are connected in parallel. Two ends of each fully-controlled device in the valve group are connected in parallel with a buffering and reclosing circuit.

Owner:NR ELECTRIC CO LTD +1

Underwater vehicle window crusher

InactiveCN106621094AConvenient and quick escapeEscape car window glass shattered quicklyBuilding rescueDriver/operatorGas passing

The invention discloses an underwater vehicle window crusher. According to key points of the technical scheme, the vehicle window crusher is conveniently and fixedly mounted on vehicle window glass by a vacuumizing device by virtue of a hard rubber edge and a soft rubber sealing edge of a vacuum chamber, an inductive water pipe is arranged, and when a certain water pressure enters the inductive water pipe, the water pressure presses an induction piston to move, and then water enters a gas production chamber and reacts with sodium so as to produce lots of gases. The produced gases push a switching piston to close the water inlet of the inductive water pipe, the produced gases are prevented from flowing out of the inductive water pipe and further push the switching piston to press the residual gases into the gas production chamber, and the residual gases further react so as to increase the gas pressure. Pressure is produced to the vehicle window glass by a crushing piston tip and a stainless steel drill, so that the glass is broken. According to the underwater vehicle window crusher disclosed by the invention, the problem that the existing underwater escape vehicle window crusher is complicated in operation and low in speed so as to influence timely escape of passengers and drivers is solved.

Owner:CHANGSHU INTEREST SHARING INFORMATION TECH CO LTD

Environment-friendly garbage crusher

InactiveCN108970756AImprove crushing effectEvenly dispersedDrying gas arrangementsGrain treatmentsEngineeringCrusher

The invention discloses an environment-friendly garbage crusher. The environment-friendly garbage crusher comprises a base, wherein a fixed rod is arranged at the top of the base; a machine case is arranged at the top of the fixed rod; a fixed plate is arranged at one side of the machine case; a first motor is arranged at the top of the fixed plate; a second motor is arranged at the top of the first motor; a rotary shaft is arranged at one side of each of the first motor and the second motor; a rotary barrel is arranged at the outer side of each rotary shaft; a fixed rod is arranged at the bottom of each rotary barrel; cutting rings are arranged at the outer sides of the rotary barrels and the fixed rods; a hollow plate is arranged at the bottom of each fixed rod; and the bottom end of each hollow plate is hinged with an inner wall of the machine case. According to the environment-friendly garbage crusher disclosed by the invention, the rotary barrels, the fixed rods, the cutting ringsand the hollow plates are arranged, and the first motor and the second motor are used for driving the cutting rings through respective rotary shafts; the cutting rings at the outer sides of the rotary barrels and the cutting rings at the outer sides of the fixed rods are driven; and garbage falls onto the hollow plates and the three cutting rings form a triangular structure, so that the garbage crushing efficiency is easy to improve and the crushing speed is increased.

Owner:肇庆市天地人科技有限公司

Constructional engineering demolition material recycling device and operation method thereof

InactiveCN113427600AImprove the universality of applicationIncrease water permeability and breathabilityMixing operation control apparatusPretreatment controlArchitectural engineeringDisposal Technique

The invention relates to the technical field of constructional construction waste treatment, in particular to a constructional engineering demolition material recycling device and an operation method thereof. The constructional engineering demolition material recycling device comprises a primary processing mechanism, the primary processing mechanism comprises a main box body, a double processing mechanism is installed on the lower portion of the interior of the main box body, a first conveying belt assembly is connected to the bottom of the main box body, a material conveying mechanism is arranged at one end of the outer side of the first conveying belt assembly, and a material mixing mechanism is connected to the outer side of the material conveying mechanism. According to the constructional engineering demolition material recycling device, raw materials are mixed through the material mixing mechanism, meanwhile, a mixture in the material mixing mechanism is fully inflated after a fan is started, therefore, the interior of the mixture is rich in a large amount of gas, a large number of bubble cavities exist in the formed mixture, the formed mixture has good water permeability and air permeability, the mixture can be used as filling ceramsite for backfilling in a light-weight space, and the application universality of recycling of the demolition material is effectively improved.

Owner:张淞睿

A kind of recycling and processing equipment for microelectronic materials and semiconductor raw materials

ActiveCN110773265BShorten the reprocessing lineReduce labor costsSolid waste disposalTransportation and packagingProduction lineProcess engineering

The invention discloses a device for recycling and processing microelectronic materials and semiconductor raw materials, which comprises a box body and a melting box arranged inside the box body. There are outriggers, an electric heating plate is fixedly installed on the inner wall of the melting box, a discharge nozzle connected with the outside of the box is provided at the lower end of the melting box, and a plurality of crushing rollers are evenly distributed on the upper end of the inner wall of the box. The invention integrates the drying, crushing and melting processes in the recycling process of semiconductor raw materials by setting the driving mechanism, crushing roller, electric heating plate, pumping mechanism, air guide chamber and gas injection port, reducing the space occupied by the production line and Labor costs can also be blown and spread the raw materials on the crushing roller to improve the crushing efficiency. At the same time, it can automatically realize the positive correlation adjustment of the production speed between each process, without manual operation, reduce labor intensity, and is not easy to make mistakes, avoiding production Into chaos.

Owner:湖州力卓机械设备技术开发有限公司

Automatic grinding device for construction waste soil

The invention relates to the technical field of processing machinery, in particular to an automatic grinding device for construction waste soil. The automatic grinding device comprises an extrusion power cavity, an extrusion cavity, a crushing cavity, a grinding cavity and a driving cavity; a hydraulic rod is arranged in the extrusion power cavity, a pressing plate is arranged at the bottom of the hydraulic rod, a feeding port is formed in the side wall of the extrusion power cavity, a pressure bearing plate is arranged at the bottom of the extrusion cavity, a fixed partition cutter plate is arranged in the crushing cavity, and a conical cutter is arranged in the middle of the fixed partition cutter plate; and a fixed bearing is fixedly installed on the side wall of the crushing cavity, a rotating shaft is arranged in the fixed bearing, a crushing disc is fixedly connected to the outer surface of the rotating shaft, a grinding disc is arranged in the grinding cavity, a conveying belt is arranged at the bottom of the grinding cavity, and a discharging opening is formed in the bottom of the grinding cavity. The problems that the construction waste soil is accumulated, so that the local land environment is damaged, the life and safety of local residents are affected, collapse possibly occurs, threats are caused, land resources are wasted, and the resources cannot be well utilized are solved.

Owner:新沂市新南环保产业技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com