Plant sample crusher for plant inspection

A pulverizer and pulverizing motor technology, applied in the field of mechanical pulverizing equipment and sample pulverization, can solve the problems of long pulverization time, easily damaged pulverizing knife service life, affecting pulverizing effect and speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

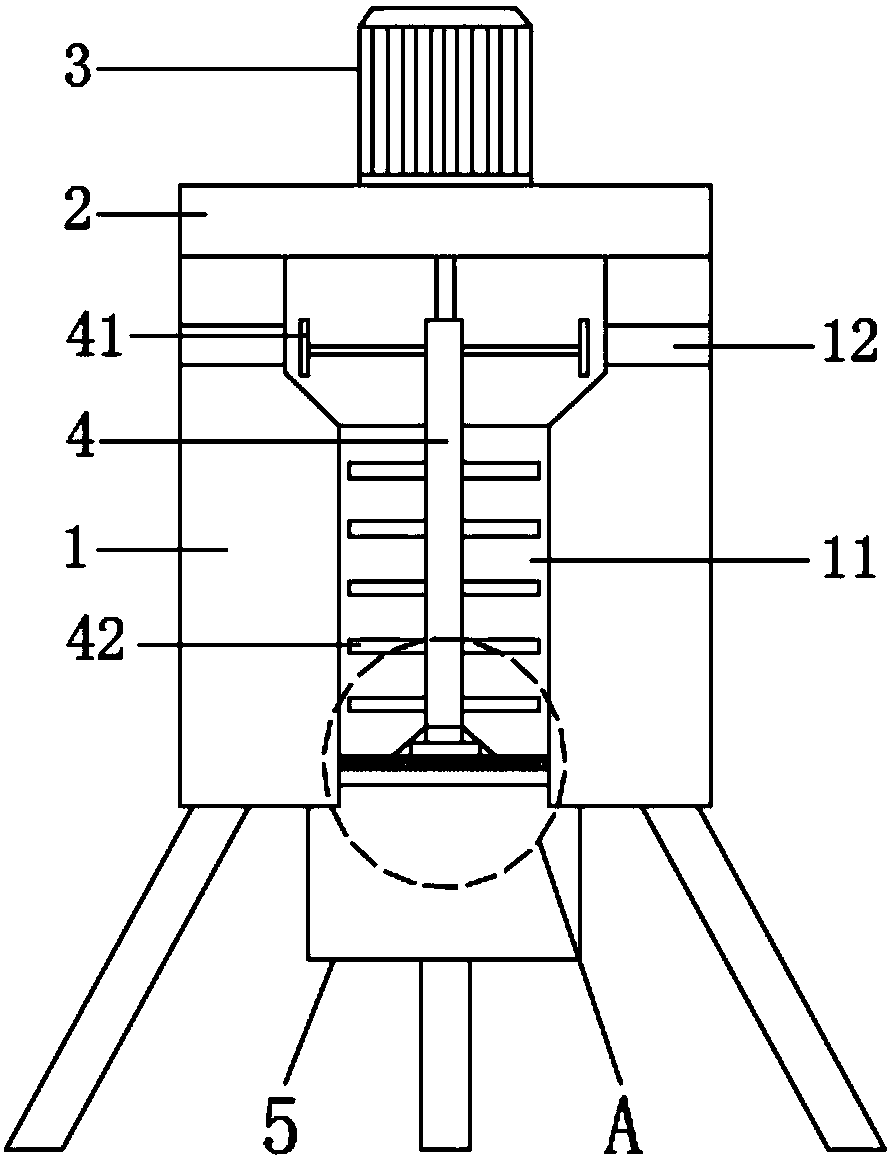

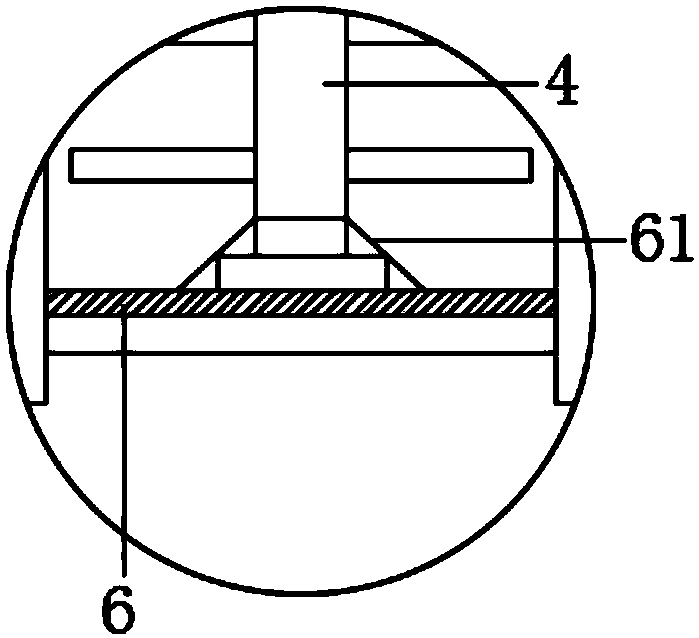

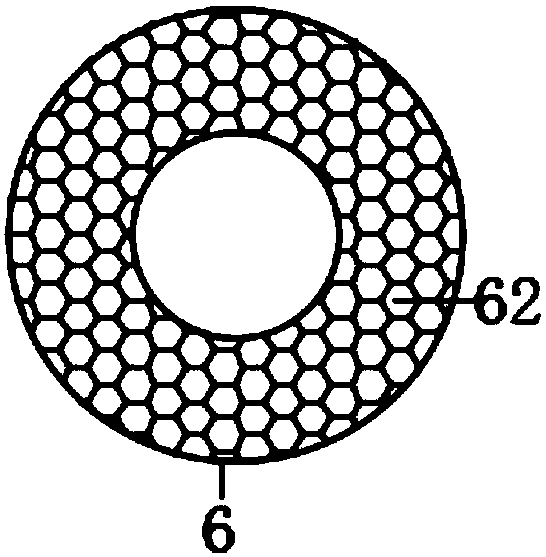

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The present invention provides a plant sample grinder for plant inspection, comprising a body 1, a crushing channel 11, a feeding channel 12, a top cover 2, buckles 21, a crushing motor 3, a rotating shaft 4, a cutter 41, and a crushing knife 42 , a cross-shaped connecting hole 43, a material barrel 5, a screen 6, a conical cover 61 and a screen hole 62; the inner middle of the body 1 is provided with a crushing channel 11, and the inside bottom of the crushing channel 11 is fixedly equipped with a screen 6 , the top of the body 1 is connected with a top cover 2 through a buckle 21, and a pulverizing motor 3 is fixed in the middle of the top of the top cover 2, and the rotating shaft of the pulverizing motor 3 passes through the top cover 2 and is connected to a cross-shaped In the connection hole 43, the top end side of the rotating shaft 4 is connected with a cutter 41, and the lower end side of the rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com