Improved construction device for road repairing

A technology of road repair and construction device, applied in the direction of road repair, roads, roads, etc., can solve the problems of low construction efficiency, slow construction speed, large floor space, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

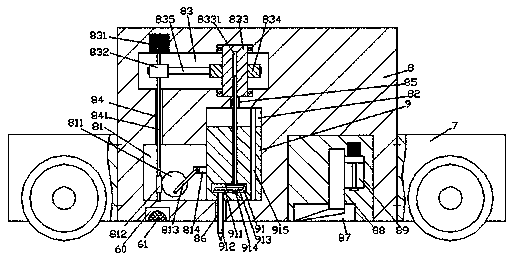

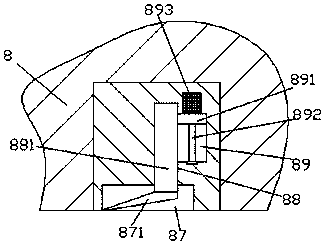

[0013] Such as figure 1 , figure 2 with image 3 As shown, an improved construction device for road repair of the present invention includes a loading vehicle body 7 and a construction machine body 8 fixedly installed in the loading vehicle body 7, and a transmission chamber 81 is provided inside the construction machine body 8. The right end of the transmission chamber 81 is communicated with a guide chamber 82 extending upward, and the inner wall of the construction body 8 on the upper side of the guide chamber 82 is provided with a drive chamber 83 extending to the left. The left extension section of the driving chamber 83 is located in the construction machine body 8 above the top of the transmission chamber 81, and the inner wall of the construction machine body 8 between the transmission chamber 81 and the drive chamber 83 is provided with a first passageway. Hole 84, the first through hole 84 is transitionally connected with a rotating shaft 841 extending up and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com