Automatic grinding device for construction waste soil

A technology for construction waste soil and powder grinding, applied in the field of processing machinery, can solve problems such as affecting residents' lives and appearing, threatening, and wasting land resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

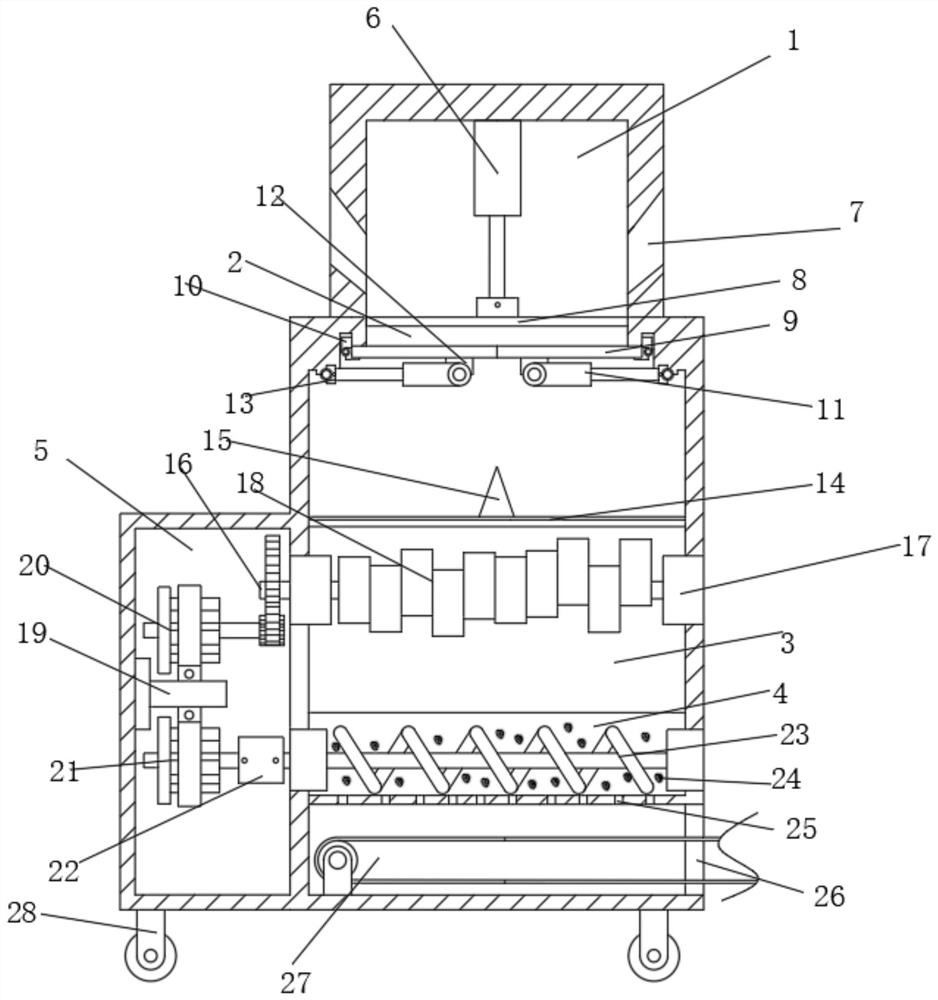

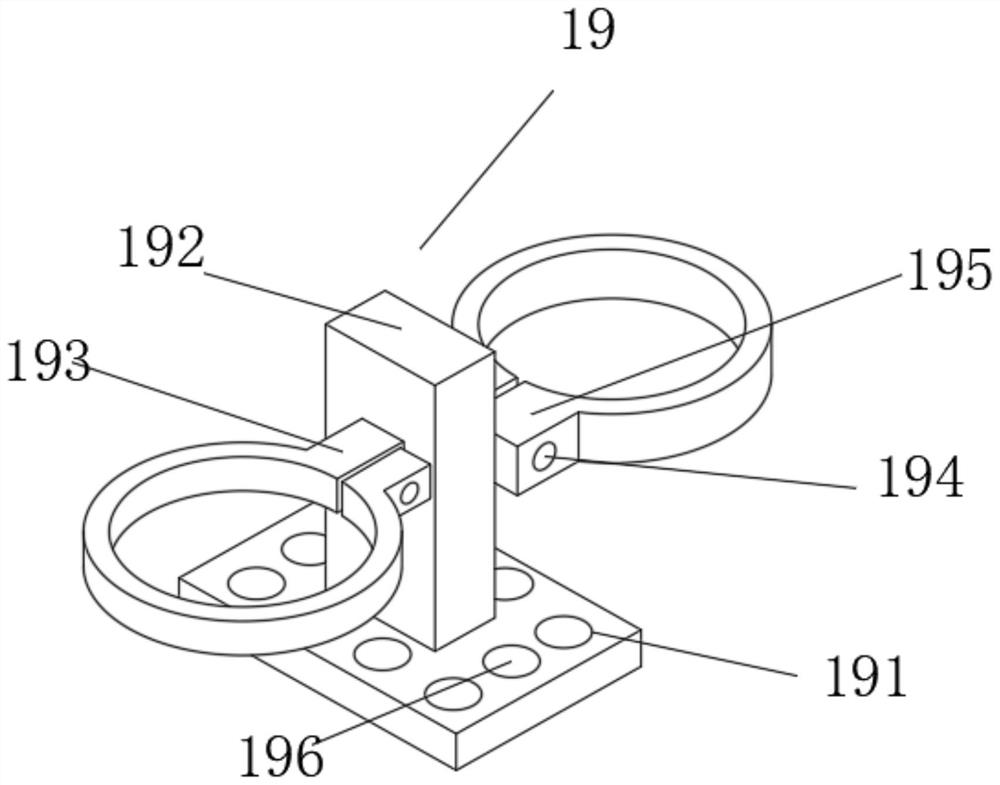

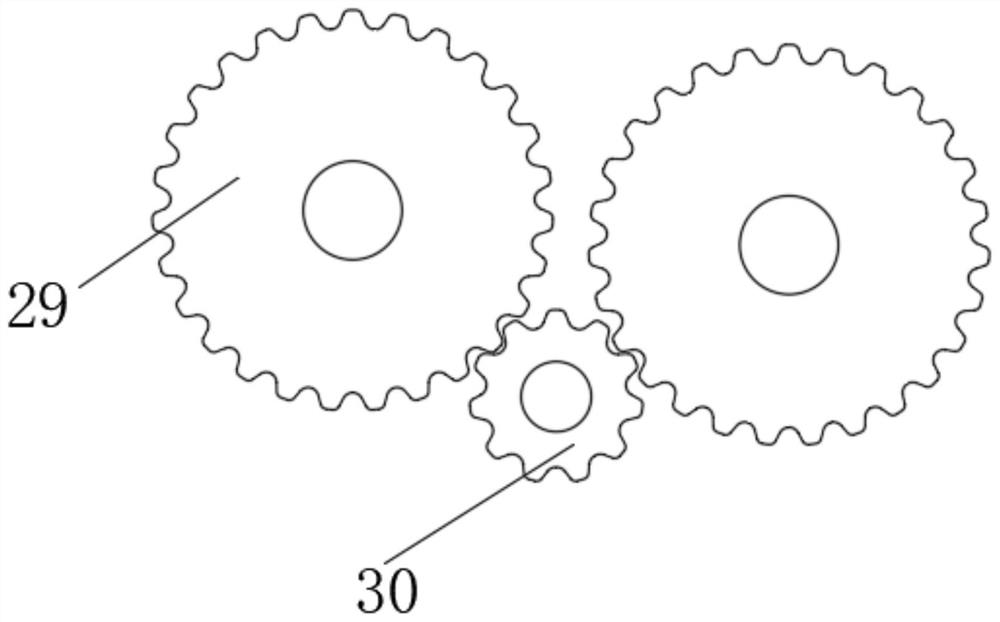

[0023] An automatic grinding device for construction waste soil, in order to solve the accumulation of construction waste soil, destroy the local land environment, affect the life of local residents and the problems that arise, as a preferred embodiment, such as figure 1 , figure 2 , image 3 As shown, this example includes an extrusion power chamber 1, an extrusion chamber 2, a crushing chamber 3, a milling chamber 4 and a driving chamber 5. The interior of the extrusion power chamber 1 is provided with a hydraulic rod 6, and the bottom of the hydraulic rod 6 A pressure plate 8 is provided, a feed port 7 is opened on the side wall of the extrusion power chamber 1, a pressure bearing plate 9 is provided at the bottom of the extrusion chamber 2, and one end of the pressure bearing plate 9 is connected to the extrusion chamber 2 through a strong hinge 10 On the outer wall of the bearing plate 9, the lower end of the pressure bearing plate 9 is fixedly connected with a fixed co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com