LED lamp tube recovering equipment

A technology of LED lamps and recycling equipment, applied in the direction of grain processing, etc., can solve the problem that the residue will splash out and hurt the staff, and achieve the effect of increasing the crushing speed and increasing the extrusion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

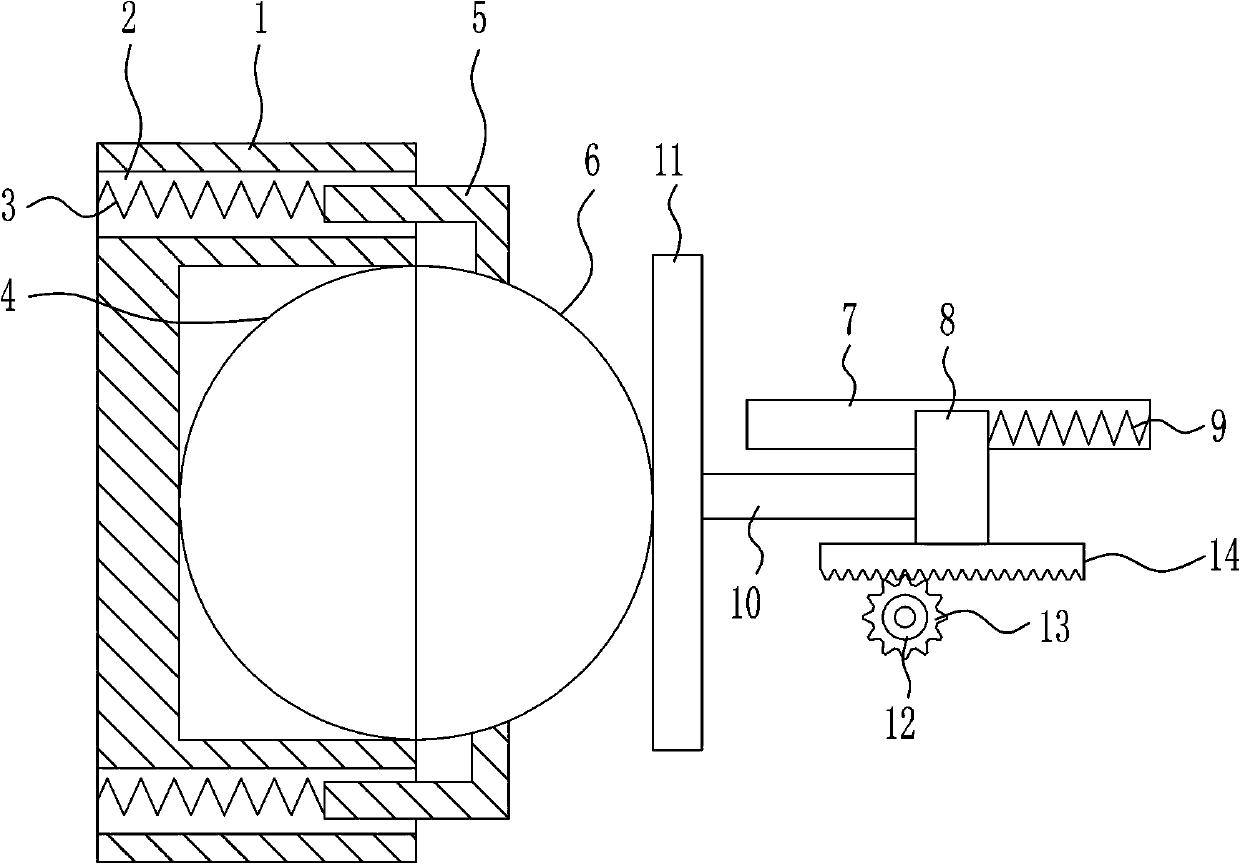

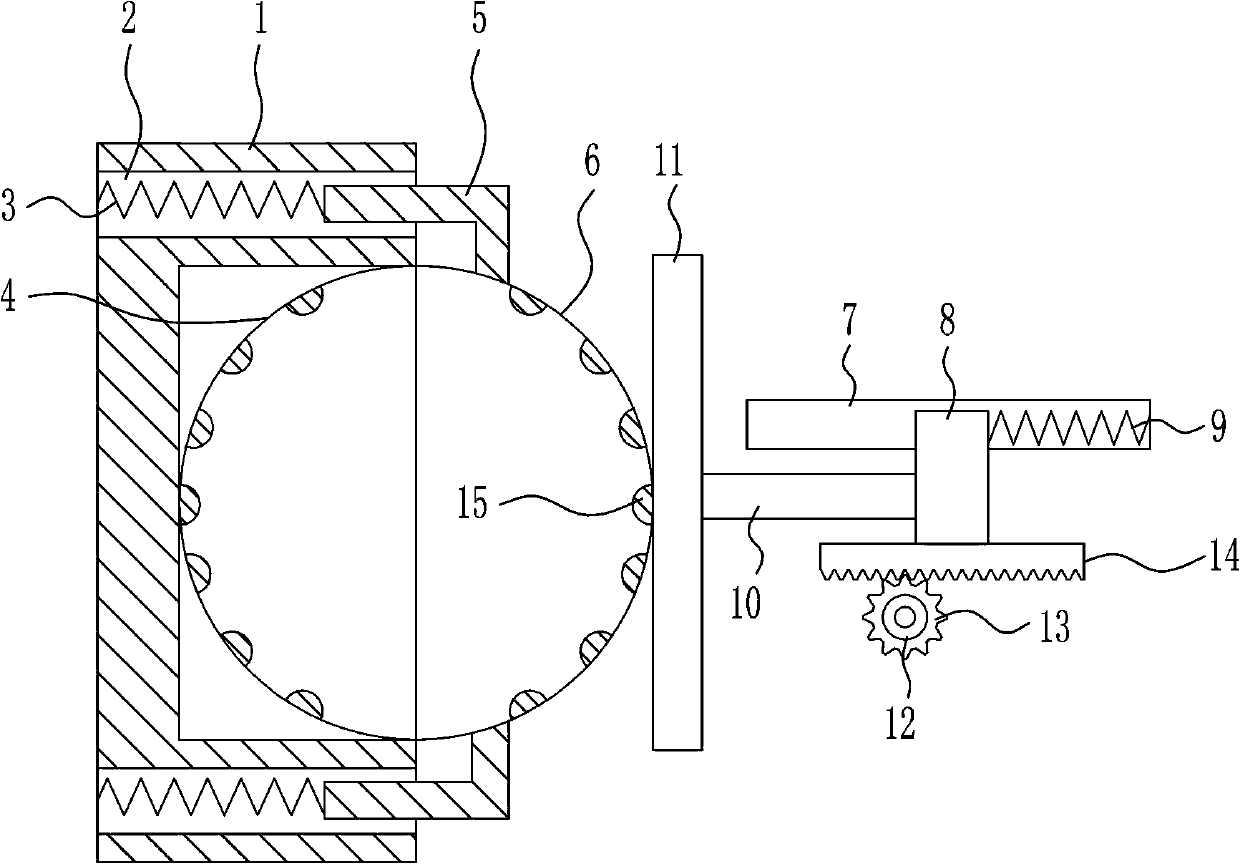

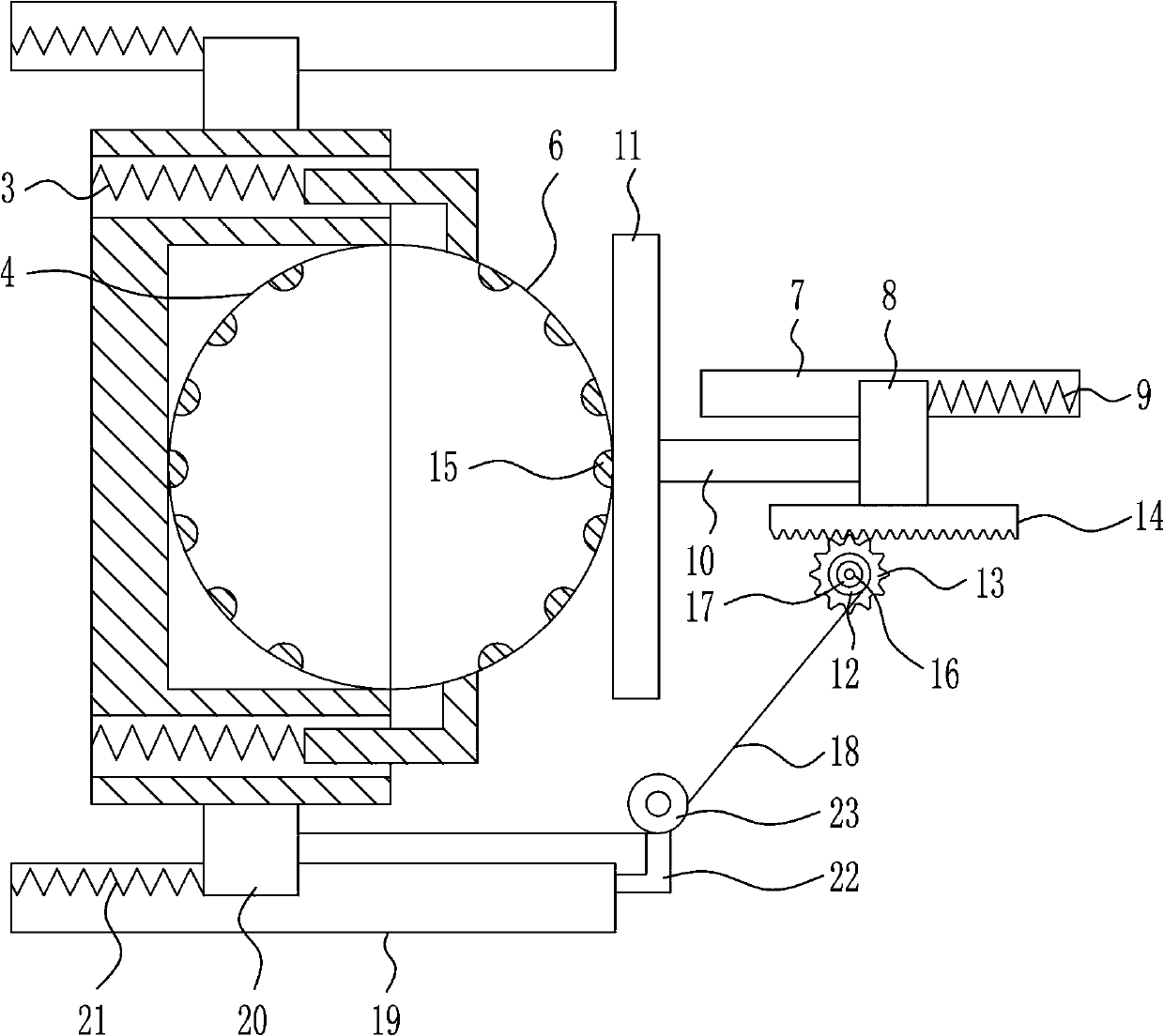

[0025] A kind of LED lamp tube recycling equipment, such as Figure 1-3 As shown, it includes a frame, a fixed plate 1, a first spring 3, a card plate 4, a moving rod 5, a rubber plate 6, a first slide rail 7, a first slider 8, a second spring 9, a connecting rod 10, Pressing plate 11, motor 12, gear 13 and rack 14, welded on the frame is connected with fixed plate 1, fixed plate 1 rear portion and front portion are symmetrically opened with small hole 2, and small hole 2 is provided with moving bar 5, and moving bar 5 and the left side of the fixed plate 1 are connected with the first spring 3 by means of a hook connection, the right side of the fixed plate 1 is welded and connected with the clamp plate 4, and the front and rear two moving rods 5 are glued and connected with the rubber plate 6, The frame is connected with a first slide rail 7 by bolt connection, the first slide rail 7 is located on the right side of the fixed plate 1, and the first slide rail 7 is slidably co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com