Improved jaw breaker

A jaw crusher and improved technology, applied in the field of compound pendulum jaw crushers, can solve the problems of easy wear and tear of the movable jaw plate, difficult replacement of the movable jaw plate 83, short service life, etc., so as to achieve weight reduction and production capacity Improved, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In the following, the technical means adopted by the present invention to achieve the intended purpose of the invention will be further described in conjunction with the accompanying drawings and preferred embodiments of the present invention.

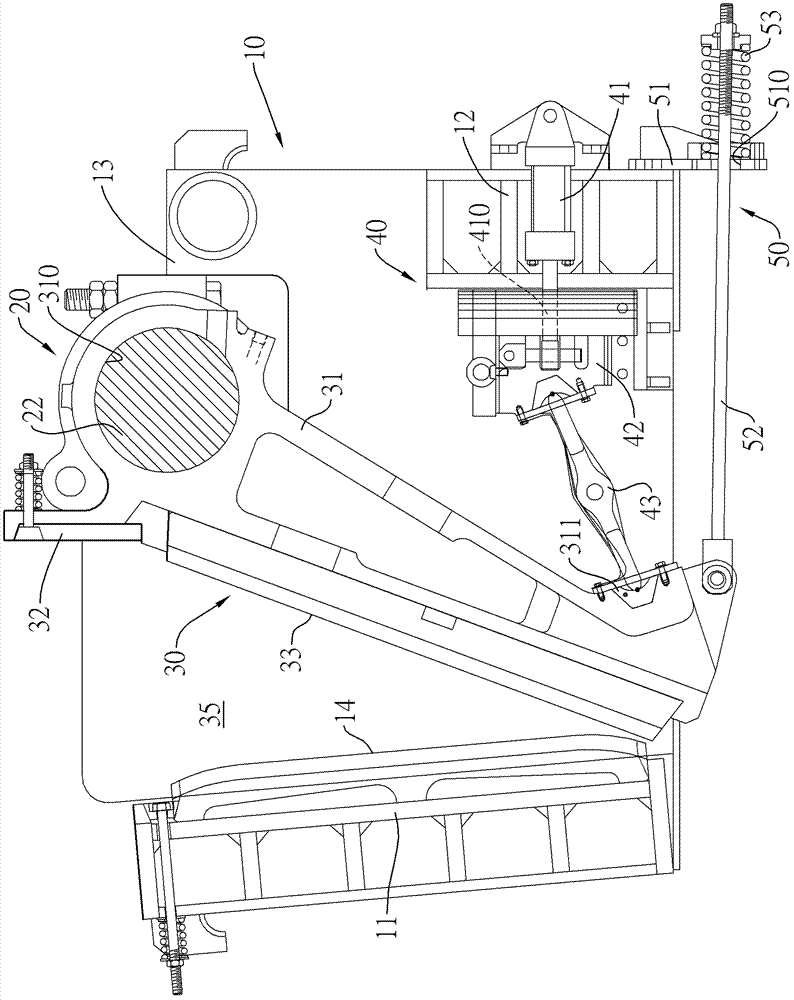

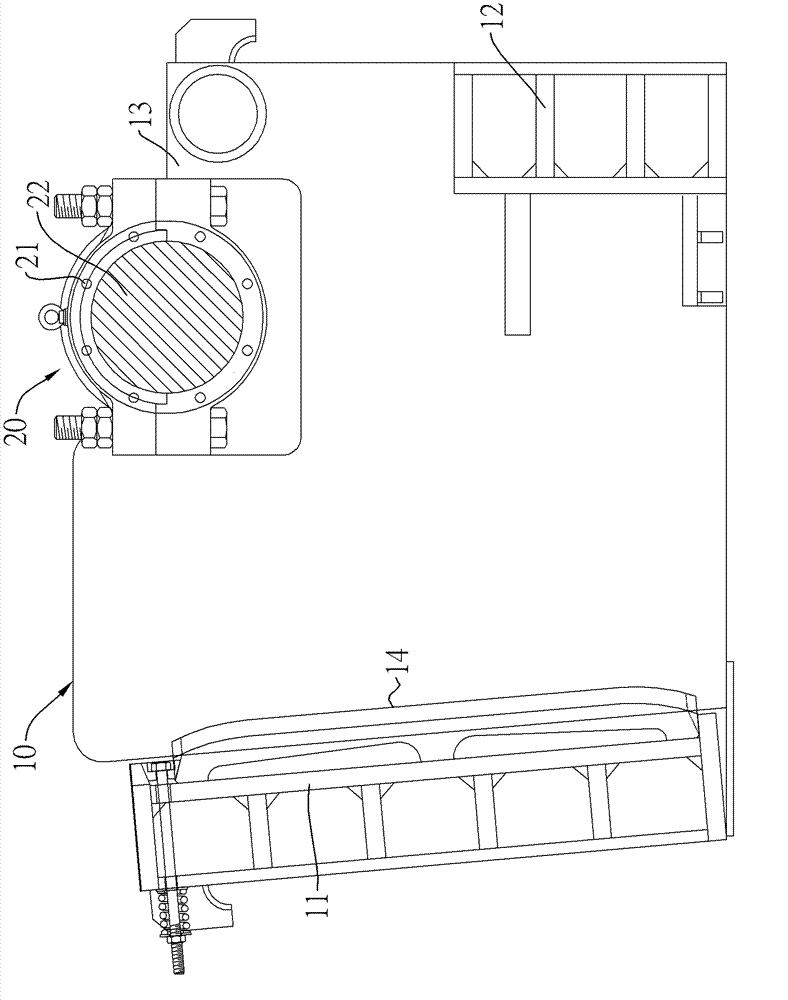

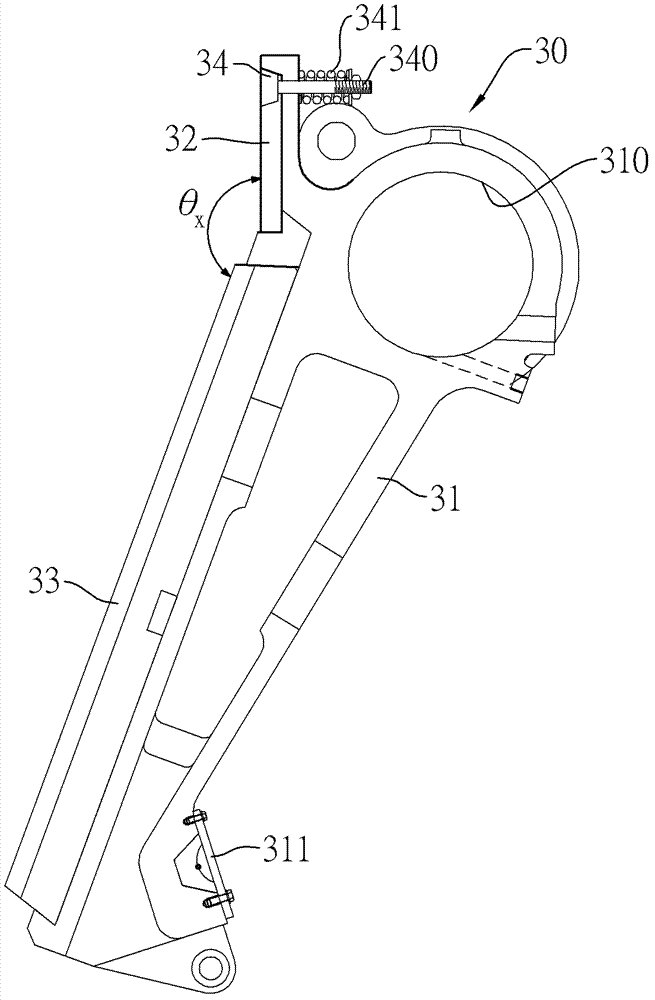

[0043] The present invention is an improved jaw crusher, please refer to figure 1 As shown, it includes a frame body 10 , a fixed jaw plate 14 , a transmission mechanism 20 , a movable jaw assembly 30 and a gap adjustment mechanism 40 .

[0044] Please refer to figure 2 As shown, the frame body 10 is a hollow frame body, the two ends of the frame body are respectively a front end and a rear end, a fixed jaw plate seat 11 is formed at the front end, and an adjustment mechanism fixing seat 12 is formed at the rear end. The frame body 10 has two opposite side panels 13, figure 1 and figure 2 The schematic diagram of one side plate 13 is omitted, and the two side plates 13 are arranged at intervals between the front end and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com