Brown sugar processing equipment and use method

A kind of processing equipment and brown sugar technology, applied in the field of brown sugar processing, can solve the problems of affecting processing efficiency and processing quality, demanding brown sugar moisture content, low degree of mechanization, etc., and achieve suitable large-scale processing, high processing quality and high degree of mechanization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

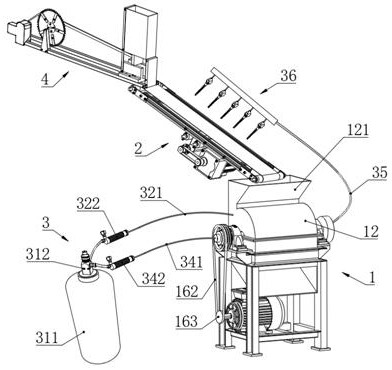

[0061] Such as Figure 1-7 Shown, a kind of brown sugar processing equipment comprises pulverizer 1, transmission device 2 and cooling device 3, pulverizer 1 is placed in the rear end of transmission device 2, and the high-pressure tank 311 of cooling device 3 is positioned at pulverizer 1 side, and cooling device 3 The second spraying unit 36 is located on one side of the conveying device 2;

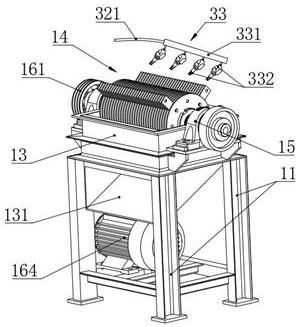

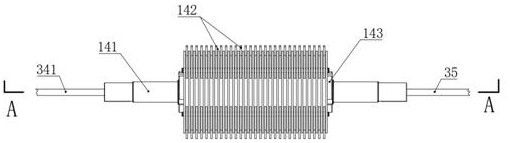

[0062] Pulverizer 1 comprises pulverizing support 11, upper housing 12, lower housing 13, pulverizing unit 14, pulverizing belt 162 and pulverizing motor 164 again, and upper housing 12 is installed in lower housing 13 upper ends, and upper housing 12 and lower housing The casings 13 are all mounted on the upper part of the crushing bracket 11, the upper end of the upper casing 12 is provided with a crushing inlet 121, and the lower end of the lower casing 13 is provided with a crushing outlet 131, and the upper casing 12 and the lower casing 13 together form a crushing space , the c...

Embodiment 2

[0076] This embodiment is a further improvement of the previous embodiment, such as Figure 1-7 Shown, a kind of brown sugar processing equipment comprises pulverizer 1, transmission device 2 and cooling device 3, pulverizer 1 is placed in the rear end of transmission device 2, and cooling device 3 is placed on the side of transmission device 2 through pulverizer 1;

[0077] Pulverizer 1 comprises pulverizing support 11, upper casing 12, lower casing 13, pulverizing unit 14, pulverizing belt 162 and pulverizing motor 164, and upper casing 12 is installed in lower casing 13 upper ends, and upper casing 12 and lower casing The bodies 13 are installed on the upper part of the crushing bracket 11, the upper end of the upper shell 12 is provided with a crushing feed port 121, and the lower end of the lower shell 13 is provided with a crushing discharge port 131, and the upper shell 12 and the lower shell 13 together form a crushing space. The pulverizing unit 14 is placed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com