A high-efficiency processing equipment for unidirectional fabric isolation film for non-weft fabric production

A technology for processing equipment and isolation membranes, which is applied in the textile field, can solve the problems that the membrane cannot be reused, and the residual glue on the membrane cannot be removed, so as to achieve the effects of efficient glue removal, improved softening effect, and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

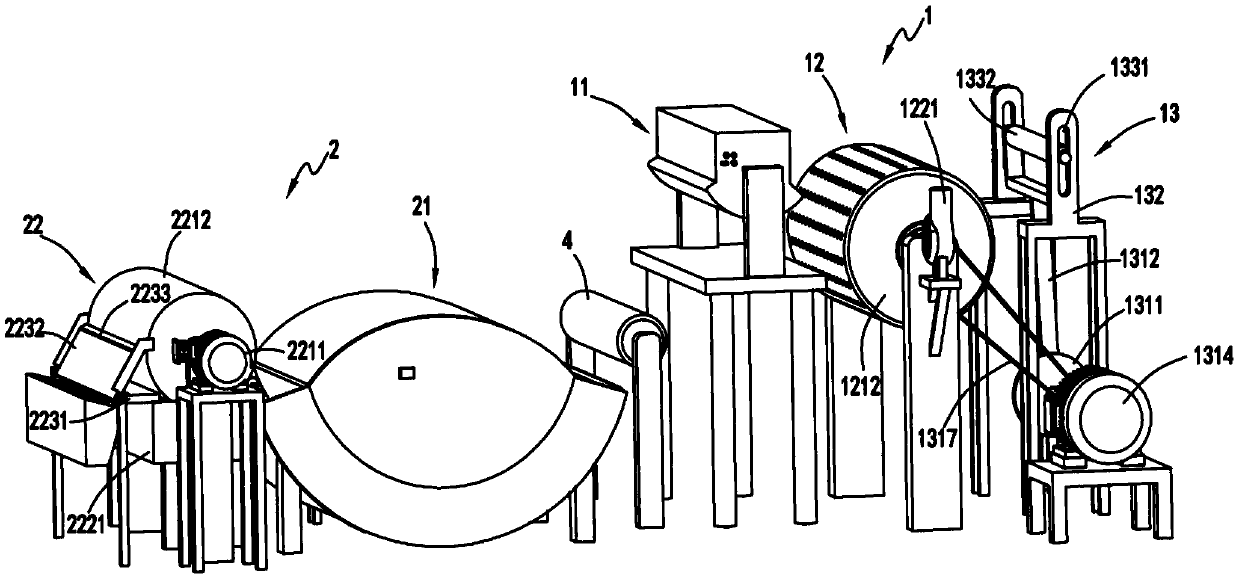

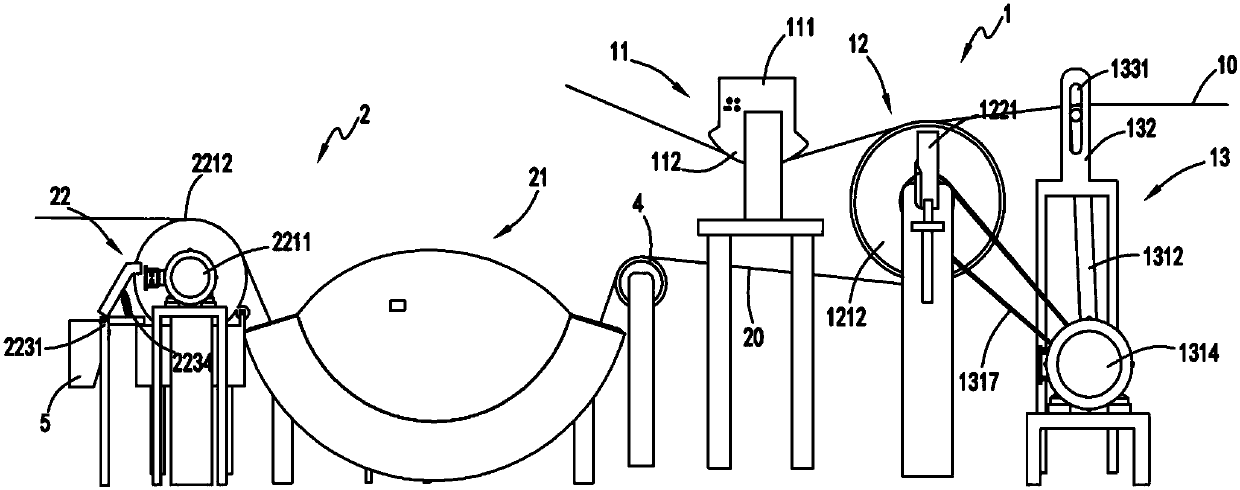

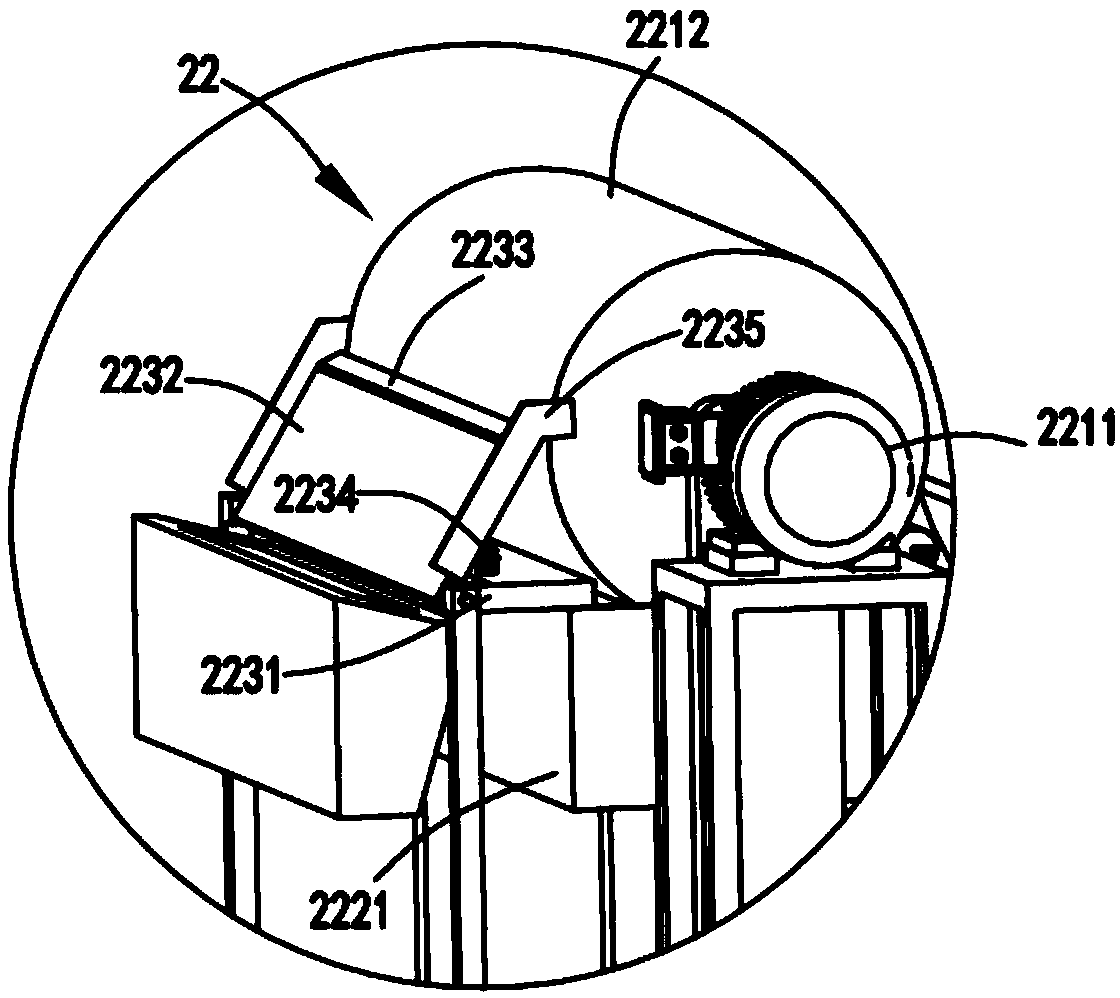

[0036] figure 1 It is a schematic diagram of the structure of the separation membrane without weft cloth and the glue removal equipment, figure 2 It is a schematic diagram of the front view of the separation membrane without weft cloth and the glue removal equipment, image 3 is the structural schematic diagram of the degumming mechanism, Figure 4 It is a schematic diagram of the structure of the gluing device and the squeegee device, Figure 5 It is a schematic diagram of the structure of the glue softening mechanism, Image 6 It is a schematic diagram of the structure of the lifting device, Figure 7 is a schematic diagram of the structure of the roller, Figure 8 A cross-sectional schematic diagram of the roller. Such as figure 1 , figure 2 ,image 3, Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, a kind of high-efficiency processing equipment for the unidirectional cloth isolation film used in the production of weft-free fabrics include...

Embodiment 2

[0052] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is that: the inside of the roller 1212 is also provided with a baffle 3, and the baffle 3 is fixed on the fixed shaft 1211 through a connecting piece 31; Rotate on the blocking roller 1212 to the adsorption hole 1215 at the baffle 3;

[0053] The setting of the baffle 3 makes the isolation film 20 move to the position of the baffle 3 along with the roller 1212, because the baffle 3 blocks the adsorption holes 1215 on the roller 1212 in this area, so that when the isolation film 20 is transported to this area , the roller 121...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com