Manufacturing method of adhesive type photo album inside pages

A production method and pasting-type technology, which is applied in the direction of albums, printing, etc., can solve the problems of protective film bubbles and wrinkles, unstable product quality, and unsmooth tearing of the film, and achieve reasonable production methods, long storage time, and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below with reference to the drawings and embodiments.

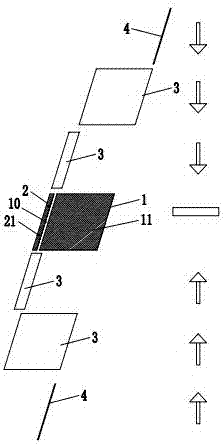

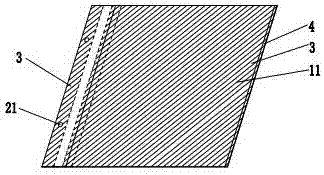

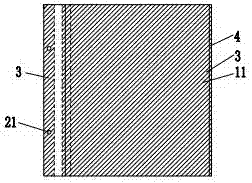

[0026] as attached Figure 1~3 As shown, the inner page of the adhesive photo album disclosed in this embodiment includes the main body 1 of the adhesive inner page, the binding edge 2 and the BOPP protective film 3, and the BOPP protective film 3 is transparent film paper. The method for making the inner page of the sticky photo album includes the following steps: machine-printing color (dyeing) on the web-first drying-coating self-adhesive glue-pressing self-adhesive glue twill glue line-second time Drying-cutting joint area-covering BOPP protective film-covering side tape-punching binding holes.

[0027] The specific production method is as follows:

[0028] 1. Put the white neutral coated paper on the machine in the form of roll paper. The coated paper is a high-grade printing coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com