Nano cable made of magnetic material and half-metallic material and preparation method thereof

A technology of semi-metallic materials and nano-cables, which is applied in metal material coating technology, nano-structure manufacturing, cable/conductor manufacturing, etc., can solve problems such as high technical requirements and complex processes, and achieve scientific and easy preparation methods. Effect suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

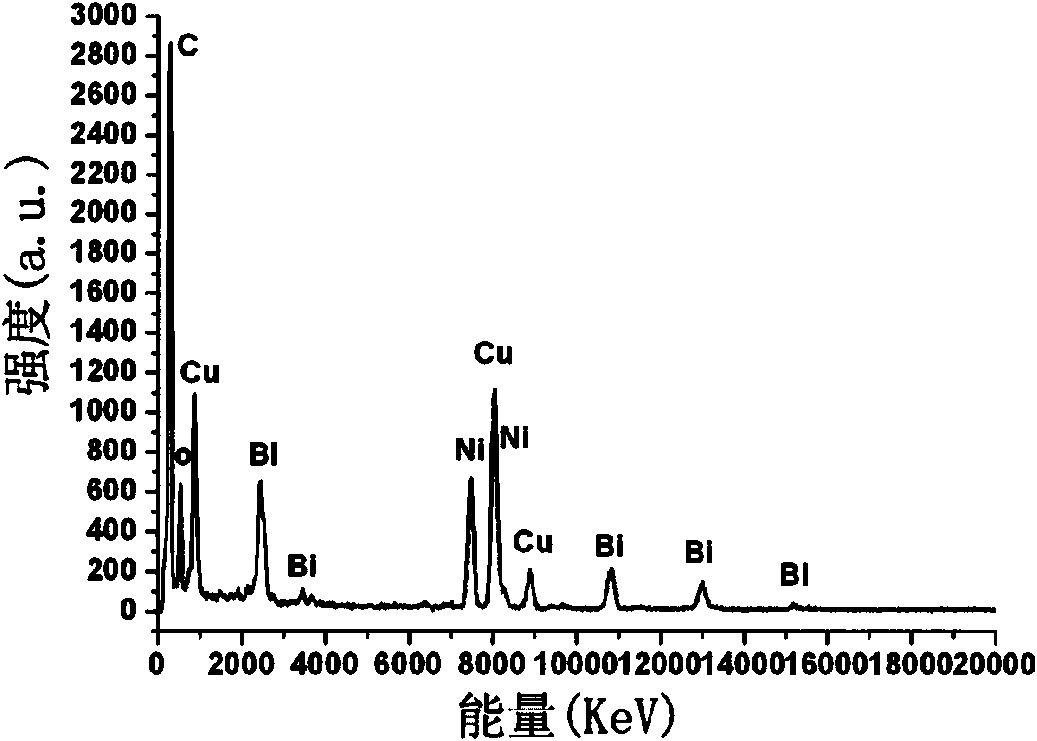

[0038] Embodiment 1: Complete the preparation successively according to the following steps

[0039] 1) Anodize the aluminum sheet, first place the aluminum sheet in an oxalic acid solution with a concentration of 0.2M, anodize it for 5 hours at a DC voltage of 30V, and then soak it in a mixed solution at a temperature of 50°C for 8 hours; Wherein, the mixed solution is 4wt% phosphoric acid and 2wt% chromic acid at 50°C.

[0040] 2) Anodizing for the second time, repeating the anodizing process of step 1) for the aluminum sheet obtained in step 1), and performing anodic oxidation for the second time on the aluminum sheet to obtain an aluminum sheet with holes at the bottom;

[0041] 3) the aluminum flake obtained after step 2) is oxidized, first remove the unoxidized aluminum on the back side with a supersaturated tin tetrachloride solution, and then corrode the aluminum oxide barrier layer at the bottom of the hole with a 3wt% phosphoric acid solution to obtain a Through-hol...

Embodiment 2

[0046] Embodiment 2: Complete the preparation successively according to the following steps

[0047] 1) Aluminum sheet anodizing, first place the aluminum sheet in an oxalic acid solution with a concentration of 0.3M, anodize it at a DC voltage of 50V for 3h, and then soak it in a mixed solution at a temperature of 50°C for 10h; among them, mixing The solution was 5 wt% phosphoric acid and 3 wt% chromic acid at 50°C.

[0048] 2) Anodizing for the second time, repeating the anodizing process of step 1) for the aluminum sheet obtained in step 1), and carrying out anodizing for the second time on the aluminum sheet;

[0049] 3) the aluminum flake obtained after step 2) is oxidized, first remove the unoxidized aluminum on the back side with a supersaturated tin tetrachloride solution, and then corrode the aluminum oxide barrier layer at the bottom of the hole with a 3wt% phosphoric acid solution to obtain a Through-hole alumina template, the diameter of the through-hole is 70nm; ...

Embodiment 3

[0055] Embodiment 3: Complete the preparation successively according to the following steps

[0056] 1) Aluminum sheet anodizing, first place the aluminum sheet in an oxalic acid solution with a concentration of 0.35M, anodize it at a DC voltage of 60V for 2h, and then soak it in a mixed solution at a temperature of 50°C for 14h; among them, mixing The solution was 5 wt% phosphoric acid and 3 wt% chromic acid at 50°C.

[0057] 2) Anodizing for the second time, repeating the anodizing process of step 1) for the aluminum sheet obtained in step 1), and carrying out anodizing for the second time on the aluminum sheet;

[0058] 3) the aluminum flake obtained after step 2) is oxidized, and the unoxidized aluminum on the back is removed with a supersaturated tin tetrachloride solution, and then the aluminum oxide barrier layer at the bottom of the hole is corroded with a 4wt% phosphoric acid solution to obtain a Through-hole alumina template, the aperture of the through-hole is 90nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com