Nano cable composed of semimetal bismuth and metallic copper and method for synthesizing the same

A technology of nano-cables and synthesis methods, which is applied in nanotechnology, nanotechnology, nanostructure manufacturing, etc., and can solve the problem of small heterojunction contact surface, difficulty in fully exerting the effect of nano-heterojunction, and failure to produce nanotubes and nanostructures. line and other problems, to achieve the effect of scientific preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

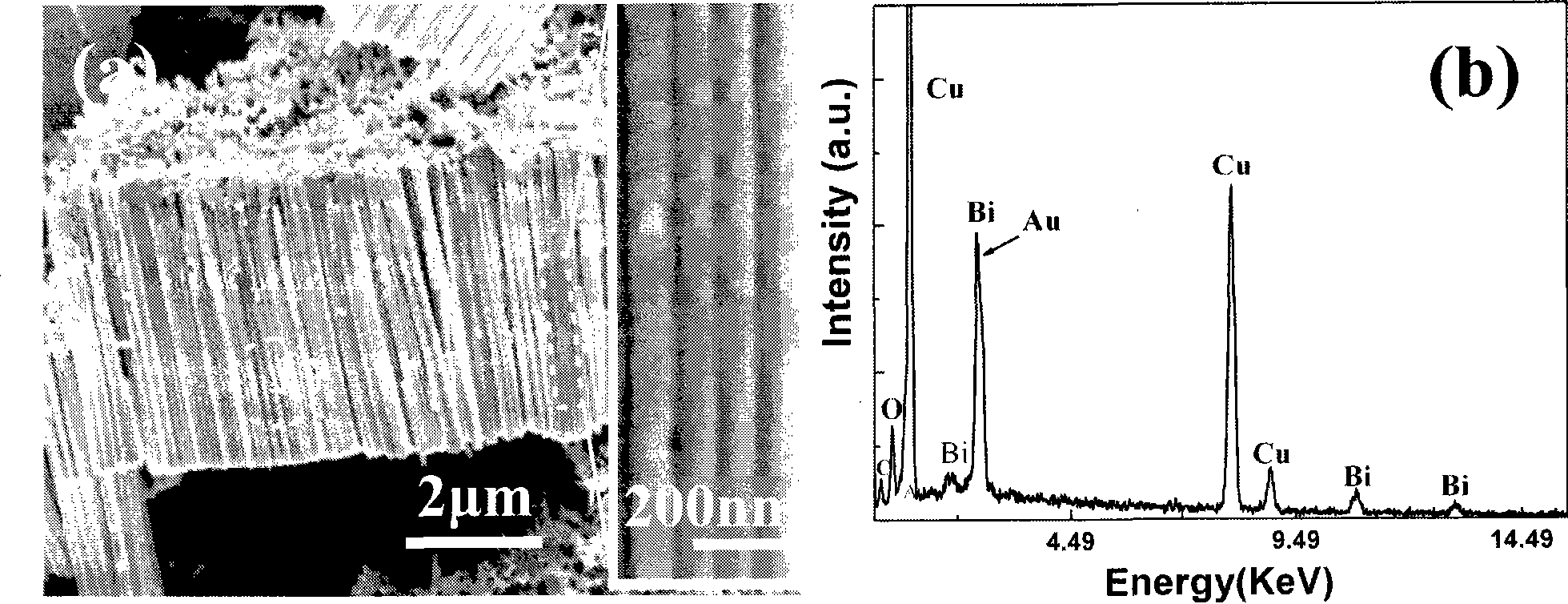

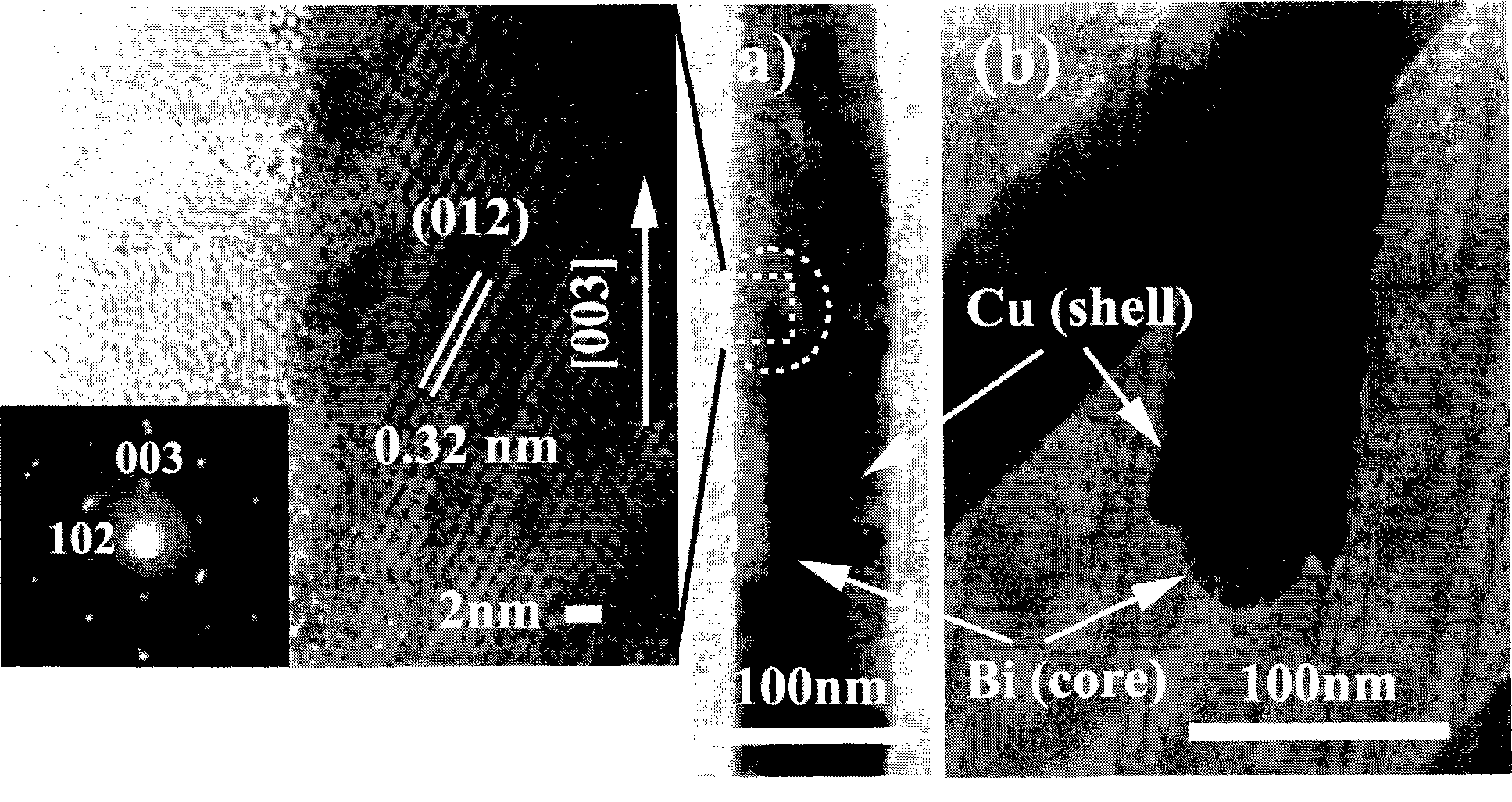

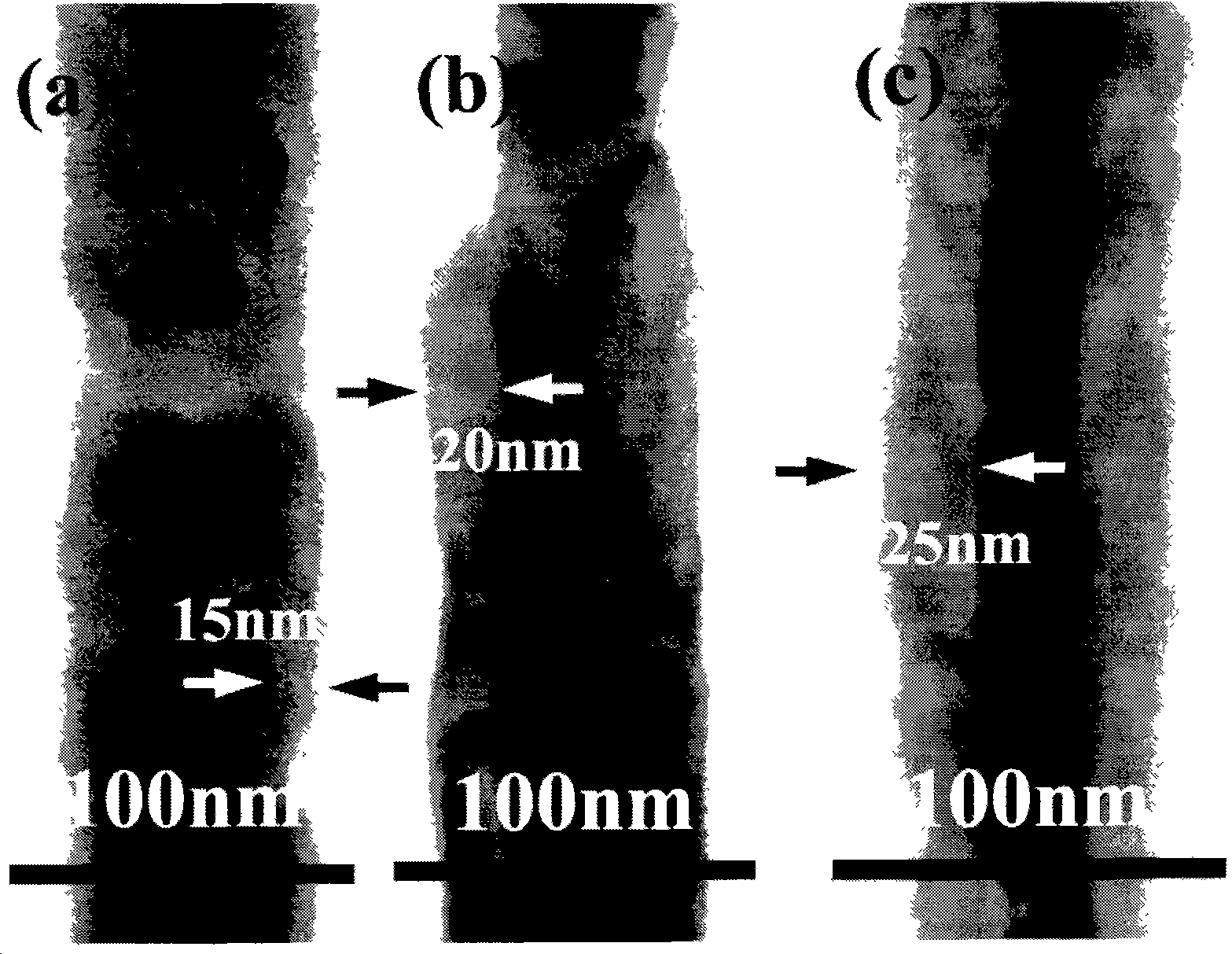

[0016] Example 1: The preparation is completed in sequence according to the following steps: In the first step, the aluminum sheet is placed in an acid solution with a concentration of 0.2M, anodized at a direct current voltage of 30V for 10 hours, and then placed in a 4wt temperature at 50°C. Soaked in a mixed solution of 2% phosphoric acid and 2wt% chromic acid for 12 hours; wherein the purity of the aluminum flakes is 99.9%, and the acid solution is an oxalic acid solution. Then, after performing the second anodization under the same process conditions, first use a supersaturated tin tetrachloride solution to remove the unoxidized aluminum on the back, and then use a 3wt% phosphoric acid solution to corrode the oxide at the bottom of the hole. An aluminum barrier layer is used to obtain a through-hole aluminum oxide template with a pore diameter of 50 nm. The second step is to deposit a 10nm thick gold film on one side of the through-hole alumina template by electron beam evapo...

Embodiment 2

[0017] Example 2: The preparation is completed in sequence according to the following steps: In the first step, the aluminum sheet is placed in an acid solution with a concentration of 0.25M, anodized at a DC voltage of 70V for 9 hours, and then placed in a 5wt temperature at 55°C. Soaked in a mixed solution of 5% phosphoric acid and 1.9wt% chromic acid for 11 hours; wherein the purity of the aluminum flakes is 99.9%, and the acid solution is an oxalic acid solution. Then, after performing the second anodization under the same process conditions, first use a supersaturated tin tetrachloride solution to remove the unoxidized aluminum on the back, and then use 4wt% phosphoric acid to etch away the oxide at the bottom of the hole. The aluminum barrier layer is used to obtain a through-hole aluminum oxide template with a pore diameter of 90 nm. In the second step, after depositing a 15nm thick gold film on one side of the through-hole alumina template by electron beam evaporation, fir...

Embodiment 3

[0018] Example 3: The preparation is completed in sequence according to the following steps: In the first step, the aluminum sheet is placed in an acid solution with a concentration of 0.3M, anodized at a DC voltage of 100V for 8 hours, and then placed in a 6wt temperature at 60°C. Soaked in a mixed solution of 5% phosphoric acid and 1.8% by weight chromic acid for 10 hours; wherein the purity of the aluminum flakes is 99.9%, and the acid solution is an oxalic acid solution. Then, after performing the second anodization under the same process conditions, first use a supersaturated tin tetrachloride solution to remove the unoxidized aluminum on the back, and then use a 5wt% phosphoric acid solution to corrode the oxide at the bottom of the hole. An aluminum barrier layer is used to obtain a through-hole aluminum oxide template with a pore diameter of 130 nm. In the second step, after depositing a 25nm thick gold film on one side of the through-hole alumina template by electron beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com