Mylar labeling machine

A labeling machine and Mylar technology, applied in the field of automatic Mylar sticking devices, can solve the problems of unstable quality, low efficiency, Mylar bubbles, etc., and achieve the effects of excellent and stable quality, improved sticking efficiency, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

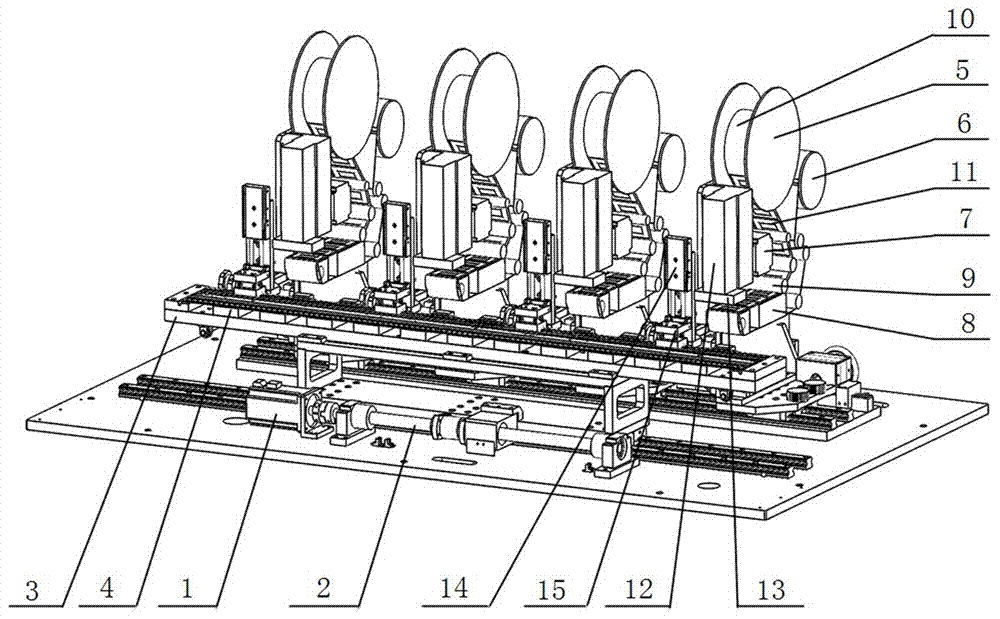

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] The Mylar labeling machine is characterized in that it includes a jig shifting mechanism and several sets of head mechanisms, each set of head mechanisms includes an adsorption mechanism, a pressing mechanism, and a feeding mechanism;

[0027] The fixture displacement mechanism includes a matching displacement motor (1) and a screw (2), the screw (2) is screwed to the product fixture (3), and the product is driven by the rotation of the screw (2) The jig (3) moves on the horizontal plane;

[0028] The feeding mechanism includes an unwinding shaft (5), a rewinding shaft (6), a feeding motor (7), a feeding cylinder (8), and several guide wheels (9); (10), the mylar roll material is wound from a release paper tape attached to a mylar sheet (11), and the release paper tape is pulled around the guide wheel (9), the horizontal feeding cylinder ( 8) Traction to the windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com