Application of stabilizer for improving film tearing performance of tire-free waterproof coiled material

A waterproof membrane and stabilizer technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problem that the surface isolation film of waterproof membrane is difficult to tear, so as to improve the tearing effect, good solubility, and reduce needles. In-degree effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation and optimization of stabilizer solutions

[0060] The stabilizer is the modified asphalt stabilizer produced by Dongying Runfeng Boyue Petroleum Technology Co., Ltd.

[0061] Preparation: After heating the base oil or asphalt to 140°C, add the stabilizer, the stirring speed is fixed (the speed of the stirring paddle in the laboratory is 300r / min), and observe whether the additive has climbing rod phenomenon (that is, the viscosity), the degree of melting of the stabilizer ( Whether it is completely dissolved), and whether there is precipitation.

[0062] Option 1: Use 90# asphalt to dissolve the stabilizer, tentatively asphalt:stabilizer is 5:1;

[0063] raw material name Raw material model Proportion / % asphalt 90# 50 stabilizer / 10

[0064] Experimental phenomenon: when the asphalt is heated to the set temperature and the stabilizer is added, the viscosity of the rubber material increases dramatically instantly, and the sti...

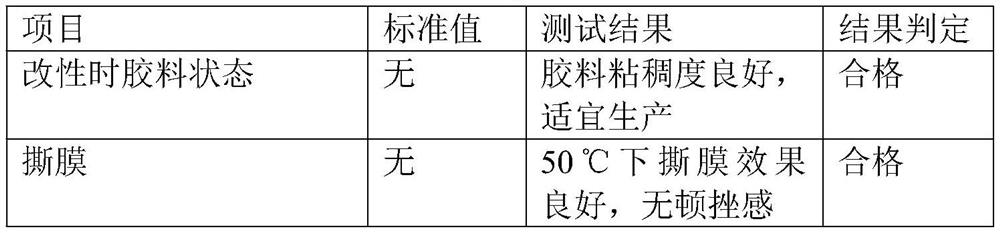

example 1

[0077] Taking the PET product of GB / T35467-2017 as an example, its base film is a transparent silicone oil film; compared with PET aluminum-coated silicone oil film and PE black film, the surface temperature of the product is the highest under the same sunshine conditions. Constant—The formula remains unchanged, and different proportions of stabilizers are added to it to test various properties.

[0078] This example provides the original GB / T35467-2017 PET product formula, which is made by mixing liquid material, powder material and granular material, and the weight percentages are as follows:

[0079] Table 1

[0080]

[0081] The asphalt compound preparation process comprises the following steps:

[0082] S1. Add asphalt and oil, heat up to 120±5°C, add SBS and sol 0506, control the temperature at 180±5°C, and stir for 100-140 minutes;

[0083] S2. Add SBR, stir for 20-40 minutes, then add rubber powder, stir for 50-70 minutes;

[0084] S3. Add modified petroleum resi...

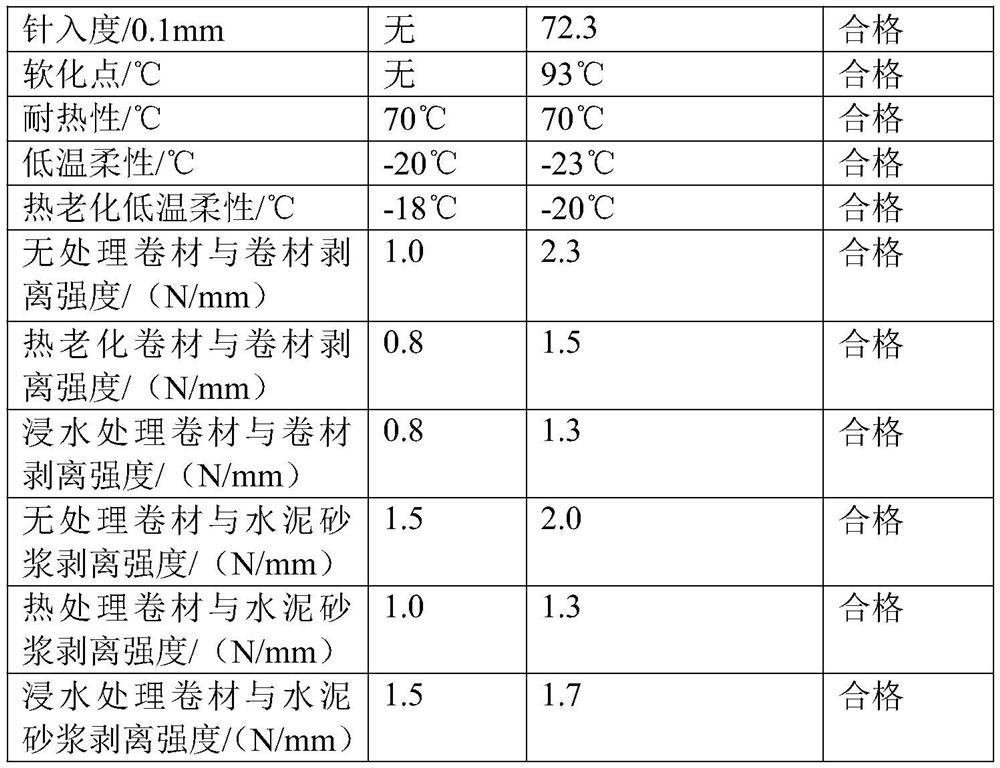

example 2

[0092] This example provides a formula for improving the tearing effect of tireless coiled materials with a stabilizer. It is made by mixing liquid material, powder material and granular material. The weight percentages are as follows:

[0093] table 3

[0094]

[0095] The asphalt compound preparation process of the coil comprises the following steps:

[0096] S1. Add asphalt and oil, heat up to 120±5°C, add SBS and sol 0506, control the temperature at 180±5°C, and stir for 100-140 minutes;

[0097] S2. Add SBR, stir for 20-40 minutes, then add rubber powder, stir for 50-70 minutes;

[0098] S3. Add modified petroleum resin and stabilizer solution, control the temperature at 180±5°C, and stir for 80-100 minutes to obtain a mixed solution; add stone powder after the mixed solution is ground, stir for 20-40 minutes, control the temperature at 155±5°C and discharge .

[0099] The test results are as follows:

[0100] Table 4

[0101]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com