Laminating machine high-temperature cloth take-up and pay-off self-cleaning device

A technology of laminating machine and high-temperature cloth, which is applied in the direction of laminating device, lamination, lamination auxiliary operation, etc., can solve the problems of corroding lamination equipment, high labor intensity, easy damage to high-temperature cloth, etc., to ensure cleaning and recycling Efficiency, cost saving, and efficiency improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

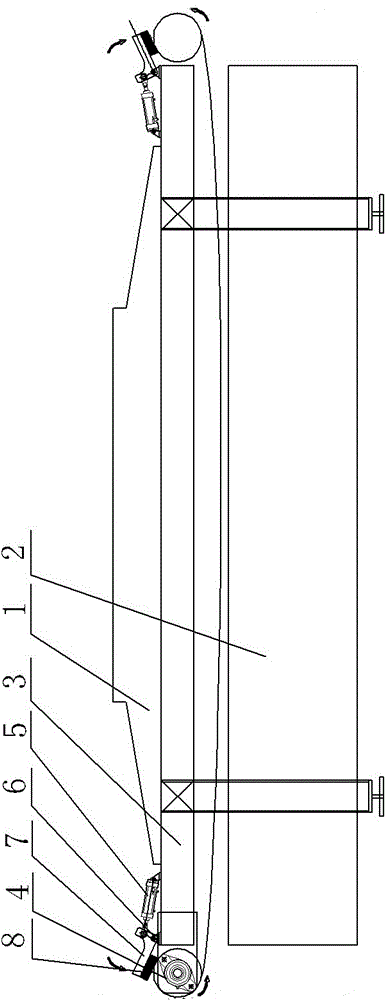

[0008] See figure 1 As shown, a high-temperature cloth self-cleaning device for a laminator includes an upper vacuum chamber 1 of a laminator and a lower vacuum chamber 2 of a laminator, and the upper vacuum chamber 1 of a laminator and the lower vacuum chamber 2 of a laminator A rewinding support 3 is arranged between them, and the two sides of the rewinding support 3 are respectively provided with a rewinding and unwinding reel 4, and the inner side of the rewinding and unwinding reel 4 is provided with a cleaning and pressing cylinder 5, which is obliquely arranged on the rewinding and rewinding support 3, On the winding support 3, a rotatable intermediate connecting block 7 is installed by a hinge seat 6. One end of the intermediate connecting block 7 is hinged to clean the piston rod of the compression cylinder 5, and the other end of the intermediate connecting block 7 is equipped with a polymer cleaning block 8. The middle connection block 7 is an L-shaped block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com