Patents

Literature

59results about How to "To achieve snap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

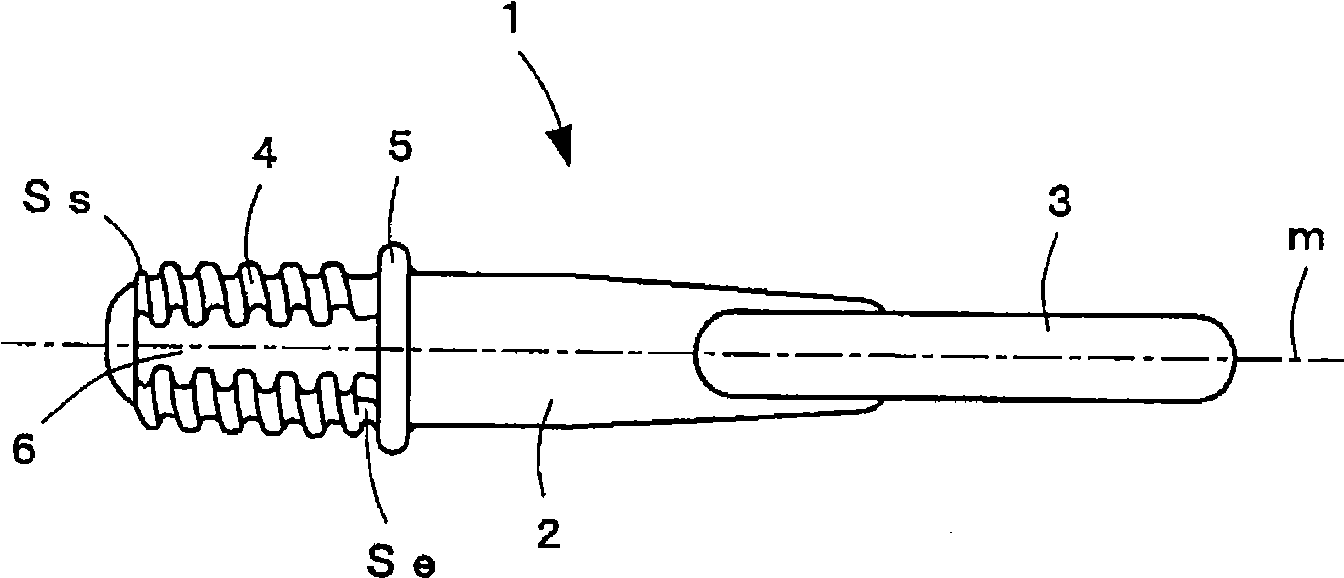

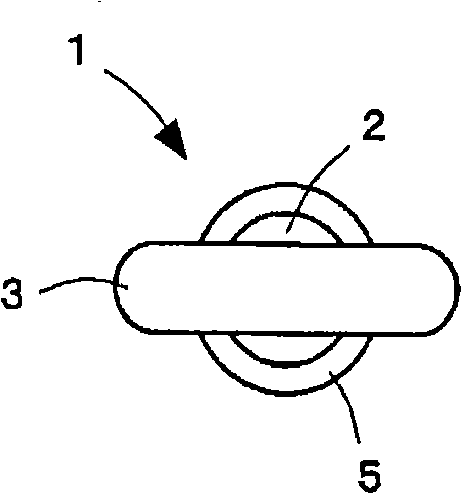

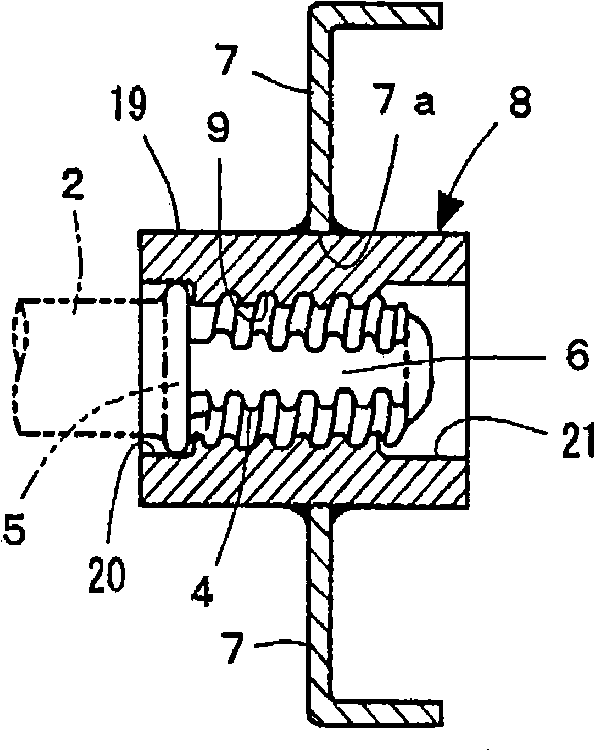

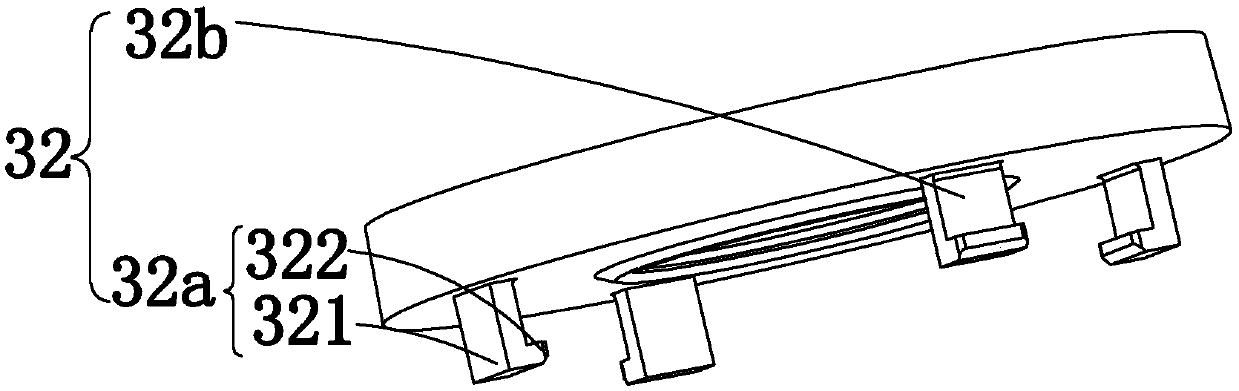

Towing device for vehicle, method of manufacturing towing hook for vehicle, and method of manufacturing connection member for vehicle

InactiveCN101547801AAvoid slackEnsure safetyMetal-working apparatusBoltsMechanical engineeringTowing

Provided are a towing device for a vehicle, a method of manufacturing a towing hook for a vehicle, and a method of manufacturing a connection member for a vehicle. The towing device is suitable for a towing device for an automobile, allows a hook part of the towing hook to be attached to a connection member on the automobile side in a specified direction, prevents lateral swing and looseness of the towing hook caused by vibration and external force during towing operation, provides reliability and safety of towing operation, enables smooth attachment of the towing hook to the connection member, allows the towing hook and the connection member to be increased in the strength and to be reduced in the size and weight, and can be easy processed and manufactured at low cost. The towing device for a vehicle includes the connection member having a female screw part and attachable to the vehicle side, and also includes the towing hook (1) having at one end a male screw part engageable with the female screw part and at the other end a hook part (3) to which a towing member (W) can be attached. The position of the hook part (3) after the male screw part is fastened to the connection member can be set to a predetermined allowable angular position (Theta).

Owner:FALTEC CO LTD

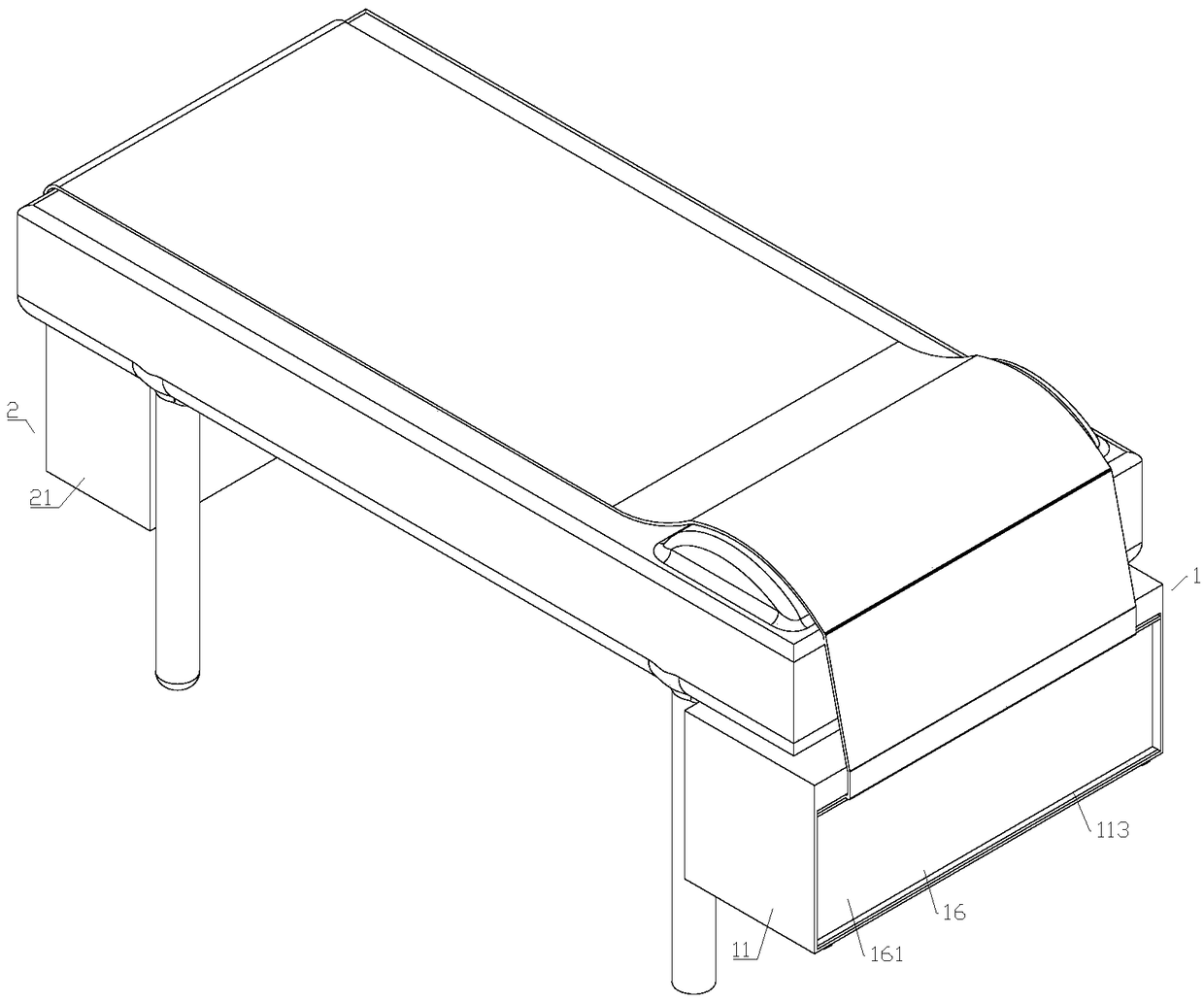

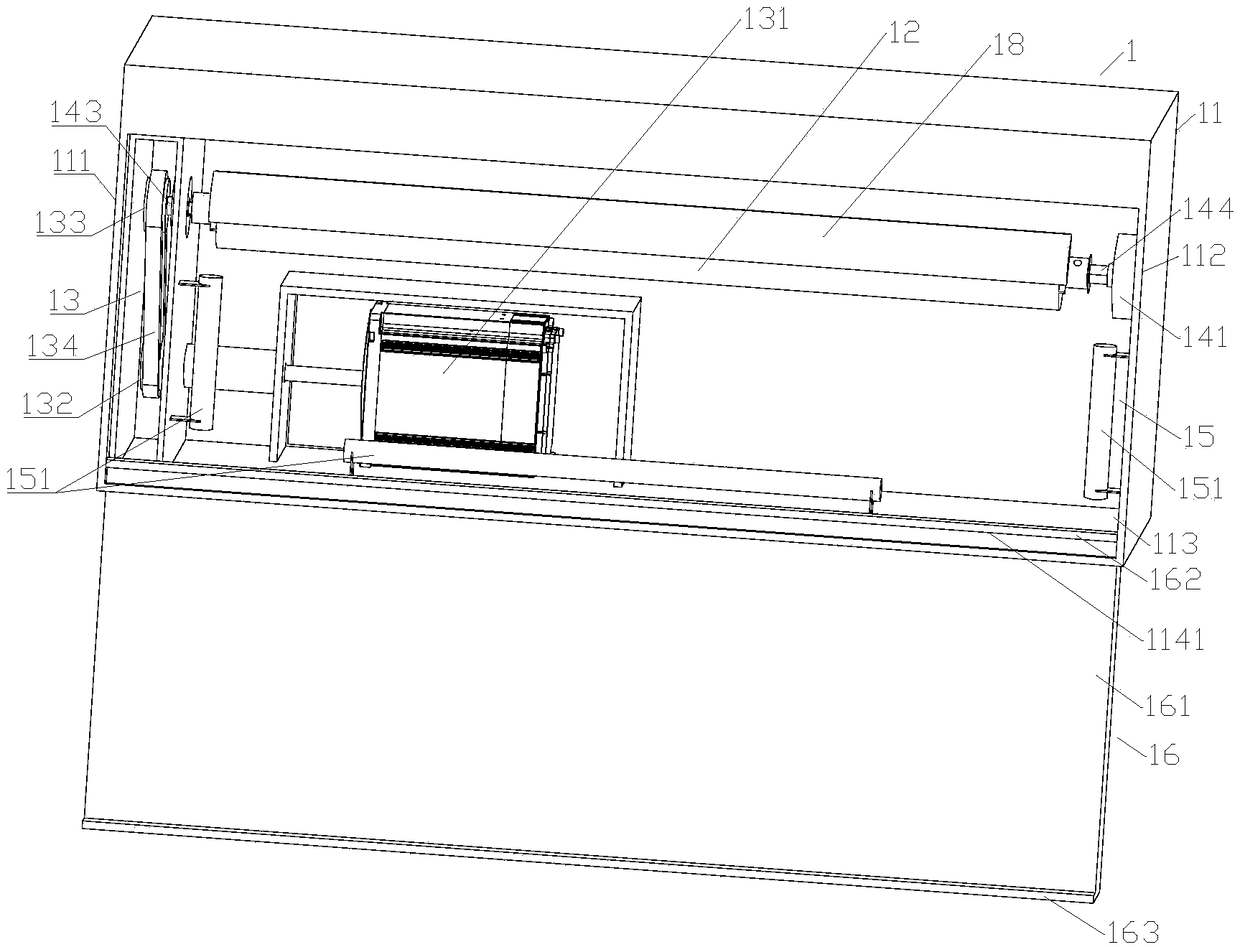

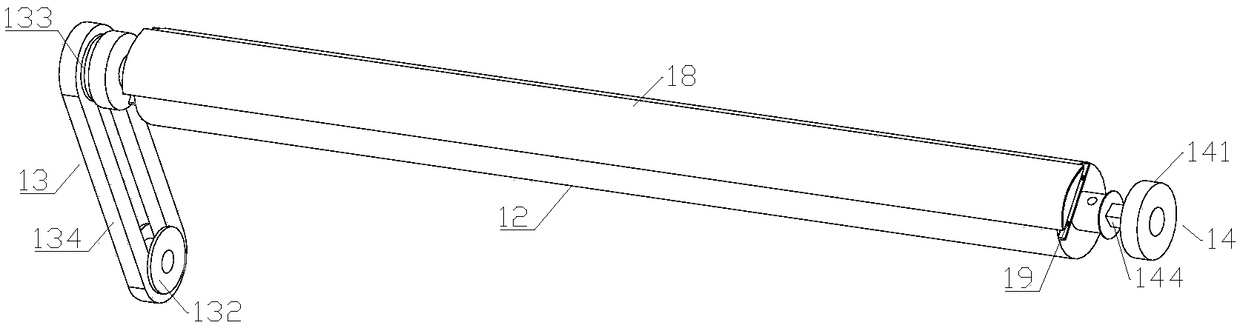

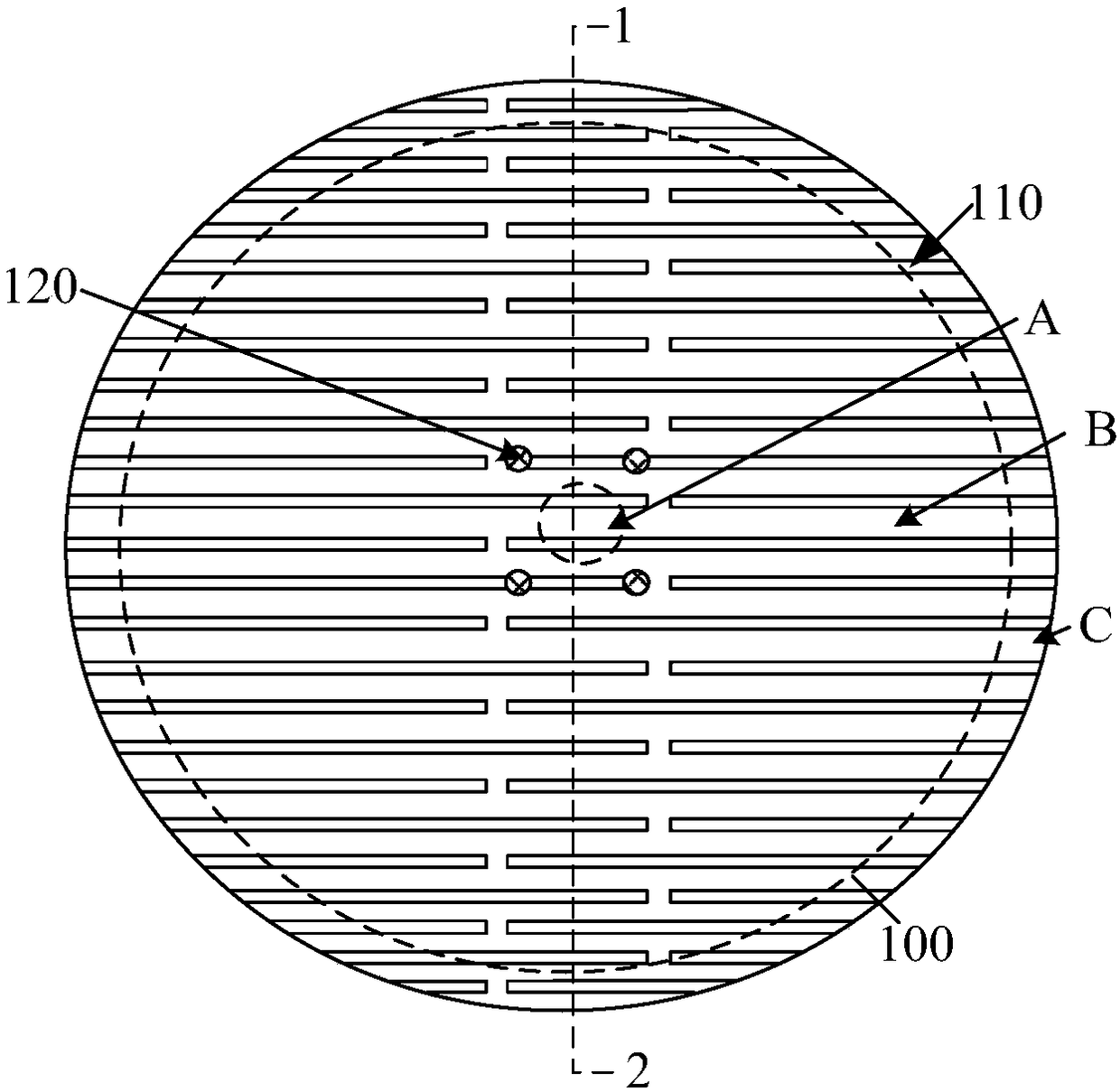

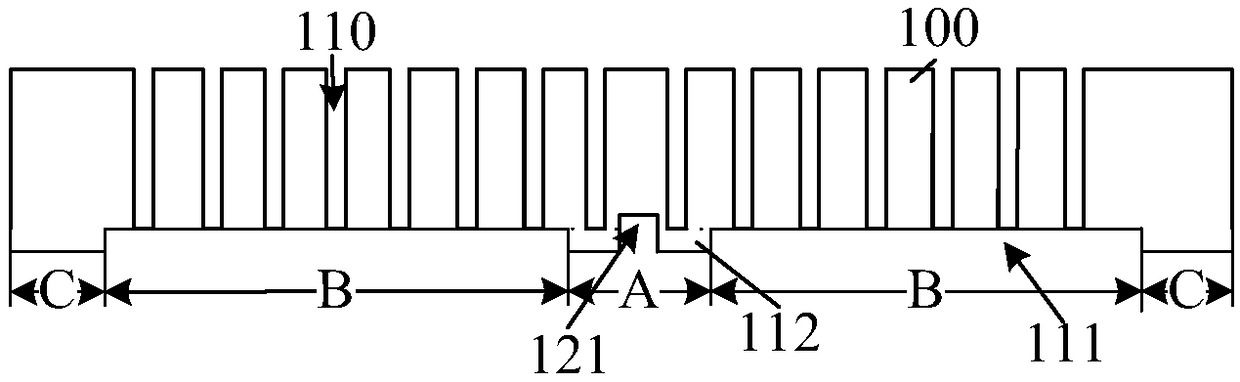

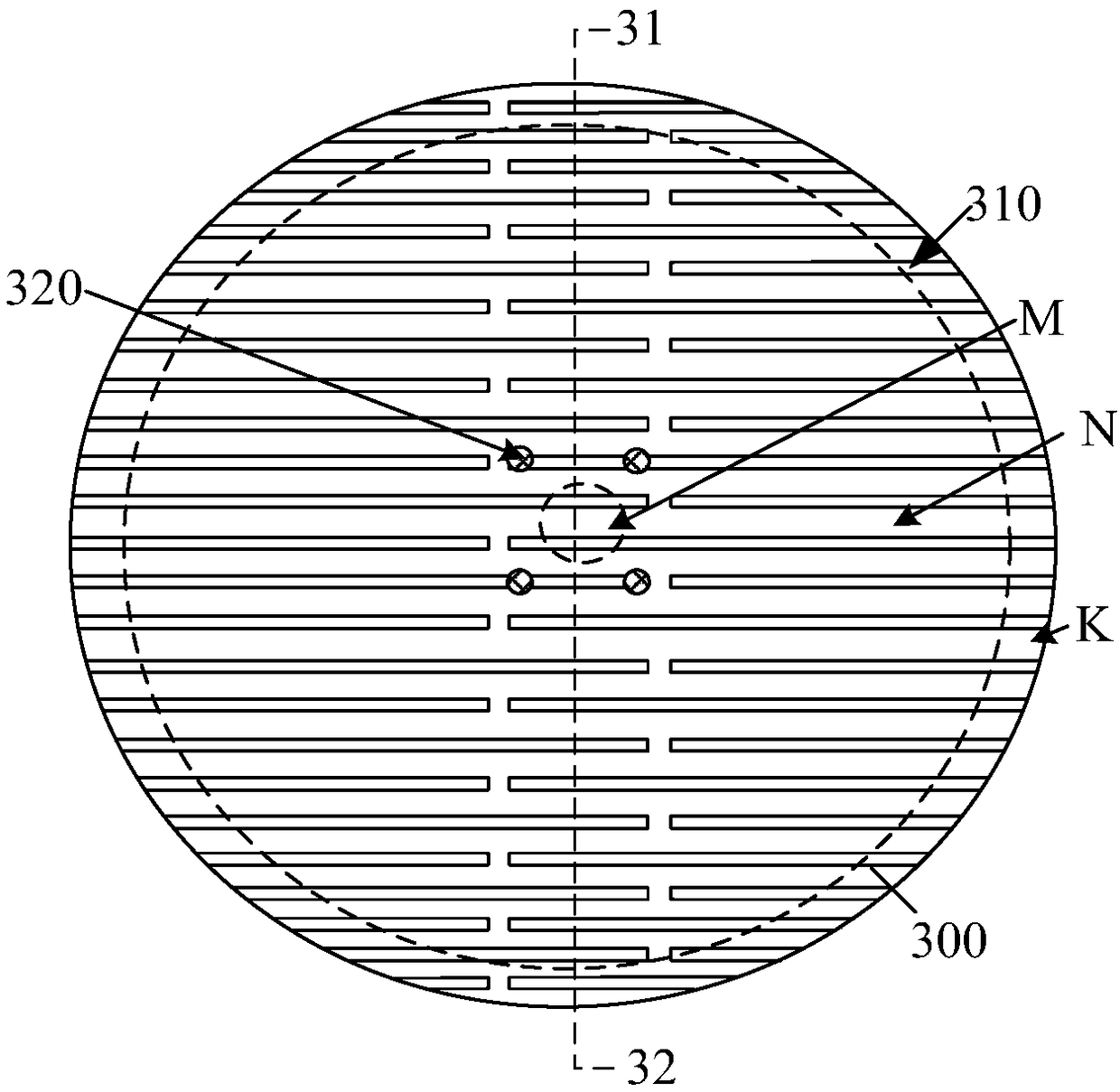

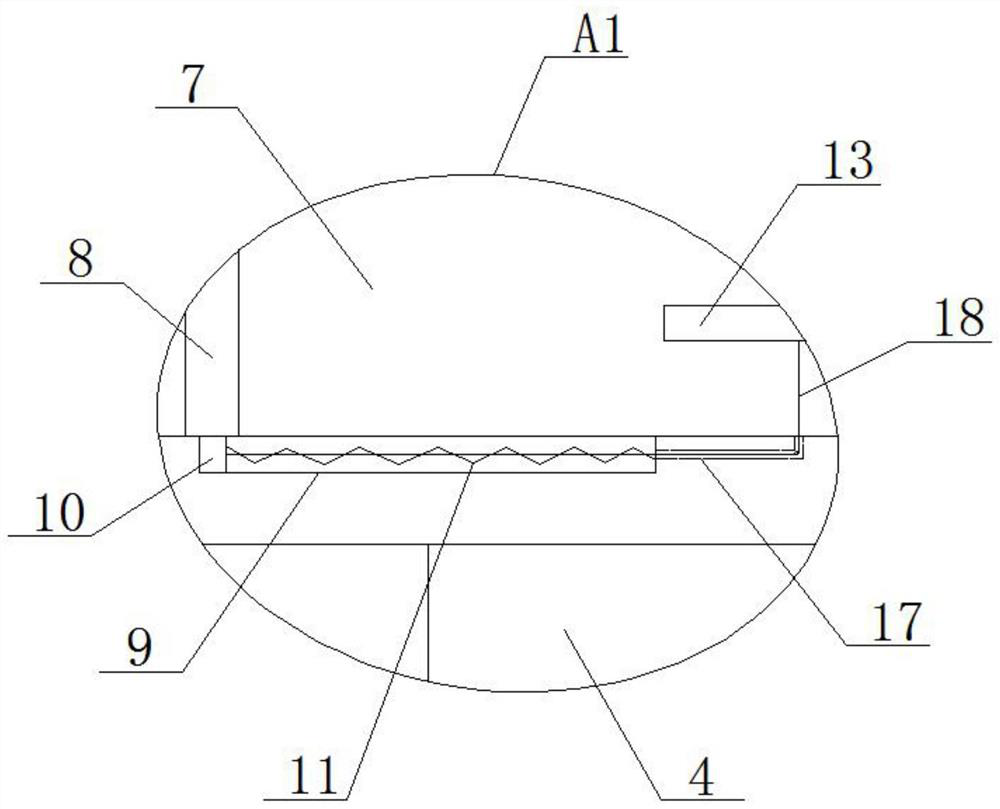

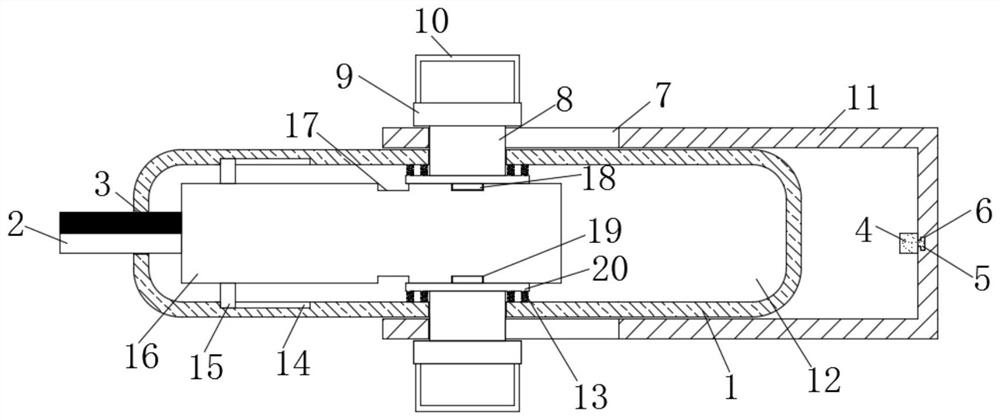

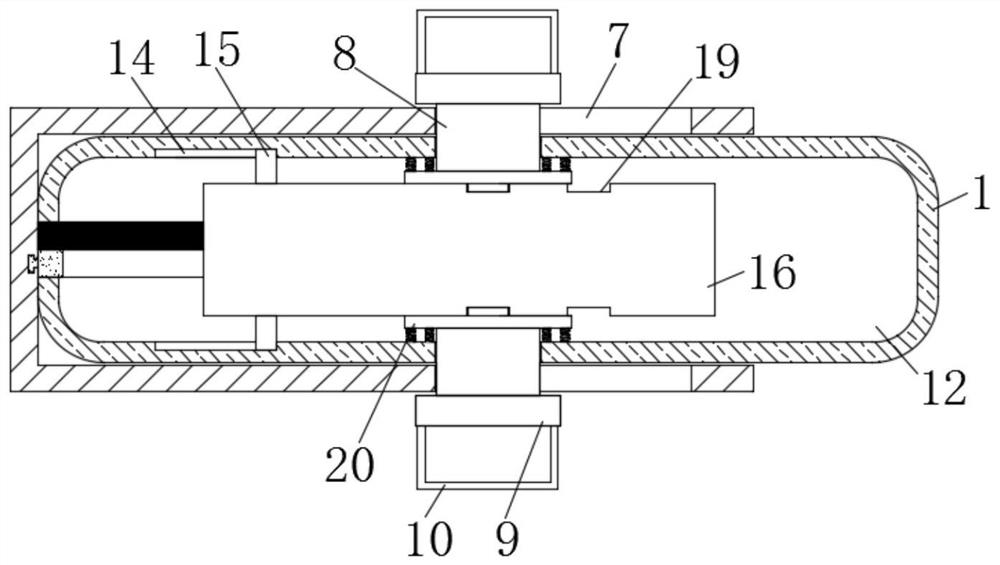

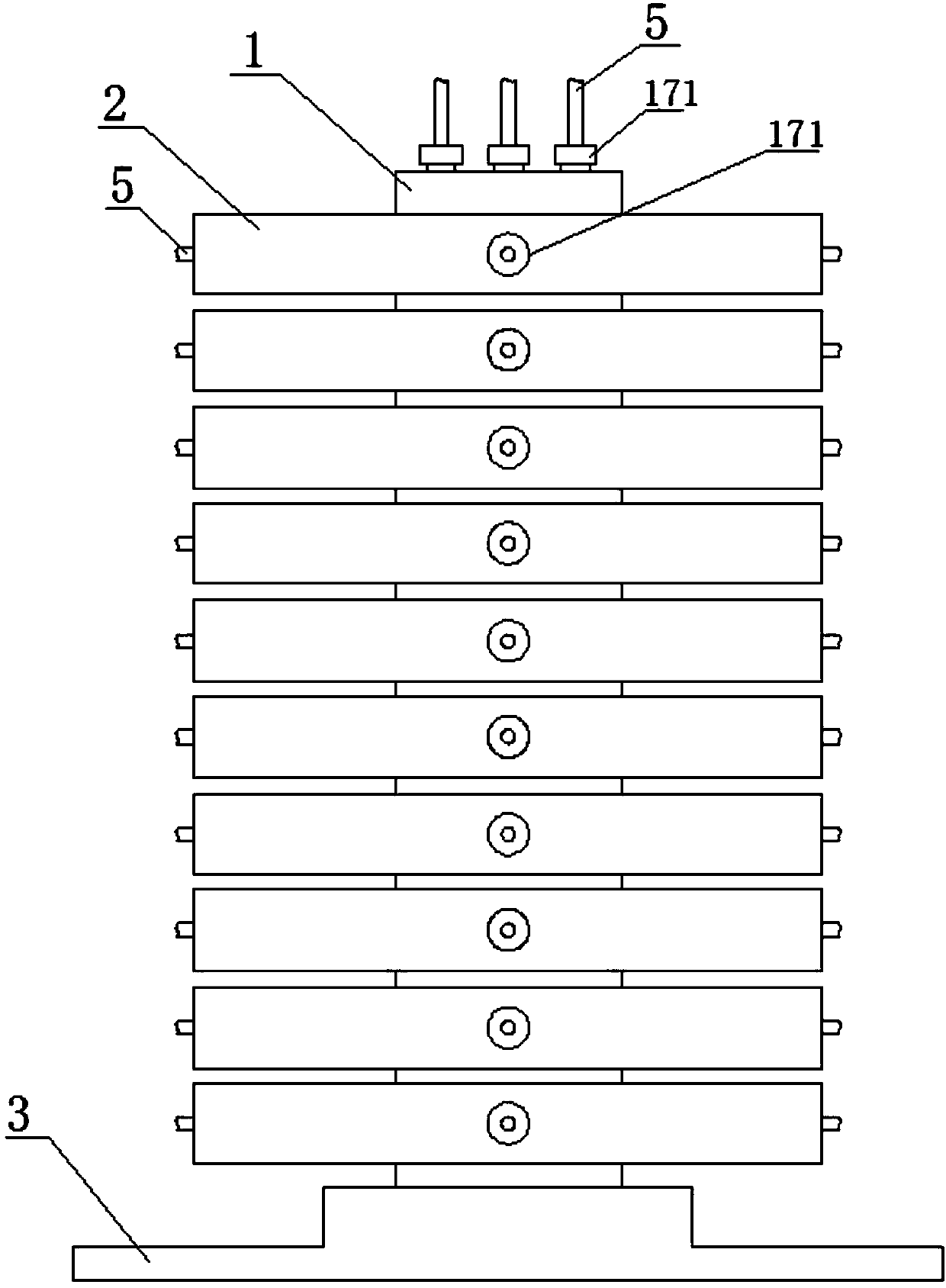

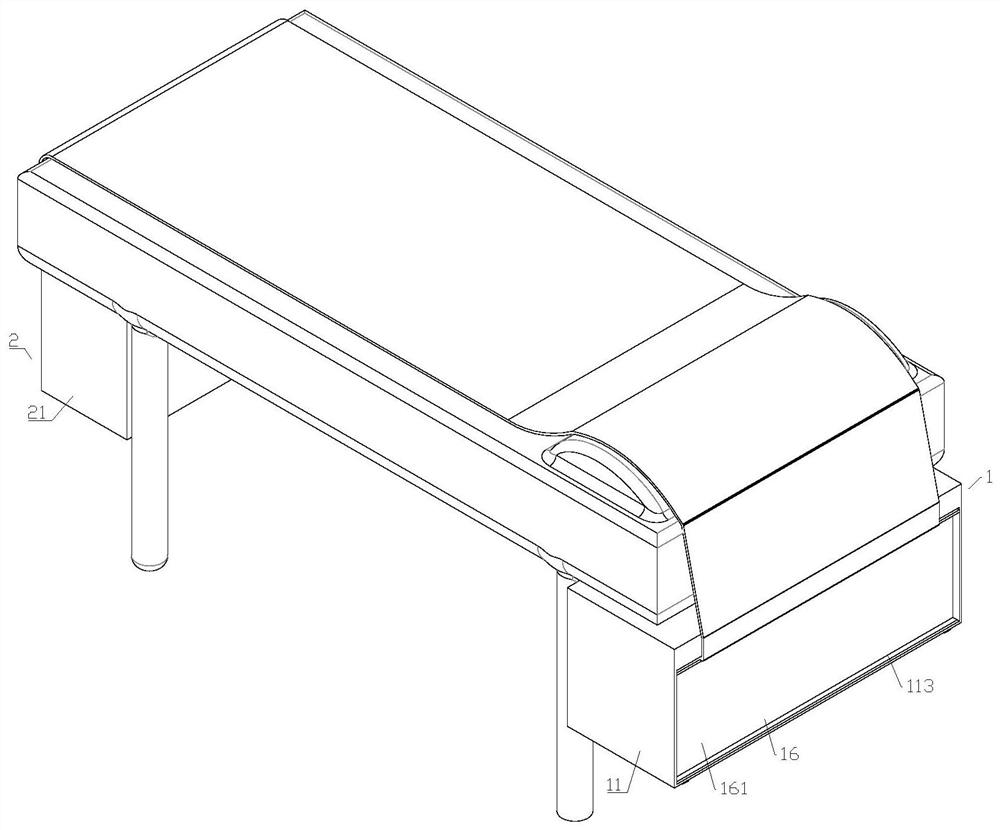

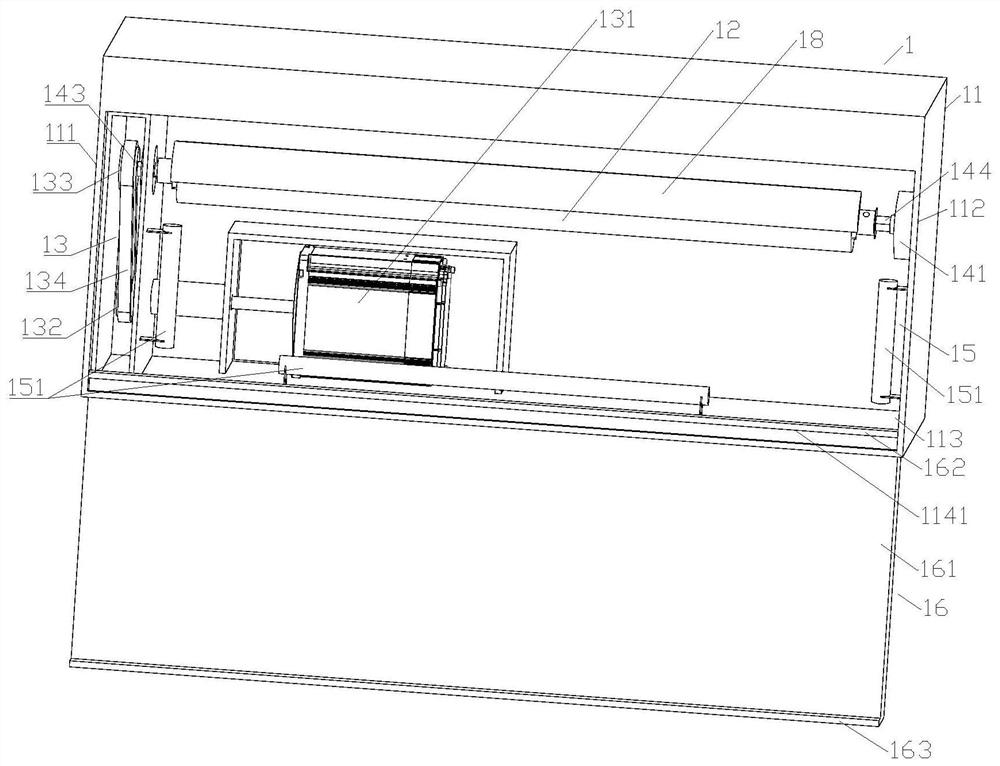

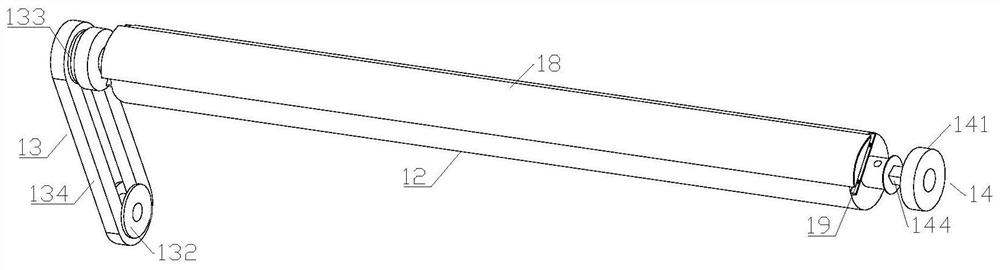

Bed sheet tidying robot for medical bed

ActiveCN109350403AEasy to operateEasy to install and replaceNursing bedsRadiationBed sheetsEngineering

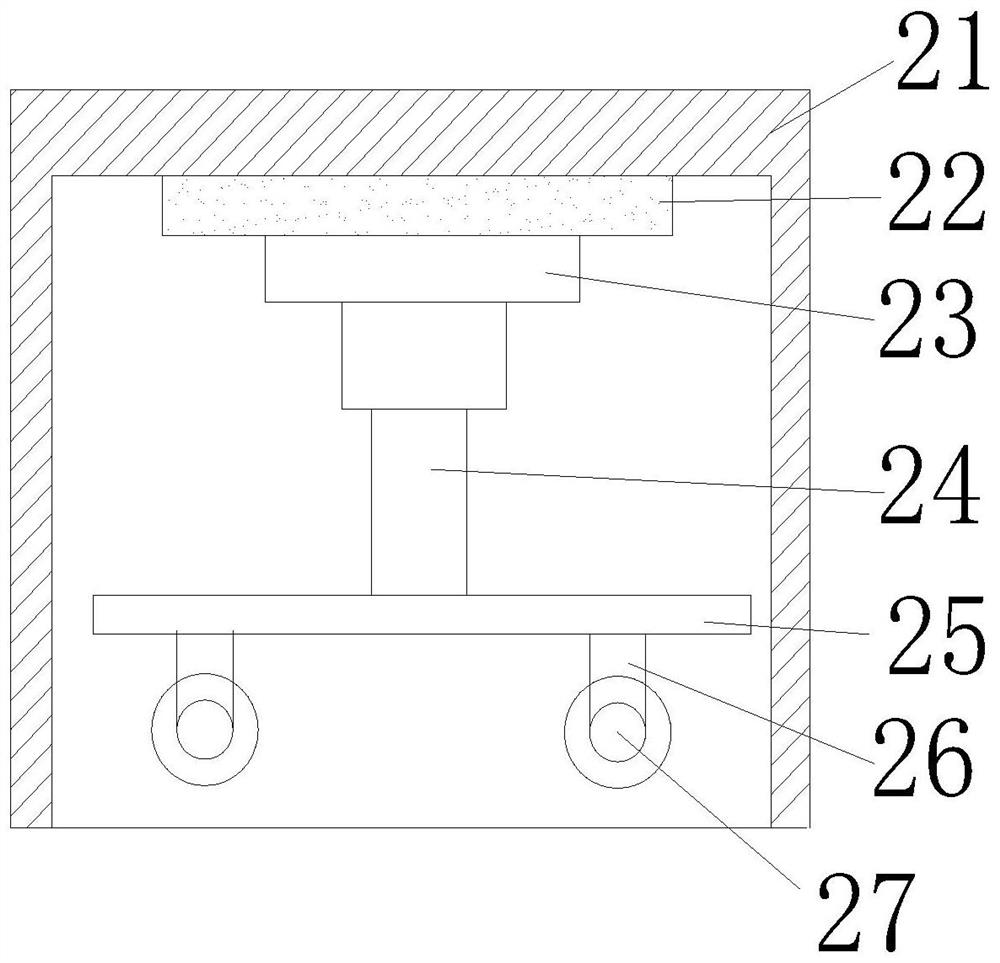

The invention relates to a bed sheet tidying robot for a medical bed. The bed sheet tidying robot for the medical bed comprises a winding mechanism and an unwinding mechanism; the winding mechanism comprises a first box body and a first roll shaft which is positioned in the first box body; the unwinding mechanism comprises a second box body and a second roll shaft which is positioned in the secondbox body; and the first box body and the second box body are respectively fixed to the two ends of the medical bed. The bed sheet tidying robot for the medical bed has the beneficial effects that when the bed sheet tidying robot for the medical bed is used, a bed sheet can be wound on the first roll shaft or the second roll shaft directly, and then the bed sheet on the medical bed is replaced byrotating the first roll shaft or the second roll shaft; and the bed sheet tidying robot for the medical bed is easy and quick to operate.

Owner:鄂州市中心医院

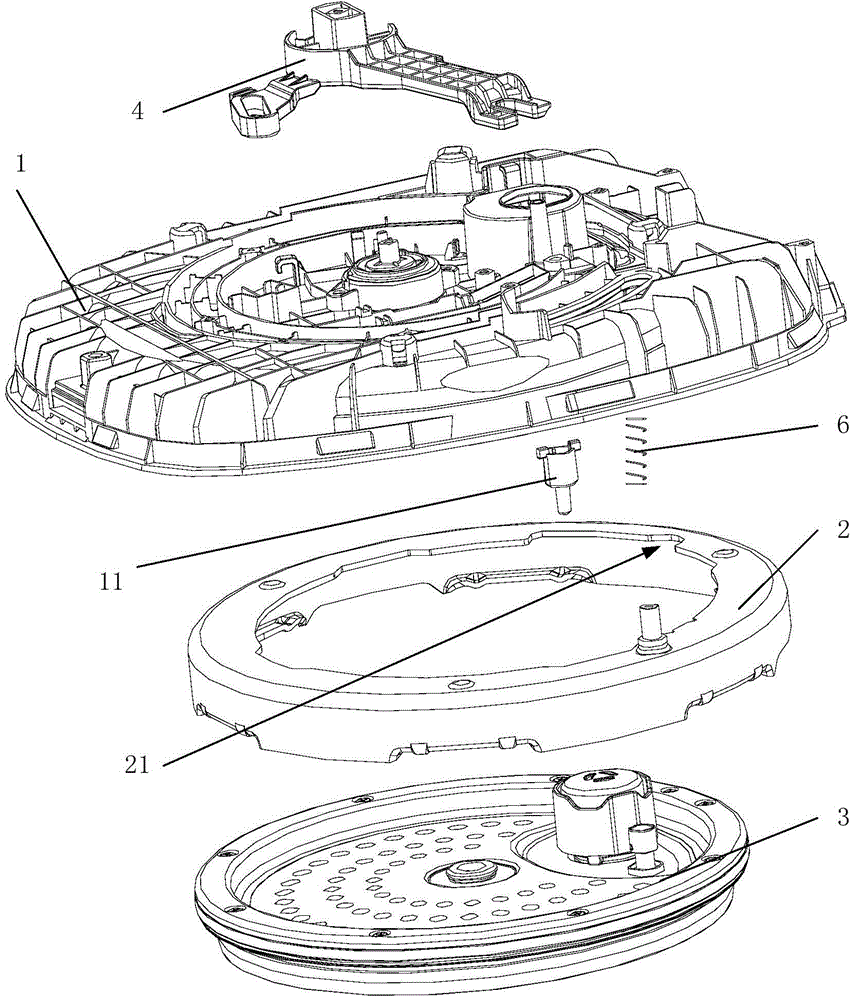

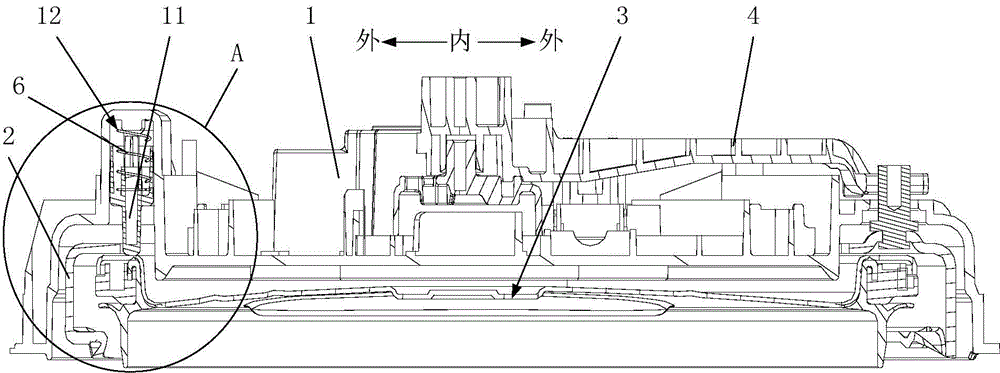

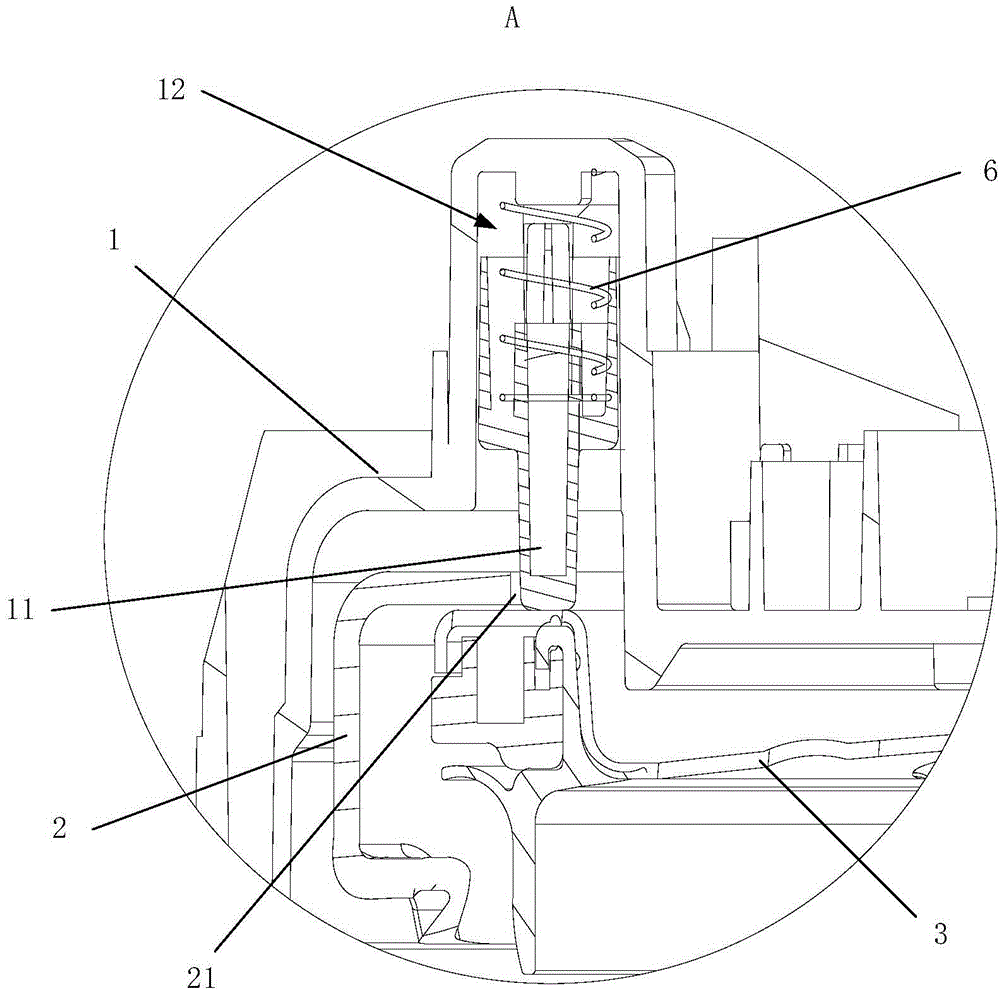

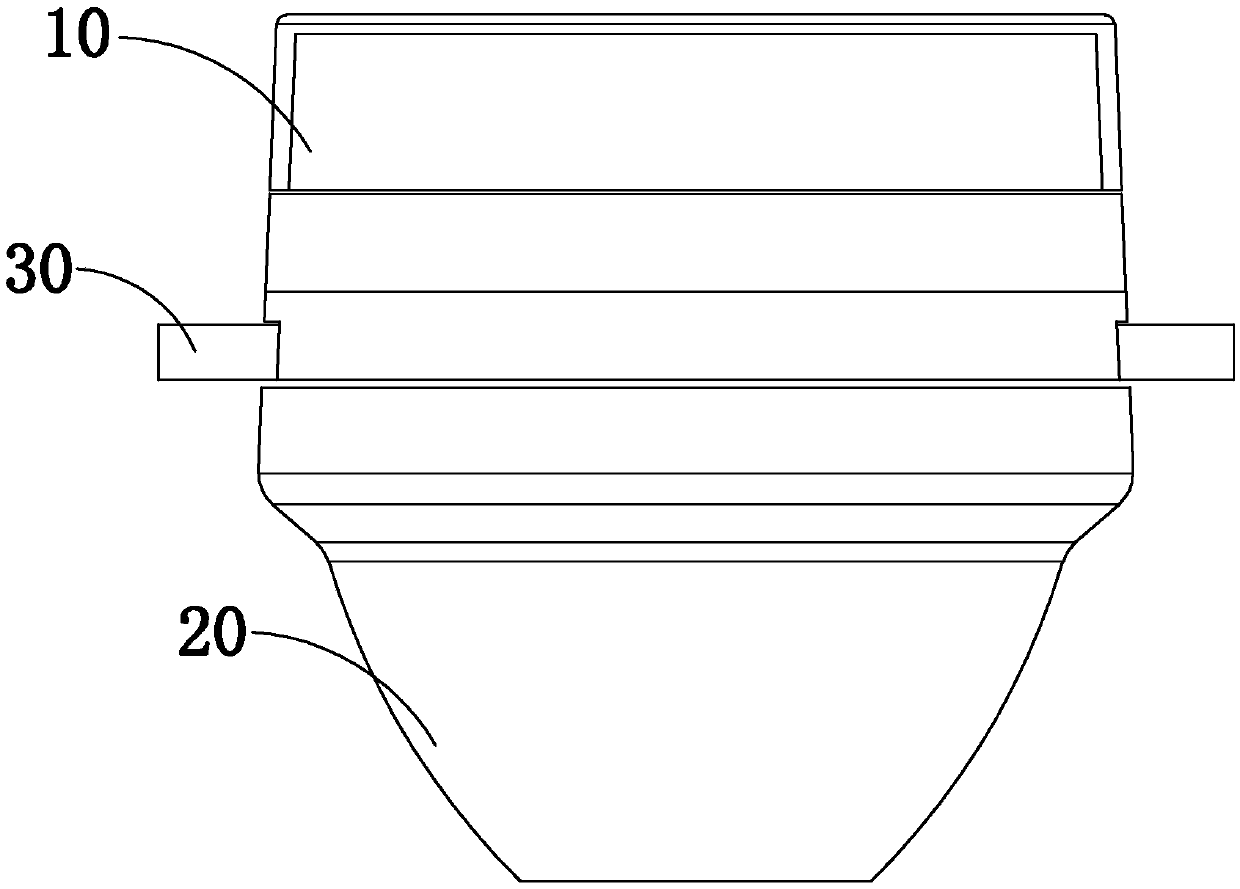

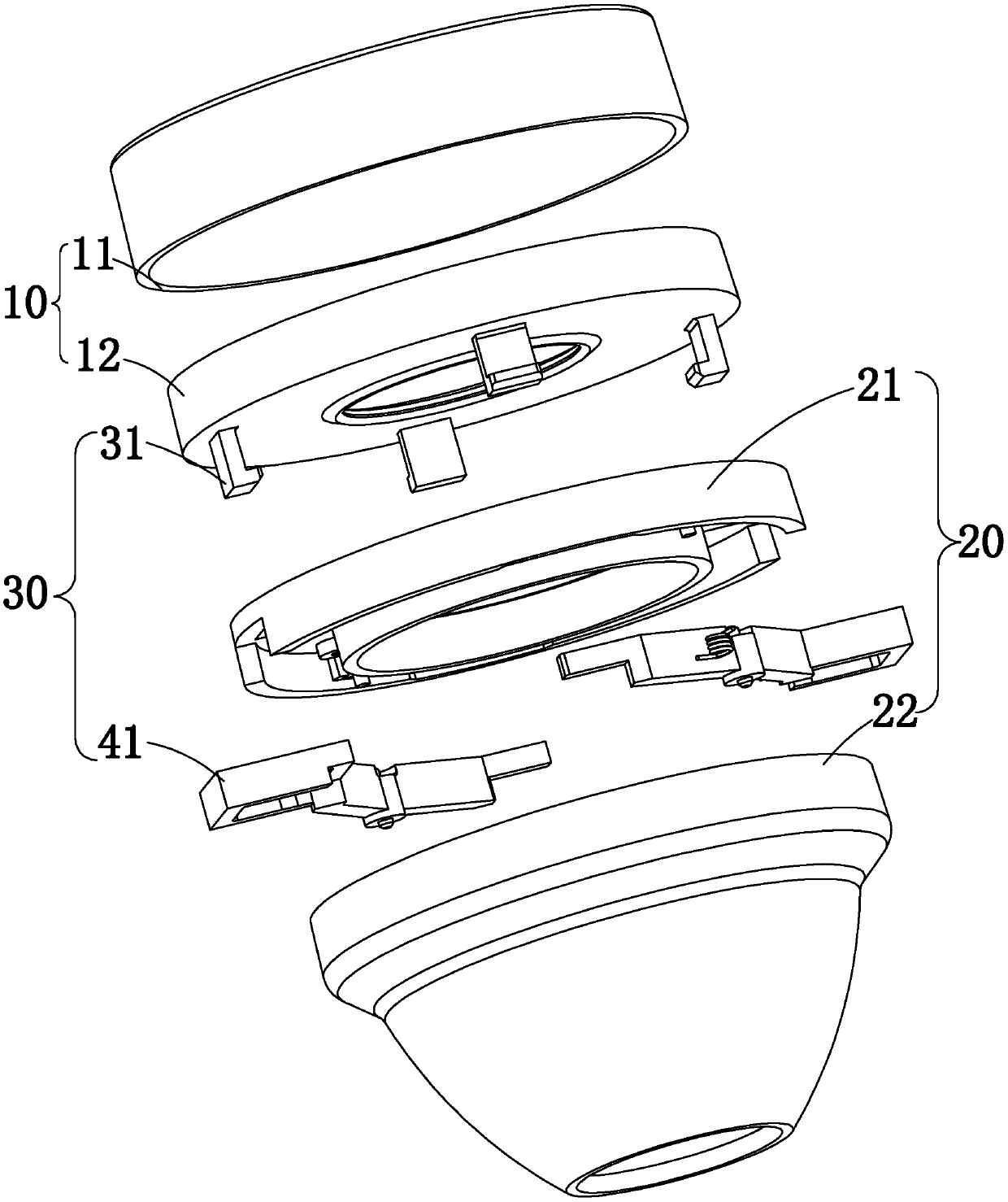

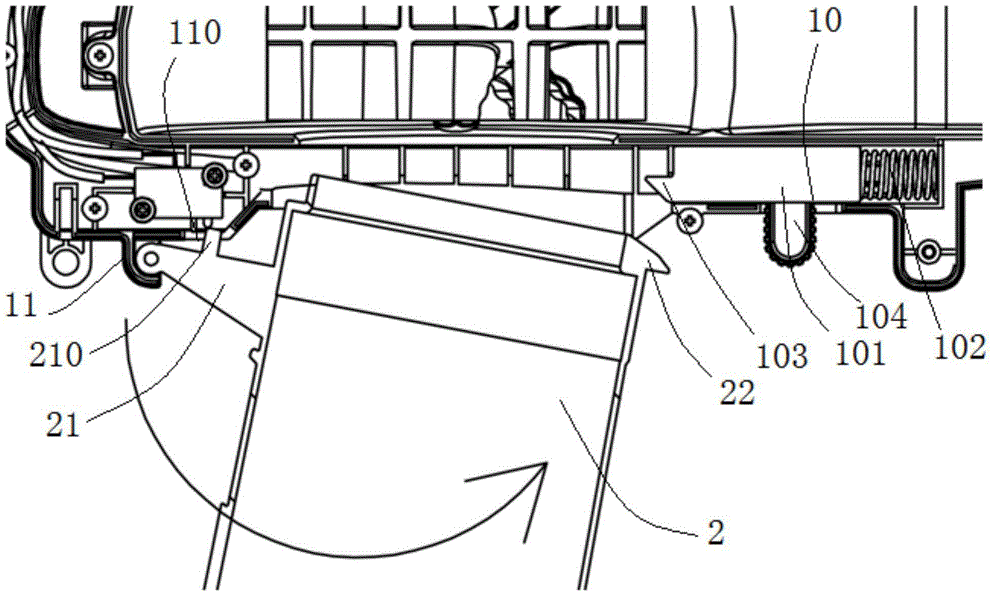

Electric pressure cooker and upper cover component thereof

The invention provides an electric pressure cooker and an upper cover component thereof. A detecting part is disposed on the inner cover of the upper cover component. A matching part is disposed on the lock of the upper cover component. When the cover plate of the electric pressure cooker is separated from the upper cover component, the detecting part is matched with the matching part to interfere the action, for driving the lock to rotate, of the connecting rod slider of the upper cover component; when the cover plate is assembled to the upper cover component, the detecting part is separated from the matching part to relieve the interference. By the upper cover component, the problem that the cover plate of the upper cover component is not mounted is solved effectively, product application safety is well guaranteed, and quality of electric pressure cookers leaving factories is increased at the same time.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

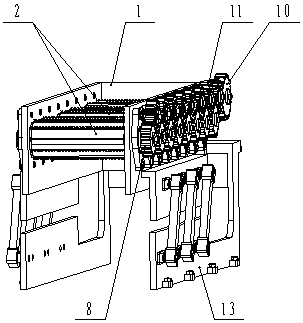

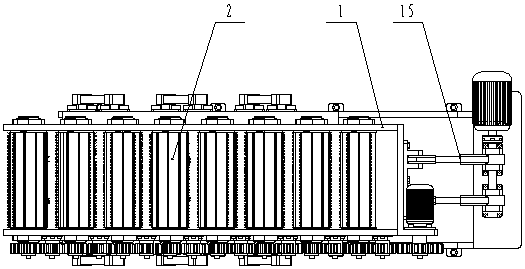

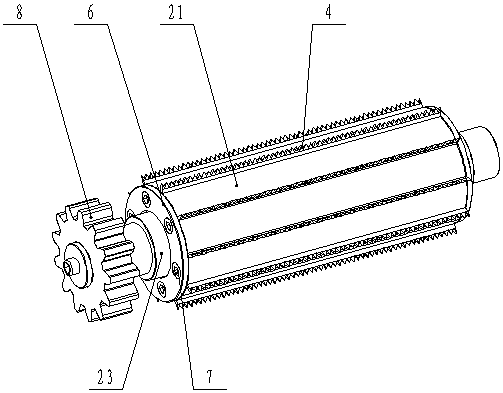

Hemp thread removal device of tobacco products

PendingCN109351586AAchieve sticky hookEfficient removal of impuritiesTobacco preparationSievingDrive wheelEngineering

The invention discloses a hemp thread removal device of tobacco products. The device comprises an impurity removal roller way arranged in a conveying groove of a vibration conveyor, an impurity removal roller is formed through combined arrangement of thread impurity removal rollers, the thread impurity removal rollers are of split type roller structures and comprise roller bodies arranged on roller shafts in a sleeving manner and each formed through abut joint of two half roller bases, multiple discharging racks made of elastic materials are evenly distributed on the roller faces of the rollerbodies in the circumference direction, the thread impurity removal rollers are arranged on the conveying groove through the corresponding roller shafts and matched bearings, transmission gears are fixedly arranged on roller shaft ends, located on the same side, of the thread impurity removal rollers, the transmission gears are in transmission connection with a drive mechanism, the drive mechanismcomprises a driving wheel and multiple driven wheels distributed on the outer wall of the conveying groove, and the driven wheels are located between two adjacent transmission gears and are in engaged connection with the transmission gears on two sides adjacent to the driven wheels. Threads such as hemp ropes and hemp browns can be subjected to efficient impurity removal and eliminating, and thedamage to the tobacco leaves can be reduced.

Owner:CHINA TOBACCO HENAN IND

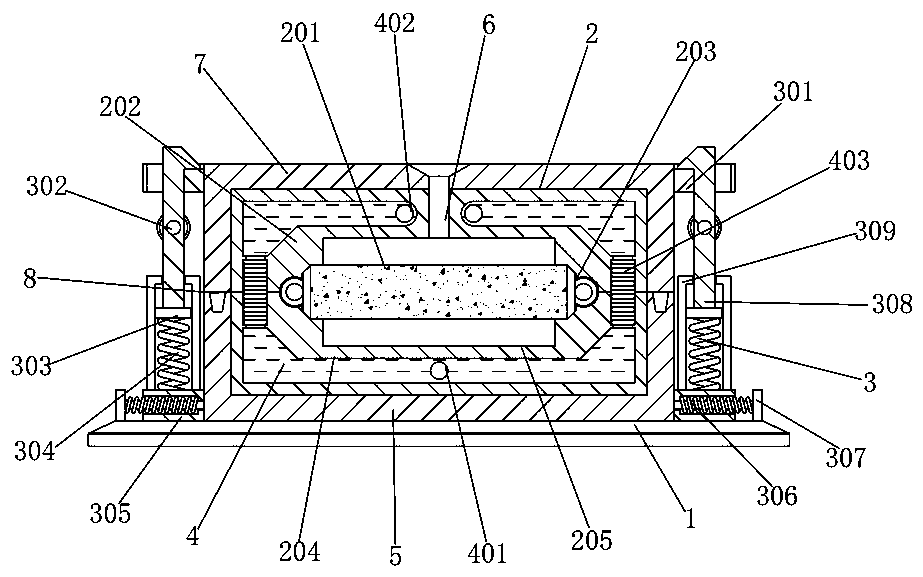

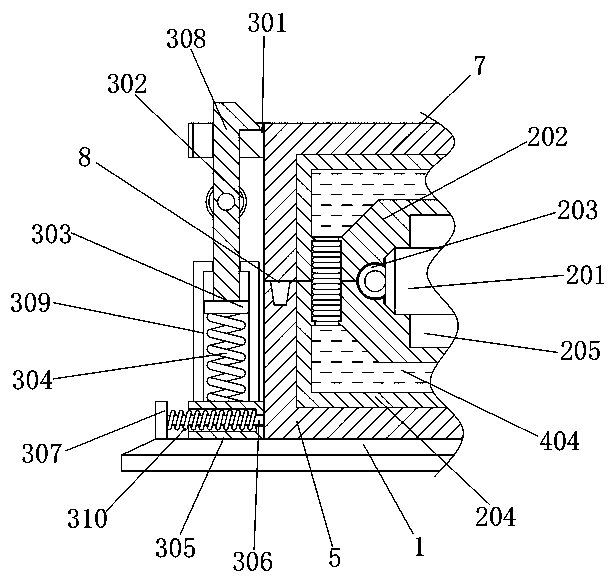

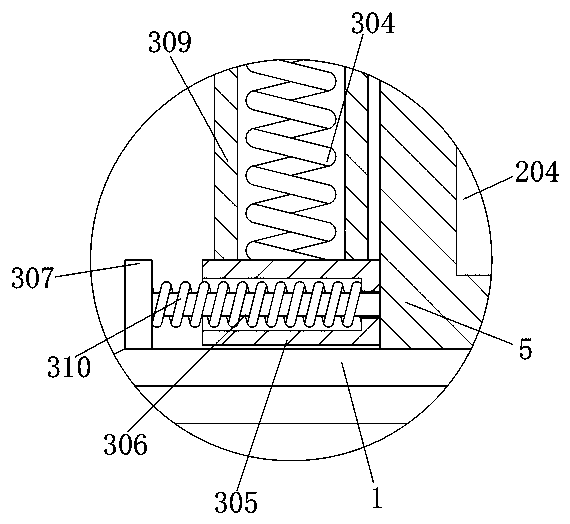

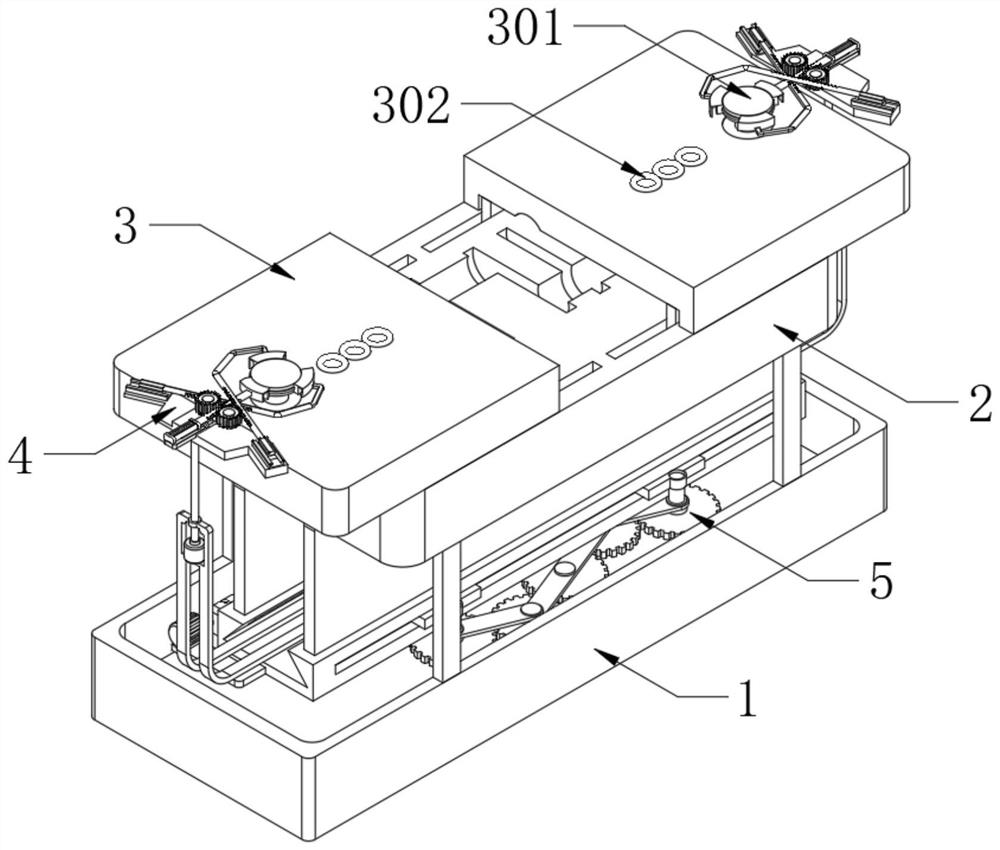

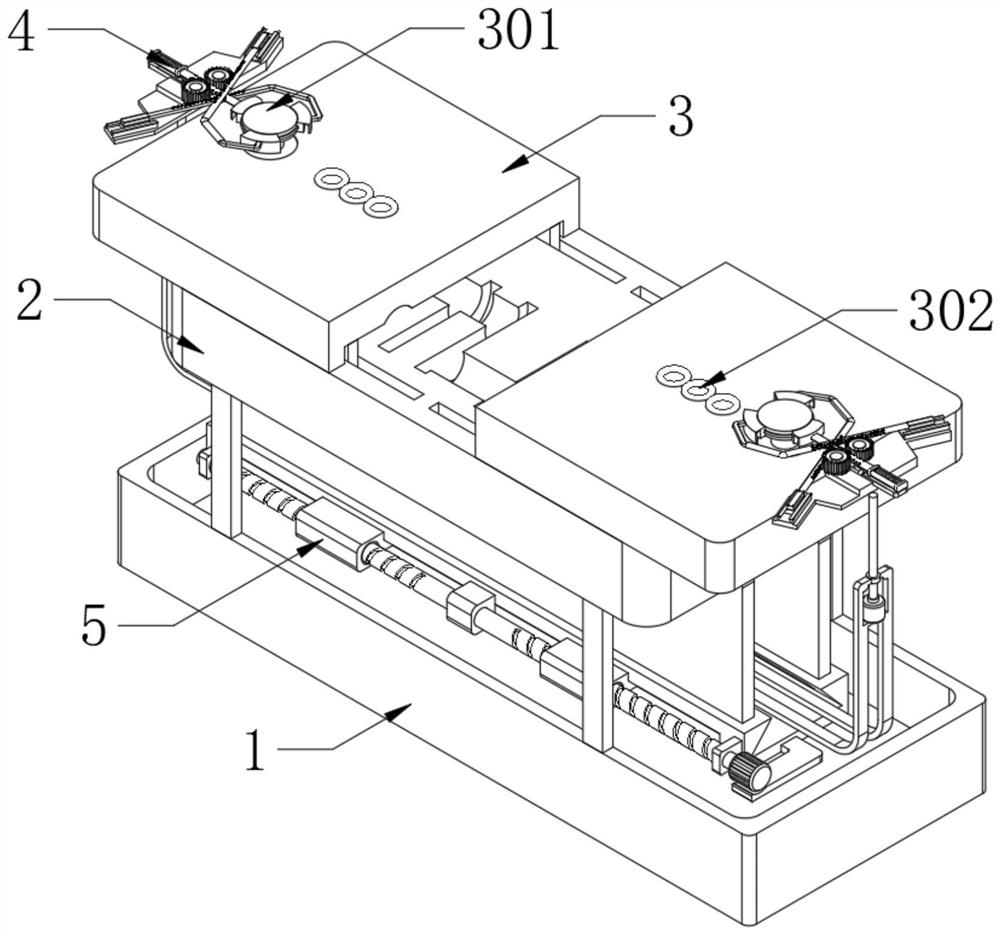

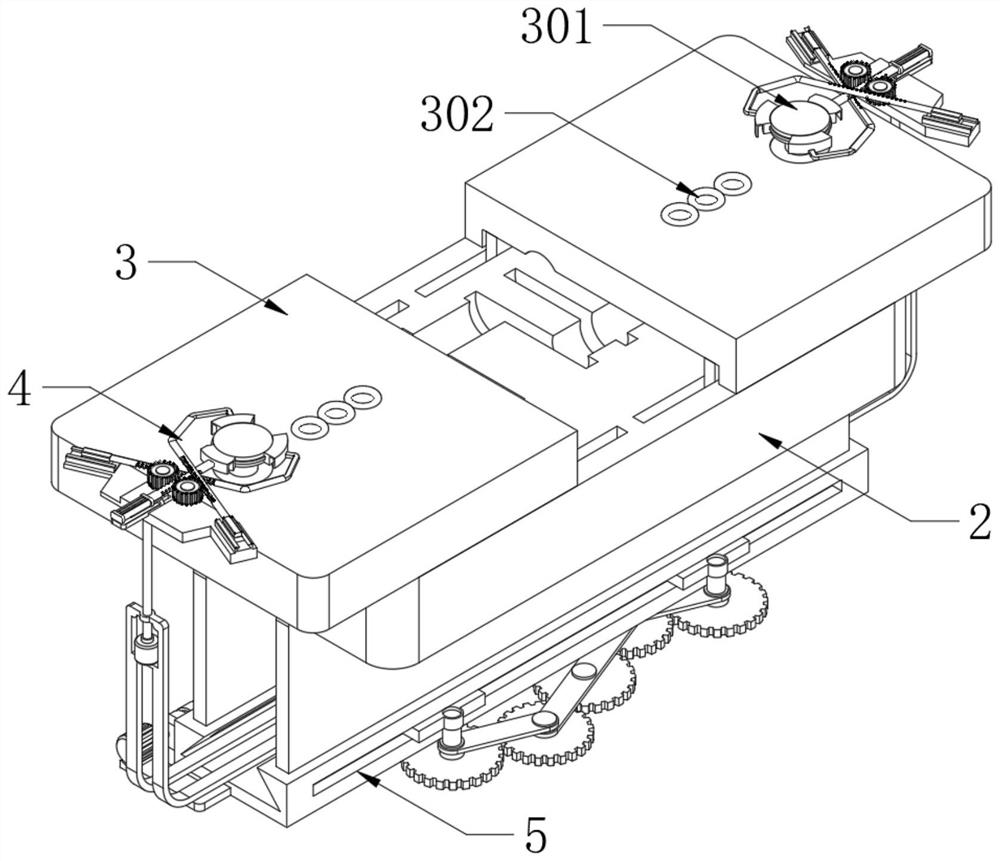

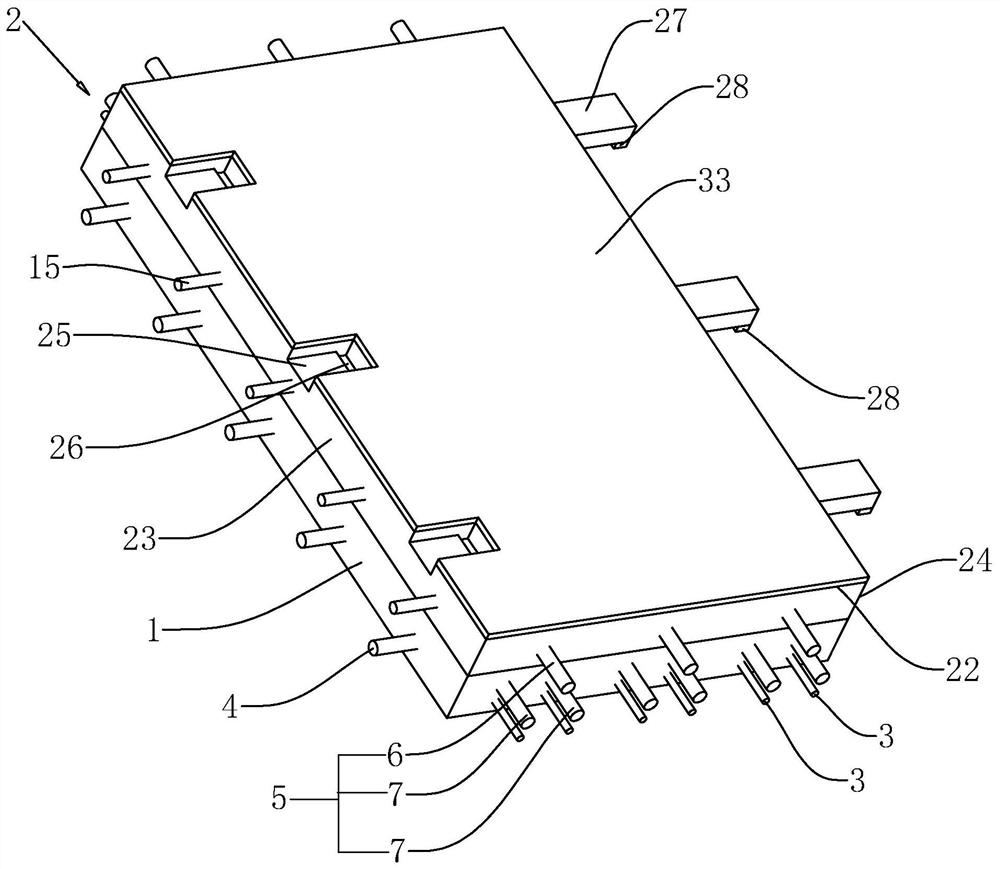

Casting equipment for light alloy motor shell

ActiveCN111468681AScientific and reasonable structureEasy to useFoundry mouldsFoundry coresElectric machineryEngineering

The invention discloses casting equipment for a light alloy motor shell. The casting equipment comprises a base plate, an upper mold and a lower mold, wherein the lower mold is fixedly connected to the upper end of the base plate, clamping assemblies are installed at the front and rear sides of the left and right ends of the upper mold and the lower mold, and comprise top plates, handles, first springs, sleeving blocks, transverse rods, end covers, clamping blocks, sleeves and second springs, and the front and rear clamping blocks are fixedly connected with each other through the handles. Thecasting equipment for the light alloy motor shell is scientific and reasonable in structure, and safe and convenient to use; through the cooperation of the base plate, the lower mold, the upper mold,the top plates, baffles, the first springs, the sleeving blocks, the transverse rods, the end covers, the clamping blocks and the second springs, a user can press the hands on the upper mold and thenmove the clamping blocks upwards, so that clamping between the clamping blocks and the top plates and close connection between the upper mold and the lower mold are achieved, and the situation that inthe using process, due to accident touch, the fitting state of the upper mold and the lower mold is changed is avoided.

Owner:襄阳派尔尼模具技术有限公司

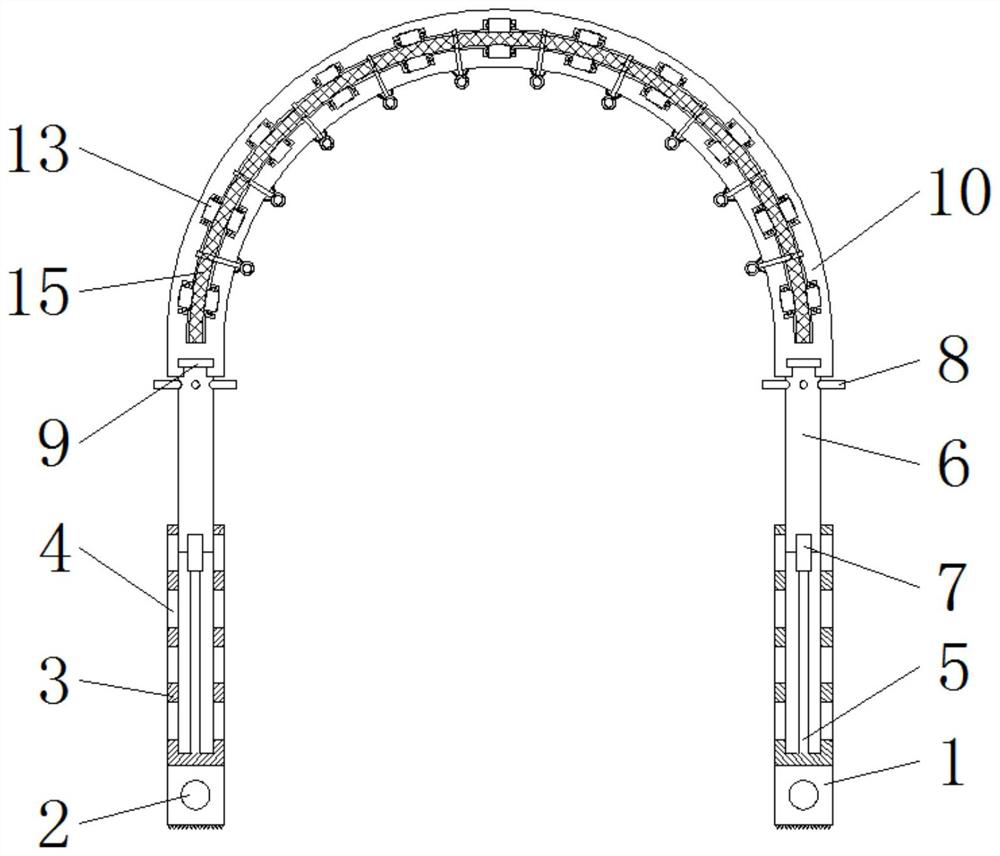

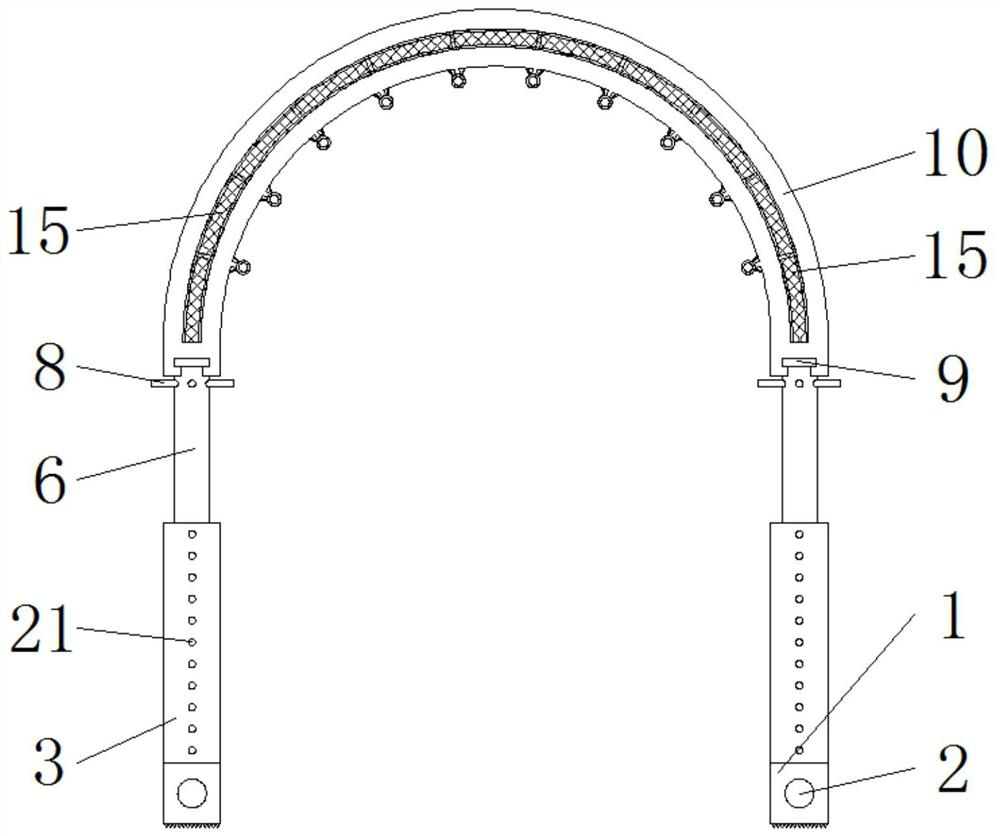

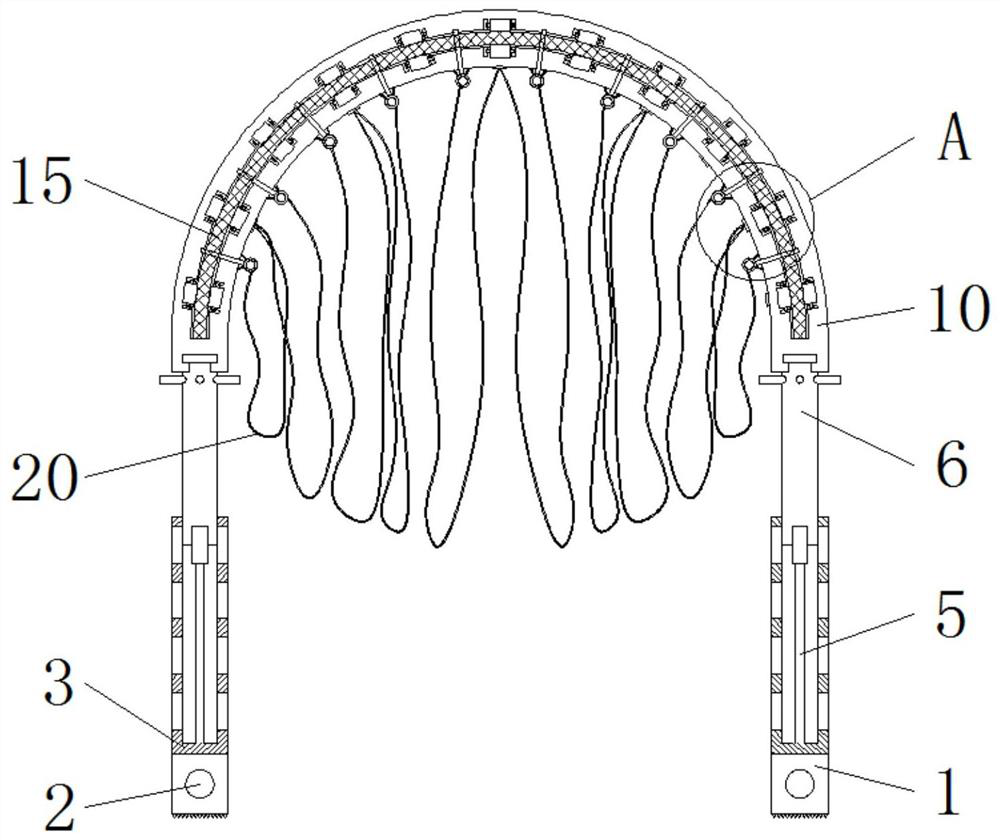

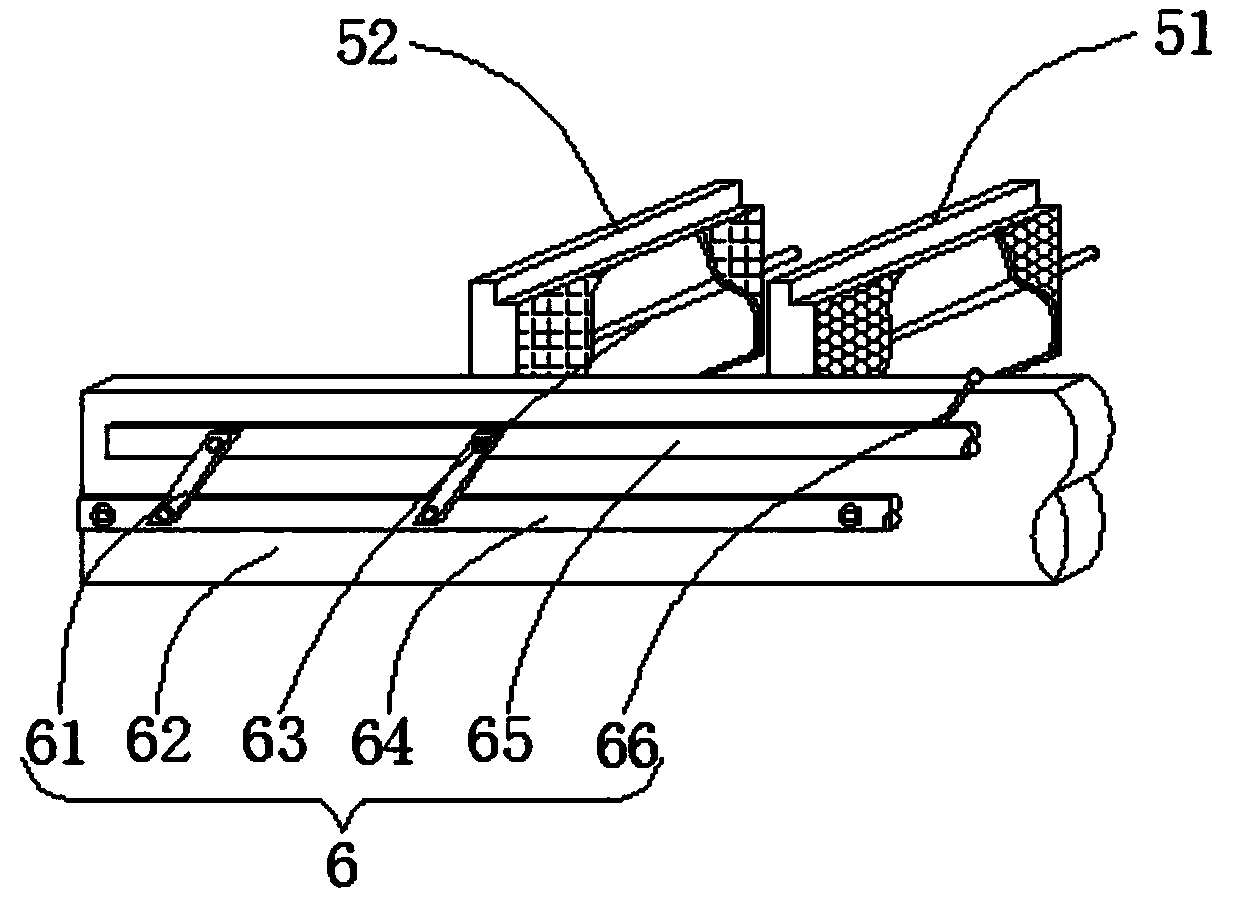

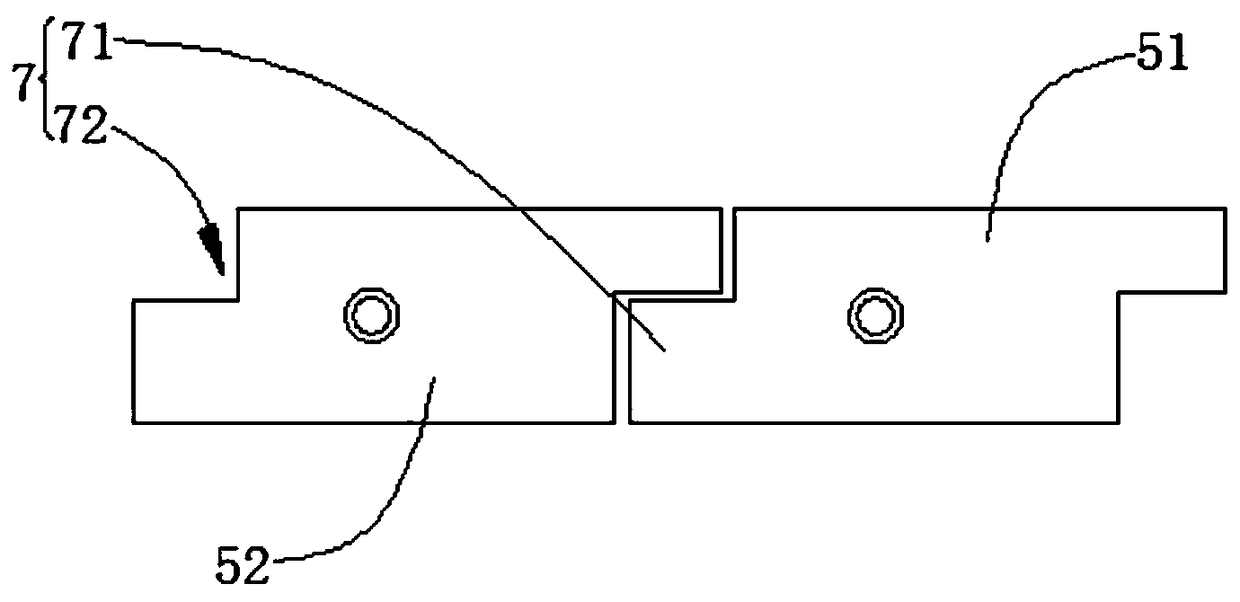

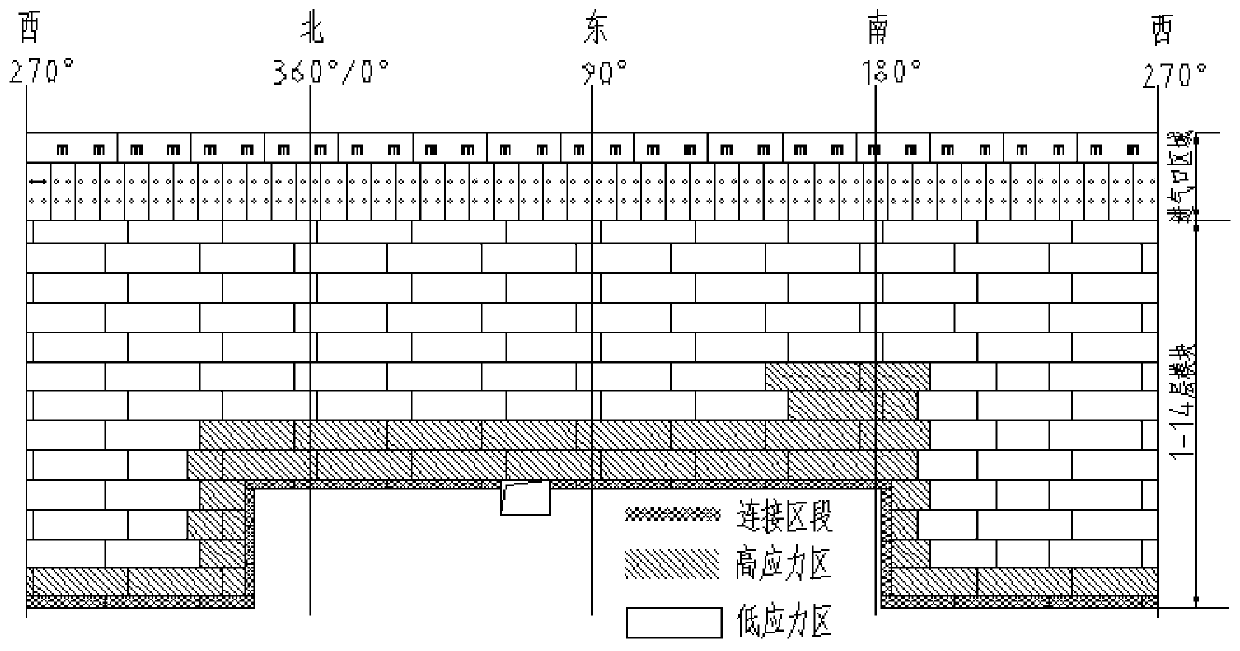

Adjustable support net rack capable of being kept attached to interior of tunnel for coal mining

ActiveCN111691904AEasy to pullAvoid injuryUnderground chambersMine roof capsSupport planeEnvironmental geology

The invention discloses an adjustable supporting net rack capable of being kept attached to the interior of a tunnel for coal mining. The adjustable supporting net rack comprises a fixed base, rollingwheels, a protective net, an elastic rope, a magnetic block and an adjusting bolt, a through hole is formed in the fixed base, a supporting frame is fixedly connected to the upper portion of the fixed base, and guiding-out grooves are formed in the left side and the right side of the supporting frame correspondingly; and a limiting rod is fixedly arranged in the supporting frame, a supporting rodis movably installed on the outer side of the limiting rod, connecting plates are fixedly connected to the front side and the rear side of the lower portion of the supporting rod, a fixing rod is fixedly connected to the surface of the upper portion of the supporting rod, a rotating block is fixedly connected to the top of the supporting rod, and a top frame is movably arranged on the outer sideof the rotating block. According to the adjustable supporting net rack capable of being kept attached to the interior of the tunnel for coal mining, the overall height of the device can be conveniently adjusted, and meanwhile the protective net can be conveniently detached subsequently while the protective net is attached to the top of the device.

Owner:神木市大柳塔东川矿业有限公司

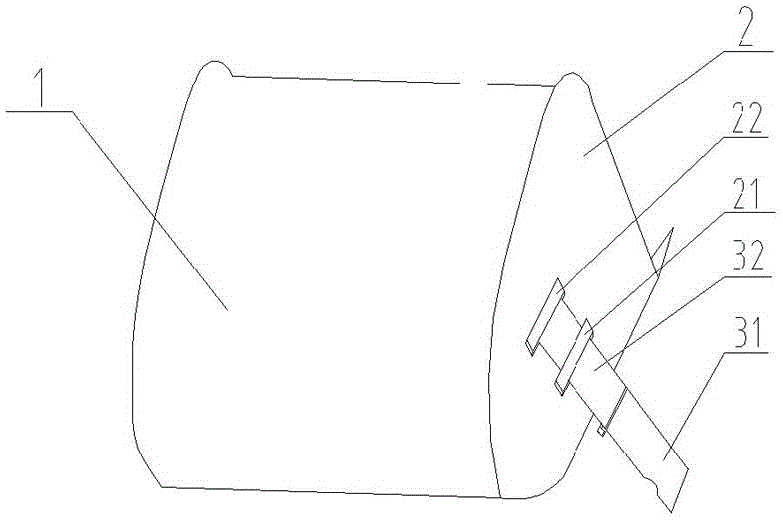

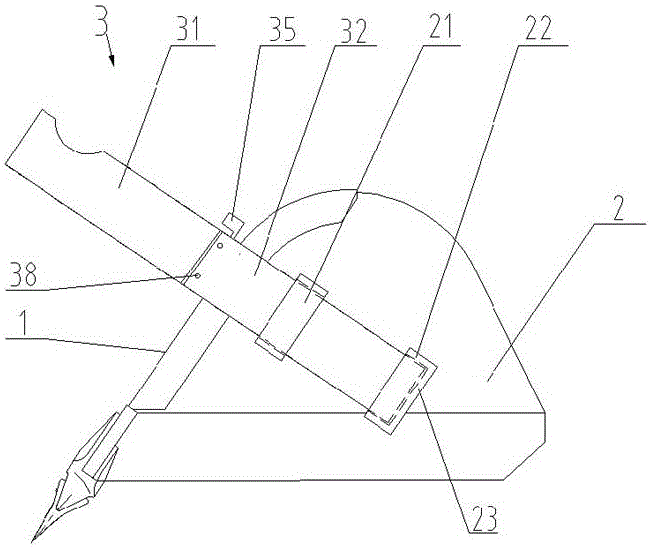

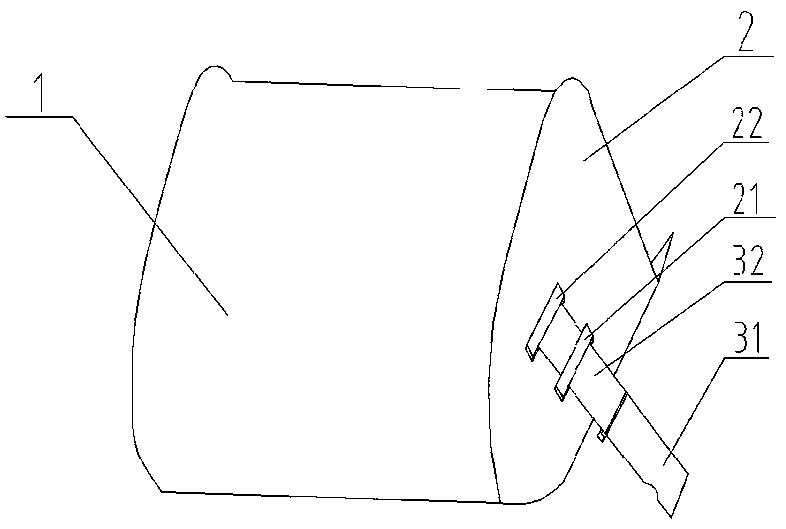

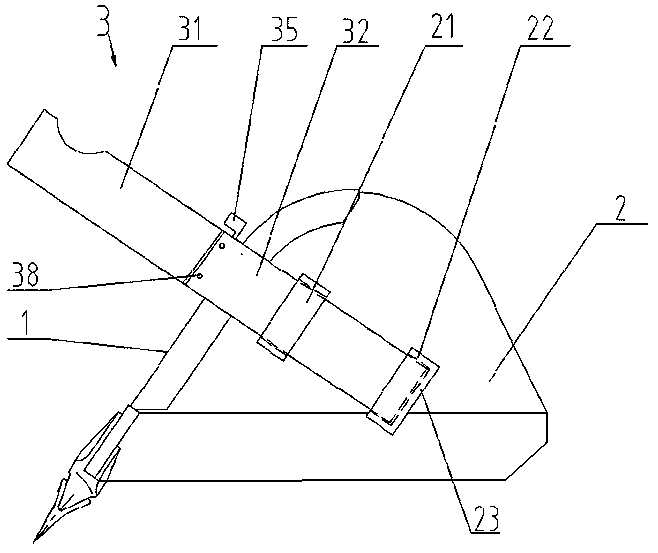

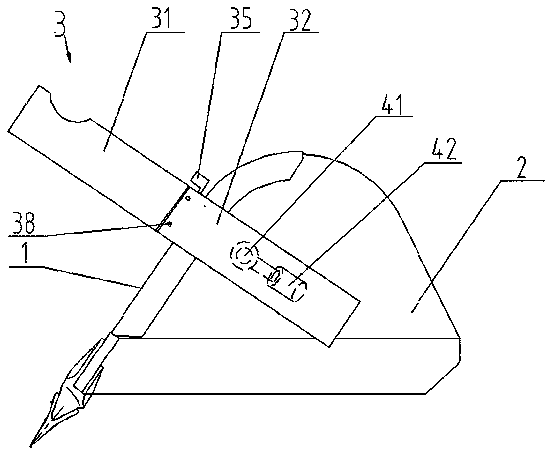

Standardbucket with scraper

ActiveCN106640095AImprove securityShorten construction timeMechanical machines/dredgersTunnelsEngineering

Owner:CSCEC STRAIT CONSTR & DEV

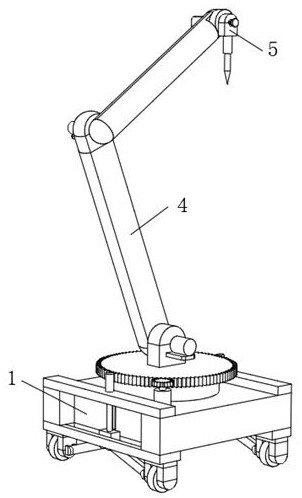

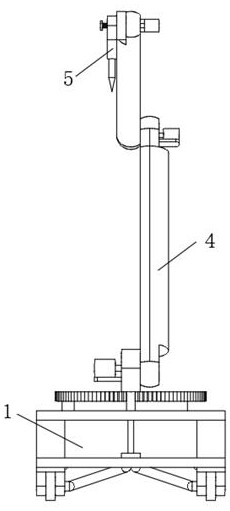

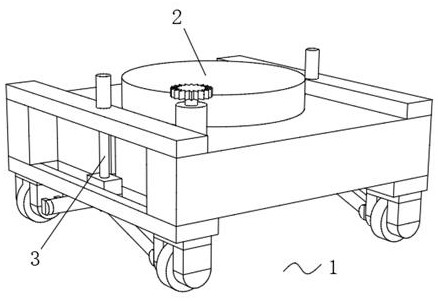

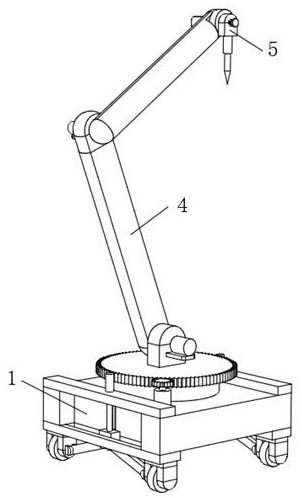

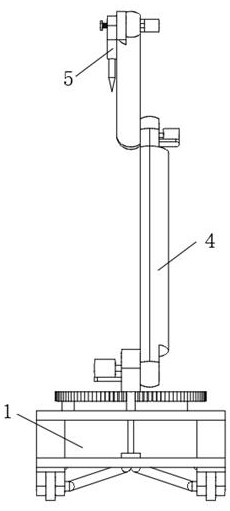

Industrial laser welding robot system and working method thereof

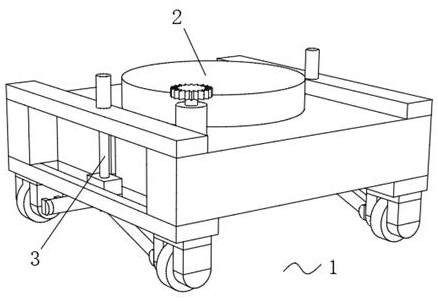

ActiveCN111822857APlace stableIncrease flexibilityLaser beam welding apparatusGear wheelElectric machinery

The invention discloses an industrial laser welding robot system and a working method thereof, and relates to the technical field of industrial manufacturing. The industrial laser welding robot systemcomprises a bottom mechanism. The upper portion of the bottom mechanism is rotationally connected with a direction adjusting assembly. The bottom mechanism comprises a bottom assembly. The two sidesof the bottom assembly are each provided with a folding assembly. The bottom assembly comprises a bottom plate, and a side groove is formed in each of the two sides of the bottom plate. A rotating plate is rotationally connected to the upper surface of the bottom plate. A first drive motor is fixedly mounted at the position, located on the outer side of the rotating plate, of the upper surface ofthe bottom plate. A gear is fixedly mounted at the output end of the first drive motor. Each folding assembly comprises an upper support plate and a lower support plate, the lower surfaces of the upper support plates are fixedly connected with the upper surface of the bottom plate, and the upper surfaces of the lower support plates are fixedly connected with the lower surface of the bottom plate.Through combined use of a connecting assembly and a welding assembly, mounting or dismounting of a laser welding head can be rapidly completed, and therefore work efficiency is greatly improved.

Owner:温州英格镭激光技术有限公司

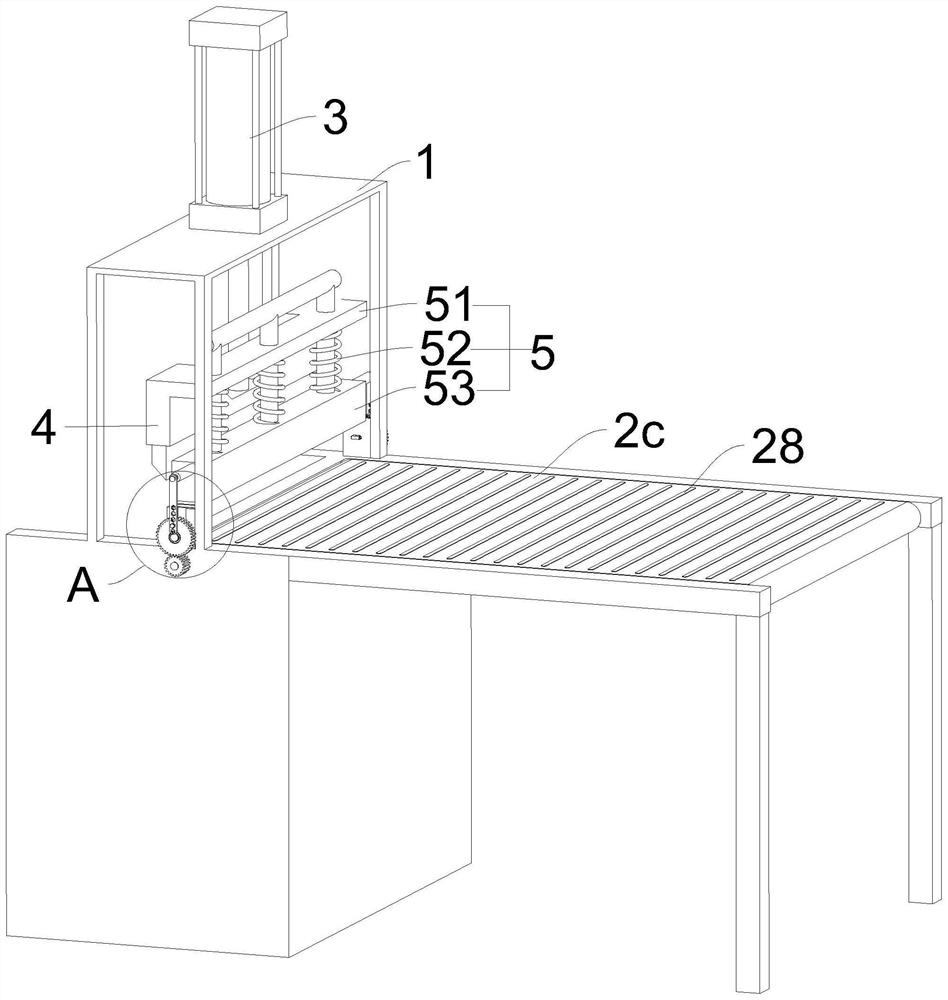

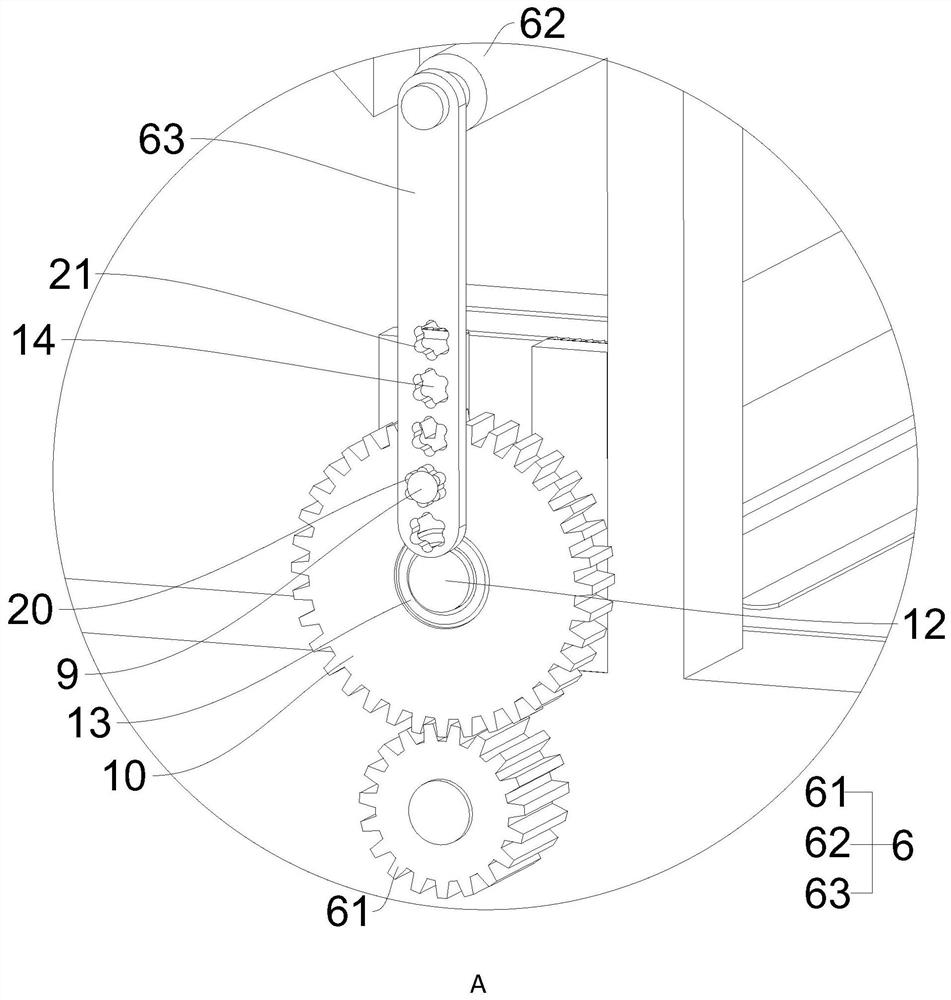

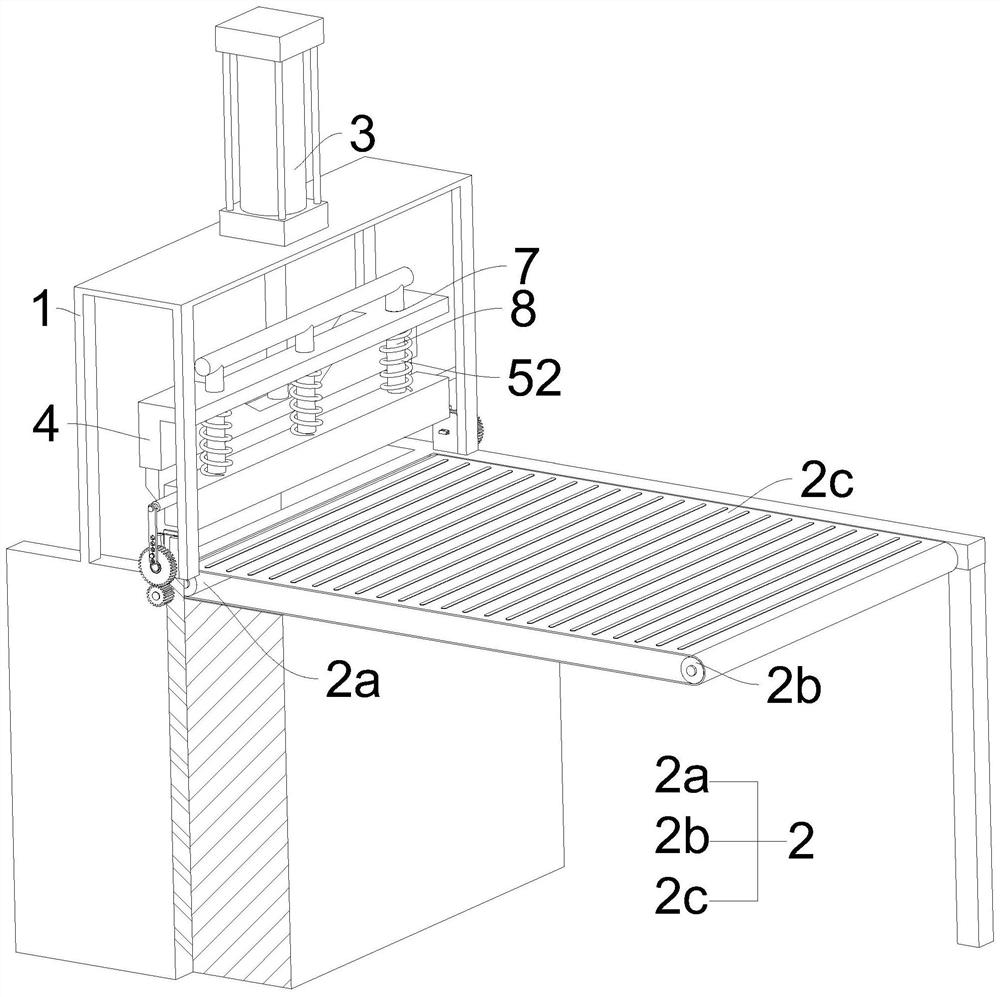

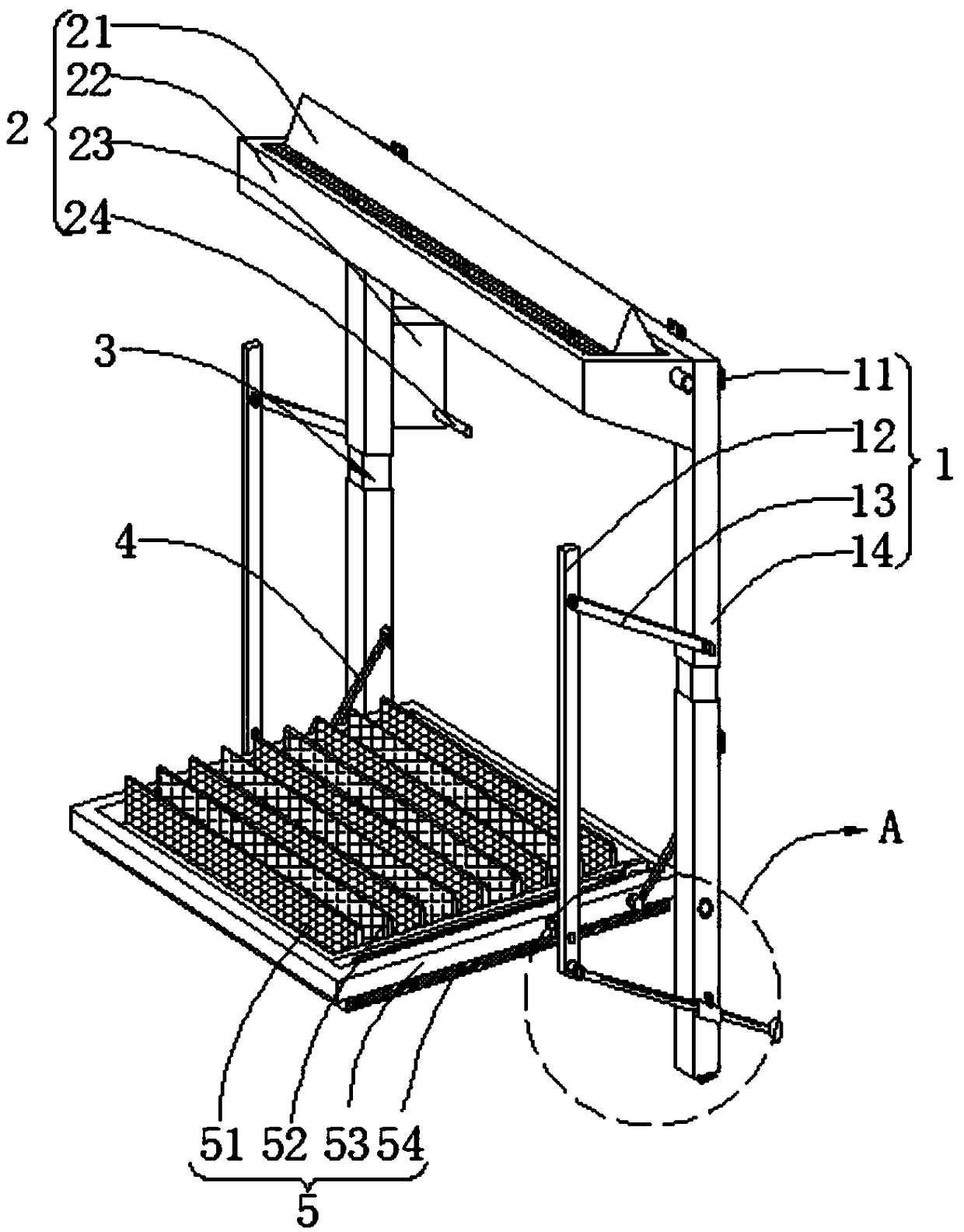

Plate shearing machine

ActiveCN113427066AImprove processing efficiencyImprove versatilityShearing machinesShearing machine accessoriesPhysicsSteel plates

The invention relates to the field of steel plate machining, and discloses a plate shearing machine which comprises a machine body, a feeding mechanism arranged on the machine body, a driving air cylinder arranged at the top of the machine body and a shearing piece arranged at the output end of the driving air cylinder in the vertical direction. A fixing mechanism for fixing a steel plate is arranged on one side of the shearing piece, the driving air cylinder can drive the fixing mechanism to move up and down in a reciprocating mode through the shearing piece, and driving mechanisms used for pushing the feeding mechanism to move in the direction close to the shearing piece are symmetrically arranged on the two sides of the fixing mechanism. In the process that the fixing mechanism drives the driving mechanism to move up and down in a reciprocating mode, the driving mechanism drives a feeding mechanism to push the steel plate forwards, the steel plate does not need to be pushed forwards manually in cooperation with movement of the shearing piece, and therefore the purpose of improving the machining efficiency is achieved.

Owner:XIANGYANG XINJINKAI PUMP CO LTD

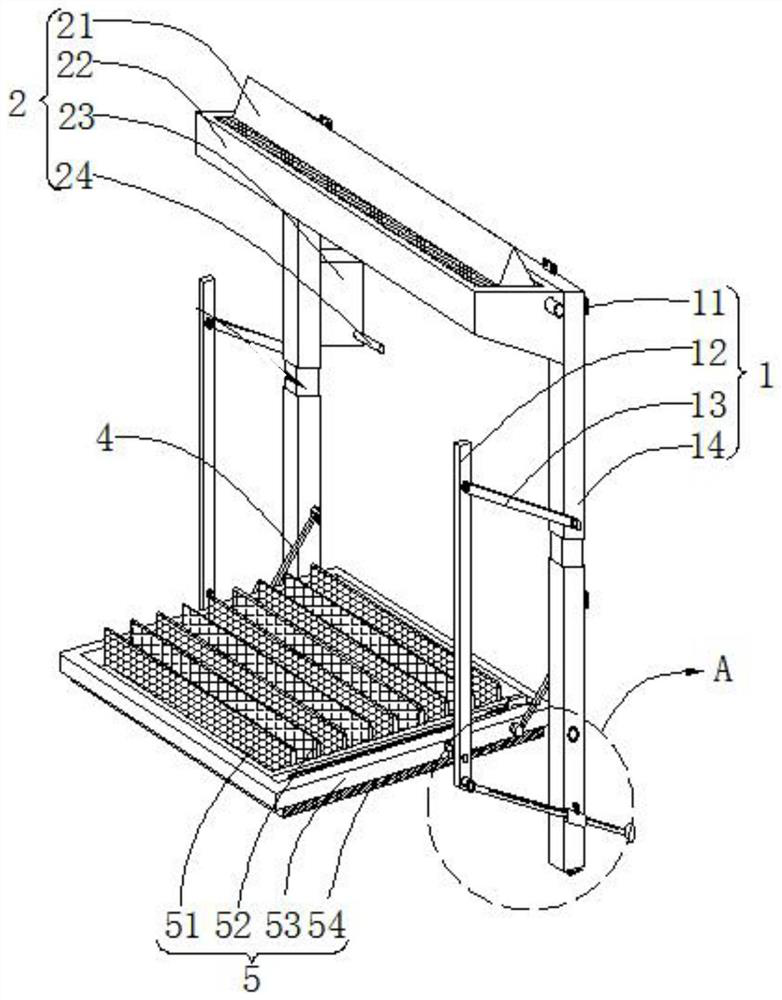

Indoor humidity adjustment method

ActiveCN108644954AFunction increaseGuaranteed not to dropFree-cooling systemsDrying chambers/containersFixed frameWater collection

The invention relates to the technical field of intelligent home, in particular to an indoor humidity adjustment method. The method adopts a folding balcony; and the folding balcony comprises a supporting mechanism, a humidifying and cooling mechanism, clamping grooves, reinforcing mechanisms, an airing mechanism, a control mechanism, clamping mechanisms, fixing mechanisms, first rotating shafts and second rotating shafts. The humidifying and cooling mechanism is installed at the top of the supporting mechanism, a water collection tank collects water in a rainy day, and a water spray pipe is opened in high-temperature weather, so that indoor cooling and plant watering are achieved; the airing mechanism is connected with the supporting mechanism through the reinforcing mechanisms, so that the airing mechanism is guaranteed not to fall; the sum of the width of a fixing frame and the lengths of the second rotating shafts are equal to the minimum inner diameters of two supporting rods, thelengths of the second rotating shafts are equal to the widths of reinforcing plates, and a distance between each supporting rod and each rotating plate is equal to one half of the length of each second rotating shaft, so that the fixing frame is clamped into the supporting rods; and the airing mechanism is connected through the control mechanism, so that aired grains are collected into a drawer rapidly.

Owner:湖南浏阳新松矿业科技有限公司

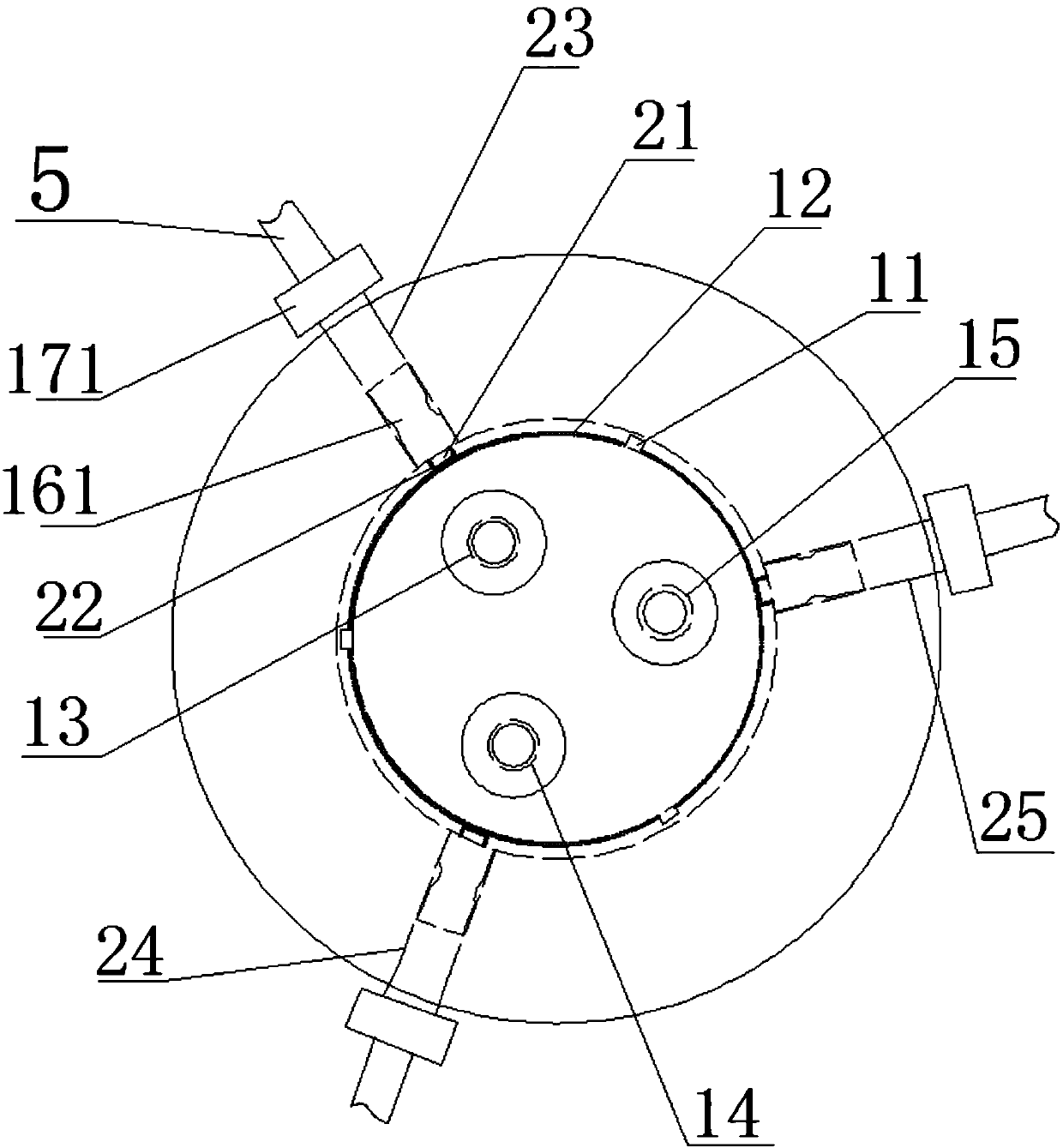

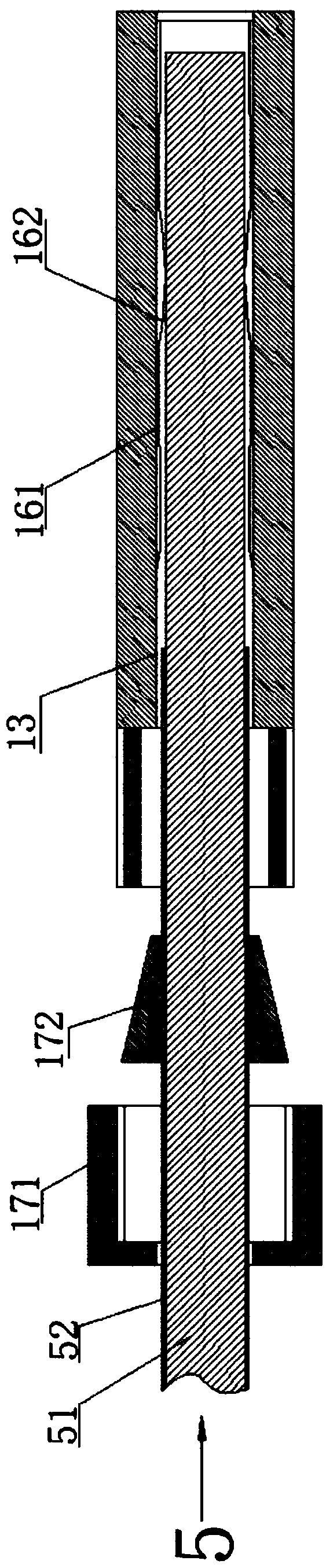

Puncture device shell and puncture device

ActiveCN110772304AImplement selective connectionAvoid the defects that are prone to jammingCannulasSurgical needlesStructural engineeringMechanical engineering

The invention discloses a puncture device shell and a puncture device. The puncture device shell comprises a first shell component, a second shell component and a locking mechanism for selectively connecting the first shell component with the second shell component, and the locking mechanism comprises a locking part and a matching part; the locking part comprises a fixing column and a rotary arm;the fixing column is rotatably arranged on the second shell component and arranged on the rotary arm; the matching part comprises a convex block arranged on the lower end face of the first shell component; and the rotary arm is pivoted through the fixing column to be in clamped fit with or disengaged from the convex block, and the first shell component and the second shell component are selectively connected. The puncture device comprises the puncture device shell. The locking mechanism in the puncture device shell does not shake and move unnecessarily, the locking mechanism is pressed to realize clamped fit and disengaging between the two puncture device shell components, and thus the defect that a rotary locking mechanism is prone to being stuck is avoided.

Owner:FENGH MEDICAL CO LTD

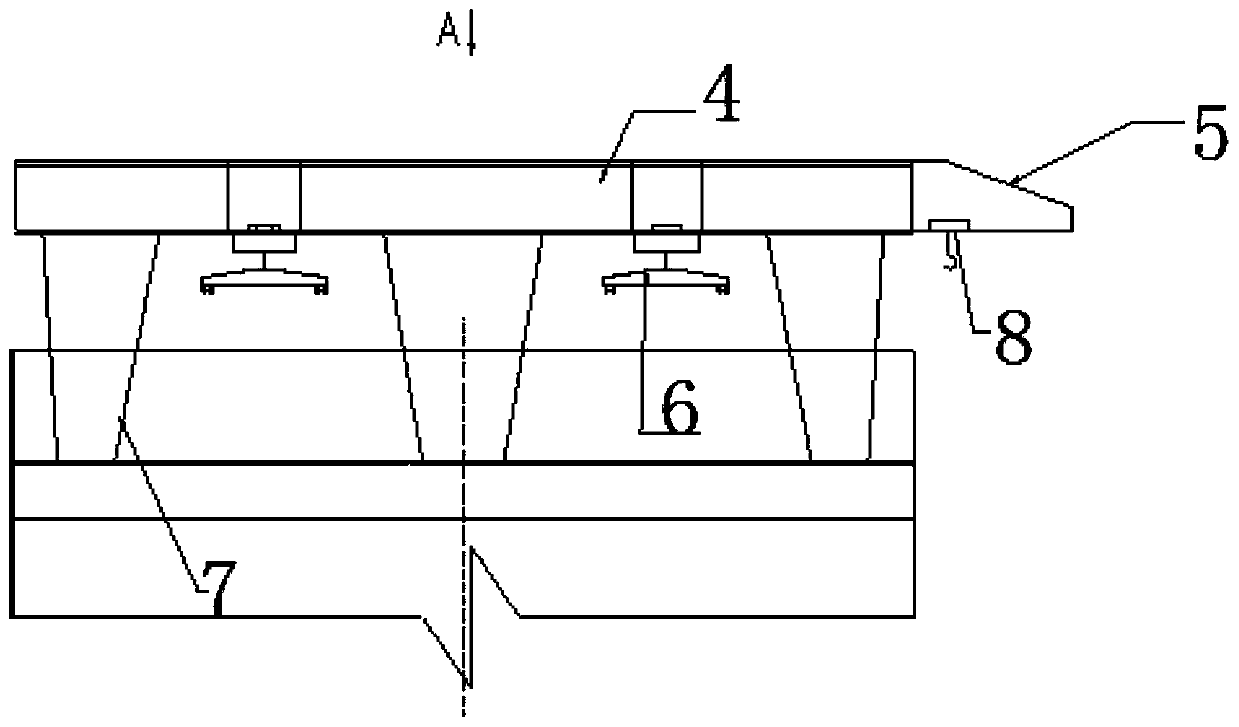

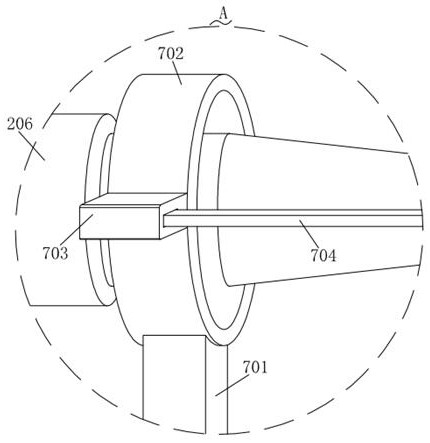

Lifting appliance equipment for nuclear power shielding factory building and installation method

InactiveCN110356983AEasy to hoist in placeUse lessLoad-engaging elementsCranesNuclear engineeringNuclear power

The invention discloses lifting appliance equipment for a nuclear power shielding factory building and an installation method. The lifting appliance equipment for the nuclear power shielding factory building and the installation method solve the problems in the prior art that the integral lifting has relatively high requirements on lifting equipment and needs a large-area assembling site, and havethe beneficial effects of reducing the use of large-tonnage lifting equipment, and occupying less floor space. According to the technical scheme, the lifting appliance equipment for the nuclear powershielding factory building comprises a main structure, a rotary cantilever and an introduction trolley, wherein the main structure is supported by supporting legs and is provided with an annular or semi-annular track; the rotary cantilever is arranged on the track of the main structure through a travelling mechanism and is provided with an introduction track; and the introduction trolley can moverelative to the rotary cantilever, is supported by the introduction track and is connected to a lifting mechanism.

Owner:SHANDONG NUCLEAR POWER EQUIP MFG

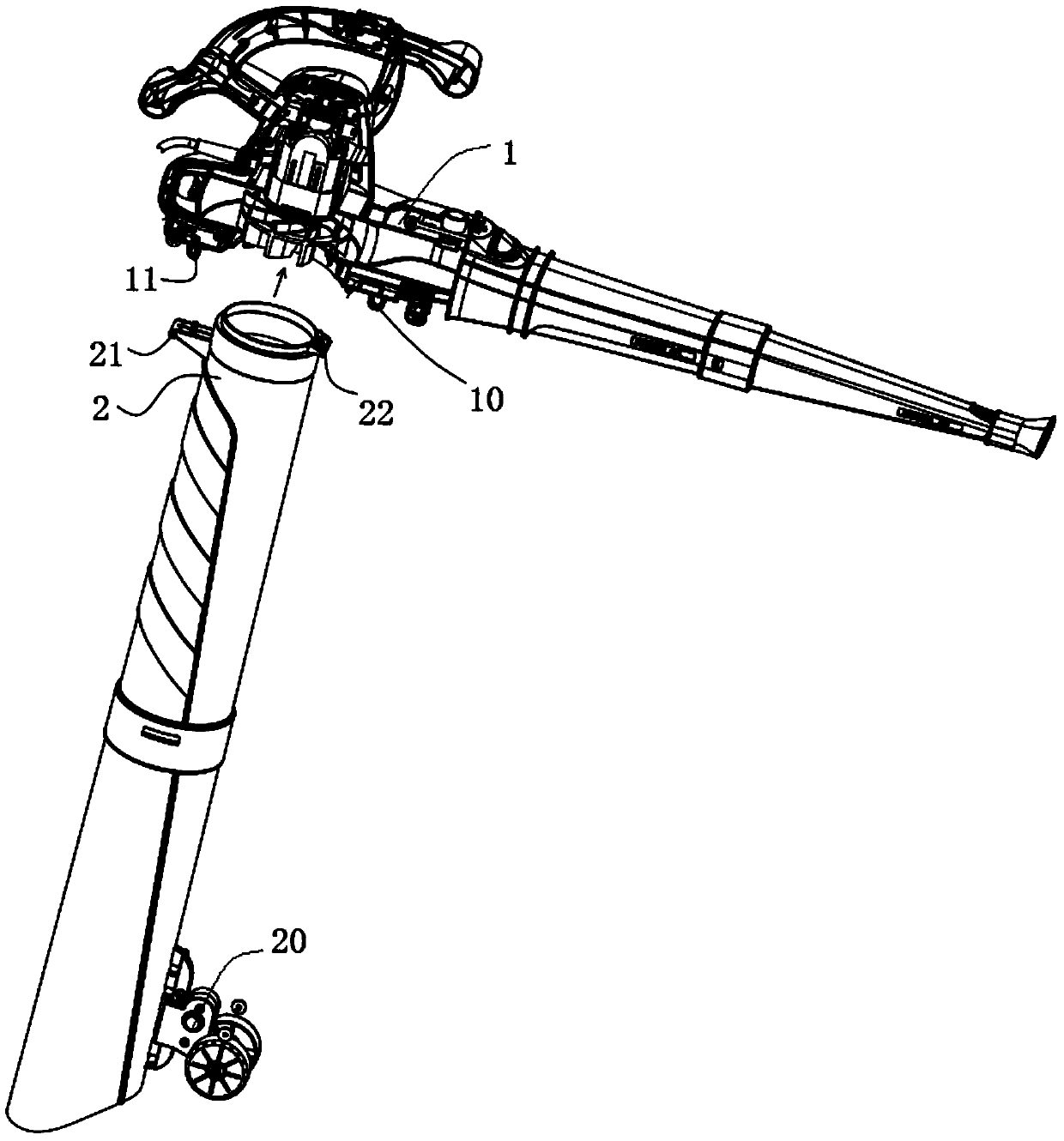

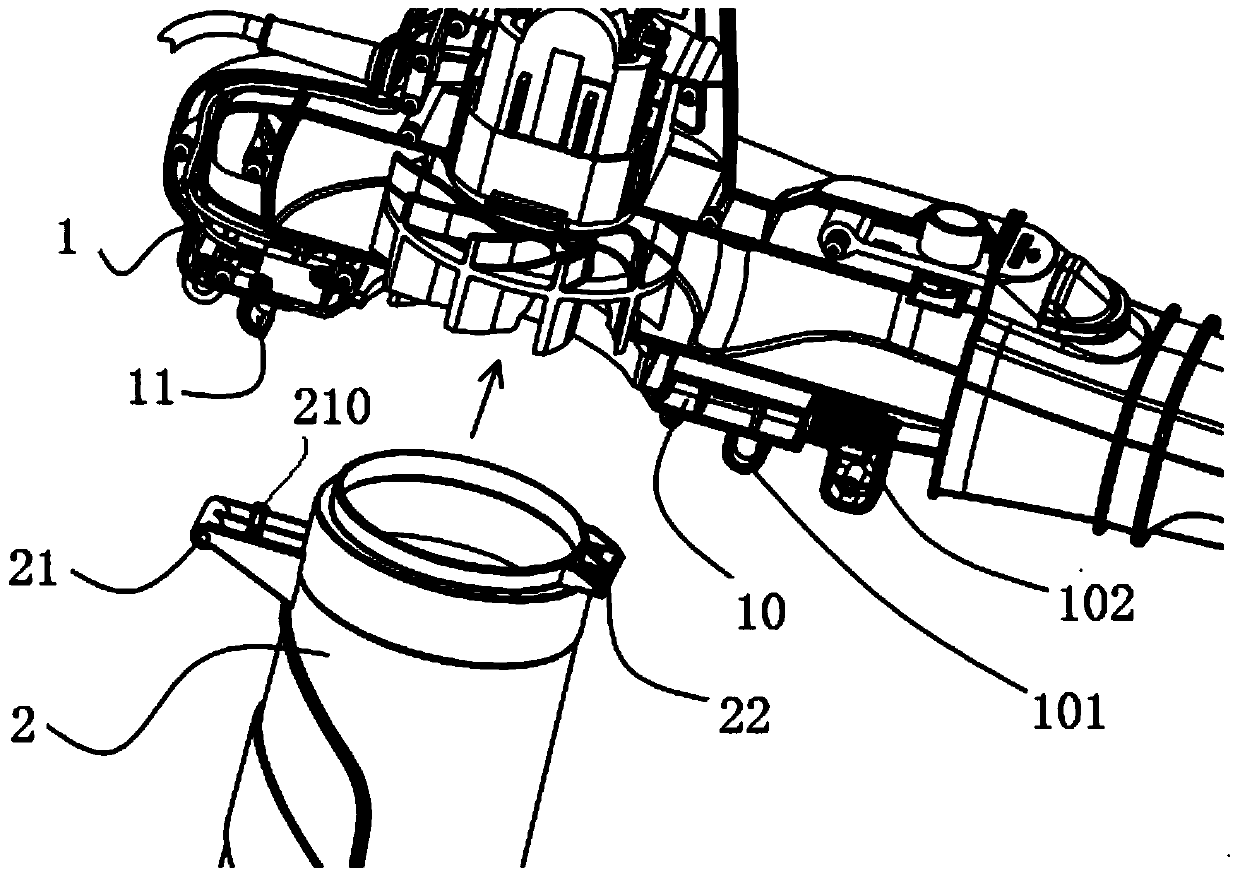

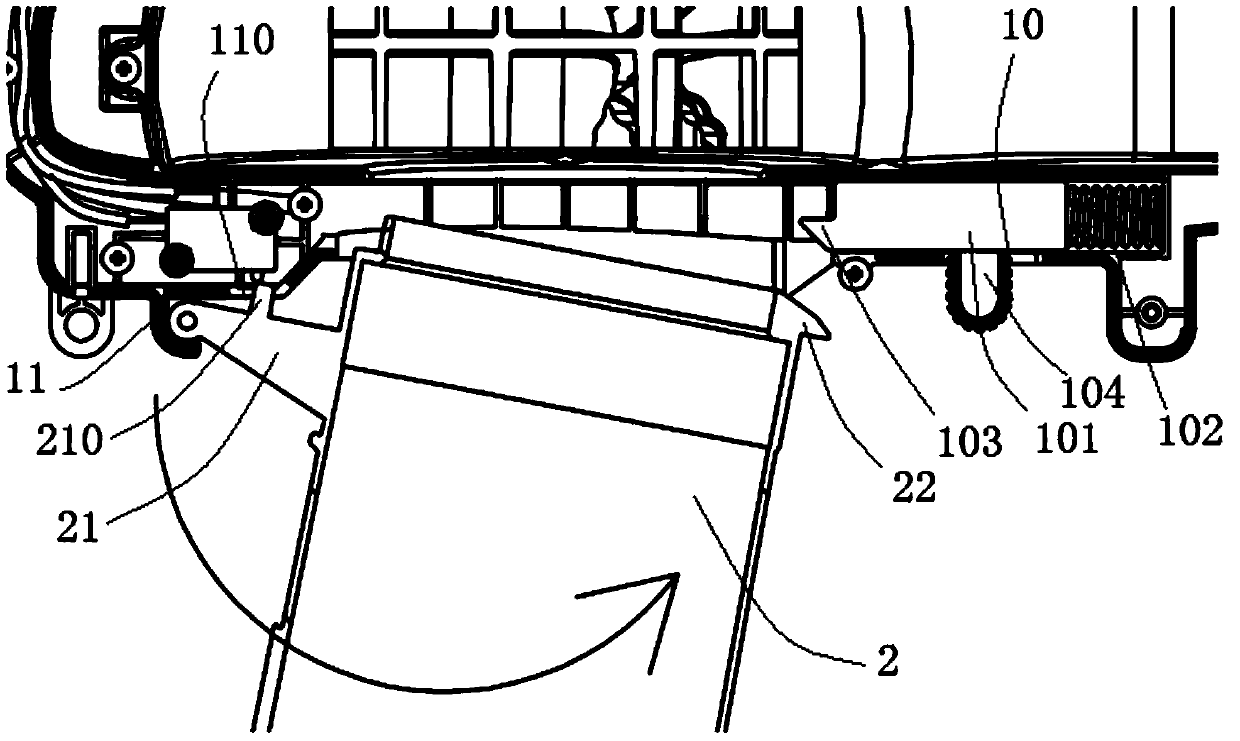

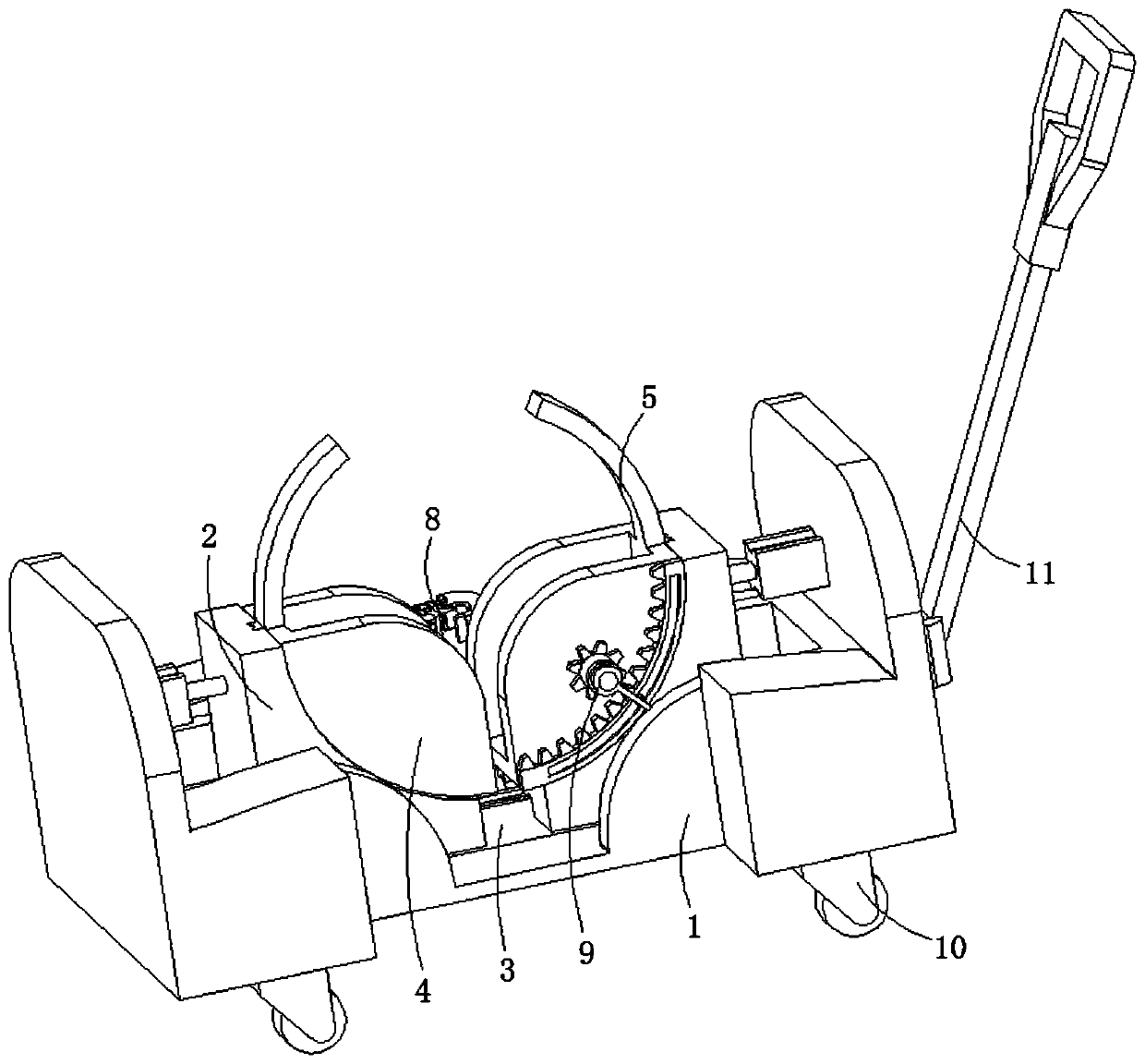

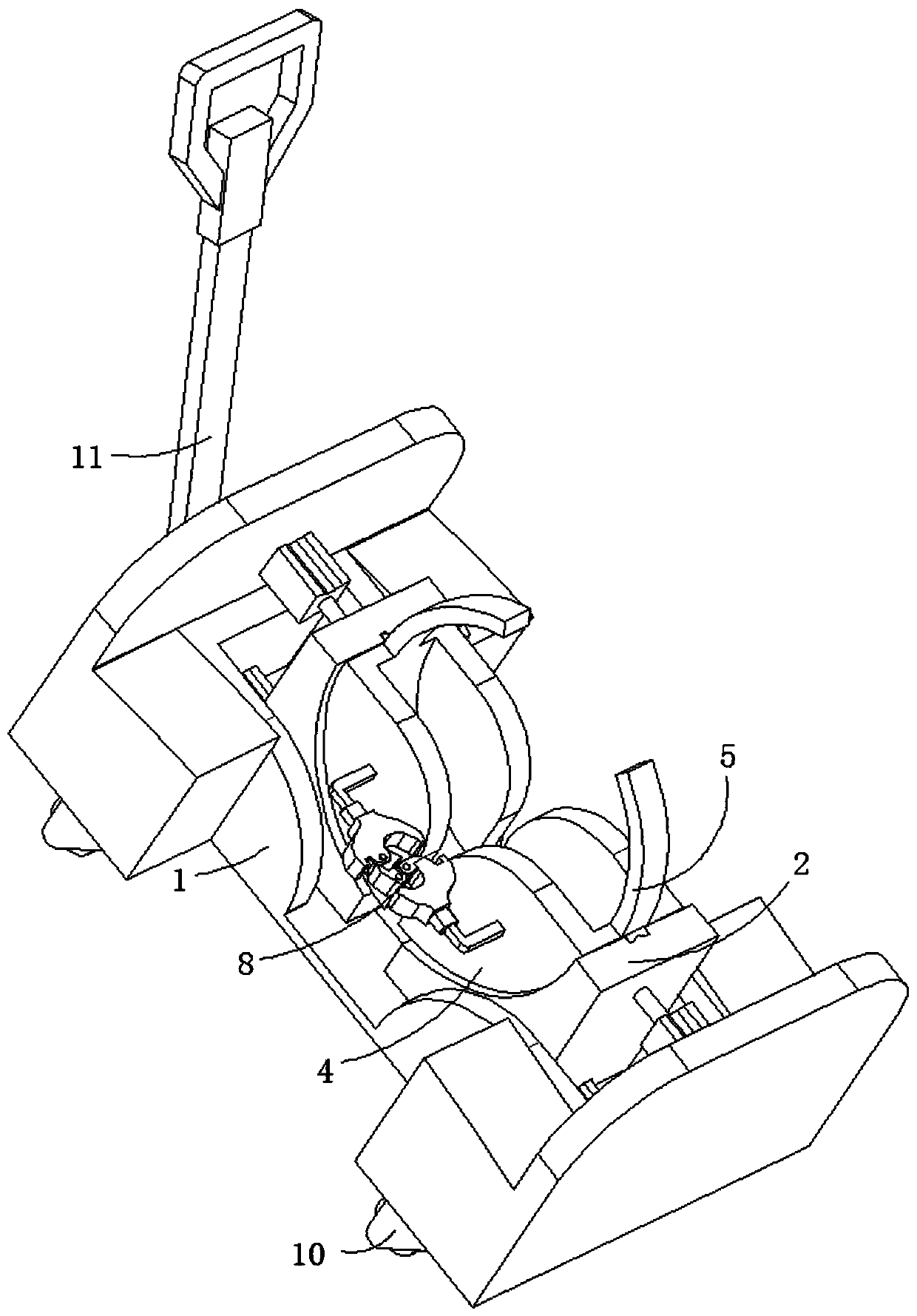

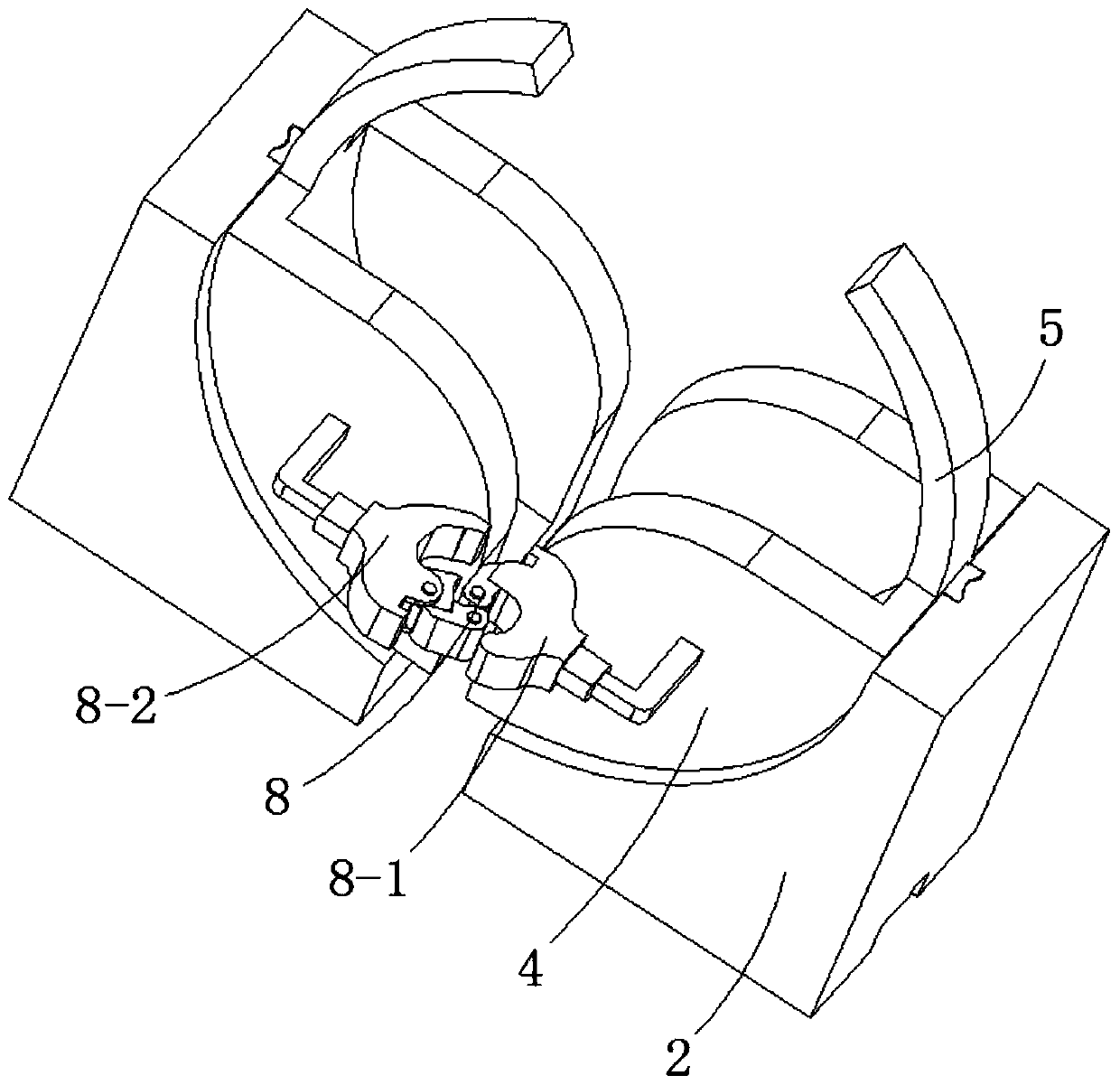

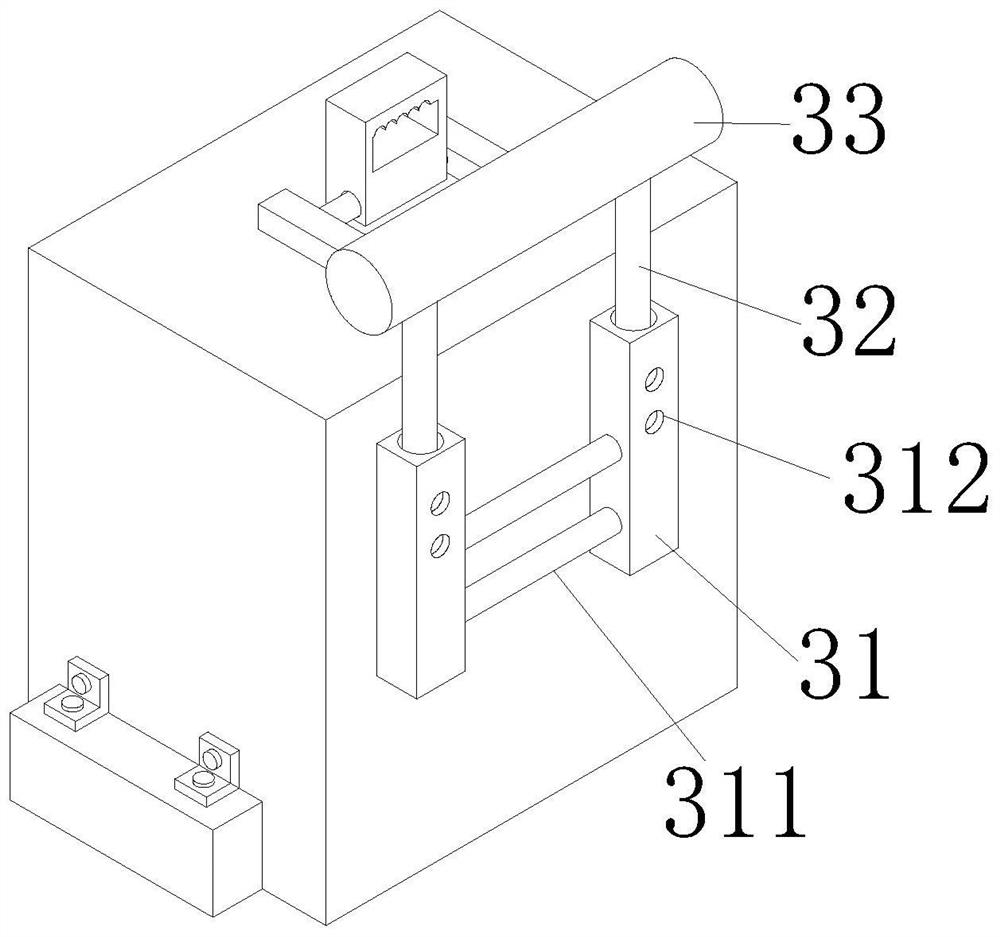

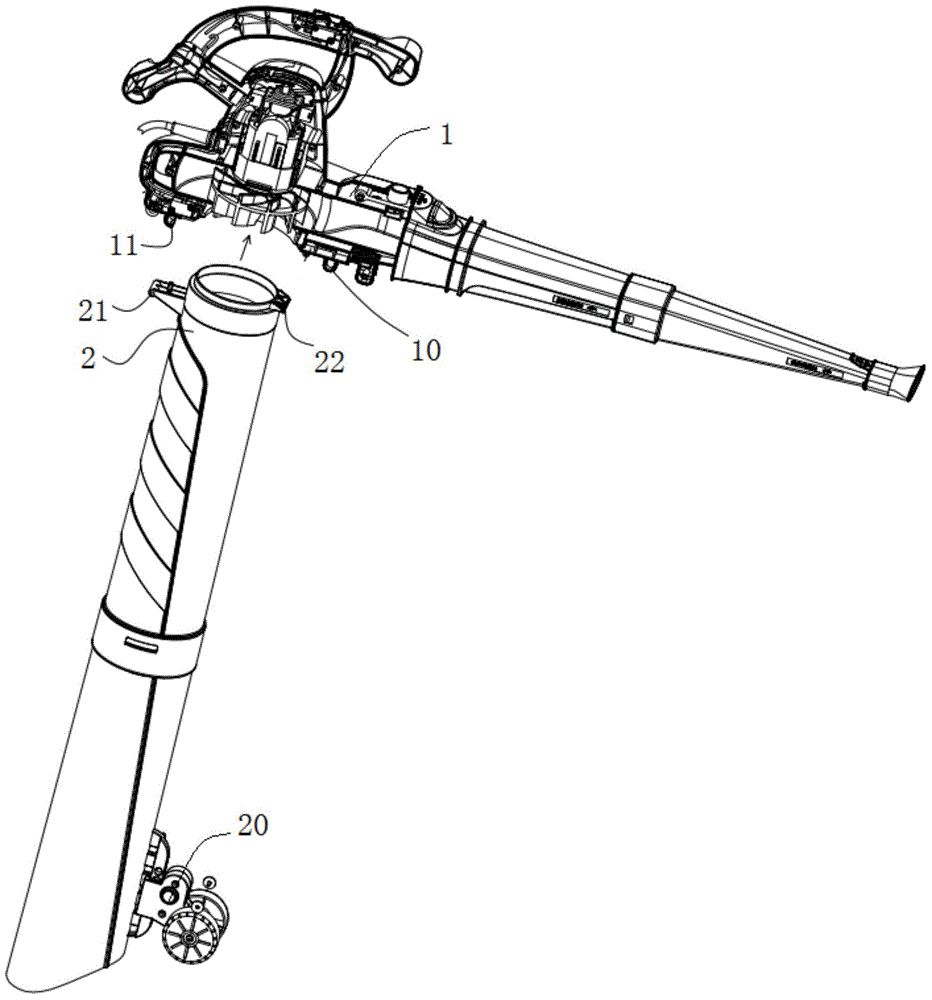

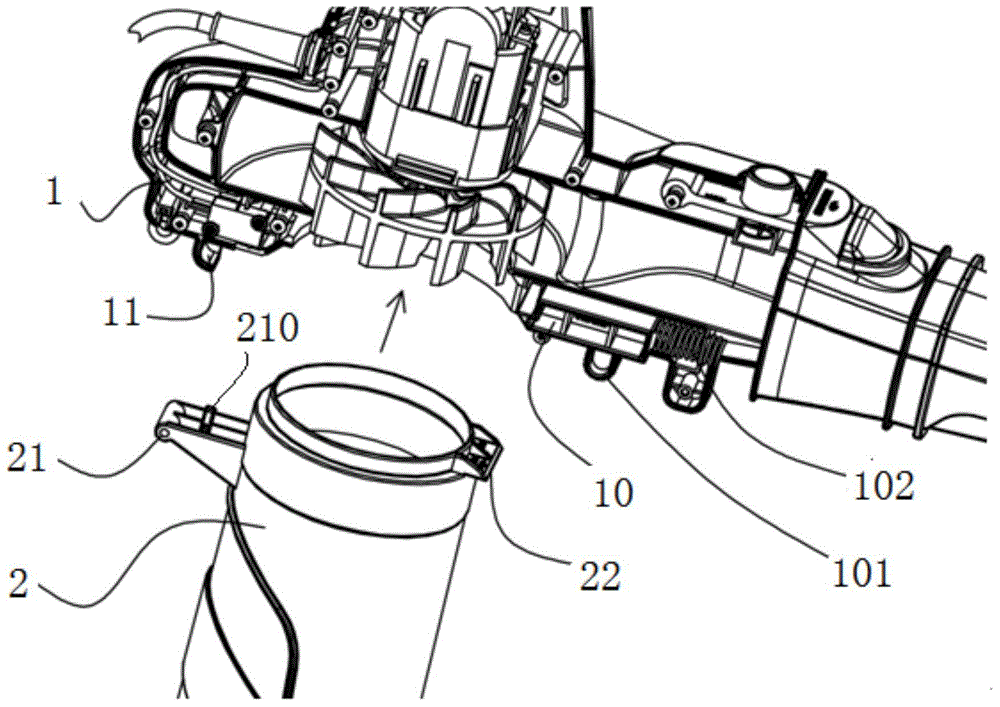

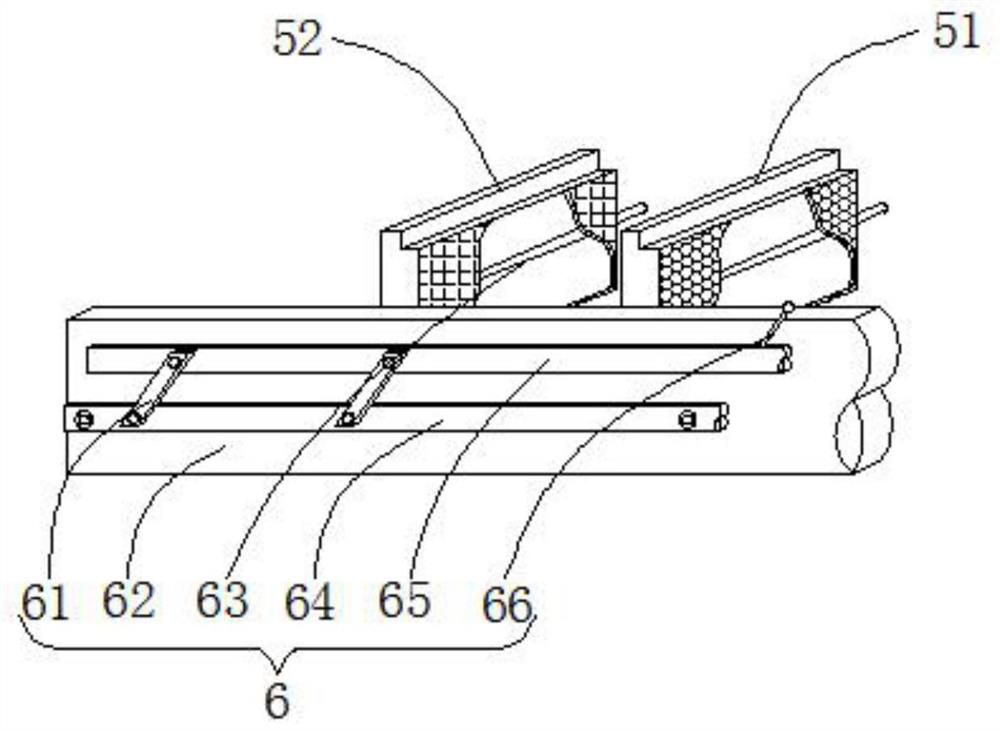

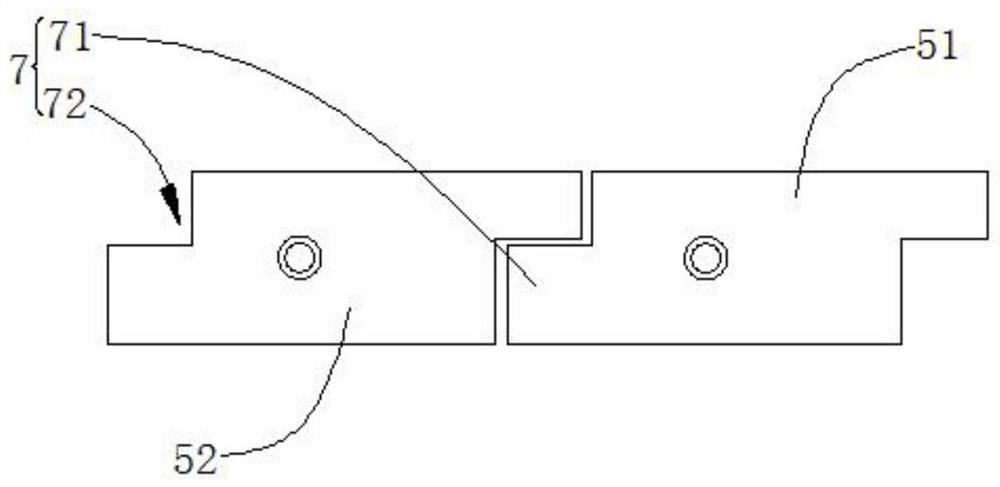

Air pipe wheel system improved structure of leaf blowing and sucking machine

ActiveCN103741626AAchieve regulationEasy to adjustHops/wine cultivationTurf growingEngineeringMechanical engineering

The invention discloses an air pipe wheel system improved structure of a leaf blowing and sucking machine. The air pipe wheel system improved structure comprises an air pipe and an air pipe wheel system which is arranged on the outer wall of the head end of the air pipe. The air pipe wheel system comprises a track and a wheel carrier, wherein the track is arranged on the outer wall of the head end of the air pipe and axially stretches along the air pipe, the wheel carrier is arranged on the track, a wheel is installed on the wheel carrier, a gear structure is arranged on the track, and a gear adjusting device is arranged on the wheel carrier. The track and the gear structure are arranged on the air pipe, the track allows the wheel system to have two direction freedom degrees to adjust the axial position of the wheel on the air pipe, the gear structure is used for fixing the wheel at the preset position, the position of the wheel carrier for allowing the wheel to be installed can be adjusted along the track and the wheel can be fixed at a certain position through the gear structure, and therefore the position of the wheel on the air pipe is very convenient to adjust.

Owner:宁波亚特电器有限公司

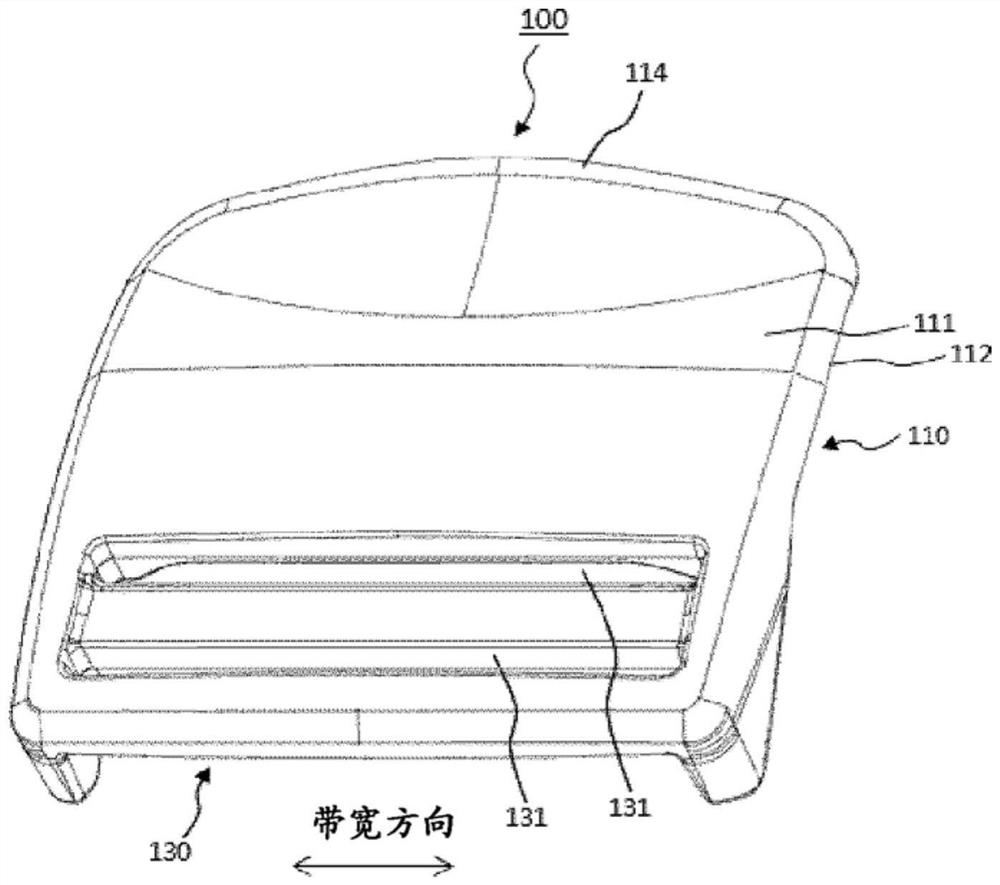

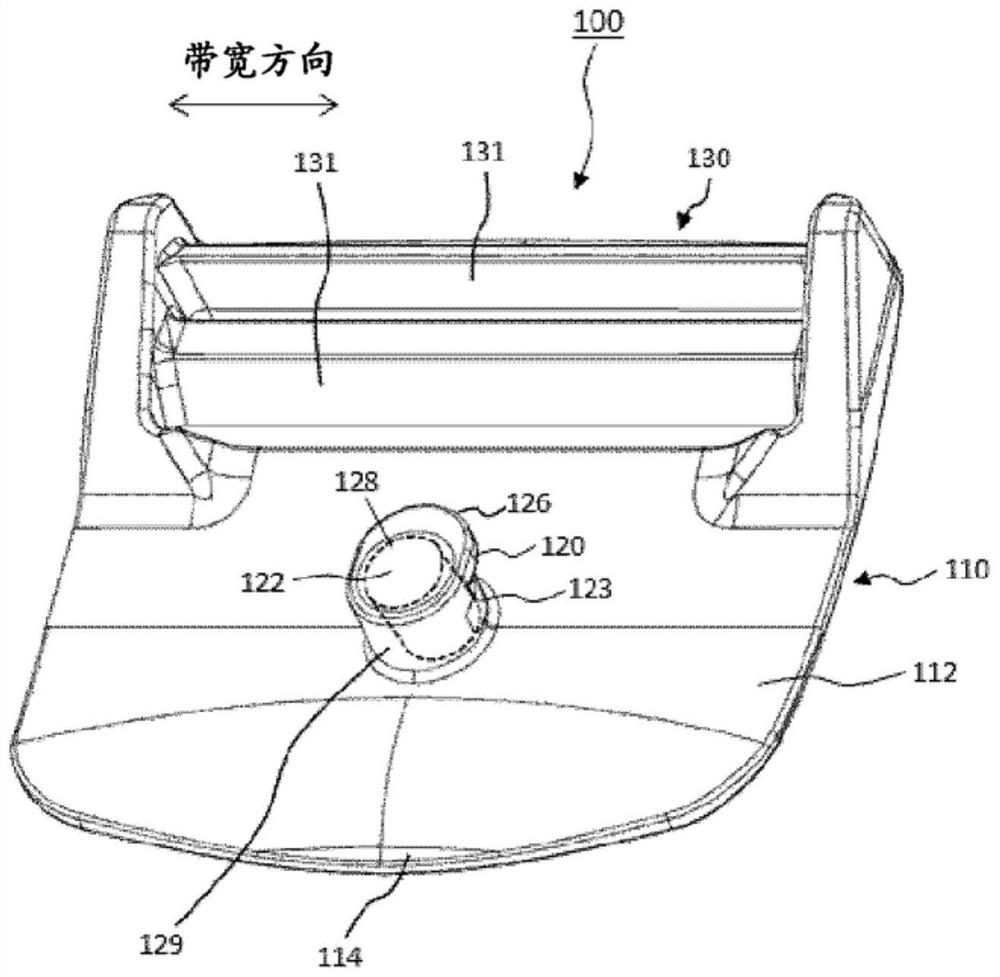

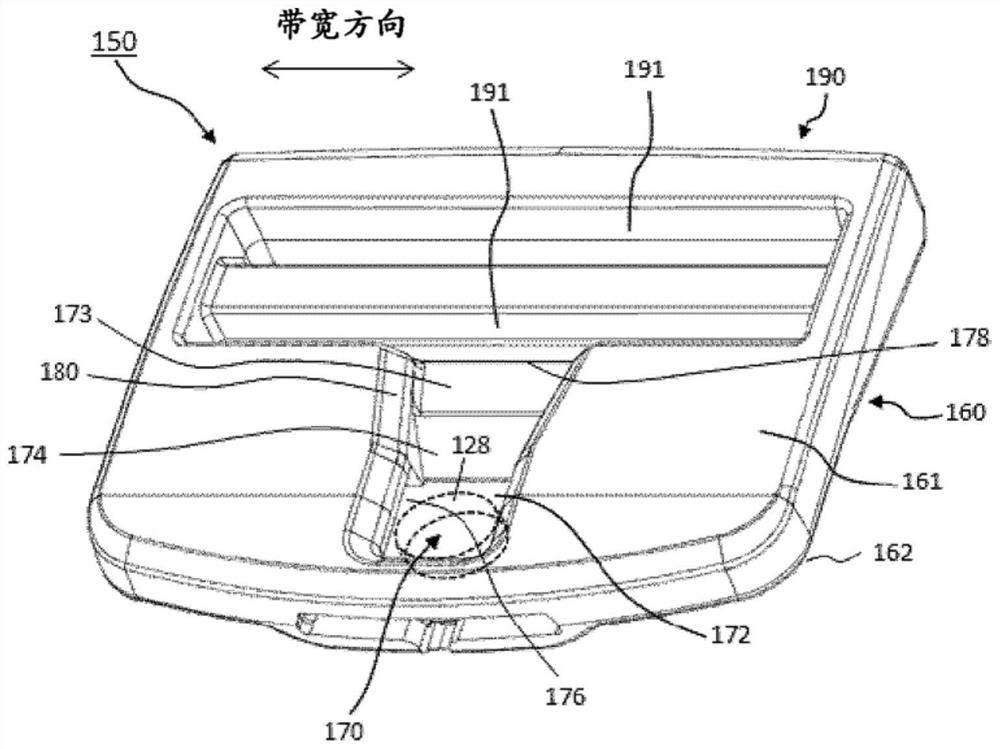

Buckle

Provided is a buckle with improved freedom of attachment and detachment operations. This buckle is provided with a male member having a projecting portion, and a female member having a recessed portion capable of engaging with the male member, wherein: the female member has an inclined surface which links a top surface of a second plate-shaped base portion and the recessed portion to guide the projecting portion toward the recessed portion; the projecting portion has a claw portion; the recessed portion has a claw receiving portion capable of engaging with the claw portion; the outline of theclaw receiving portion that is visually recognized when the female member is seen from the top surface side is a polygonal line shape or a curved line shape which extends out toward the opposite sideto a second belt fitting portion; a magnet is embedded in one of the projecting portion and the recessed portion; and a magnet of which the magnetic poles are oriented in such a way as to be attractedby the magnet, or a metal attracted by the magnet, is embedded in the other.

Owner:YKK CORP

An industrial laser welding robot system and its working method

ActiveCN111822857BPlace stableIncrease flexibilityLaser beam welding apparatusManufacturing technologyGear wheel

The invention discloses an industrial laser welding robot system and a working method thereof, and relates to the technical field of industrial manufacturing. The invention includes a bottom mechanism, a direction adjustment assembly is connected to the upper part of the bottom mechanism, the bottom mechanism includes a bottom assembly, and a folding assembly is provided on both sides of the bottom assembly, and the bottom assembly includes a bottom plate, and a side groove is opened on both sides of the bottom plate , the upper surface of the base plate is rotatably connected with a rotating plate, the upper surface of the base plate is fixedly installed on the outer side of the rotating plate with a first drive motor, the output end of the first drive motor is fixedly equipped with a gear, and the folding assembly includes an upper support plate and a lower plate The support plate, the lower surface of the upper support plate is fixedly connected with the upper surface of the base plate, and the upper surface of the lower support plate is fixedly connected with the lower surface of the base plate. The invention can quickly complete the installation or disassembly of the laser welding head through the combined use of the connecting component and the welding component, thereby greatly improving the work efficiency.

Owner:温州英格镭激光技术有限公司

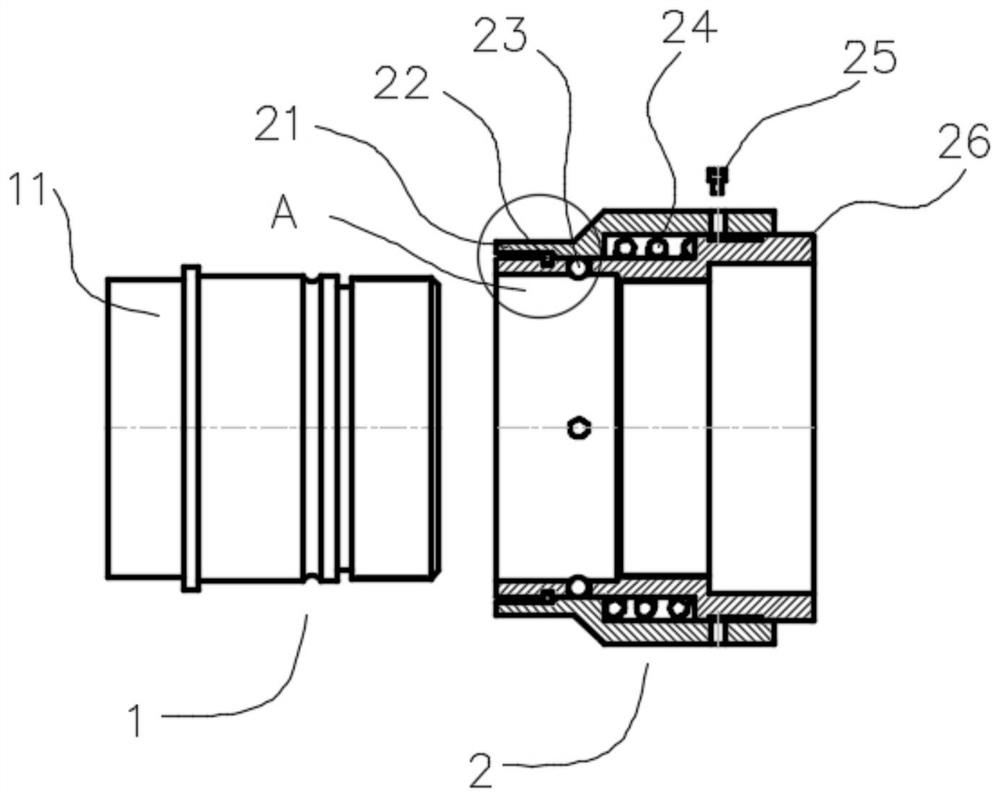

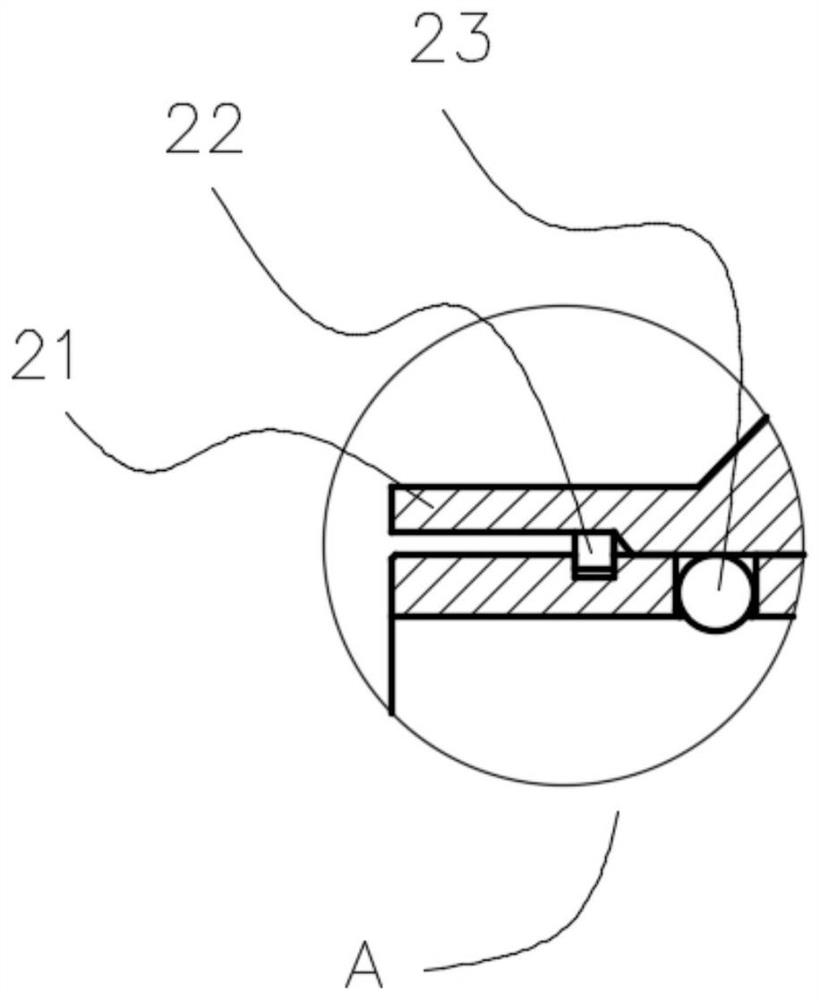

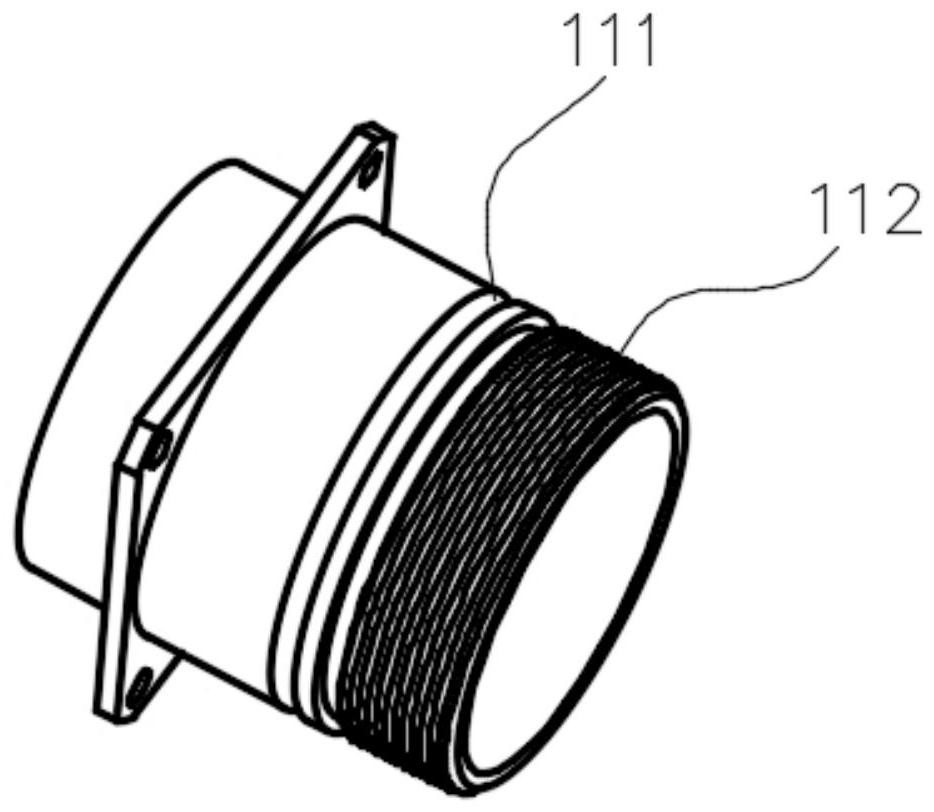

Double-locking electric connector

PendingCN113161824ATo achieve snapRealize the locking functionCoupling device detailsTwo-part coupling devicesElectrical connectionStructural engineering

The invention discloses a double-locking electric connector. The double-locking electric connector comprises a socket and a plug, wherein the plug comprises a plug locking sleeve and a plug clamping cap; the plug locking sleeve is movably connected to the outer side of the plug clamping cap in a sleeving mode; at least two buckling pieces are arranged on the side wall of the plug clamping cap; and the socket is in threaded connection with the plug clamping cap. When the socket and the plug clamping cap are locked in a threaded mode, the plug locking sleeve is moved to enable the buckling pieces to tightly press the side wall of the socket, and therefore, clamping of the socket and the plug is achieved. The double-locking electric connector in the invention is used for electric signal connection or current transmission of equipment and has the advantages of being reliable in contact, resistant to vibration and impact, convenient to use and the like.

Owner:TAIZHOU HANGYU ELECTRICAL DEVICE

Target material packaging method and packaging tool

ActiveCN109018702AReduce distortionAvoid deformationClosuresPackaging under vacuum/special atmosphereEngineeringMechanical engineering

The invention provides a target material packaging method and packaging tool. A target material comprises a sputtering surface and a groove located in the sputtering surface of the target material. Asfor the packaging method, a protection body and a clamping piece are included; the protection body comprises a contact surface and a center area, and the portion, in the center area, of the contact surface of the protection body is used for being attached to the sputtering surface of the target material; and the clamping piece is located on the portion, in the center area, of the contact surfaceof the protection body and used for being placed in the groove. The sputtering surface of the target material is attached to the contact surface of the protection body, and the protection body can reduce deformation of the target material in the direction perpendicular to the sputtering surface. The clamping piece is arranged in the groove and can support the portions, on the two sides of the groove, of the target material so that the target material can be prevented from deforming in the direction parallel to the sputtering surface. Thus, deformation of the target material can be reduced by means of the target material packaging method.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

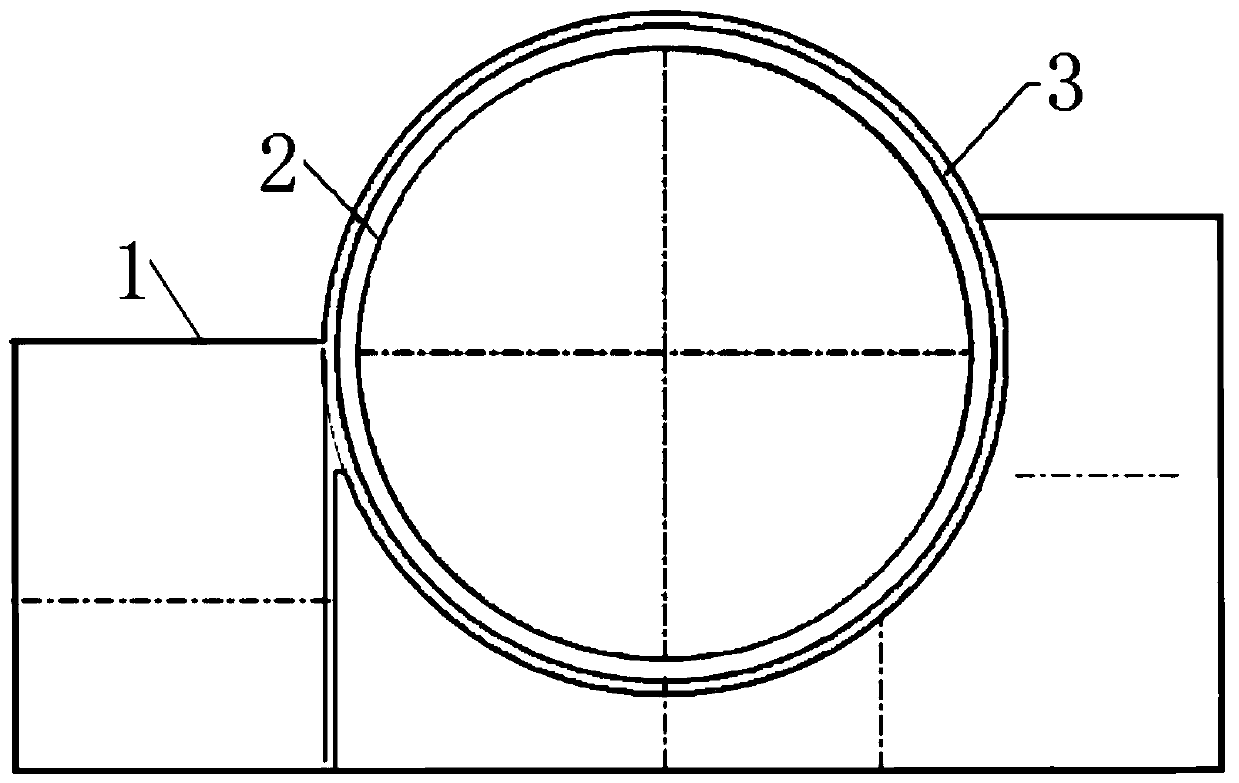

Aircraft tire mounting device

InactiveCN111231576AAchieve regulationHigh precisionWheel mounting apparatusGround installationsButt jointAirplane

The invention provides an aircraft tire mounting device. The aircraft tire mounting device comprises a base; an arc-shaped seat; a sliding guide rail is arranged in an inner cavity of the base, the arc-shaped base is arranged on the sliding guide rail in a sliding mode, an arc-shaped protective plate is connected to the inner side of the arc-shaped base in a sliding mode, and an arc-shaped clamping plate is fixedly arranged at the top of the arc-shaped protective plate. An arc-shaped sliding groove is formed in the inner side wall of the arc-shaped base, and a sliding strip block matched withthe sliding groove is fixedly arranged on the outer side wall of the arc-shaped protective plate. A telescopic mechanism is further fixedly arranged on the inner wall of the base, and the output end of the telescopic mechanism is fixedly connected with the outer side wall of the arc-shaped seat; a butt joint mechanism is arranged on the side wall of one side of the arc-shaped protective plate andcomprises first driving blocks symmetrically arranged on the side wall of the arc-shaped protective plate. According to the technical scheme, the problem that in the prior art, when the axial positionof the tire needs to be finely adjusted in the installation process, the function of finely adjusting the axial position of the aircraft tire cannot be achieved is effectively solved.

Owner:荆门怡盛源环保科技有限公司

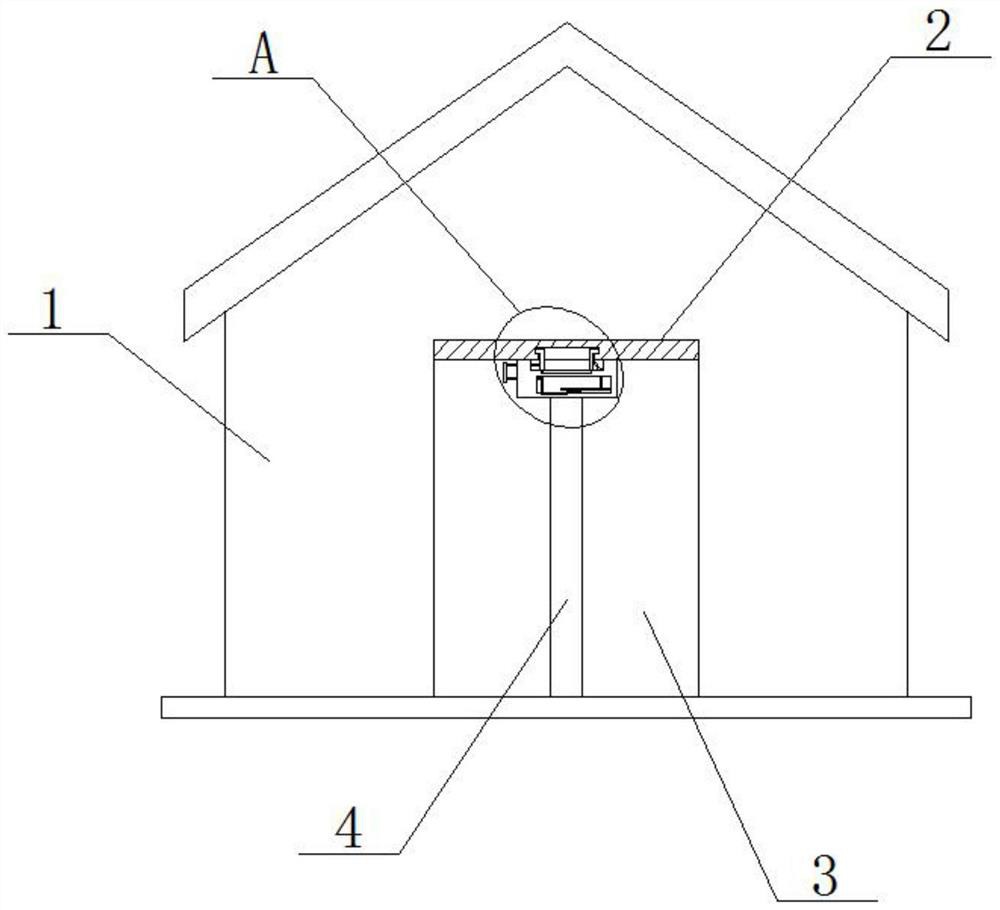

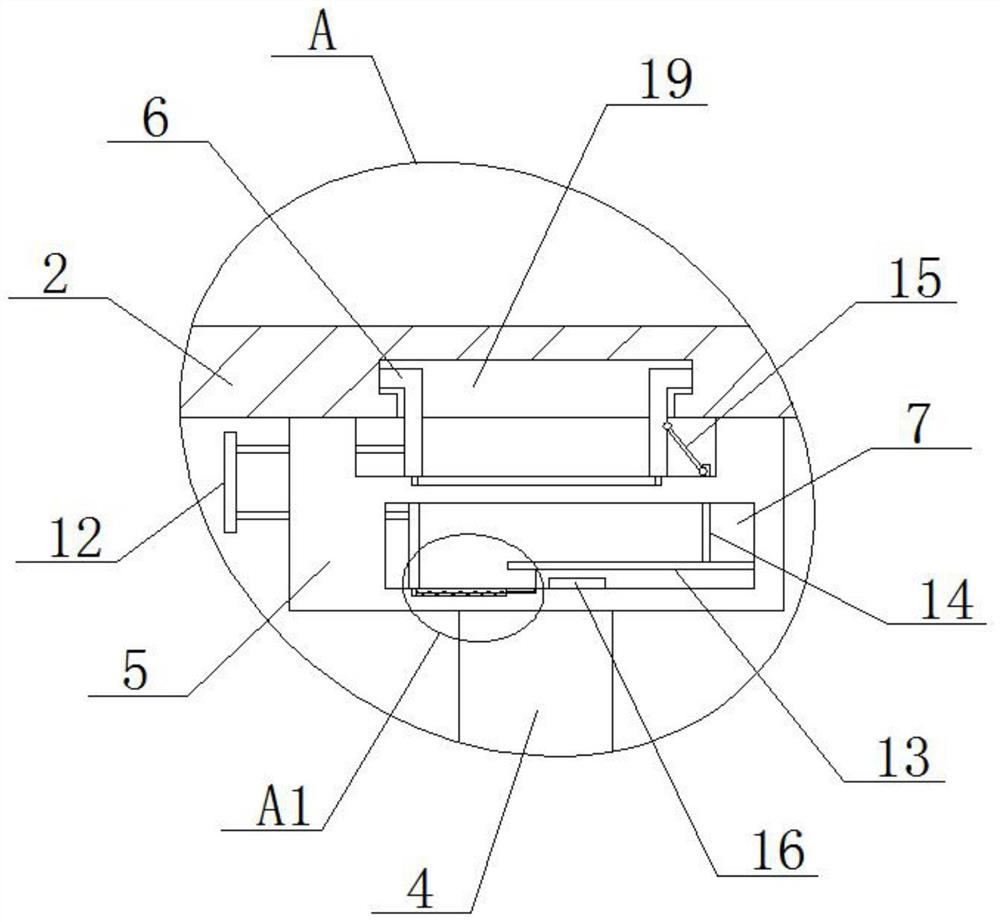

Basalt fiber composite flame-retardant military field tent

PendingCN114412273ATo achieve snapMeet needsTents/canopiesSpecial door/window arrangementsStructural engineeringBasalt fiber

The invention belongs to the field of tents, and particularly relates to a basalt fiber composite flame-retardant military field operation tent which comprises a tent body, an entrance is reserved in one side of the tent body, a top frame is connected to the top of the entrance, cloth doors are sewn to the two sides of the entrance, and the top frame is connected to the top of the entrance. The same zipper is installed between the two cloth doors, a zipper is installed on the zipper, two fixing pins are installed in the zipper in a sliding mode, a cavity is formed in the zipper, a moving plate is installed on the inner wall of the bottom side of the cavity in a sliding mode, and the same push frame is fixedly installed on the moving plate and the fixing pins; the defects in the prior art are overcome, the closing position of the zipper can be fixed, the zipper is prevented from being opened due to tearing force, and the requirements of people are met.

Owner:中北玄武科技发展有限公司

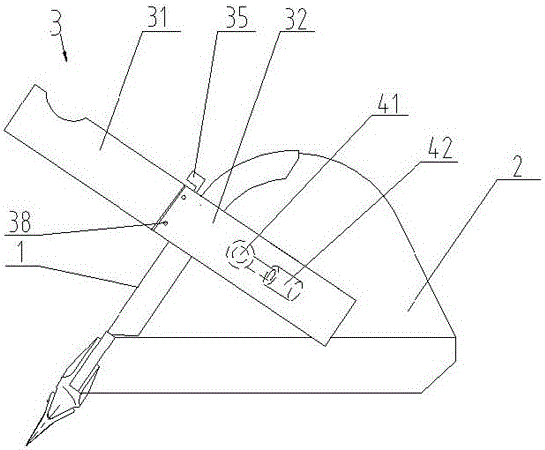

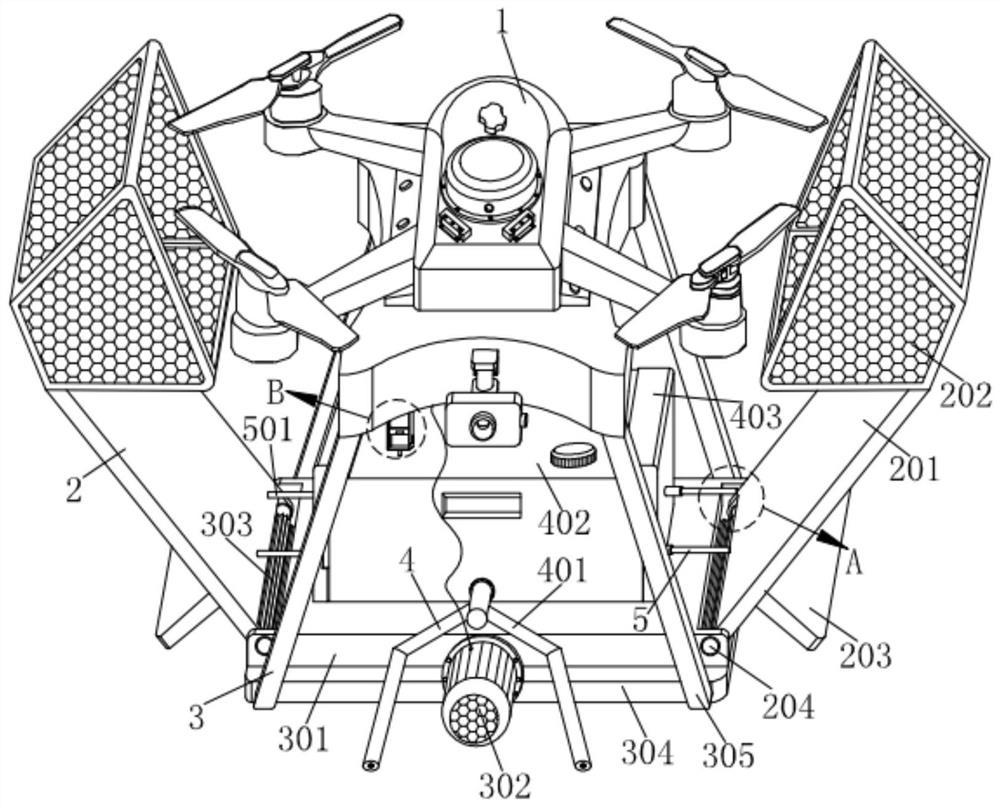

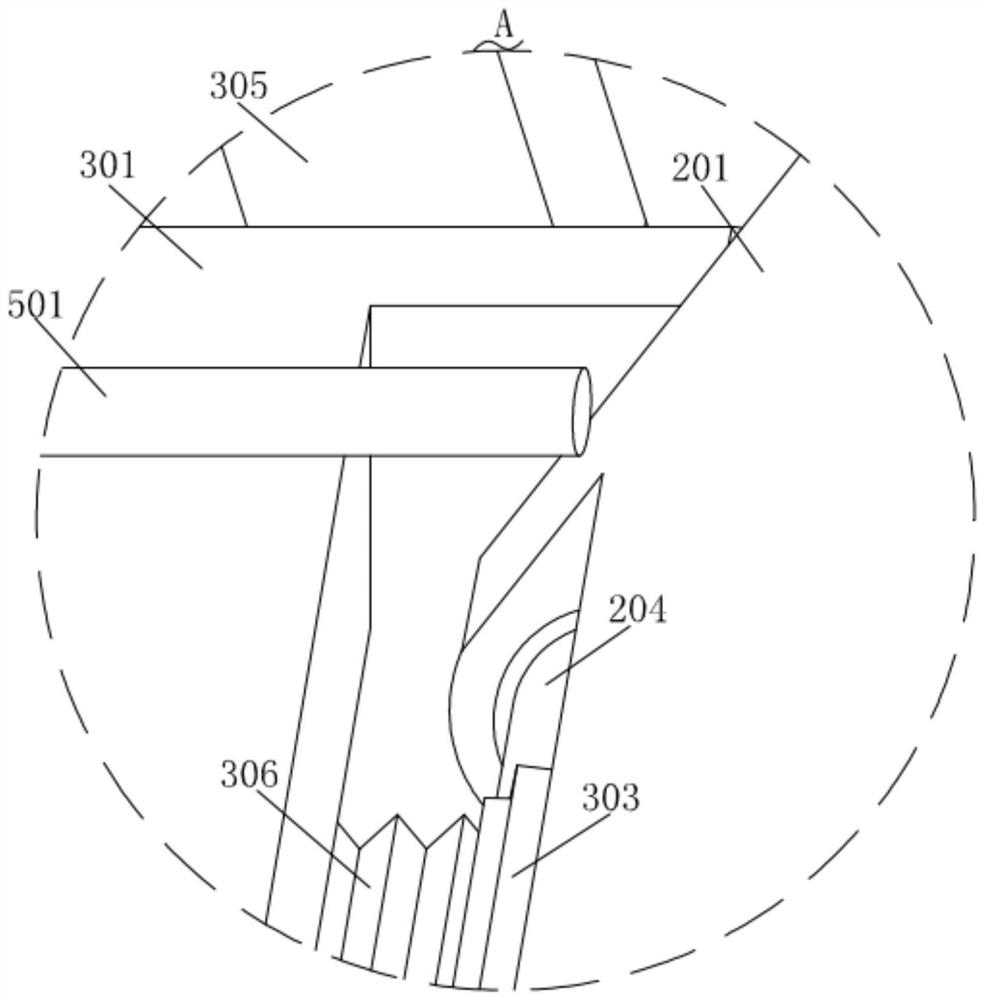

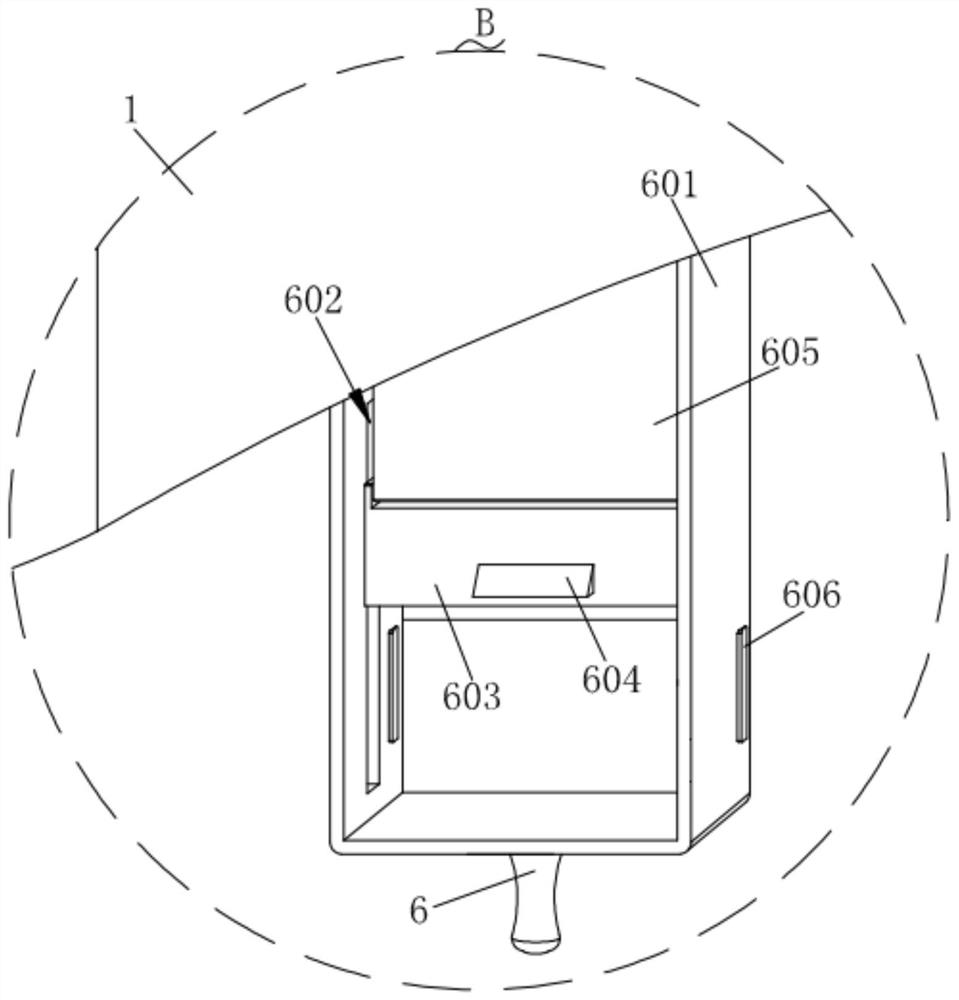

Marking mechanism of large unmanned aerial vehicle for forest farm nursery stock inspection

InactiveCN113911331AImprove stabilityGuaranteed normal rotationAircraft landing aidsInsect catchers and killersAgricultural scienceTree farm

The invention relates to the technical field of unmanned aerial vehicle marking, and in particular, relates to a marking mechanism of a large unmanned aerial vehicle for forest farm nursery stock inspection, wherein the marking mechanism comprises an unmanned aerial vehicle body; a driving mechanism is mounted on the unmanned aerial vehicle body, and a protection mechanism for protecting propellers is mounted on the driving mechanism; and a pesticide spraying mechanism for treating plant diseases and insect pests is mounted on the protection mechanism, two limiting mechanisms are oppositely arranged on the pesticide spraying mechanism, two reinforcing mechanisms are oppositely arranged on the pesticide spraying mechanism, the protection mechanism abuts against the reinforcing mechanisms, and a marking mechanism for positioning and marking the positions of the plant diseases and insect pests is mounted on the unmanned aerial vehicle body. The driving mechanism is mounted on the unmanned aerial vehicle body, when the unmanned aerial vehicle lands, the driving mechanism controls the protection mechanism to be opened without protecting the propellers, at the moment, the protection mechanism makes contact with the ground, the stability of the landing state of the unmanned aerial vehicle is improved, and when the unmanned aerial vehicle body inspects nursery stocks, the driving mechanism controls the protection mechanism to protect the propellers.

Owner:四川省天域航通科技有限公司

Excavator bucket with scraper

ActiveCN106640095BImprove securityShorten construction timeMechanical machines/dredgersTunnelsEngineeringExcavator

Owner:CSCEC STRAIT CONSTR & DEV

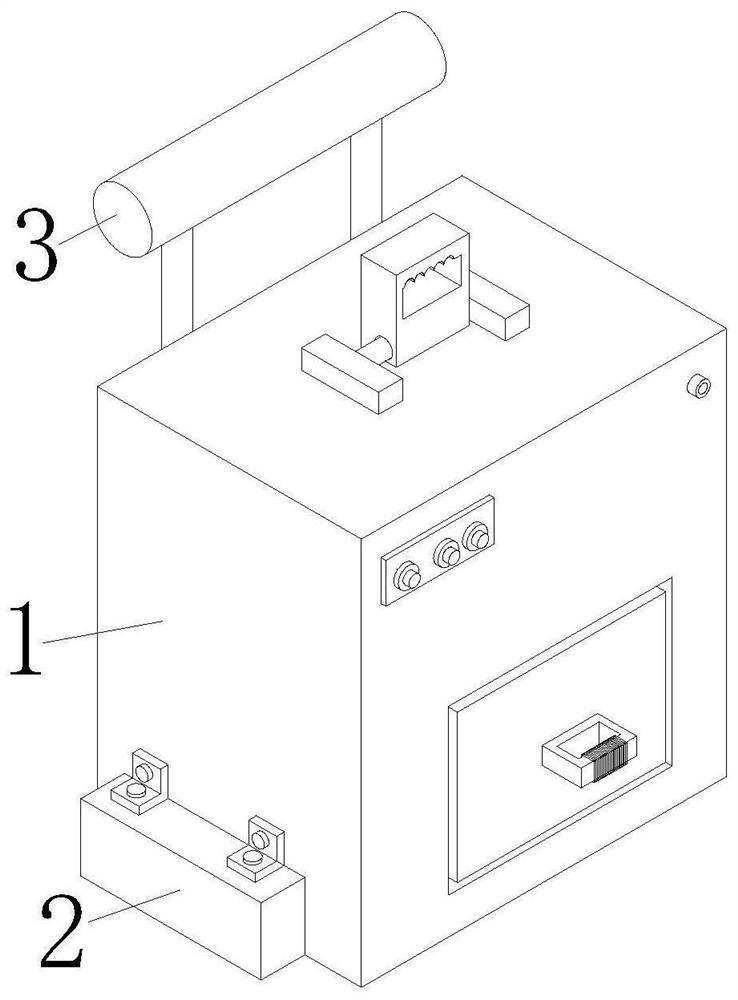

Silver needle sterilization device for traditional Chinese medicine hospital

PendingCN112274666ACarry it anywhereTo achieve snapLavatory sanitoryRadiationMechanical engineeringBiomedical engineering

The invention relates to a silver needle sterilization device for the traditional Chinese medicine hospital, which comprises a box body, moving devices are symmetrically arranged at the lower ends ofthe two sides of the outer wall of the box body, each moving device comprises a protective shell, a driving machine shell is arranged on the upper surface of the inner wall of each protective shell, and each driving machine shell is connected with an electric telescopic rod through a connecting module; a rectangular supporting plate is arranged at the lower end of each electric telescopic rod, thelower surface of each rectangular supporting plate is connected with universal wheels through a first support, a portable device is installed on one side of the outer wall of the box body and comprises a sleeve rod, a pull rod is arranged in each sleeve rod, and a groove is formed in one side of the outer wall of each pull rod; a limiting assembly is arranged in each groove, a portable working mode is achieved through a moving device and a portable device, and therefore a patient needing to be treated can be diagnosed and treated in time, the treatment opportunity cannot be delayed, and the treatment efficiency is improved.

Owner:桃源县中医医院

Improved Structure of Air Duct Wheel System of Leaf Blower and Aspirator

ActiveCN103741626BAchieve regulationEasy to adjustHops/wine cultivationTurf growingEngineeringMechanical engineering

The invention discloses an air pipe wheel system improved structure of a leaf blowing and sucking machine. The air pipe wheel system improved structure comprises an air pipe and an air pipe wheel system which is arranged on the outer wall of the head end of the air pipe. The air pipe wheel system comprises a track and a wheel carrier, wherein the track is arranged on the outer wall of the head end of the air pipe and axially stretches along the air pipe, the wheel carrier is arranged on the track, a wheel is installed on the wheel carrier, a gear structure is arranged on the track, and a gear adjusting device is arranged on the wheel carrier. The track and the gear structure are arranged on the air pipe, the track allows the wheel system to have two direction freedom degrees to adjust the axial position of the wheel on the air pipe, the gear structure is used for fixing the wheel at the preset position, the position of the wheel carrier for allowing the wheel to be installed can be adjusted along the track and the wheel can be fixed at a certain position through the gear structure, and therefore the position of the wheel on the air pipe is very convenient to adjust.

Owner:宁波亚特电器有限公司

Engine crankshaft forging die for hydrogen fuel cell hybrid power system

InactiveCN113843389ATake it out smoothlyTo achieve snapForging/hammering/pressing machinesEngine componentsHydrogen fuel cellControl theory

The invention discloses an engine crankshaft forging die for a hydrogen fuel cell hybrid power system, and belongs to the technical field of crankshaft forging. The engine crankshaft forging die for the hydrogen fuel cell hybrid power system comprises an upper die body and a lower die body, the upper die body is divided into two parts, the two parts of the upper die body are movably connected with the upper side of the lower die body respectively, and a sealable injection hole is formed in the upper die body; a positioning column is fixedly connected to the edge of the upper side of the upper die body, a positioning assembly is arranged at the outer side of the positioning column in a matched mode, and the lower side of the positioning assembly is connected to the upper portion of a mounting box through a transverse adjusting piece; the transverse adjusting part comprises a mounting rail, the mounting rail is fixedly connected to the inner bottom face of the mounting box, and the two ends of the lower side of the lower die body are fixedly connected to the upper side of a mounting rail through mounting plates correspondingly; and a transverse moving groove is formed in the mounting rail, and two transverse moving sliding blocks are connected into the transverse moving groove in a sliding mode. The engine crankshaft forging die solves the problem that in the prior art, an upper die body of a crankshaft forging die is difficult to disassemble and separate rapidly.

Owner:XIHUA UNIV

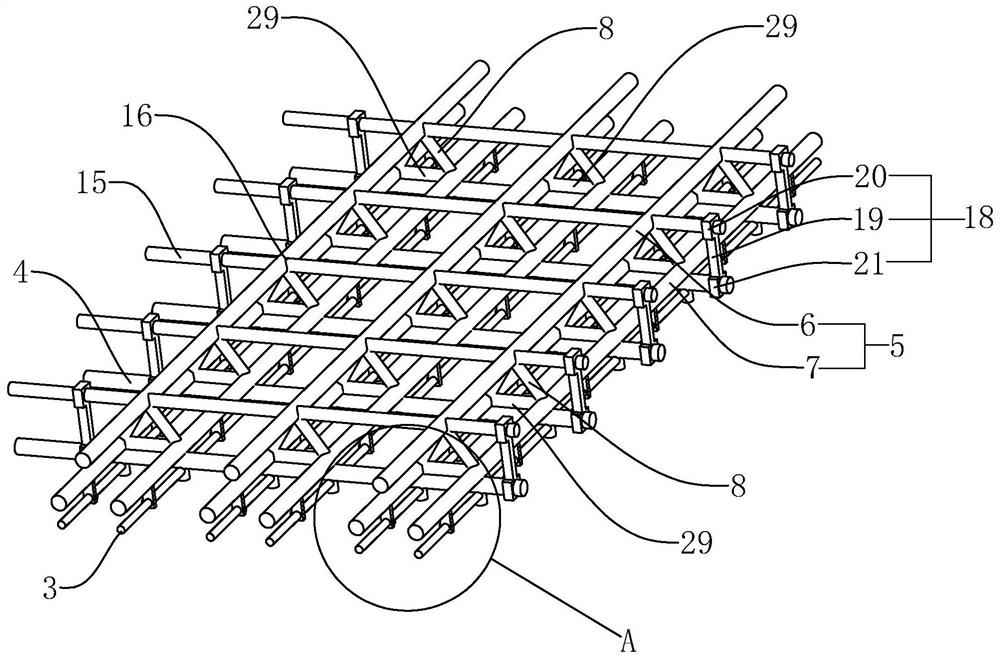

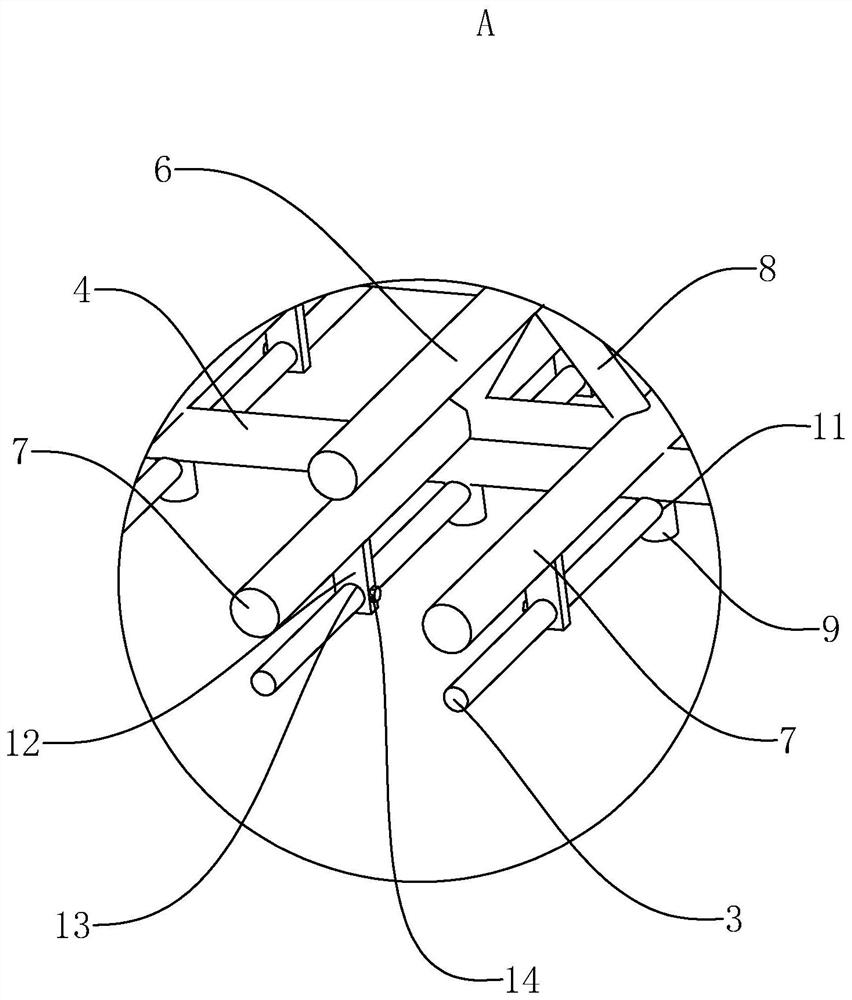

An energy-saving and stable laminated board

InactiveCN112177220BImprove stabilityAchieve connectionFloorsBuilding reinforcementsClassical mechanicsRebar

This application relates to an energy-saving and stable laminated slab, which includes a prefabricated bottom slab and a cast-in-place reinforced concrete layer. There are several transverse and longitudinal reinforcements inside the prefabricated bottom slab, and several truss reinforcements are arranged above the longitudinal reinforcement. The truss reinforcement includes main reinforcement and two Auxiliary reinforcement, several connecting rods are arranged between the main reinforcement and the auxiliary reinforcement. The end of the connecting rod away from the main reinforcement is fixedly connected with a positioning rod. The positioning rod passes through the auxiliary reinforcement and is fixedly connected with the auxiliary reinforcement. The vertical hole matched with the rod, and the lower end of the positioning rod is provided with a horizontal hole matched with the transverse steel bar. The positioning rod passes through the vertical hole on the longitudinal reinforcement, and the transverse reinforcement passes through the horizontal hole on the positioning rod, and the horizontal reinforcement, longitudinal reinforcement and truss reinforcement are connected together through the positioning rod, which improves the stability of the prefabricated floor during casting , thereby improving the stability of the laminated plate after forming.

Owner:WEIHAI YUQUAN NEW BUILDING MATERIAL

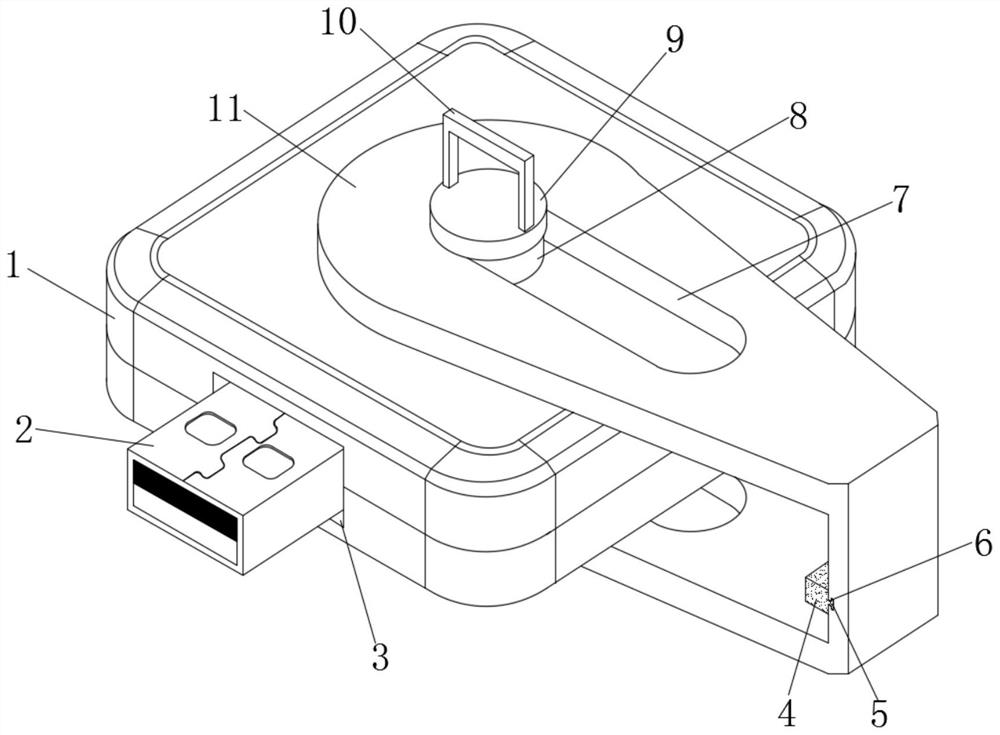

A portable mobile storage device and backup system

InactiveCN109389202BTo achieve snapAvoid damageRecord carriers used with machinesRedundant operation error correctionUSBEmbedded system

The invention discloses a portable mobile storage device and a backup system, comprising two symmetrically arranged shells, the two shells are clamped to form an inner cavity, each of the shells is provided with an installation slot, and the two shells are The installation grooves are connected to form a limiting cavity, and a portable storage device body is provided in the inner cavity, and a USB connector is connected to the portable storage device body, and two first card slots are symmetrically opened on the portable storage device body and two second card slots, each of the housings is inserted with a connecting block, one end of the connecting block extends out of the housing and is fixedly connected with a fixing seat, and the other end of the connecting block extends to A mounting plate is fixedly connected to the casing. The advantages are: the present invention is ingenious in structure, easy to use, can effectively isolate external dust from entering into the USB connector, and at the same time, the housing, the turret and the felt block can effectively protect the portable storage device and the USB connector, and can prolong the service life of the USB connector.

Owner:矩阵纵横(北京)科技有限公司

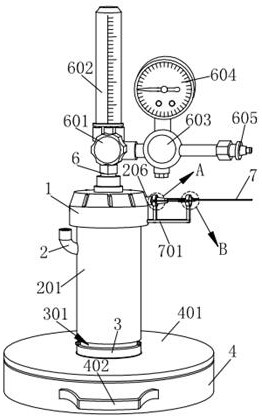

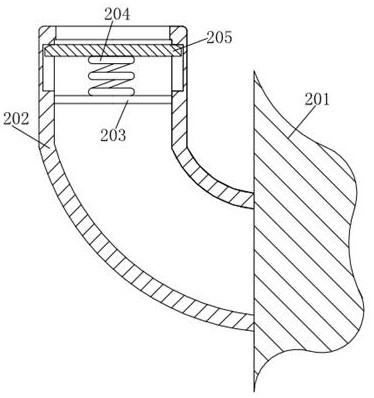

Humidifier structure of pneumology department nursing oxygen uptake tube

The invention relates to the technical field of oxygen inhalation tube humidifiers, in particular to a humidifier structure of a pneumology department nursing oxygen inhalation tube, which comprises a fixed cover, a control mechanism is mounted on the fixed cover, and a containing mechanism for containing water is mounted at the bottom of the fixed cover. The bottom of the containing mechanism is connected with a placing mechanism for placing an oxygen mask of a patient through a connecting mechanism, a pushing mechanism is installed on one side of the fixing cover, a reinforcing mechanism for reinforcing an oxygen inhalation pipeline is installed on the pushing mechanism, and the reinforcing mechanism is connected with the pushing mechanism. The bottom of the containing mechanism is connected with the placing mechanism through the connecting mechanism, when the patient temporarily leaves the sickbed, a nurse can take off the oxygen mask, rotate the placing mechanism and place the oxygen mask in the placing mechanism, and the situation that dust enters the oxygen mask to affect the oxygen quality when the patient uses the oxygen mask again is avoided.

Owner:张素梅

A bamboo-shaped free-steering junction box

ActiveCN107069611BExtended service lifeMoisture-proof and waterproofCouplings bases/casesFree rotationEngineering

The present invention relates to a bamboo-shaped free turning junction box. The bamboo-shaped free turning junction box comprises an insulated center cylinder and a plurality of outer cylinders rotationally sleeving on the center cylinder in order; three first raised lines are arranged at the outer portion of the center cylinder along the axis direction; the three first raised lines perform equal division of the outer circumference of the center cylinder; the outer surface of the center cylinder between two adjacent first raised lines is provided with arc first conducting strips; three second raised lines are arranged at the inner circles of the outer cylinders; the three second raised lines perform equal division of the circumference of the inner circles of the outer cylinders; the second raised lines are coated with second conducting strips; the second conducting strips are in respective sliding electrical contact with the first conducting strips; the center cylinder is provided with a main firing line hole, a main null line hole and a main ground wire hole along the axis direction; and the outer cylinders comprise branch firing line holes, branch null line holes and branch wire holes along the radial direction of the outer cylinders. The bamboo-shaped free turning junction box can allow each branching to have a free rotation angle approach to 120 degrees to facilitate wiring, and has moistureproof, waterproof and convenient dismounting and mounting, and the service life of the wire is long.

Owner:福建永坤电力设备有限公司

A sheet cleaning robot for medical beds

ActiveCN109350403BEasy to operateEasy to install and replaceNursing bedsRadiationPhysical medicine and rehabilitationEngineering

The invention relates to a bed sheet tidying robot for medical beds, which includes a rolling mechanism and a stretching mechanism. The winding mechanism includes a first box and a first roller shaft located in the first box, and the stretching mechanism includes a second box. Body and the second roller shaft located in the second box body, the first box body and the second box body are respectively fixed on the two ends of the medical bed. The beneficial effects of the present invention are: when in use, the bed sheet can be directly wound on the first roller shaft or the second roller shaft, and then the bed sheet on the medical bed can be replaced by rotating the first roller shaft or the second roller shaft, the operation is simple, fast.

Owner:鄂州市中心医院

A method for regulating indoor humidity

ActiveCN108644954BFunction increaseGuaranteed not to dropFree-cooling systemsDrying chambers/containersFixed frameEngineering

The invention relates to the technical field of intelligent home, in particular to an indoor humidity adjustment method. The method adopts a folding balcony; and the folding balcony comprises a supporting mechanism, a humidifying and cooling mechanism, clamping grooves, reinforcing mechanisms, an airing mechanism, a control mechanism, clamping mechanisms, fixing mechanisms, first rotating shafts and second rotating shafts. The humidifying and cooling mechanism is installed at the top of the supporting mechanism, a water collection tank collects water in a rainy day, and a water spray pipe is opened in high-temperature weather, so that indoor cooling and plant watering are achieved; the airing mechanism is connected with the supporting mechanism through the reinforcing mechanisms, so that the airing mechanism is guaranteed not to fall; the sum of the width of a fixing frame and the lengths of the second rotating shafts are equal to the minimum inner diameters of two supporting rods, thelengths of the second rotating shafts are equal to the widths of reinforcing plates, and a distance between each supporting rod and each rotating plate is equal to one half of the length of each second rotating shaft, so that the fixing frame is clamped into the supporting rods; and the airing mechanism is connected through the control mechanism, so that aired grains are collected into a drawer rapidly.

Owner:湖南浏阳新松矿业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com