Air pipe wheel system improved structure of leaf blowing and sucking machine

A technology of improved structure and blower, which is applied in gardening, botany equipment and methods, agriculture, etc., can solve the problem of inconvenient adjustment of the wheel position for consumers, and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

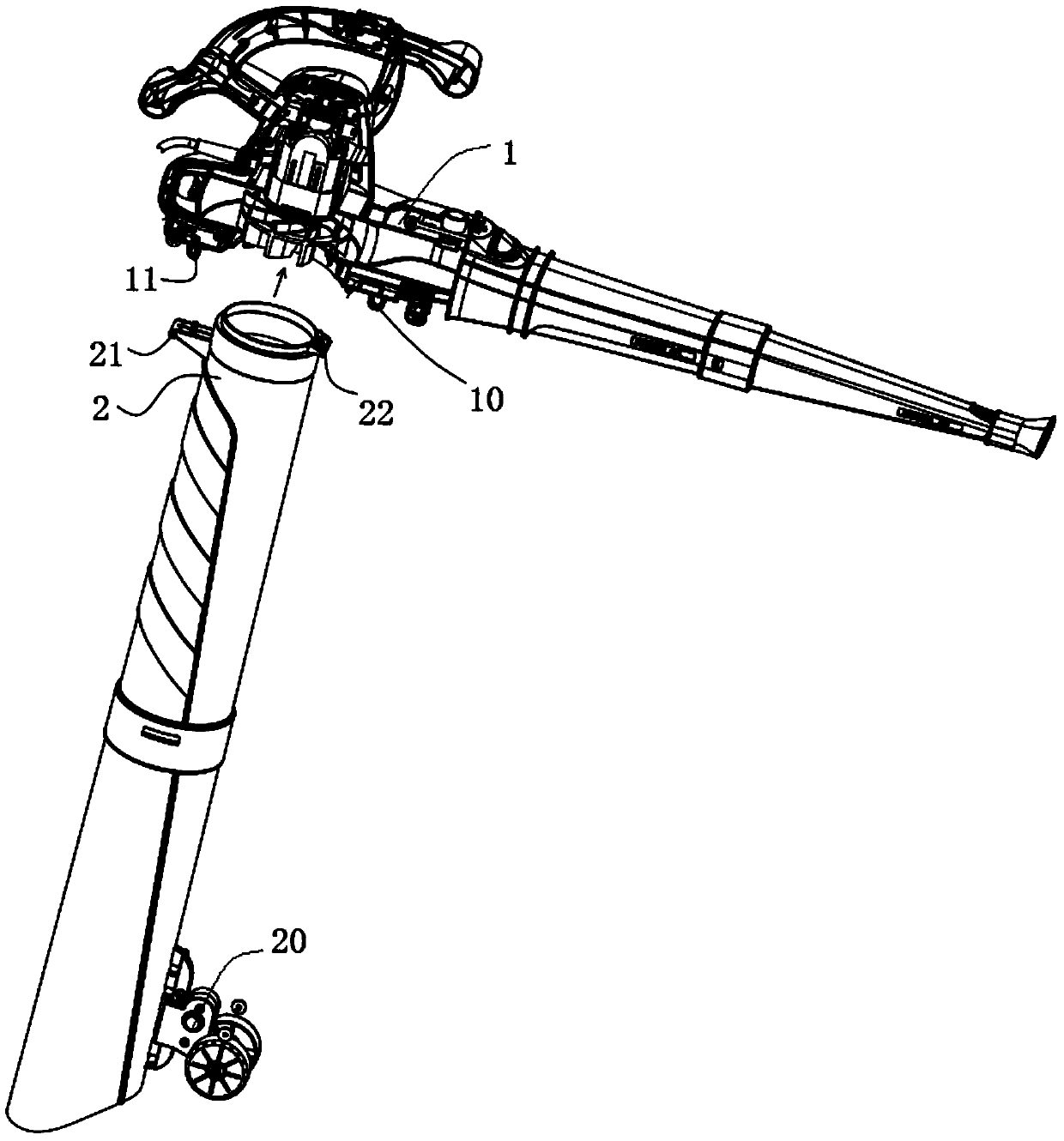

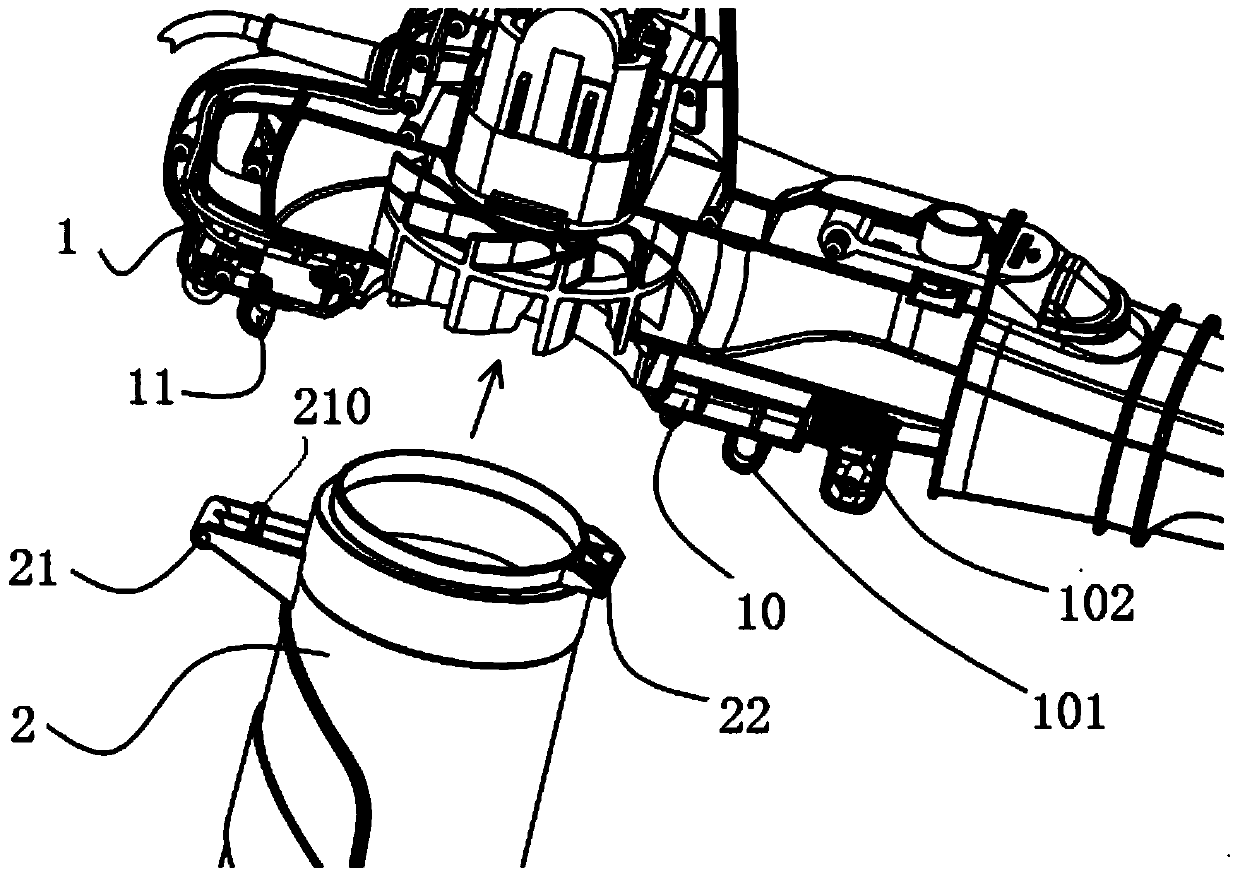

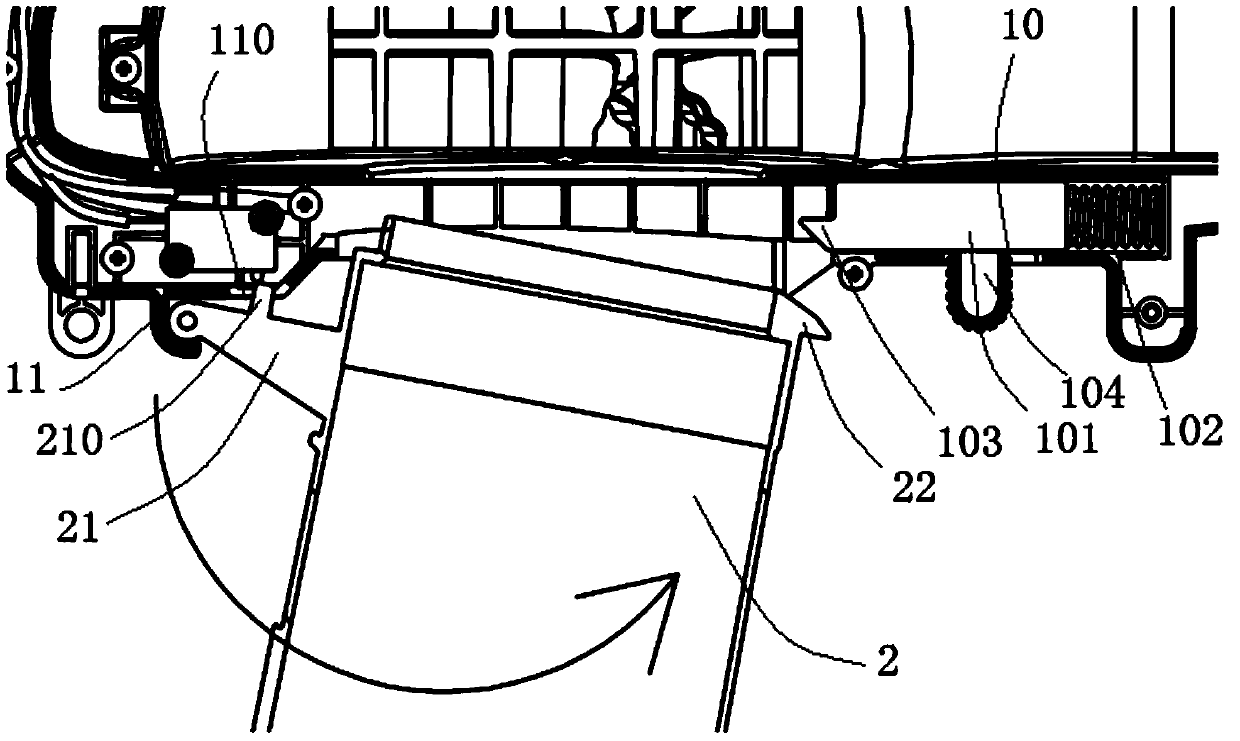

[0023] like Figure 1 to Figure 5 As shown, the leaf blower includes a casing 1, the casing 1 is connected with an air duct 2, an air duct disassembly and fixing structure is arranged between the casing 1 and the air duct 2, and the air duct in the casing 1 is provided with For the air outlet, the tail end of the air duct 2 is provided with a stepped head with a smaller diameter, which is just inserted into the air outlet after the air duct 2 is installed. The outer wall of the tail end of the air duct 2 is provided with a hinged seat 21 to be hinged with the casing 1. The hinged seat is arranged in front of the step head, and a rotating shaft is provided on the hinged seat 21. The support 11 for shaft rotation is provided with a fulcrum for the rotation of the rotation shaft. The outer wall of the tail end of the air duct 2 is provided with a fixed head 22 at a circumferential interval of 180 degrees from the hinge seat, and the fixed head is arranged on the step head, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com