An energy-saving and stable laminated board

A laminated board, stable technology, applied in the direction of floor slabs, buildings, building reinforcements, etc., can solve the problems of weak connection strength, bending and breaking of main bars, etc., to achieve good stability, improve connection stability, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

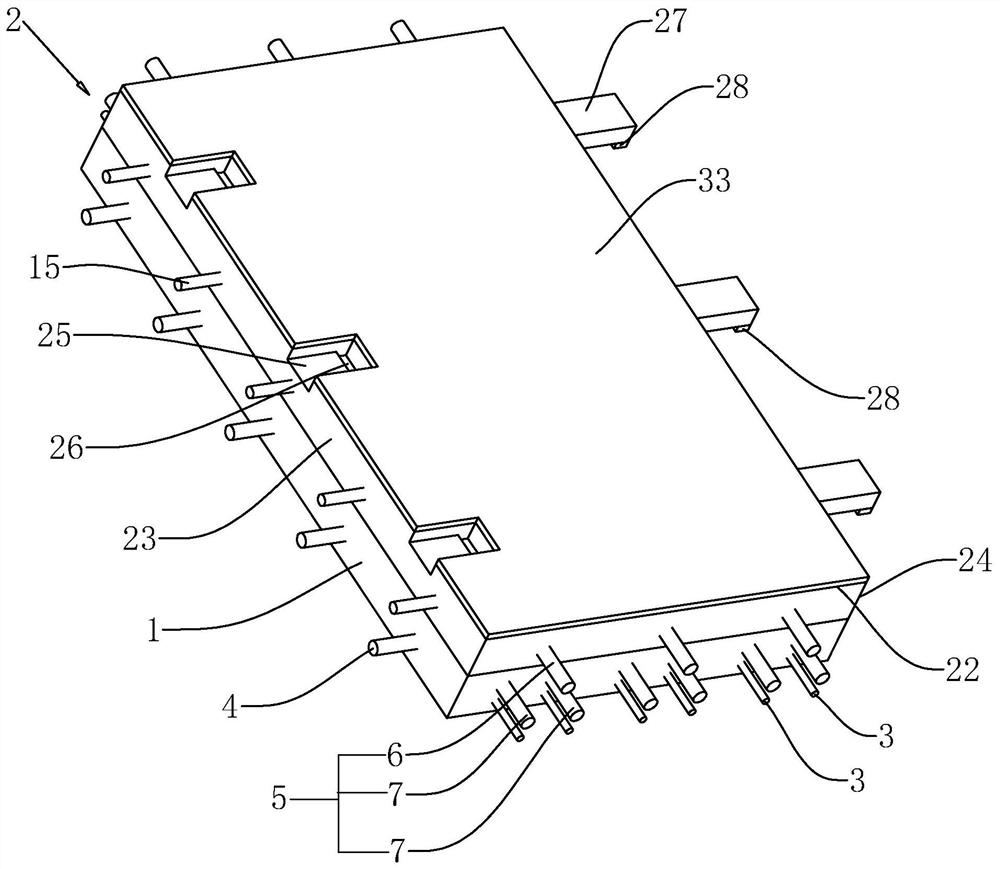

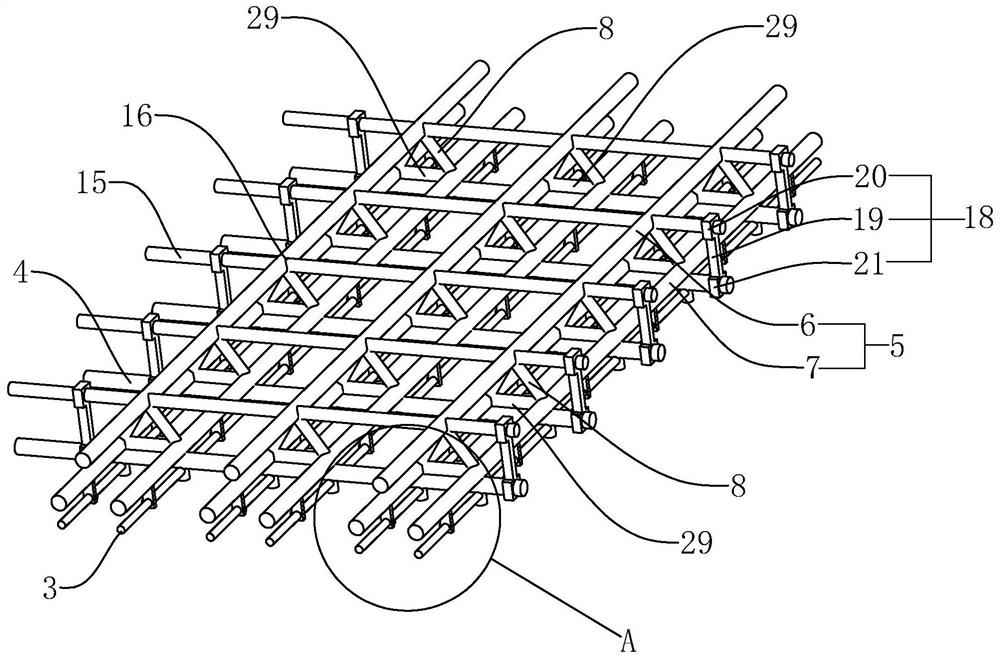

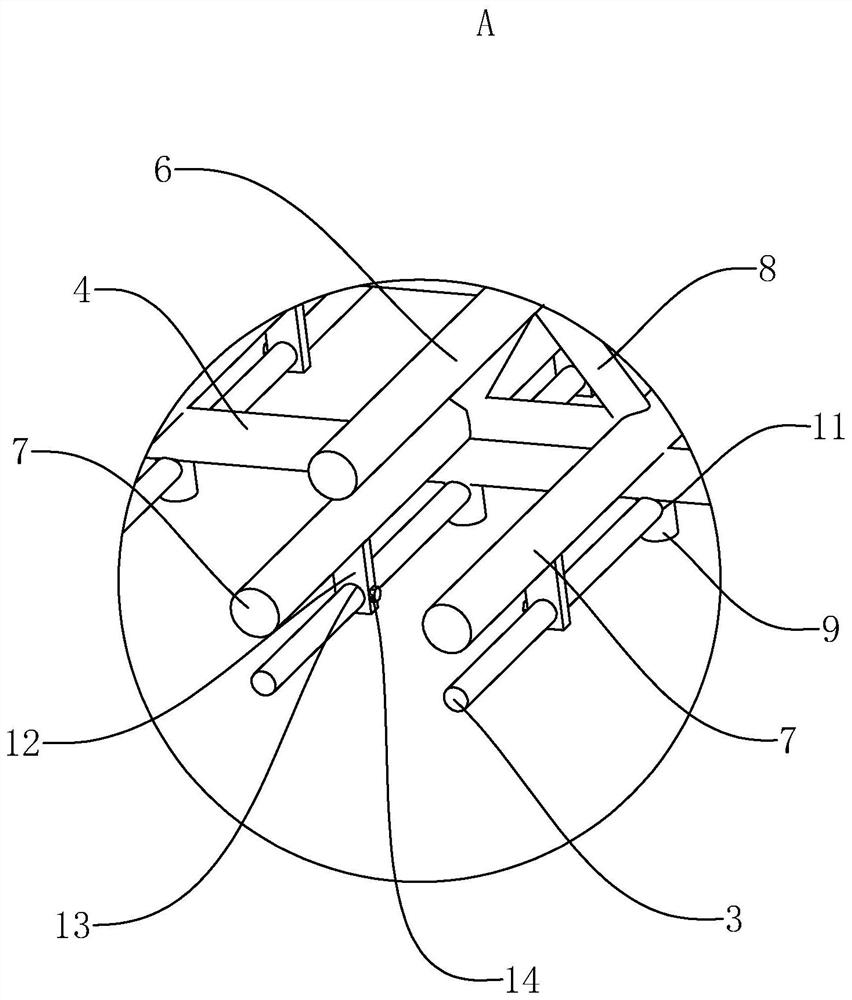

[0035] refer to figure 1 and figure 2 , an energy-saving and stable laminated slab, comprising a prefabricated floor 1 and a cast-in-place reinforced concrete layer 2, the interior of the prefabricated floor 1 is provided with a number of transverse reinforcement bars 3 and longitudinal reinforcement bars 4, the longitudinal reinforcement bars 4 and the transverse reinforcement bars 3 are vertically arranged, and above the longitudinal reinforcement bars 4 There are a number of truss bars 5 parallel to the transverse bars 3. The truss bars 5 include a main bar 6 and two auxiliary bars 7. Several connecting rods 8 are arranged between the main bars 6 and the auxiliary bars 7. The two ends of the connecting bars 8 are connected to the main bar respectively. 6 and the auxiliary reinforcement 7 are fixedly connected, and the main reinforcement 6 of the truss reinforcement 5 and the two auxiliary reinforcement 7 are fixed by the connecting rod 8, so that the overall stability of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com