Method for rehabilitating oil-gas pipeline without transportation interruption

A technology for oil and gas pipelines and pipelines, applied in the field of non-stop repairing oil and gas pipelines, which can solve problems such as pollution, low work efficiency, and complicated operations, and achieve the effects of reducing switching process time, improving work efficiency, and simplifying repair operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

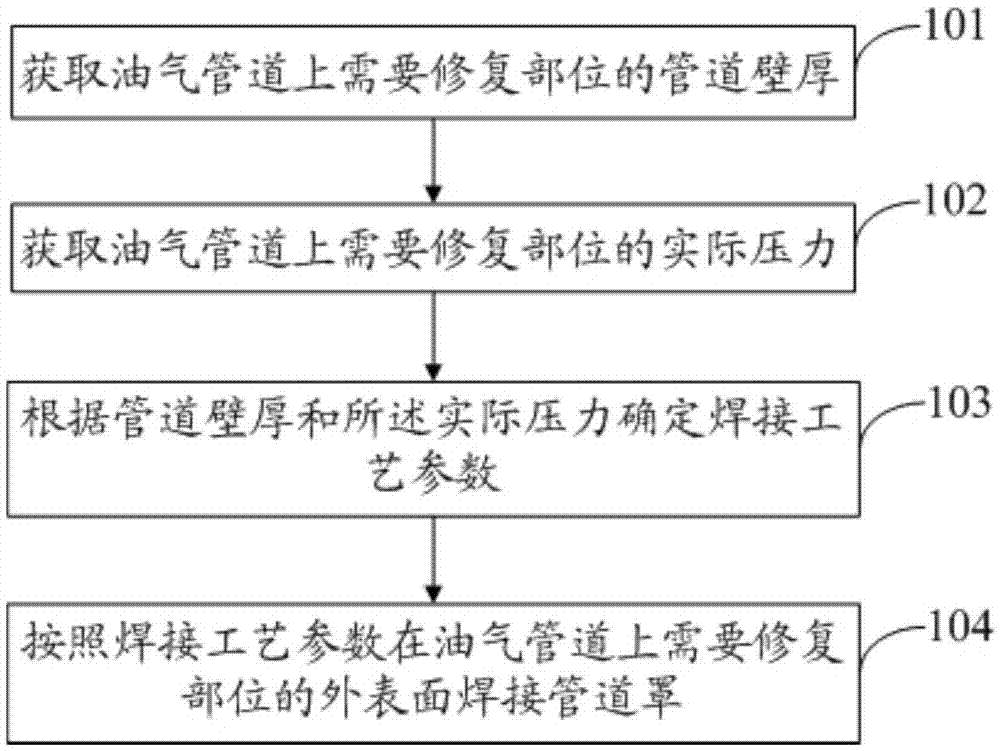

[0040] This embodiment provides a method for repairing oil and gas pipelines without losing power, see figure 1 The method for repairing the oil and gas pipeline includes the following steps:

[0041] Step 101, obtaining the pipeline wall thickness of the part to be repaired on the oil and gas pipeline;

[0042] Step 102, obtaining the actual pressure of the parts on the oil and gas pipeline that need to be repaired;

[0043] Step 103, determining the welding process parameters according to the pipe wall thickness and the actual pressure, the welding process parameters include the diameter of the welding rod, the output current of the electric welding machine and the electric welding time;

[0044] Step 104, welding the pipe cover on the outer surface of the oil and gas pipeline to be repaired according to the welding process parameters.

[0045] In the oil and gas pipeline repair method provided in this embodiment, the welding process parameters such as the diameter of the ...

Embodiment 2

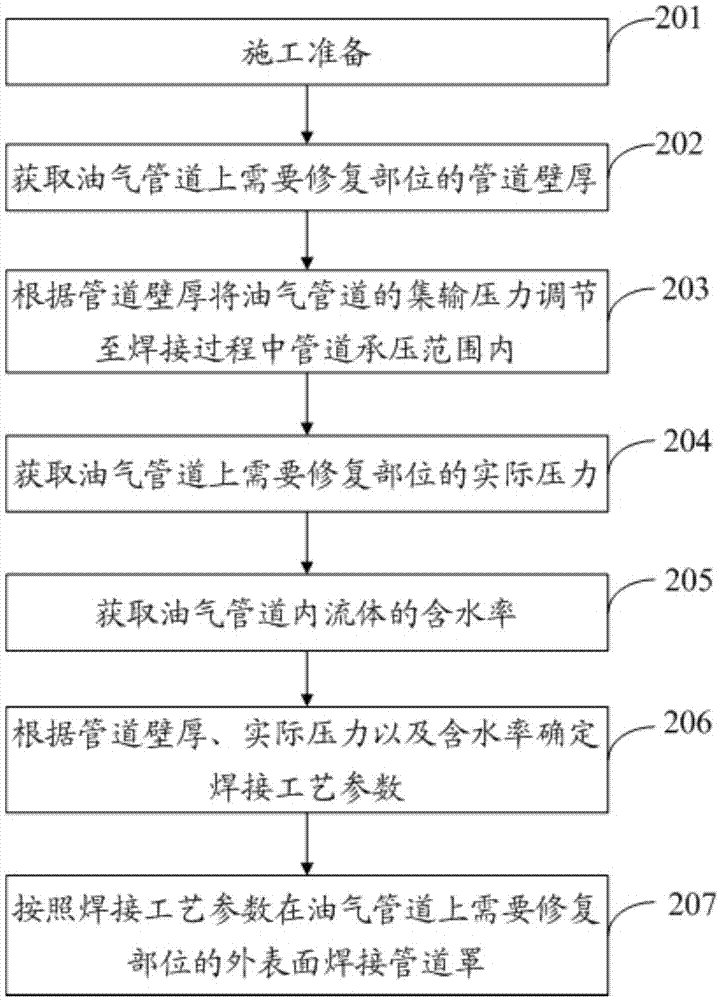

[0047] This embodiment provides a method for repairing oil and gas pipelines without losing power. By matching the welding process parameters such as the diameter of the welding rod, the output power of the electric welding machine, and the welding time with the wall thickness of the pipeline and the pressure of the pipeline, the welding part of the oil and gas pipeline can withstand welding. Changes in conditions such as temperature and pressure during the welding process prevent the oil and gas pipeline from breaking during the welding process, so as to realize the repair of the oil and gas pipeline without losing power. see figure 2 , the method for repairing the oil and gas pipeline comprises the following steps:

[0048] Step 201, construction preparation.

[0049] First of all, in the standardized construction operation pit, clean up the parts that need to be repaired on the oil and gas pipeline, and remove the insulation layer and anti-corrosion layer on the surface. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com