Method and system for detecting tobacco shred material flow on conveying belt based on light field imaging

A technology of flow detection and light field imaging, which is applied in the directions of liquid/fluid solid measurement, volume measurement, fluid transportation, and measurement devices, which can solve the problems of difficult installation process and achieve high measurement accuracy and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0059] Specifically include the following steps:

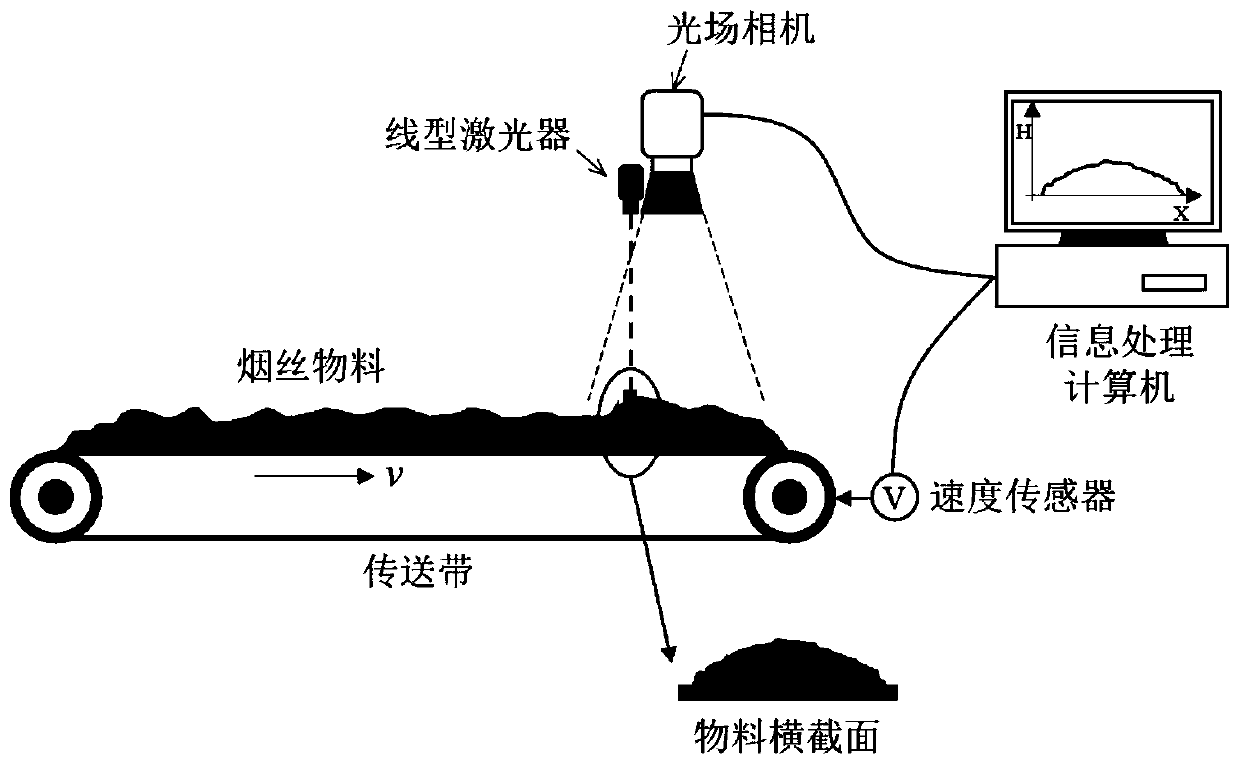

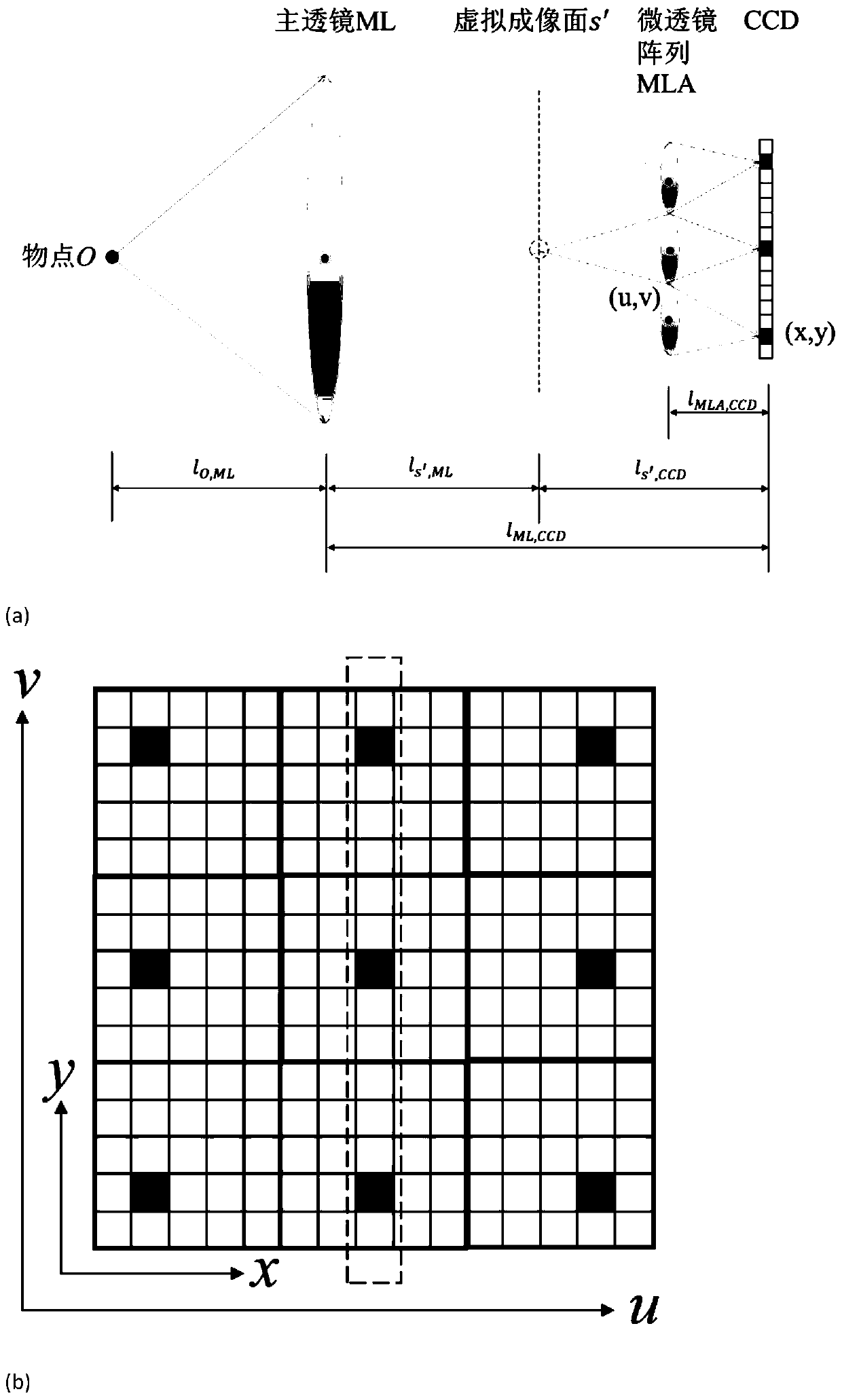

[0060] Step 1. Build as figure 1 The cut tobacco material flow detection system on the conveyor belt based on light field imaging is shown. The cut tobacco material is conveyed through the conveyor belt. Above the material conveyor belt, a light field camera and a linear laser are installed, both of which point vertically to the cut tobacco material below. The light field camera The function is to collect the light field information of shredded tobacco particles to realize the height detection of shredded tobacco on a certain cross section of the belt. The function of the linear laser is to enhance the surface texture of shredded tobacco particles to improve the accuracy of detection; a speed sensor is installed at the roller of the conveyor belt. It is used to measure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com